Rotary graphene stripping device, graphene production system and production method

A technology of peeling device and production system, applied in the field of graphene production, can solve the problems of fragmentation, limited shear force, and uneven pressure exerted by graphite, achieve good quality, reduce the probability of being pulverized, and maintain the natural plane size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

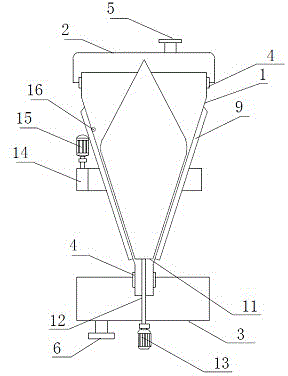

[0047] The present invention relates to a rotary graphene stripping device 1 and a graphene production system, and also relates to a graphene production method.

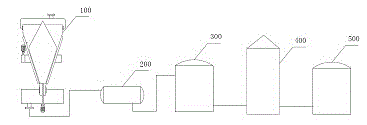

[0048] The graphene production system, such as figure 1 As shown, along the process sequence, the rotary graphene stripping device 100, the storage tank 200, the centrifuge 300, the vacuum filter unit 400 and the freeze drying device 500 are successively included; the storage tank 200 is used for collecting and standing the rotary graphene stripping After the device 100 is processed, the product is discharged. The centrifuge 300 is used to centrifuge the upper layer suspension in the storage tank 200 to separate exfoliated graphene and unexfoliated graphite. The vacuum filter device 400 is used to centrifuge the supernatant obtained by the centrifuge 300. Filtration and washing are performed, and the freeze-drying device 500 is used to dry the graphene after vacuum filtration. Here, the discharge port 6 of the rotar...

Embodiment 2

[0052] In Example 1, the gradual exfoliation of graphene will cause the volume expansion of the suspension. If the gap between the inner cylinder 11 and the rotating cylinder 1 is designed to increase axially downward, although the volume expansion requirement of the suspension can be satisfied, the shearing and grinding effects will be weakened.

[0053] Different from Embodiment 1, the rotary graphene peeling device 100 in this embodiment, such as image 3 As shown, the lower part of the inner cylinder 11 is a truncated cone with the cone angle upward, and the upper part of the inner cylinder 11 is conical; the rotating cylinder 1 is in the shape of a truncated cone with the cone angle upward. By designing the rotary cylinder 1 with the cone angle facing upward and the lower part of the inner cylinder 11 matched with the lower part of the rotary cylinder, the capacity of the suspension that can be accommodated per unit height between the inner cylinder 11 and the rotary cyli...

Embodiment 3

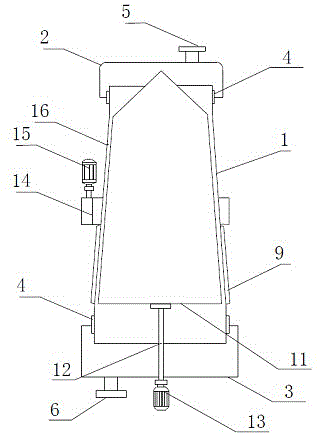

[0055] In Example 1, the gradual exfoliation of graphene will cause the volume expansion of the suspension. If the gap between the inner cylinder and the rotating cylinder is designed to increase in the axial direction, although the increase in volume required by the volume expansion of the suspension can be met, the shearing and grinding effects will be weakened.

[0056] Different from Embodiment 1, the rotary graphene peeling device 100 in this embodiment, such as Figure 4 As shown, the inner cylinder 11 is conical with the cone angle facing upwards; the middle and lower part of the rotary cylinder 1 is in the shape of a truncated cone, and the upper part of the rotary cylinder 1 is cylindrical. By designing the middle and lower part of the rotary cylinder 1 with the cone angle facing upwards and the inner cylinder 11 matched with the middle and lower part of the rotary cylinder, the unit height between the inner cylinder 11 and the rotary cylinder 1 can accommodate the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com