Building construction wall stripping device with dust fall and noise reduction functions

A technology of building construction and stripping device, which is applied in construction, building maintenance, building construction, etc. It can solve the problems of affecting the health of workers, incomplete peeling of wall skin, and low work efficiency, so as to ensure physical health and improve stability and safety, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

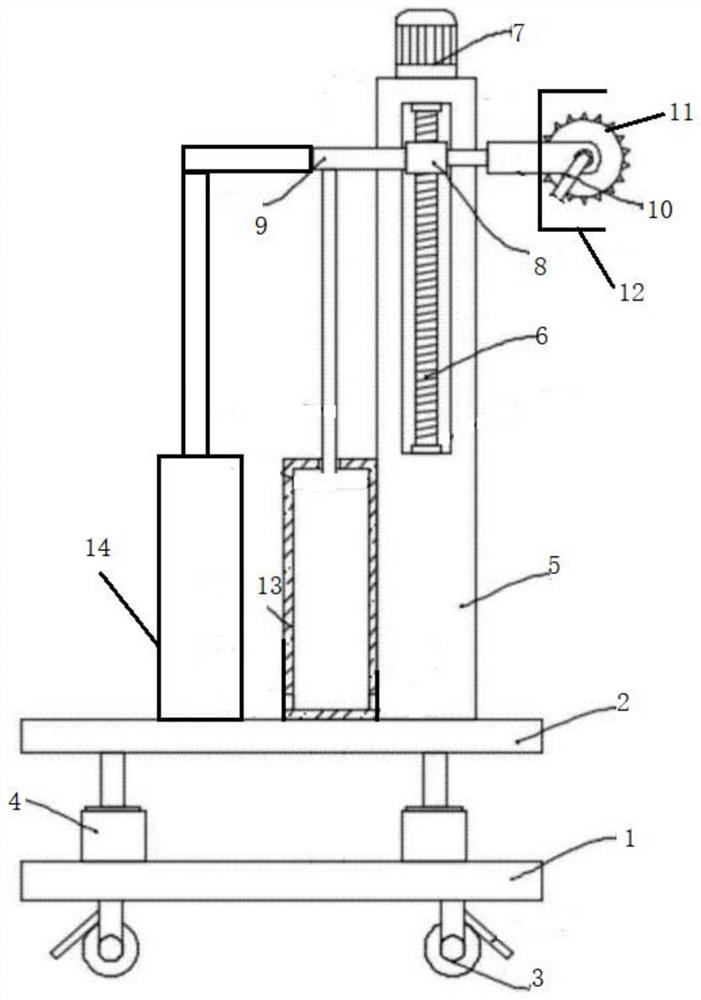

[0025] see figure 1 , a wall stripping device with dust and noise reduction functions, comprising a bracket 1, a lifting platform 2 and a control device, the bottom of the bracket 1 is equipped with a universal wheel 3, and the bracket 1 and the lifting platform 2 are equipped with lifting Device 4; the top right side of the lifting table 2 is fixed with a construction frame 5, and a screw mandrel 6 is installed on the construction frame 5, and a lead screw motor 7 is installed on the top of the construction frame 5, and the output end of the lead screw motor 7 is connected to the screw motor. The screw rod 6 is connected; the outer cover of the screw rod 6 is provided with a screw slider 8 matched with it; The control device controls and rotates relative to the screw mandrel slide block 8, and can carry out stripping construction to multiple positions such as walls and ceilings as required; the front end of the stripping construction frame 9 is equipped with a stripping tool ...

Embodiment 2

[0035] see figure 1, a wall stripping device with dust and noise reduction functions, comprising a bracket 1, a lifting platform 2 and a control device, the bottom of the bracket 1 is equipped with a universal wheel 3, and the bracket 1 and the lifting platform 2 are equipped with lifting Device 4; the top right side of the lifting table 2 is fixed with a construction frame 5, and a screw mandrel 6 is installed on the construction frame 5, and a lead screw motor 7 is installed on the top of the construction frame 5, and the output end of the lead screw motor 7 is connected to the screw motor. The screw rod 6 is connected; the outer cover of the screw rod 6 is provided with a screw slider 8 matched with it; The control device controls and rotates relative to the screw mandrel slide block 8, and can carry out stripping construction to multiple positions such as walls and ceilings as required; the front end of the stripping construction frame 9 is equipped with a stripping tool 1...

Embodiment 3

[0047] see figure 1 , a wall stripping device with dust and noise reduction functions, comprising a bracket 1, a lifting platform 2 and a control device, the bottom of the bracket 1 is equipped with a universal wheel 3, and the bracket 1 and the lifting platform 2 are equipped with lifting Device 4; the top right side of the lifting table 2 is fixed with a construction frame 5, and a screw mandrel 6 is installed on the construction frame 5, and a lead screw motor 7 is installed on the top of the construction frame 5, and the output end of the lead screw motor 7 is connected to the screw motor. The screw rod 6 is connected; the outer cover of the screw rod 6 is provided with a screw slider 8 matched with it; The control device controls and rotates relative to the screw mandrel slide block 8, and can carry out stripping construction to multiple positions such as walls and ceilings as required; the front end of the stripping construction frame 9 is equipped with a stripping tool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com