Molybdenum disulfide peeling method as well as molybdenum disulfide prepared by molybdenum disulfide peeling method and application thereof

A molybdenum disulfide and ultrasonic stripping technology, applied in the field of nanomaterials, can solve the problems of high environmental temperature requirements, high environmental temperature requirements, and inapplicability, and achieve good antibacterial performance, high efficiency of the stripping process, and improved dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A stripping method of molybdenum disulfide comprises the steps:

[0056] (1) Molybdenum disulfide powder, water and sodium lauryl sulfate are mixed in a mass ratio of 5:1000:1 to obtain a mixed solution;

[0057] (2) At room temperature, the mixed solution was ultrasonically stripped for 12 hours with a power of 250W to obtain molybdenum disulfide;

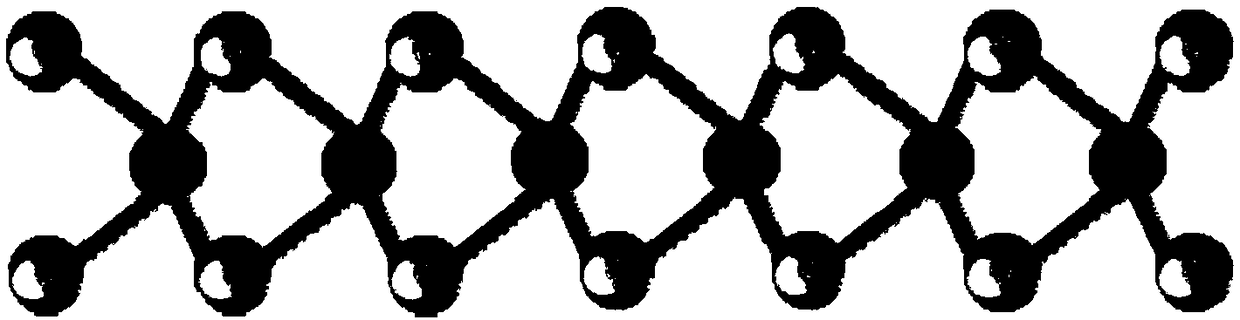

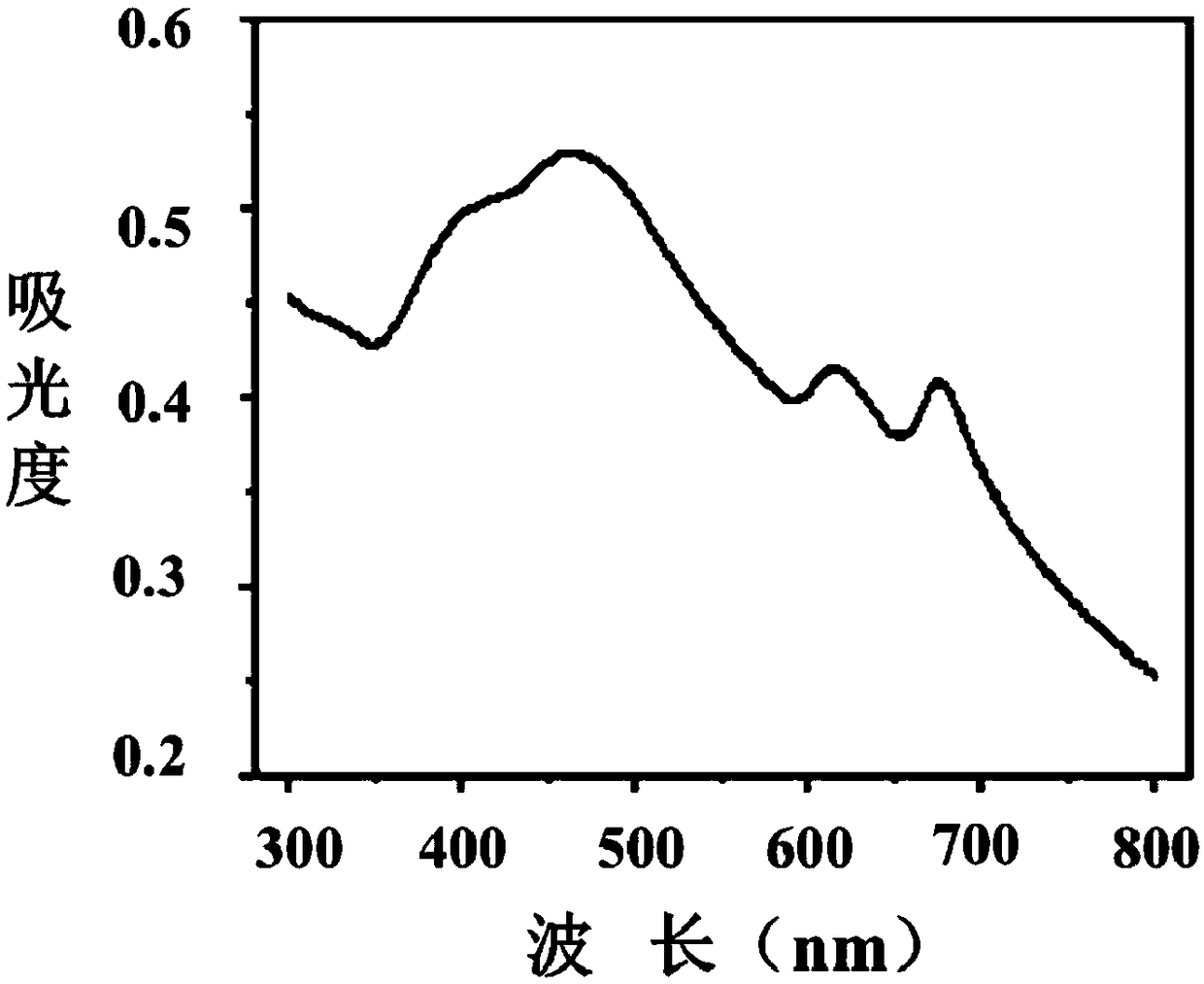

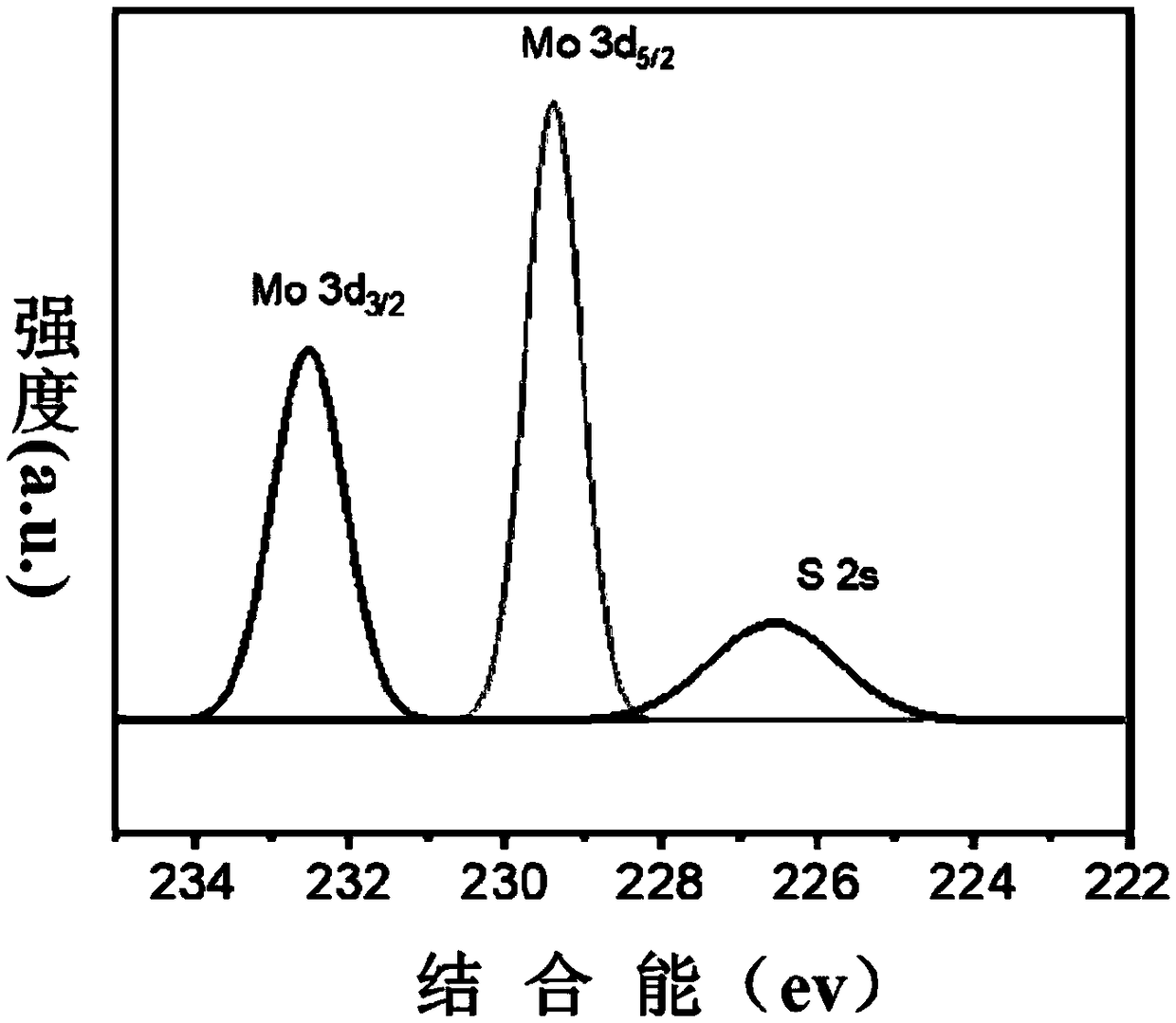

[0058] (3) Centrifuge the molybdenum disulfide at 3000rpm for 30min, collect the upper layer filtrate, then centrifuge the upper layer filtrate for 3 times, each time the centrifugal speed is 12000rpm, and the time of each centrifugal time is 30min, collect the lower layer sediment matter, the lower precipitate was dissolved in water to obtain a molybdenum disulfide dispersion, figure 1 To obtain the structure diagram of molybdenum disulfide, figure 2 For making the ultraviolet-visible light absorption spectrum of molybdenum disulfide, as can be seen from the figure, the molybdenum disulfide prepared is the nano molybden...

Embodiment 2

[0060] The difference with Example 1 is that sodium lauryl sulfate is replaced by sodium deoxycholate in step (1).

Embodiment 3

[0062] The difference with Example 1 is that sodium lauryl sulfate is replaced by sodium cholate in step (1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com