Wire stripper for coaxial wire metallic shielding layer

A technology of metal shielding layer and coaxial cable, which is applied in the field of metal shielding layer stripping machine of coaxial cable, can solve the problems such as unsatisfactory stripping effect of large-sized coaxial cable, shorten processing time, improve work efficiency, The effect of peeling thoroughly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

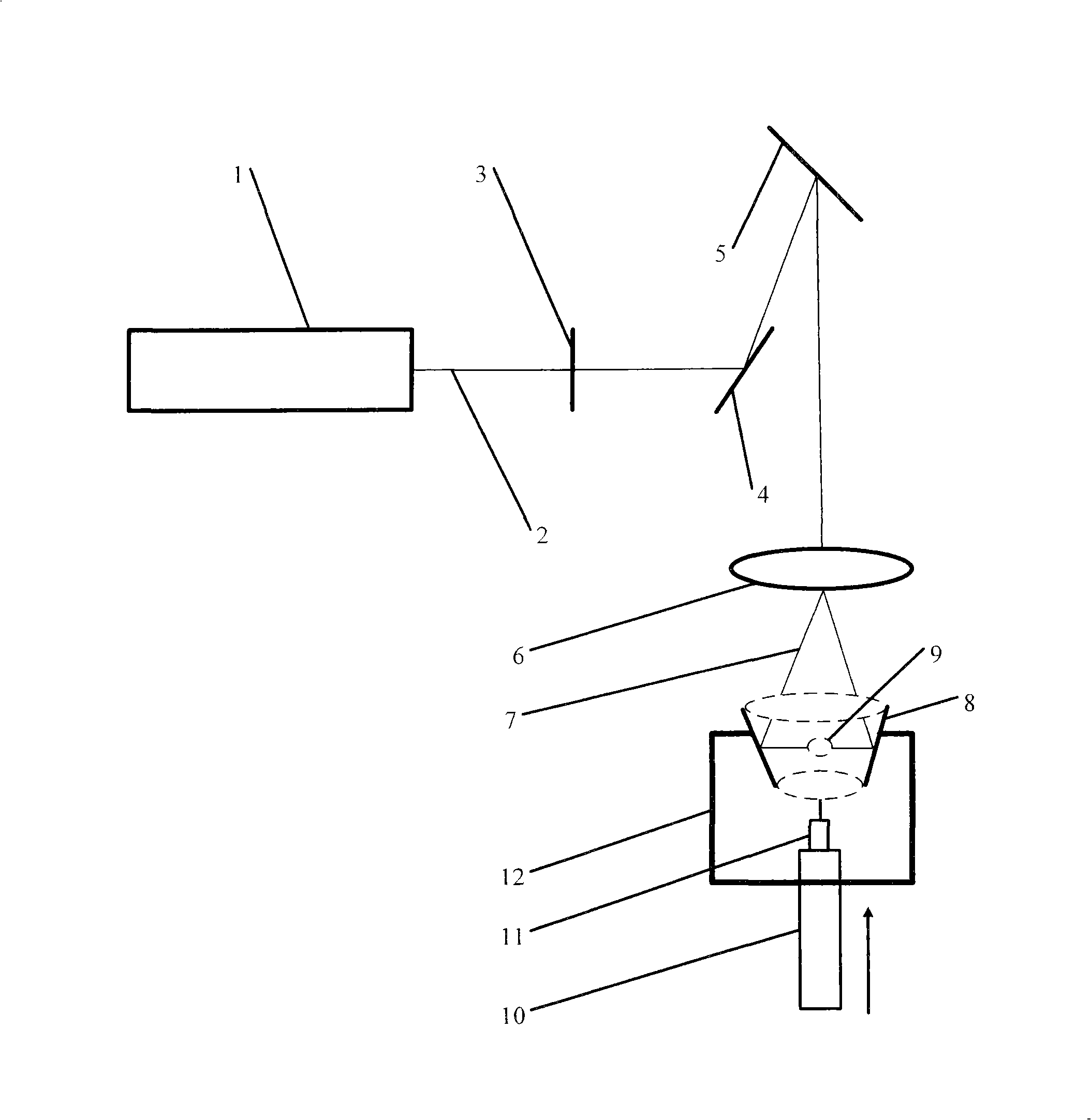

[0011] The present invention combines the attached figure 1 , its technical scheme is described in detail as follows:

[0012] Such as figure 1 As shown, a coaxial metal shielding layer stripping machine adopts a laser light source 1, the laser 1 radiates a laser 2, the power of the laser 2 is 80W, the wavelength of the laser is 1064nm, and the laser 2 is collimated by a beam expander 3 Magnification, the magnification of the beam expander 3 is 3, then through a X-direction galvanometer 4 and a Y-direction galvanometer 5, and then through an F-THETA lens 6, the focal length of the F-THETA lens 6 is f=80mm, scanning The format is 80mm*80mm, and a conical optical path 7 is formed in space. The conical optical path 7 passes through an annular optical path reflector 8. The shape of the annular optical path reflector 8 is a section of a cone or a rotating paraboloid. The conical optical path 7 is in the ring The incident angle on the light path reflector 8 is 30 degrees, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com