Laser paint stripping machine

A laser paint stripping and paint stripping technology, which is applied in the direction of electrical components, circuits, connections, etc., can solve problems such as inability to strip paint online, achieve the effects of reducing rework rate, increasing application range, and improving stripping speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

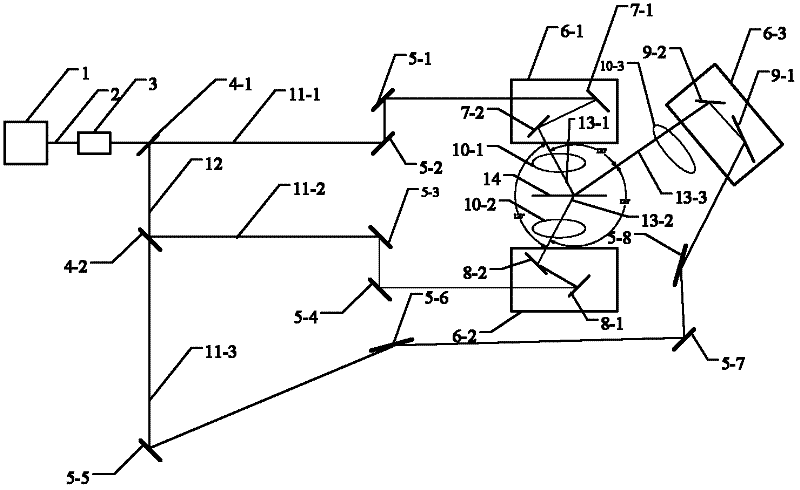

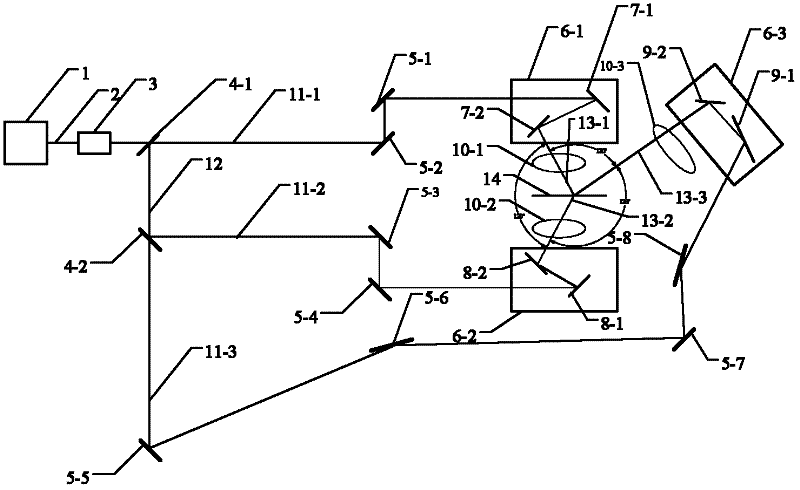

[0017] The present invention combines the attached figure 1 And embodiment, its technical scheme is described in detail as follows:

[0018] The laser paint stripping machine of the present invention comprises a solid-state laser light source 1, and the solid-state laser light source 1 adopts an end-pumped solid-state laser, and its laser wavelength is 1064nm, and its laser power is 20W; a beam expander 3, whose beam expansion rate is 9 times; Beam splitter 4-1 and beam splitter 4-2; Total reflection mirror 5-1, Total reflection mirror 5-2, Total reflection mirror 5-3, Total reflection mirror 5-4, Total reflection mirror 5-5, Total reflection mirror 5-6, total reflection mirror 5-7, total reflection mirror 5-8; galvanometer scanning system 6-1, galvanometer scanning system 6-2, galvanometer scanning system 6-3, these three galvanometer scanning systems The angle between them in space is 120°. The galvanometer scanning system 6-1 includes an X-direction galvanometer 7-1, a Y-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com