Pulling method of array optical fiber optical tweezers

A technology of array optical fiber and manufacturing method, which is applied in the direction of optics, light guides, optical components, etc., can solve the problems of loose fiber arrangement, inconsistent fiber taper angle, and affecting the use of optical tweezers, so as to achieve complete stripping, improve efficiency, and shorten adjustment time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

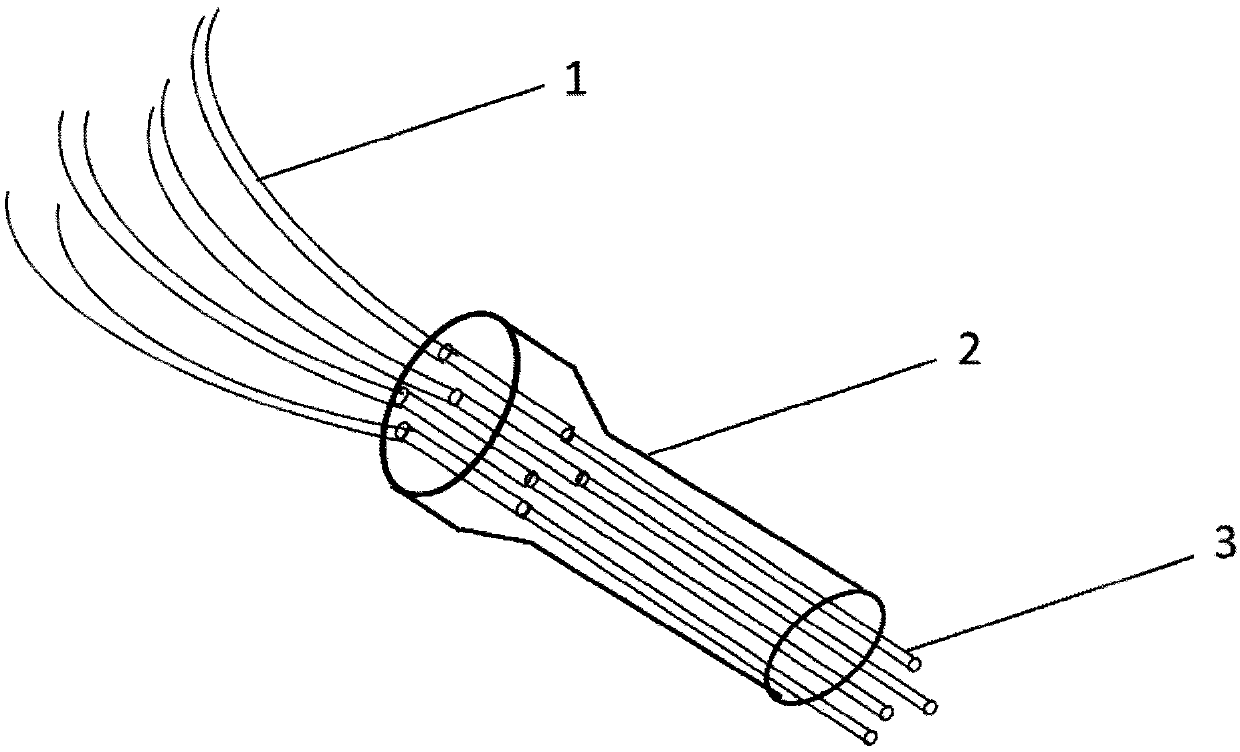

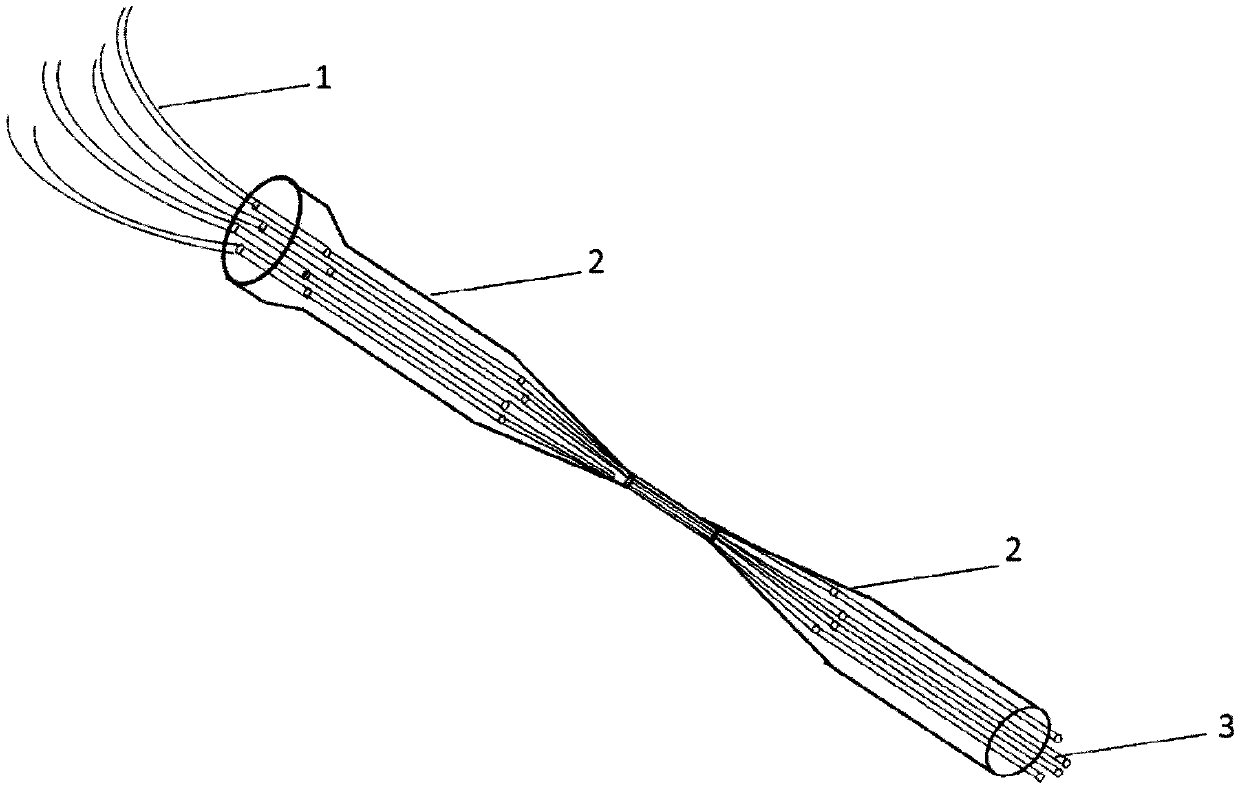

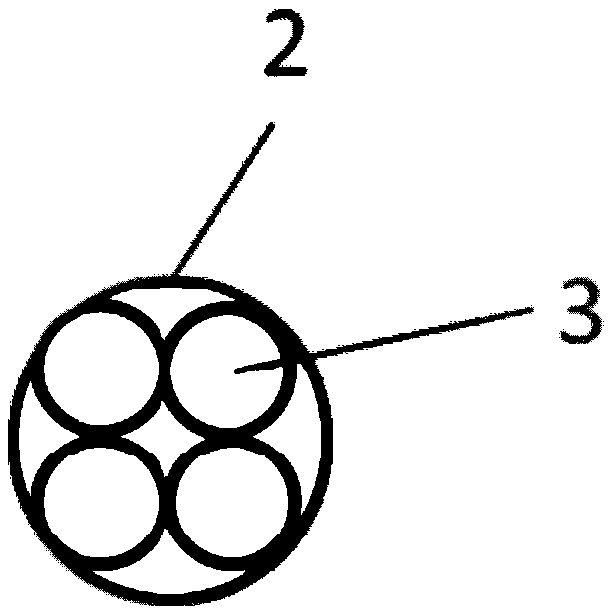

[0034] The embodiment of the drawing method of the array optical fiber optical tweezers is to draw a 4-core 2×2 array optical fiber optical tweezers.

[0035] A method for drawing an array optical fiber optical tweezers, comprising the following main steps:

[0036] Ⅰ. Removal of optical fiber coating

[0037] Take multiple optical fibers of the same specification, soak one end of each optical fiber with a length of 65 mm in concentrated sulfuric acid, and take out the optical fibers whose coating has been corroded for 20 to 30 minutes. Use ethanol and acetone solution to fully wipe the uncoated bare fiber, and observe the bare fiber part under a microscope to confirm that no scars are caused during the treatment process, and it will be used after drying.

[0038] The method of stripping the optical fiber coating layer by chemical solvent etching is superior to mechanical stripping and flame ablation stripping. Although mechanical stripping is easy to operate and implement, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com