Double-clad fiber cladding light stripping heat radiation device based on chemical etching method

A double-clad optical fiber and cladding optical stripping technology, which is applied in the direction of laser cooling devices, lasers, laser components, etc., can solve the problems that the degree of stripping cannot meet high requirements, and it is difficult to achieve stripping light absorption and heat conduction treatment. Effect of good output beam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

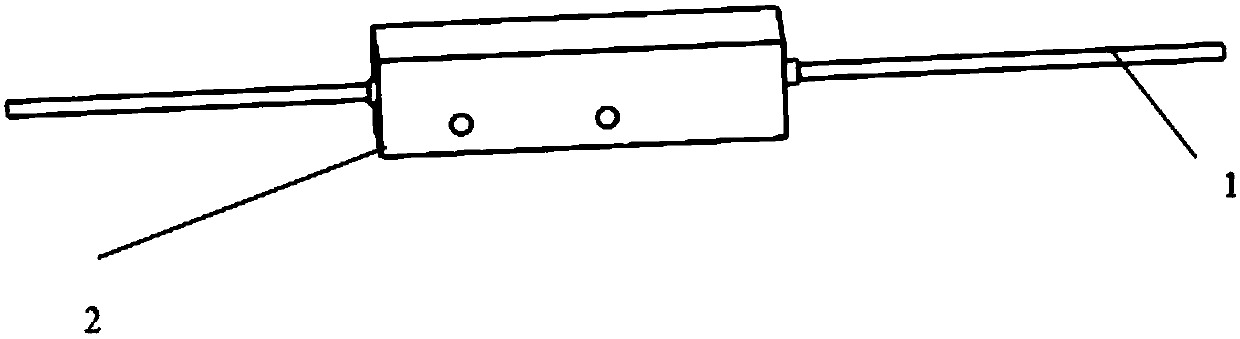

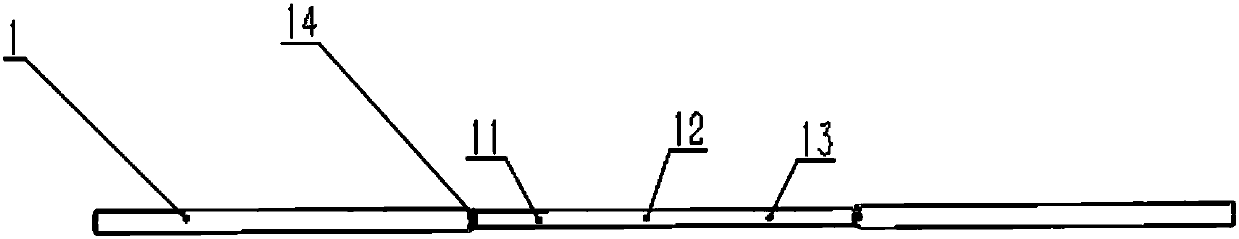

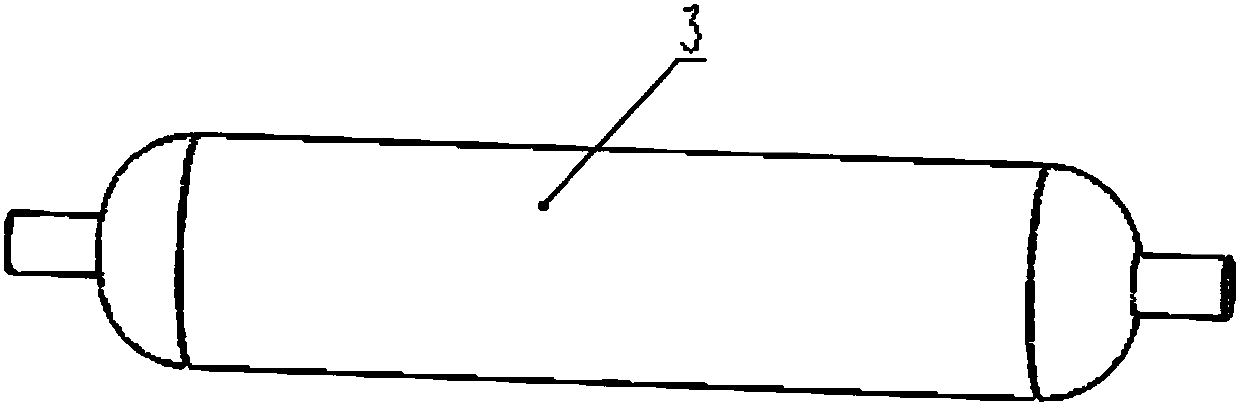

[0018] to combine figure 1 , figure 2 with image 3 , a double-clad optical fiber cladding optical stripping cooling device based on chemical corrosion method, double-clad optical fiber 1, quartz glass tube 3 and heat-conducting metal shell 2, the corroded part of double-clad optical fiber 1 is arranged in the center of the quartz glass tube 3 , and fixed with glue, the heat-conducting metal shell 2 is set on the outer wall of the quartz glass tube 3, and the two ends are fixed with glue.

[0019] The corroded part of the double-clad optical fiber 1 is divided into three stages of corroding, so that the degree of peeling increases sequentially. Both end points of the corroded position are 10 mm away from the peeling point, and the peeling point 14 is a round chamfer.

[0020] The stripping degree of the double-clad optical fiber 1 increases sequentially, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com