Grinding device for producing moxa

A grinding device and grinding mechanism technology, applied in cocoa, grain processing, food science, etc., can solve the problems of long fibers being easily damaged, and achieve the effects of large-scale production, thorough mesophyll peeling, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

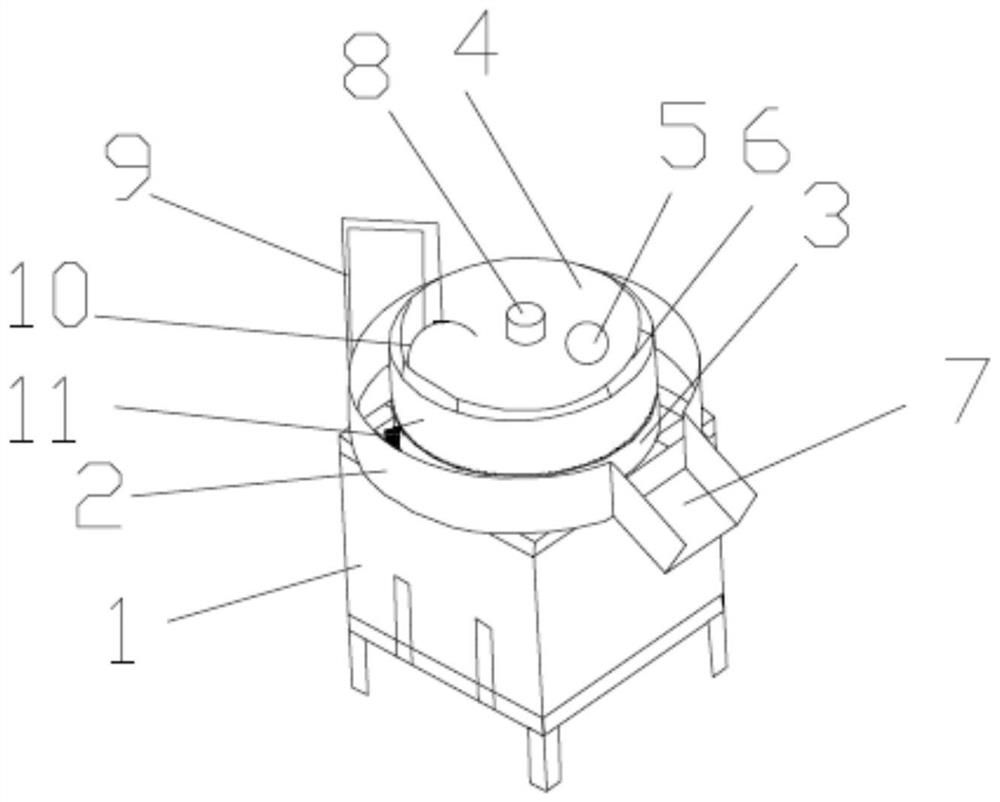

[0020]Example 1: A grinding device for making a Ai Ran, such asfigure 1As shown, the base 1 is included, and the support is supported; the controller is used to control the driving device and the adjustment device; the driving device is used to drive the polishing mechanism to rotate, mounted in the base 1, connected to the controller; polishing mechanism, Used to grinding the leaves, disposed on the base 1, connected to the drive device; the adjustment device, for adjusting the size of the gap of the polishing mechanism, and is disposed within the base 1, connected to the controller.

[0021]The grinding mechanism includes a top grinding disc 4, a lower grinding disk 3, a collecting pocket 2, a link 9, a scraper plate 10, a fence 6, and a pusher plate 11, and the collecting pocket is disposed at the upper end of the base 1, and the lower grinding disc is fixedly mounted In the collection pocket, the lower disc 3 is mounted to form a receiving groove in the housing pocket 2, and the co...

Embodiment 2

[0025]Embodiment 2 A grinding apparatus for making an Ai Vei, the present embodiment is compared to the embodiment 1, and the adjustment device of the present embodiment includes a mounting bracket provided in the base 1, driving the motor and deceleration aversion. In the mounting bracket, there is a pulley on both sides of the mounting bracket, and the inner side of the base 1 is provided with a slider, and the mounting bracket is connected to the electric push rod, the control terminal of the electric push rod is connected to the controller. The mounting bracket is moved by the electric push rod to move up and down in the base 1, thereby driving the drive motor, the reducer, and the rotating shaft 8 to move up and down, and drive the upper disc 4 to move, so that the gap between the upper grinding disc 4 and the lower grinding disc is increased or Reduce; the remaining structure is in the same embodiment.

[0026]In the specific application, the relationship between Ai Ye and the Di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com