Remover for removing biological slime in recirculated cooling water and method for removing biological slime in recirculated cooling water system

A technology of circulating cooling water and biological slime, applied in water/sludge/sewage treatment, water/sewage treatment, chemical instruments and methods, etc. Reduced deposition, thorough peeling, enhanced slime peeling effect

Active Publication Date: 2014-05-07

CHINA PETROLEUM & CHEM CORP +1

View PDF4 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disadvantage is that trihydroxymethylnitromethane will slowly decompose and release formaldehyde in slightly alkaline solution, and the service life will be shortened, so it is not suitable for slightly alkaline circulating water

[0008] In order to remove the slime in the circulating cooling water system, the existing slime stripping agent needs to use a large amount of chemically synthesized surfactants, and also causes serious pollution to the environment. With the enhancement of human environmental protection awareness, it is urgent to develop a A slime stripping agent that can effectively strip the slime in the circulating cooling water system and is environmentally friendly

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

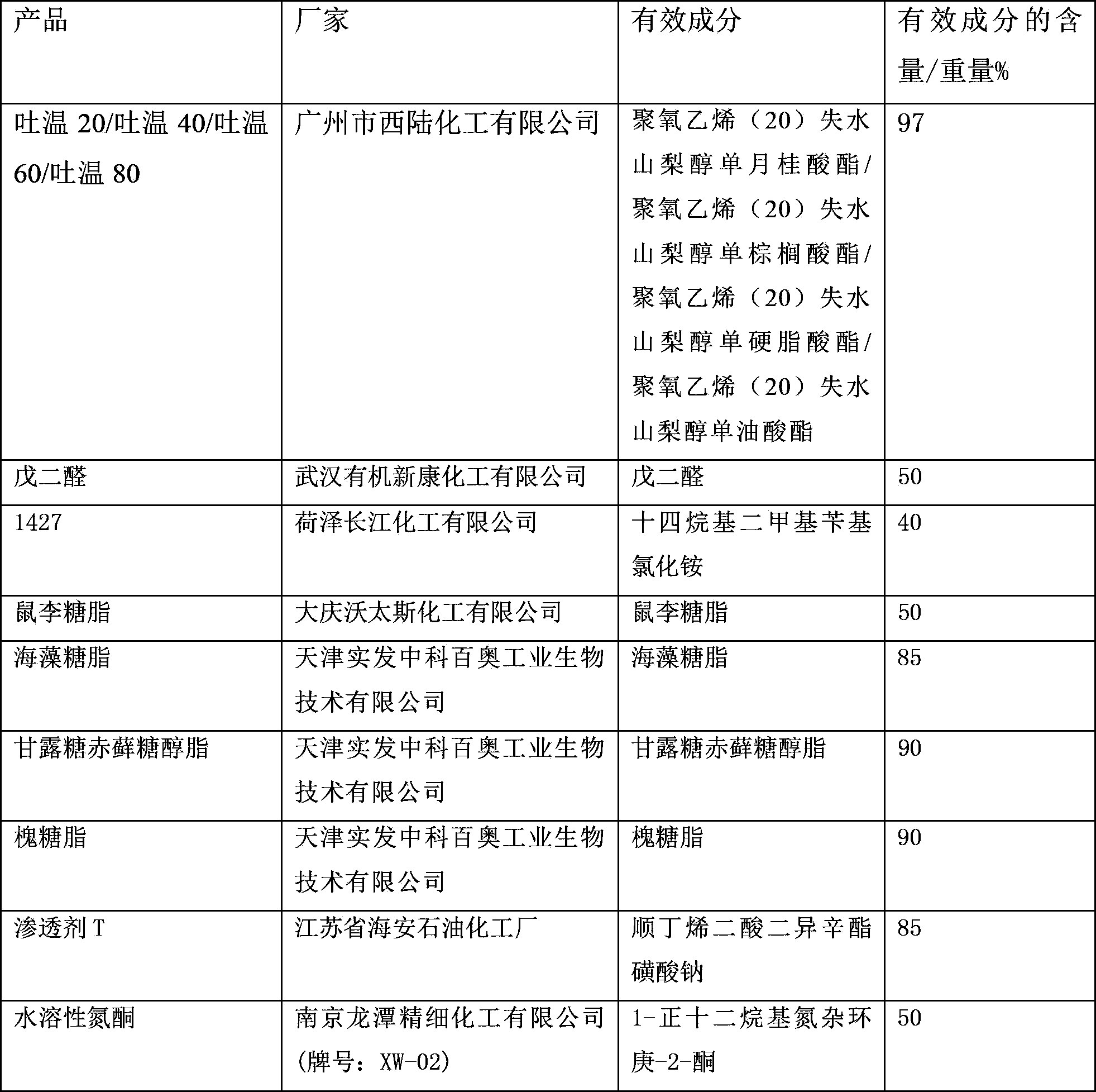

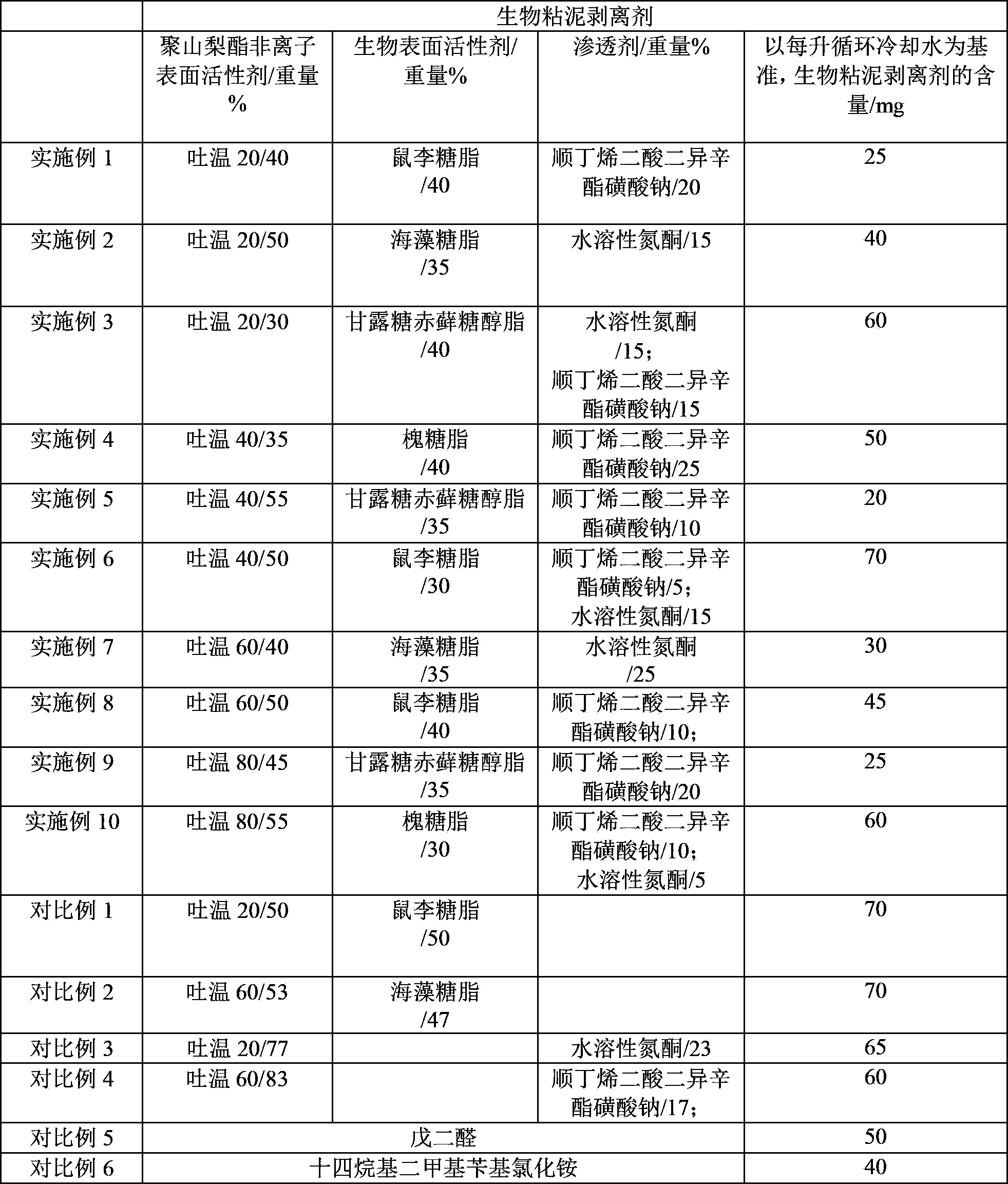

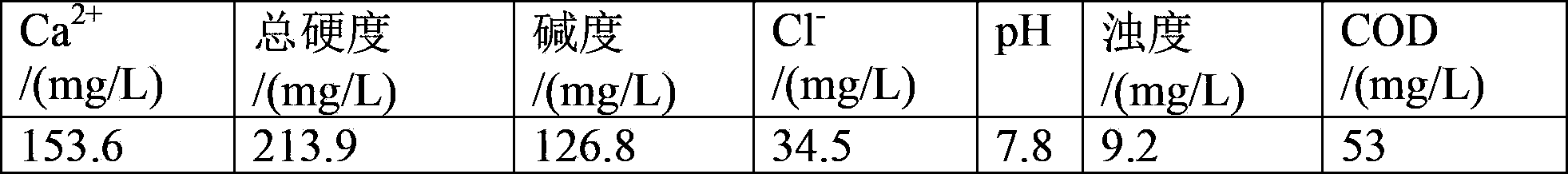

Embodiment 1-10 and comparative example 1-6

[0030] Take each component at room temperature (25°C) according to the mixing ratio of the formula in Table 2, stir and mix evenly, and serve.

[0031] Table 2

[0032]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a remover for removing biological slime in recirculated cooling water. The remover contains a polysorbate nonionic surfactant, a biosurfactant and an osmotic agent. The biosurfactant is a glycolipid-type biosurfactant. The invention also provides a method for removing biological slime in a recirculated cooling water system by the remover. The method comprises putting the remover into the recirculated cooling water. The remover effectively removes biological slime deposited on the equipment and pipes of the recirculated cooling water system, effectively improves effects of removing biological slime of the recirculated cooling water system, reduces a synthetic surfactant use amount, and reduces draining environment pollution caused by use of the synthetic surfactant.

Description

technical field [0001] The invention relates to a biological slime stripping agent and a method for stripping slime in a circulating cooling water system, in particular to an environmentally friendly biological slime stripper suitable for circulating cooling water that can effectively strip the slime in a circulating cooling water system. A slime stripping agent and a method for stripping slime in a circulating cooling water system. Background technique [0002] In the treatment of industrial cooling water, problems of corrosion, scaling and slime are often encountered. With the improvement of water treatment technology, most of the problems of corrosion and scale inhibition of cooling water have been better solved, but the problem of slime and bacteria and algae in the system is more prominent, especially in the case of material leakage, the slime often peels off not good. Once a large amount of microbial slime is formed, it will not only reduce the cooling effect of heat...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C11D1/825C11D3/34C11D3/28C02F1/00

Inventor 魏新胡艳华郦和生王洪英

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com