Temper mill applying chromium-plated roller

A technology of skin pass mill and roll, applied in the field of skin pass mill, can solve the problems of increased cost consumption, delayed production schedule, rapid roll consumption, etc., and achieves the effect of improving production efficiency and production quality, improving operation rate, and high chrome plating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

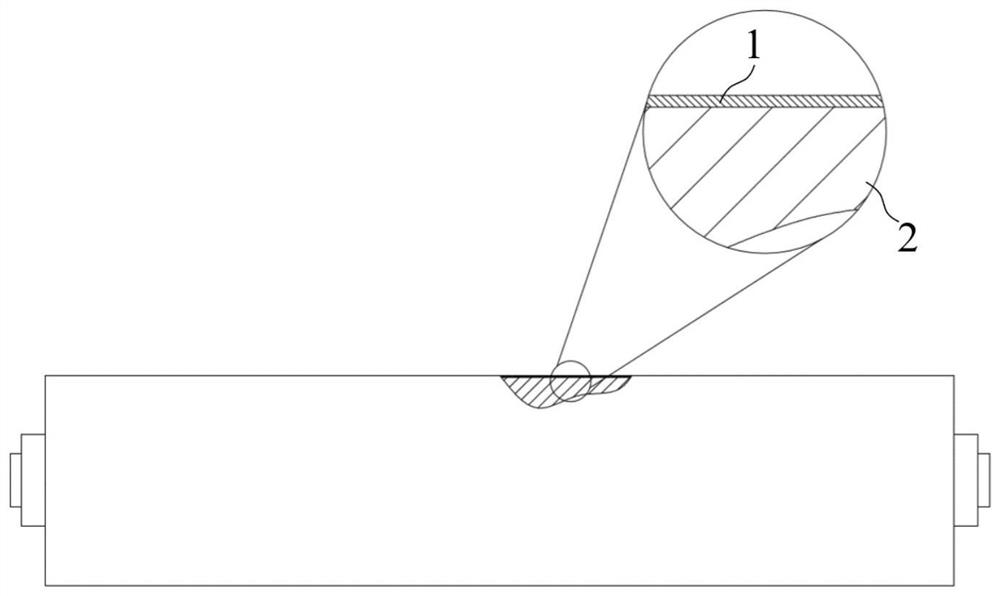

[0043] In the tempering mill using chrome-plated rolls in this embodiment, the rolls of the tempering machine are chrome-plated rolls with a diameter of 450 mm.

[0044] The chrome-plated roll that the tempering machine of the present embodiment adopts is as figure 1 As shown, a chrome-plated layer 1 is formed on the roll substrate 2. By using a chrome-plated roll, the single rolling time of the roll can be increased by 3 to 10 times, reducing the downtime for roll change, improving the operating rate, and the chrome-plated roll. The wear resistance of the roll improves the uniformity of the surface roughness of the strip during the rolling cycle. The chrome-plated roll also improves the hardness of the roll surface and reduces scratches on the roll surface, which is beneficial to improving the surface quality of the strip and the cleanliness of the plate surface. The lubricating ability of the roll.

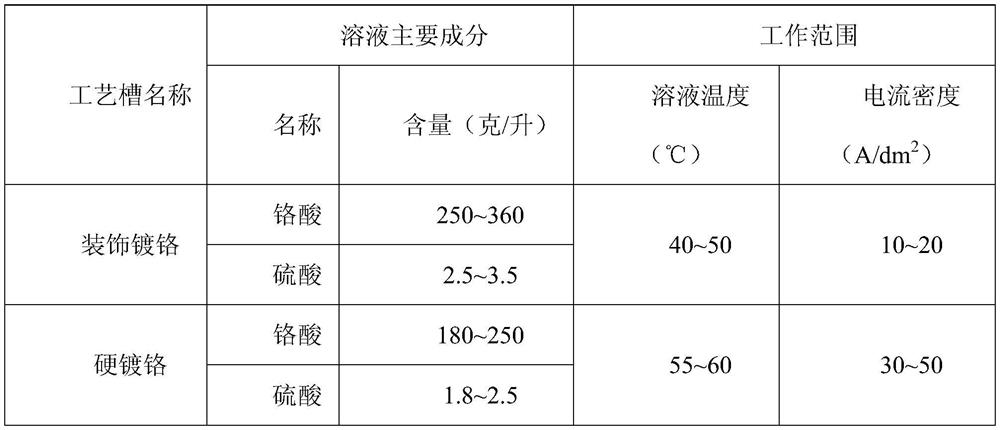

[0045] Further, for the chrome-plated roller used in this embodiment, the ...

Embodiment 2

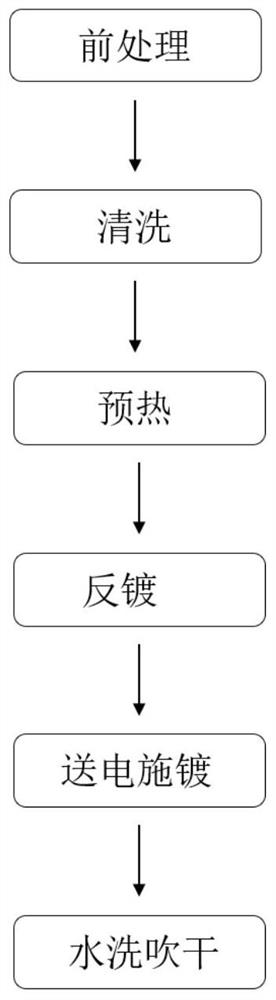

[0055] The skin pass mill of the application chrome-plated roll of the present invention adopts the following method to process the chrome-plated roll of 450mm:

[0056] 1. Pretreatment: use a clean silk cloth to dip in the degreasing agent along the circumferential direction of the roller and rotate with the roller body to scrub the surface of the roller body to remove oil and impurities; the scrubbing operation is repeated three times;

[0057] 2. Cleaning: Use a pure water high-pressure water gun with a water temperature of 40°C to rinse the surface of the roll to be plated; after cleaning, check whether the water-hanging film is uniform. If it is uniform, proceed to step 3. If not, repeat the operations of step 1 and step 2;

[0058] 3. Preheating: Put the cleaned roll into the chrome plating tank and preheat it;

[0059]4. Anti-plating: Anti-plating is carried out on the roll to be plated. During anti-plating, the rotation speed of the roll is 5 rpm, the anti-plating time...

Embodiment 3

[0072] The skin pass mill of the application chrome-plated roll of the present invention adopts the following method to process the chrome-plated roll of 450mm:

[0073] 1. Pretreatment: use a clean silk cloth to dip in the degreasing agent along the circumferential direction of the roller and rotate with the roller body to scrub the surface of the roller body to remove oil and impurities; the scrubbing operation is repeated three times;

[0074] 2. Cleaning: Use a pure water high-pressure water gun with a water temperature of 40°C to rinse the surface of the roll to be plated; after cleaning, check whether the water-hanging film is uniform. If it is uniform, proceed to step 3. If not, repeat the operations of step 1 and step 2;

[0075] 3. Preheating: Put the cleaned roll into the chrome plating tank and preheat it;

[0076] 4. Anti-plating: Anti-plating is carried out on the roll to be plated. During anti-plating, the rotation speed of the roll is 5 rpm, the anti-plating tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com