MXene-ACF composite material for catalyzing hydrochlorination reaction of acetylene as well as preparation method and application of MXene-ACF composite material

A technology of acetylene hydrochlorination and composite materials, which is applied in the field of MXene-ACF composite materials and its preparation, can solve the problems of restricting the excellent characteristics of MXene, MXene stacking and agglomeration, and decreasing electrical conductivity, and achieves acetylene conversion rate and vinyl chloride selectivity. High, improve catalytic performance, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

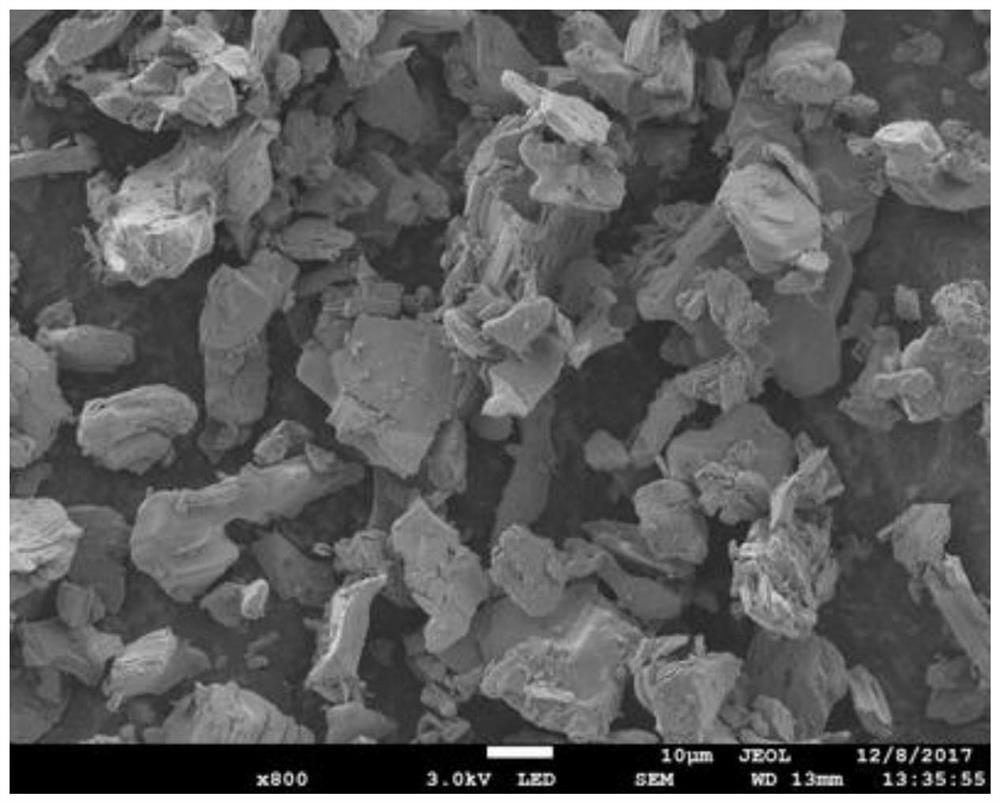

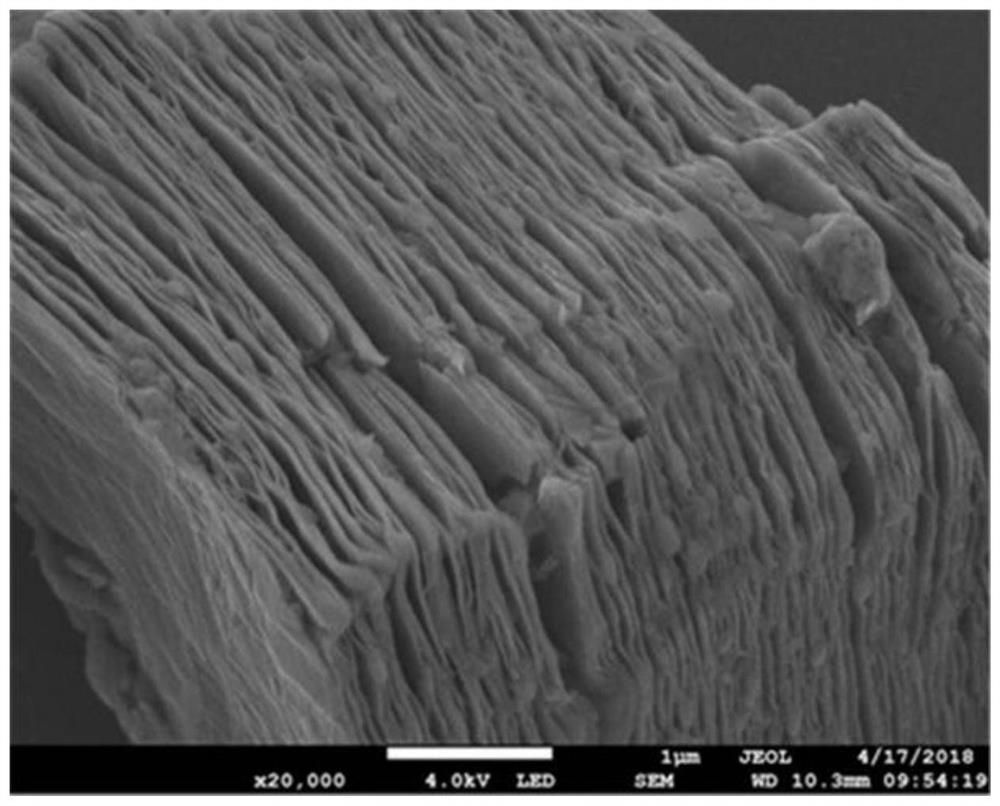

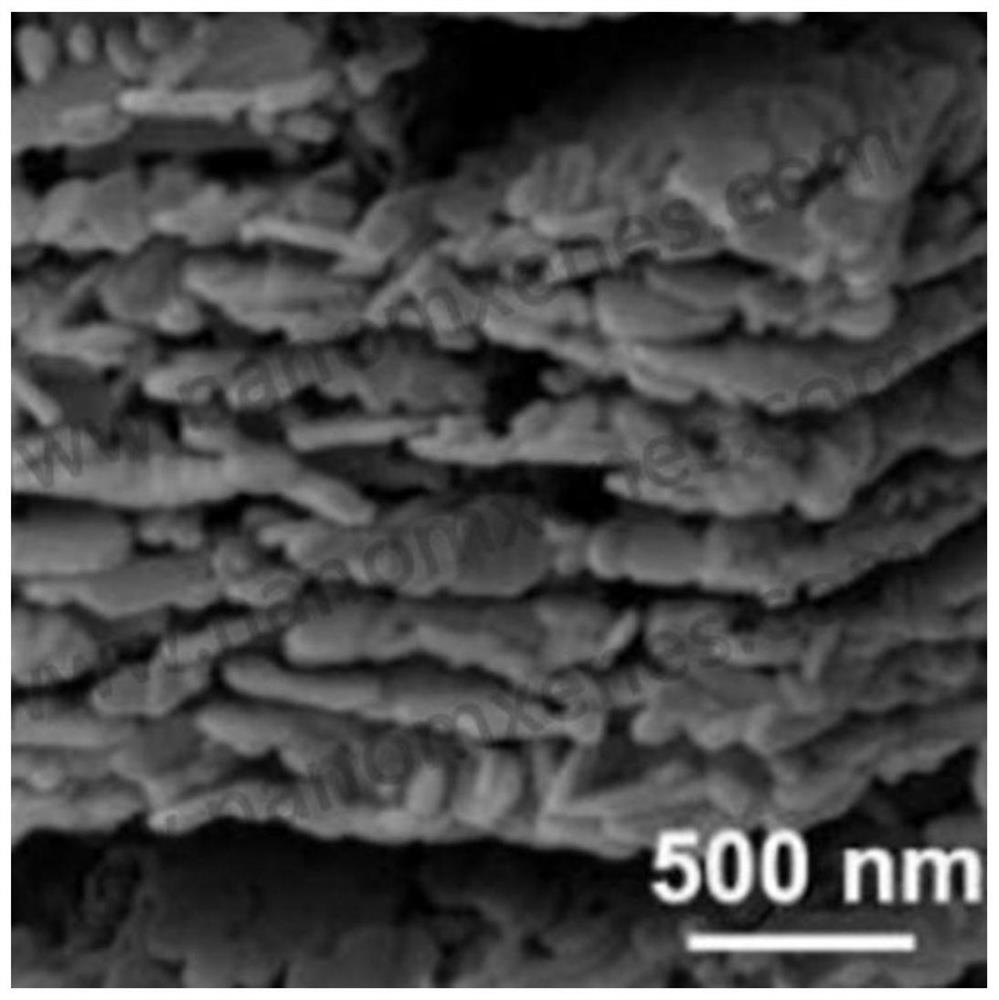

[0036] A preparation method and application of an MXene-ACF composite material for acetylene hydrochlorination, comprising the following steps:

[0037] 1) Add 1g of LiF powder to 20ml of HCl solution with a concentration of 8mol / L, fully dissolve and then slowly add 1g of MAX powder, in an oil bath at 20°C assisted by 20kHz ultrasonic waves, stirring at a rate of 500r / min, stirring and etching for 8h Finally, use deionized water to repeatedly centrifuge and wash at a speed of 2000rpm, the washing time is 30min, and wash to pH=6 to obtain multi-layer MXene precipitation;

[0038] 2) Redisperse the multi-layer MXene precipitate into deionized water to form a 4mg / mL suspension, then dry 10g of ACF in an oven at 100°C for 6h and then cut it into pieces of 1cm*1cm*0.1cm. ACF is immersed in the suspension to form MXene / ACF through electrostatic self-assembly;

[0039] 3) Take out the obtained MXene / ACF at a wavelength of 280nm and an intensity of 40μW / cm 2 Vacuum drying at 40°C for...

Embodiment 2

[0042] A preparation method and application of an MXene-ACF composite material for acetylene hydrochlorination, comprising the following steps:

[0043] 1) Add 1g of LiF powder to 30ml of HCl solution with a concentration of 9mol / L, fully dissolve and then slowly add 1g of MAX powder, in an oil bath at 30°C assisted by 30kHz ultrasonic waves, stirring at a rate of 600r / min, stirring and etching for 12h Finally, use deionized water to repeatedly centrifuge and wash at a speed of 3000rpm, the washing time is 60min, and wash to pH=6 to obtain multi-layer MXene precipitation;

[0044] 2) Redisperse the multi-layered MXene precipitate into deionized water to form a 4mg / mL suspension, then dry 10g of ACF in an oven at 100°C for 8 hours and cut it into pieces of 1.5cm*1.5cm*0.1cm. The ACF is immersed in the suspension to form MXene / ACF through electrostatic self-assembly;

[0045] 3) Take out the obtained MXene / ACF at a wavelength of 250nm and an intensity of 40μW / cm 2 Vacuum dryin...

Embodiment 3

[0048] A preparation method and application of an MXene-ACF composite material for acetylene hydrochlorination, comprising the following steps:

[0049] 1) Add 2g of LiF powder to 40ml of HCl solution with a concentration of 8mol / L, fully dissolve and then slowly add 2g of MAX powder, in an oil bath at 40°C assisted by 40kHz ultrasonic waves, stirring at a rate of 700r / min, stirring and etching for 14h Finally, use deionized water to repeatedly centrifuge and wash at a speed of 3000rpm, the washing time is 60min, and wash to pH=6 to obtain multi-layer MXene precipitation;

[0050] 2) Redisperse the multi-layer MXene precipitate into deionized water to form a 4mg / mL suspension, then dry 10g of ACF in an oven at 100°C for 8 hours and cut it into pieces of 1.5cm*1.5cm*0.1cm. The ACF is immersed in the suspension to form MXene / ACF through electrostatic self-assembly;

[0051] 3) Take out the obtained MXene / ACF at a wavelength of 250nm and an intensity of 40μW / cm 2 Vacuum drying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com