Rework liquid medicine, preparation method thereof, and rework device

A technology of heavy industry and liquid medicine, which is applied in the direction of photomechanical equipment, photosensitive material processing, photoplate making process of pattern surface, etc., can solve the problems of poor heavy industry effect and incomplete peeling of color filter layer, etc., to achieve thorough peeling and improve The effect of heavy industry and the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 of the present invention provides a heavy-duty medicinal liquid, which includes the following components in parts by weight:

[0042] Deionized water: 20-30 parts;

[0043] Tetramethylammonium hydroxide: 3 to 10 parts;

[0044] Dimethyl sulfoxide: 30-45 parts;

[0045] N-methylpyrrolidone: 1 to 5 parts;

[0046] Diethylene glycol-methyl ether: 10-20 parts;

[0047] Hydroxylamine: 1 to 5 parts.

[0048] The rework chemical solution is used to remove the color resist material layer (color filter layer) in the color filter substrate or COA substrate. Specifically, the color-resisting material layer, PS (Photo Spacer, photosensitive spacer), BM (BlackMatrix, black matrix) on the substrate are dissolved and peeled off by using a heavy industrial chemical solution. Since the physical peeling in the prior art is changed to chemical Dissolution and peeling, so the peeling is more thorough, and the rework effect is good.

[0049] Among them, deionized water (D...

Embodiment 2

[0094] This embodiment provides a method for preparing a heavy chemical solution, which is used to prepare the heavy chemical solution described in Example 1. The method includes: adding components other than deionized water into deionized water to obtain a heavy chemical solution.

[0095] Specifically, tetramethylammonium hydroxide, dimethyl sulfoxide, N-methylpyrrolidone, diethylene glycol-methyl ether, and hydroxylamine can be added to deionized water and mixed uniformly to prepare a heavy-duty medicinal solution. Certainly, in the case that the heavy industrial chemical liquid also includes other components, other components besides the above-mentioned components can also be added into the deionized water and mixed uniformly.

[0096] Among them, adding tetramethylammonium hydroxide, dimethylsulfoxide, N-methylpyrrolidone, diethylene glycol-methyl ether, and hydroxylamine into deionized water specifically refers to adding tetramethylammonium hydroxide, dimethylsulfoxide, ...

Embodiment 3

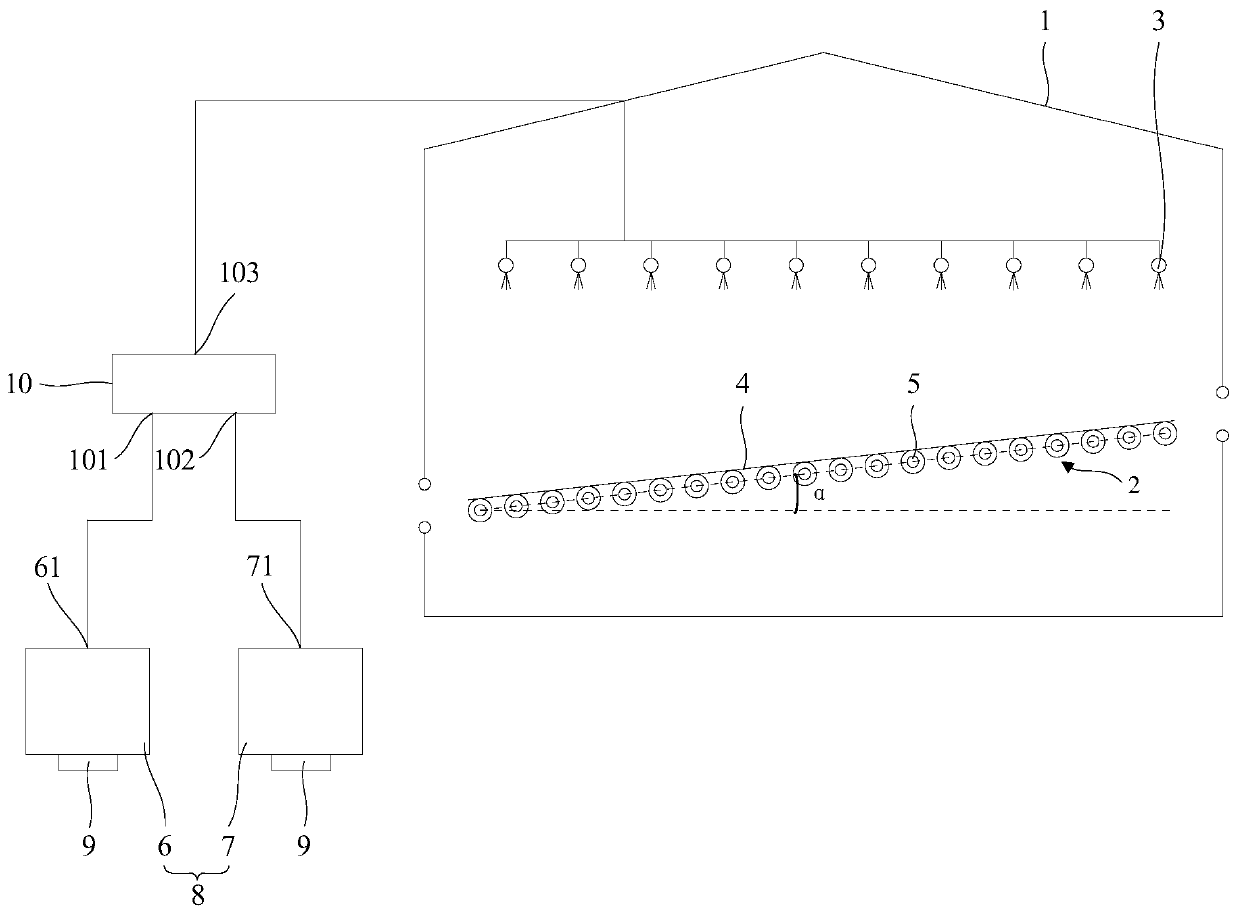

[0114] figure 1 The structure schematic diagram of the heavy industry device provided for the present invention, as figure 1 As shown, this embodiment provides a heavy industrial device, and the heavy industrial liquid used in the heavy industrial device of this embodiment is the heavy industrial chemical liquid described in the first embodiment, which is prepared by the method described in the second embodiment. The specific components and specific preparation methods of the heavy industrial liquid have been described in detail in Example 1 and Example 2, and will not be repeated here.

[0115] The rework device provided in this embodiment includes: a reaction chamber 1, a substrate carrying assembly 2 and a shower head 3 arranged inside the reaction chamber 1, the substrate carrying assembly 2 is used to place the substrate to be reworked, so the substrate to be reworked 4 Placed on the substrate carrier assembly 2, the shower head 3 is arranged above the substrate carrier ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com