A kind of silver powder with high sintering activity and its preparation method and application

A sintering activity, silver powder technology, applied in transportation and packaging, metal processing equipment, coating and other directions, can solve the problems of low surface sintering activity, affecting the application effect, and changing the physical and chemical properties of tap density, so as to improve the surface sintering activity, The effect of improving performance and reducing sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

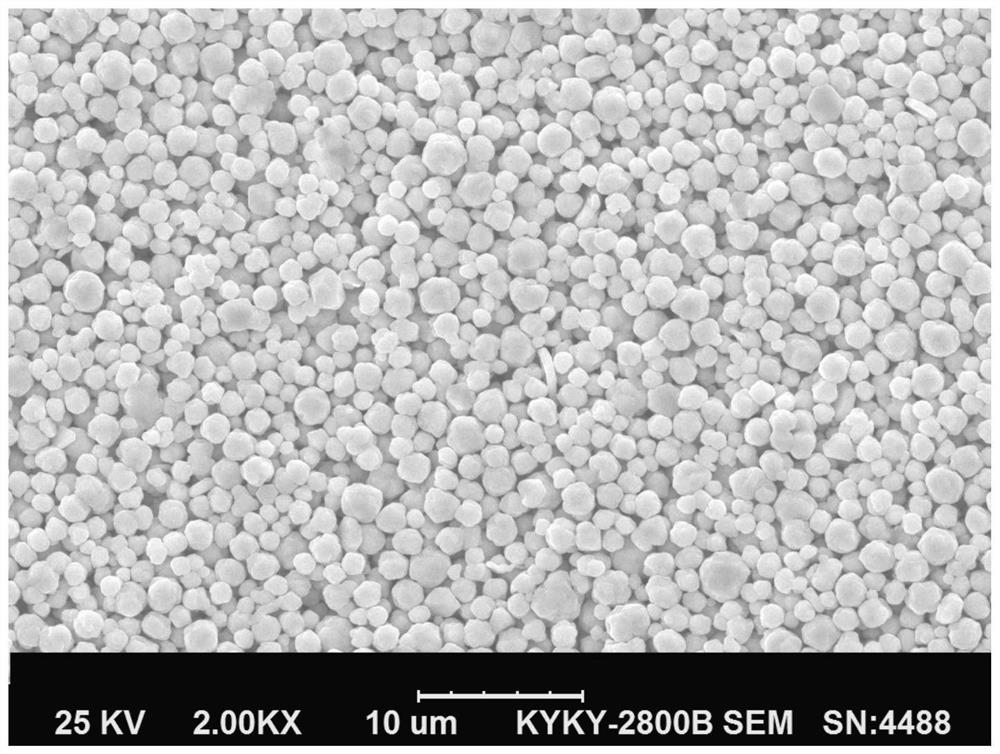

[0055] A kind of highly active silver powder is prepared by the following method:

[0056] (1) Weigh 15kg of raw silver powder and pour it into the batching barrel, add water to form a 25kg material system, turn on the high-pressure homogenizer to circulate and homogeneously disperse the material; during the dispersion process, weigh 0.7kg of silver nitrate and dissolve 10g of gum arabic Liquid, 150g diethanolamine is added in the material, makes material form uniform system.

[0057] (2) During the homogeneous dispersion process of the material, the material in the batching tank is heated. After the material is heated to a temperature of 75° C., a solution containing 200 g of sodium hydroxide is added to the material by using a peristaltic pump to make the material react.

[0058] (3) After the material is homogeneously dispersed and the reaction is completed, add water to wash the material until the conductivity is lower than 20μs / cm. After centrifugation, add a solution con...

Embodiment 2

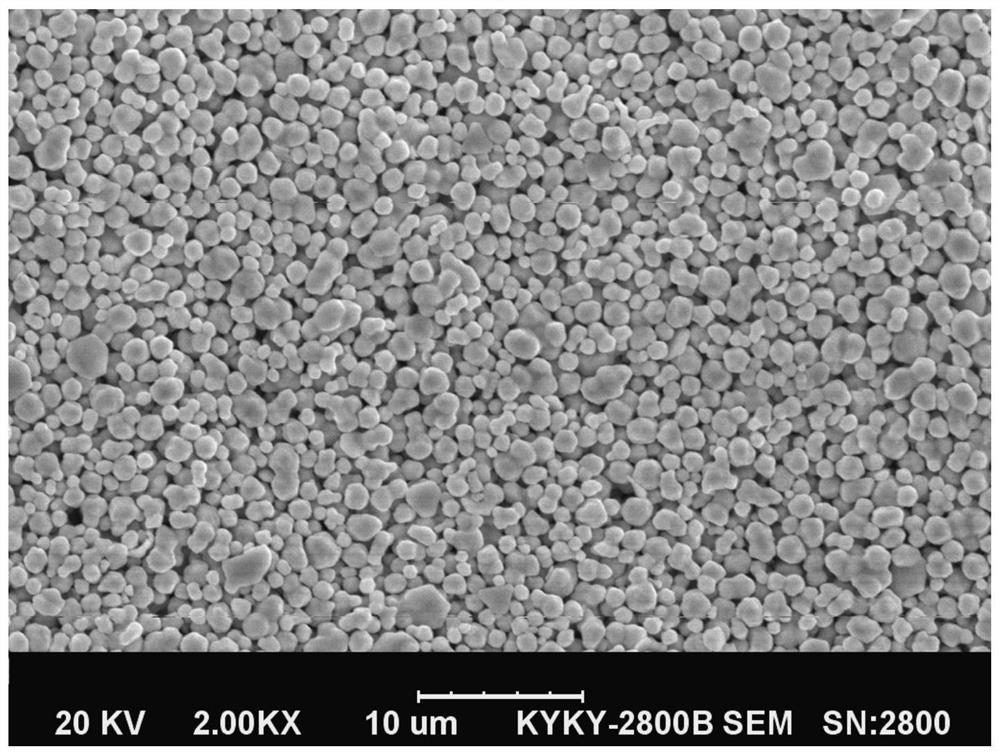

[0061] A kind of highly active silver powder is prepared by the following method:

[0062] (1) Weigh 15kg of raw silver powder and pour it into the batching barrel, add water to form a 25kg material system, turn on the high-pressure homogenizer to circulate and homogeneously disperse the material; weigh 1.5kg of silver nitrate and a solution containing 60g of gelatin during the dispersion process 230g of triethanolamine is added to the material to make the material form a uniform system.

[0063] (2) During the homogeneous dispersion process of the material, the material in the batching tank is heated. After the material is heated to a temperature of 50° C., a solution containing 450 g of sodium hydroxide is added to the material by using a peristaltic pump to make the material react.

[0064] (3) After the material is homogeneously dispersed and the reaction is completed, add water to wash the material until the conductivity is lower than 20μs / cm. After centrifugation, add a ...

Embodiment 3

[0067] A kind of highly active silver powder is prepared by the following method:

[0068] (1) Weigh 20kg of raw silver powder into the batching barrel, add water to form a 27kg material system, turn on the high-pressure homogenizer to circulate and homogeneously disperse the material; during the dispersion process, weigh 1.0kg of silver nitrate, 50g of gelatin and 10g of poly A solution of vinyl alcohol (P-2000) and 150 g of glycerol were added to the material to form a uniform system.

[0069] (2) During the homogeneous dispersion process of the material, the material in the batching tank is heated, and after the material is heated to a temperature of 65° C., a solution containing 250 g of sodium hydroxide is added to the material by using a peristaltic pump to make the material react.

[0070] (3) After the material is homogeneously dispersed and the reaction is completed, add water to wash the material until the conductivity is lower than 20μs / cm. After centrifugation, add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com