Graphene grinding and stripping device, graphene production system and production method

A technology of peeling device and production system, applied in the field of graphene production, can solve the problems of uneven pressure applied to graphite, limited shear force, insufficient powder shear force, etc., to maintain the natural plane size, reduce structural defects or The effect of less chipping, structural defects and burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

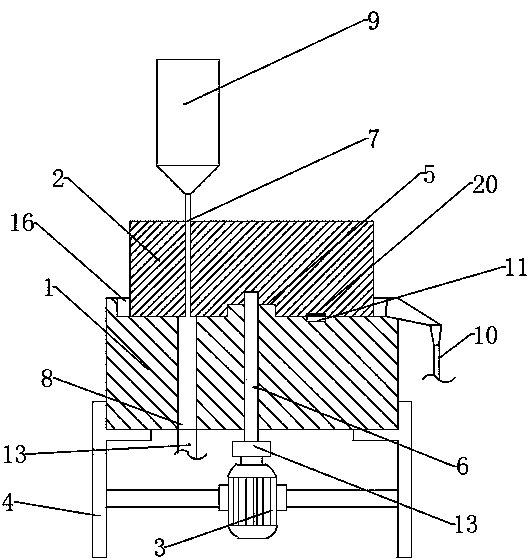

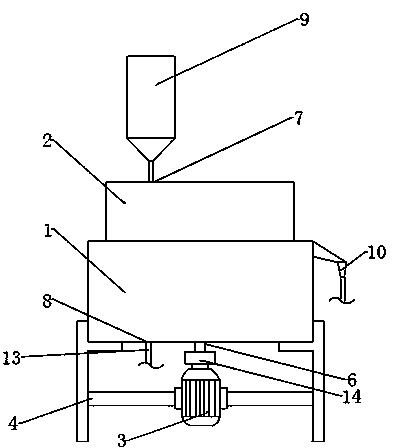

[0052] The present invention relates to a graphene grinding and stripping device 1 and a graphene production system, and also relates to a graphene production method.

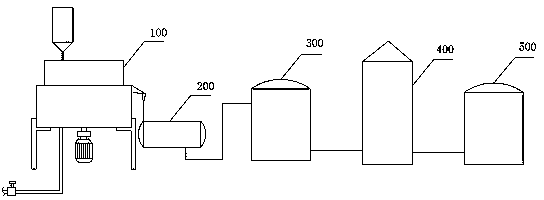

[0053] The graphene production system, such as figure 1 As shown, the graphene grinding and peeling device 100, the storage tank 200, the centrifuge 300, the vacuum filter device 400 and the freeze-drying device 500 are included successively along the process sequence; the graphene grinding and peeling device 100 is used for grinding in the direction of parallel graphite sheets For exfoliating graphene, the storage tank 200 is used to collect and leave the graphene grinding and peeling device 100 to discharge the product after processing, and the centrifuge 300 is used to centrifuge the upper layer suspension in the storage tank 200 to separate the exfoliated graphene and unexfoliated graphite The vacuum filtration device 400 is used to filter and wash the supernatant liquid obtained after centrifugation by the...

Embodiment 2

[0063] On the basis of embodiment 1, as an improvement, in this embodiment, as Figure 6 and Figure 7 As shown, a frosted part 20 is also provided on the lower end surface of the upper grinding disc 2 , and the grinding part 20 is opposite to the groove 11 of the lower grinding disc 1 . The grinding part 20 has increased the frictional force to the graphite flakes entering the groove. By setting the grinding part 20, the stone grinding sheet layer can be spread faster and better at the oil-water interface, which further ensures the parallel grinding of the graphite flakes and makes the peeling Graphene better maintains the natural size of the graphite sheet surface.

[0064] The frosted part 20 can also be changed into other structures that can moderately increase the frictional force on the graphite sheet, such as a brush.

Embodiment 3

[0066] On the basis of Embodiment 1, as an improvement, in the present embodiment, the water inlet pipe 13 is connected to the water storage tank 600, and the feed hopper 9 is connected to a dispersion tank 700 for dispersing graphite in the oily solvent, such as Figure 8 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com