High-concentration high-dispersity ultrathin molybdenum disulfide dispersion liquid and preparation method thereof

A molybdenum disulfide, high dispersibility technology, applied in the direction of molybdenum sulfide, etc., can solve the problems of molybdenum disulfide nanosheet structure defects, low concentration of molybdenum disulfide dispersion liquid, etc., achieve complete peeling, low production cost, and improve dispersibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

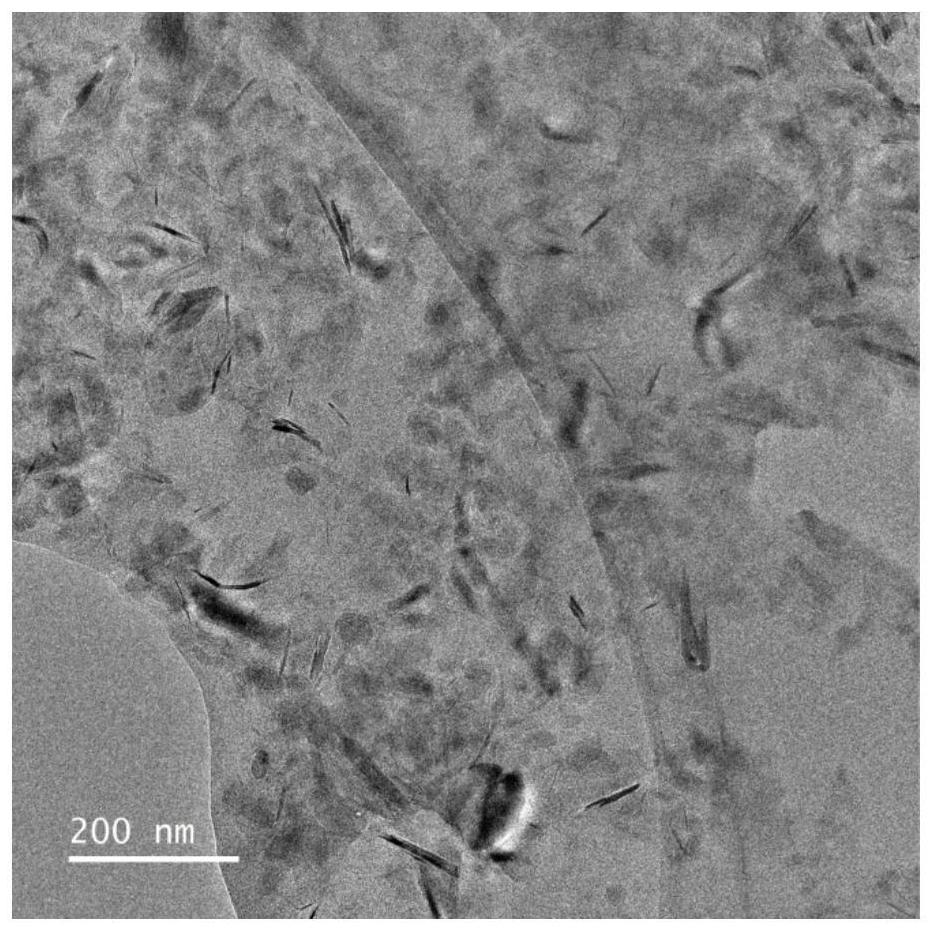

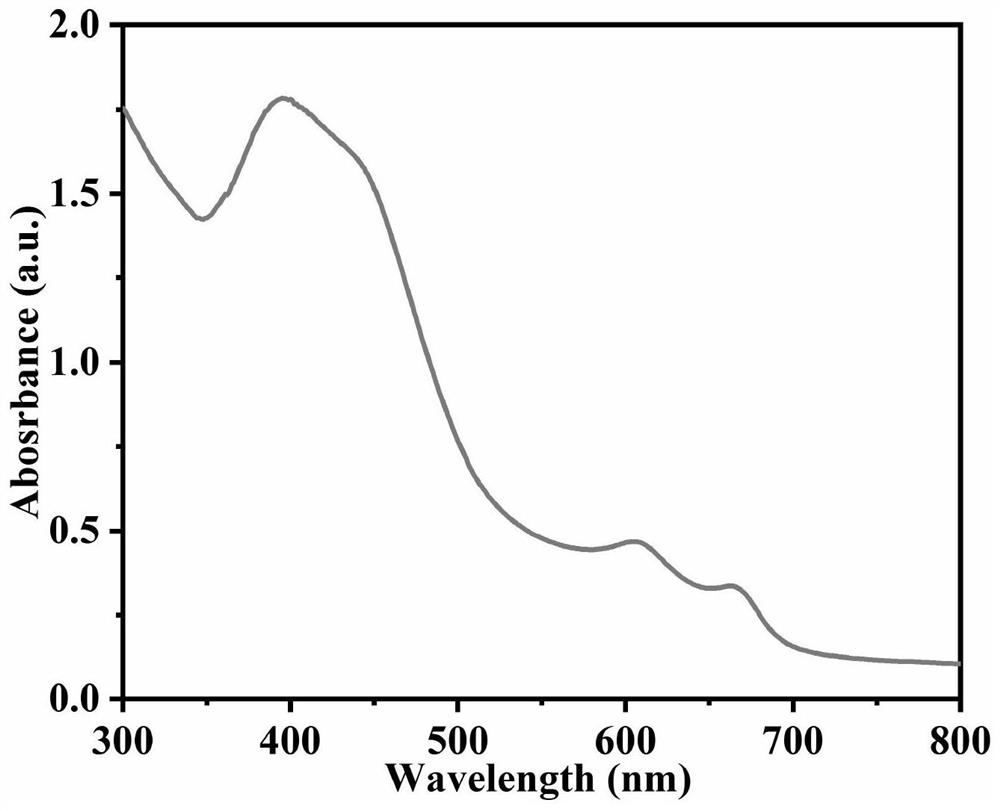

Image

Examples

Embodiment 1

[0028] (1) Weigh 50mg of ionic liquid crystal-1-hexadecyl-3-methylimidazole bromide and add it to 20mL of deionized water, and vigorously stir until fully dissolved in water to obtain an aqueous solution of ionic liquid crystal for stripping molybdenum disulfide (concentration 2.5mg / mL);

[0029] (2) Take by weighing 0.05g molybdenum disulfide powder and add it to the ionic liquid crystal solution, stir until it is uniformly dispersed to obtain a mixed solution of molybdenum disulfide and ionic liquid crystal;

[0030] (3) Ultrasonic treatment of molybdenum disulfide and ionic liquid crystal mixed solution for 20min, the ultrasonic power is 100W, and the frequency is 40KHz;

[0031] (4) The ultrasonically treated molybdenum disulfide dispersion is subjected to centrifugal separation through a centrifuge, the centrifugal speed is 2000rpm, and the centrifugation time is 30min;

[0032] (5) After centrifugation, two-thirds of the supernatant liquid was taken to obtain a highly d...

Embodiment 2

[0034] (1) Weigh 100 mg of ionic liquid crystal-1-hexadecyl-3-methylimidazolium tetrafluoroborate and add it to 20 mL of deionized water, stir vigorously until fully dissolved in water to obtain ionic liquid crystal for stripping molybdenum disulfide Aqueous solution (concentration is 5mg / mL);

[0035] (2) Take 0.5g molybdenum disulfide powder and add it to the ionic liquid crystal solution, and stir until it is uniformly dispersed to obtain a mixed solution of molybdenum disulfide and ionic liquid crystal;

[0036] (3) ultrasonically treat the molybdenum disulfide and ionic liquid crystal mixed solution for 30min, the ultrasonic power is 200W, and the frequency is 40KHz;

[0037] (4) The ultrasonically treated molybdenum disulfide dispersion is subjected to centrifugal separation through a centrifuge, the centrifugal speed is 2000rpm, and the centrifugation time is 30min;

[0038] (5) After centrifugation, two-thirds of the supernatant liquid was taken to obtain a highly dis...

Embodiment 3

[0040] (1) Weigh 200 mg of ionic liquid crystal-1-hexadecyl-3-methylimidazolium hexafluorophosphate and add it to 20 mL of deionized water, and stir vigorously until fully dissolved in water to obtain an aqueous solution of ionic liquid crystal for stripping molybdenum disulfide (Concentration is 10mg / mL);

[0041] (2) Take 1g of molybdenum disulfide powder and add it to the ionic liquid crystal solution, stir until it is uniformly dispersed to obtain a mixed solution of molybdenum disulfide and ionic liquid crystal;

[0042] (3) ultrasonically treat the molybdenum disulfide and ionic liquid crystal mixed solution for 40min, the ultrasonic power is 300W, and the frequency is 40KHz;

[0043] (4) The ultrasonically treated molybdenum disulfide dispersion is subjected to centrifugal separation through a centrifuge, the centrifugal speed is 3000rpm, and the centrifugation time is 20min;

[0044] (5) After centrifugation, two-thirds of the supernatant was taken to obtain a highly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com