Magnetic resin water purification equipment

A technology of magnetic resin and water purification equipment, applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc. The problems of large investment in stirring paddles can improve the service life, better exchange and adsorption effect, and reduce investment costs and maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

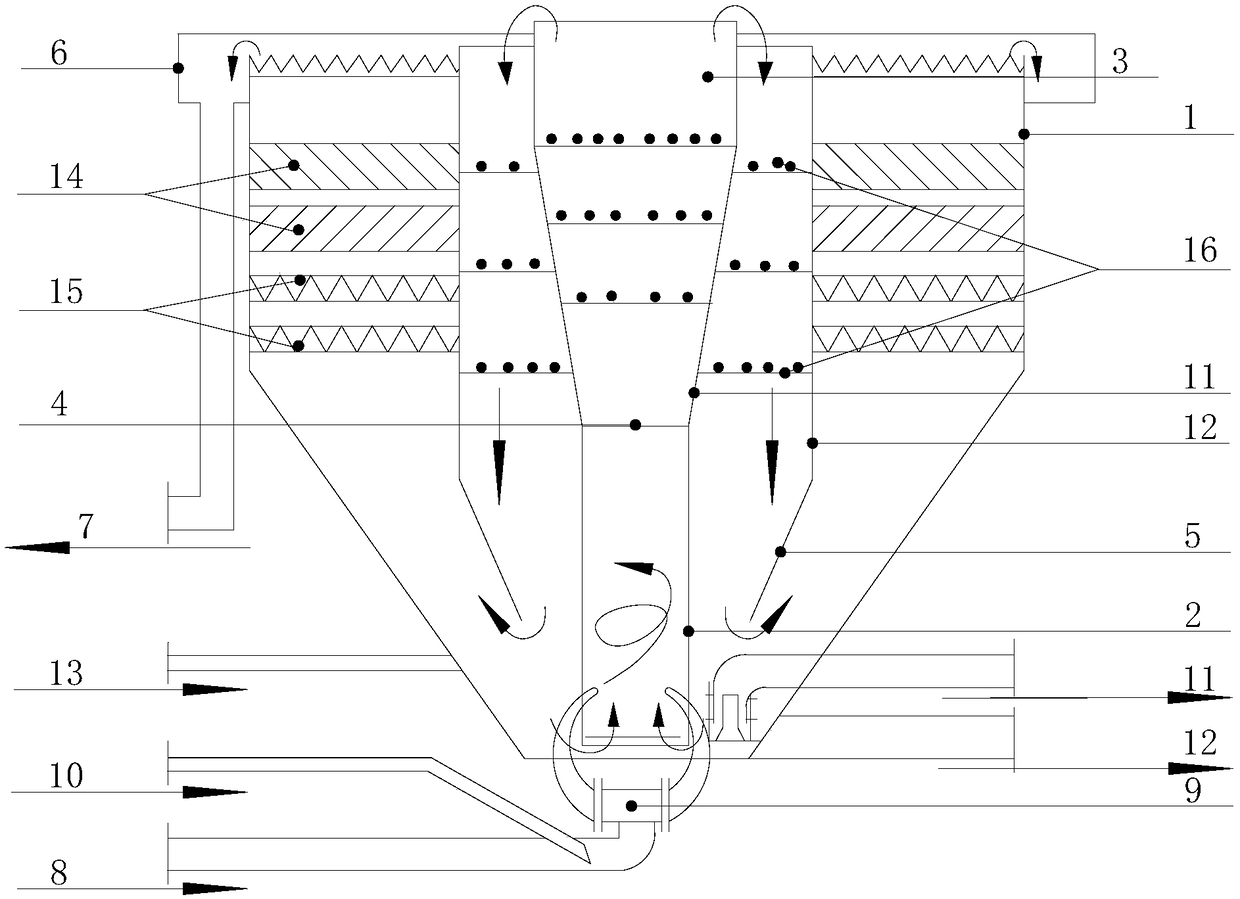

[0020] The present invention will be further explained below in conjunction with the accompanying drawings.

[0021] The invention discloses a magnetic resin water purification device, which comprises a large cylinder body 1, an exchange cylinder body 2 is arranged below the large cylinder body 1, an exchange cylinder body chamber 3 is arranged above the exchange cylinder body 2, and an exchange cylinder body chamber 3 is covered with an exchange The second chamber 4 of the cylinder body, the lower end of the second chamber 4 of the exchange cylinder body is provided with an anti-skirt plate 5 at the lower opening of the second chamber; the large cylinder body 1 is divided into a separation area and a clean water area; the top of the large cylinder body 1 is provided with a water collection tank 6; There is a water outlet pipe 7, which communicates with the water collection tank 6; the bottom of the large cylinder 1 is provided with a water inlet pipe 8, and the water inlet pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com