Bottle reject mechanism of online visual inspection robot for visible foreign matters in bottled liquid

A technology for visual inspection and bottled liquid, which is applied in the direction of optical inspection of flaws/defects, sorting, etc. It can solve the problems of unimproved detection accuracy and accuracy, poor mechanical motion stability, and increased cost, so as to facilitate maintenance and function changes , strong adaptability, the effect of reducing impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

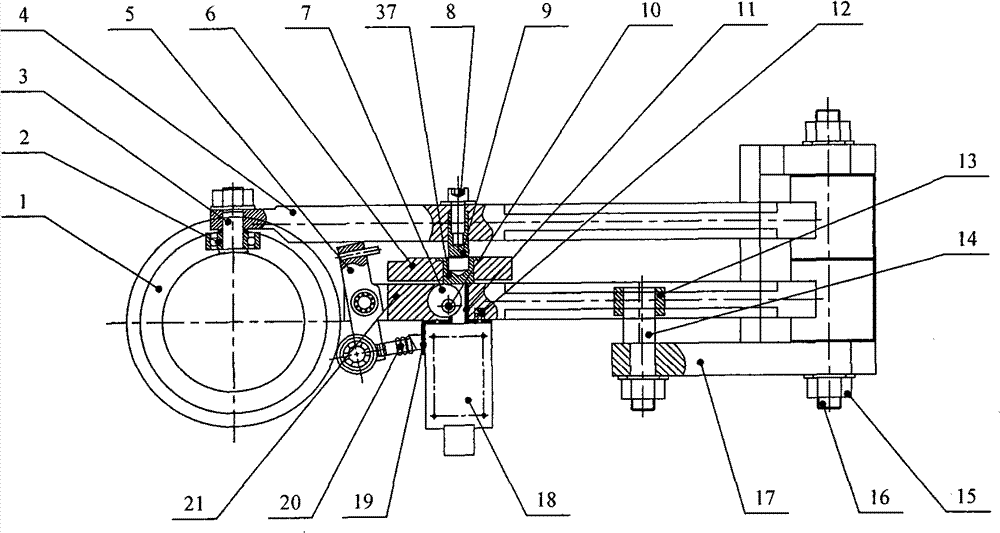

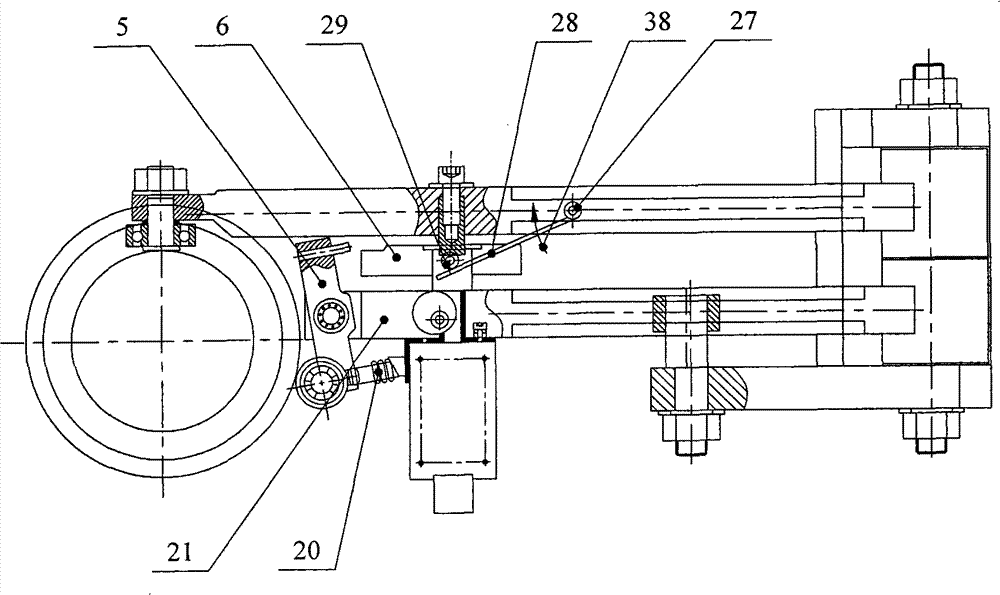

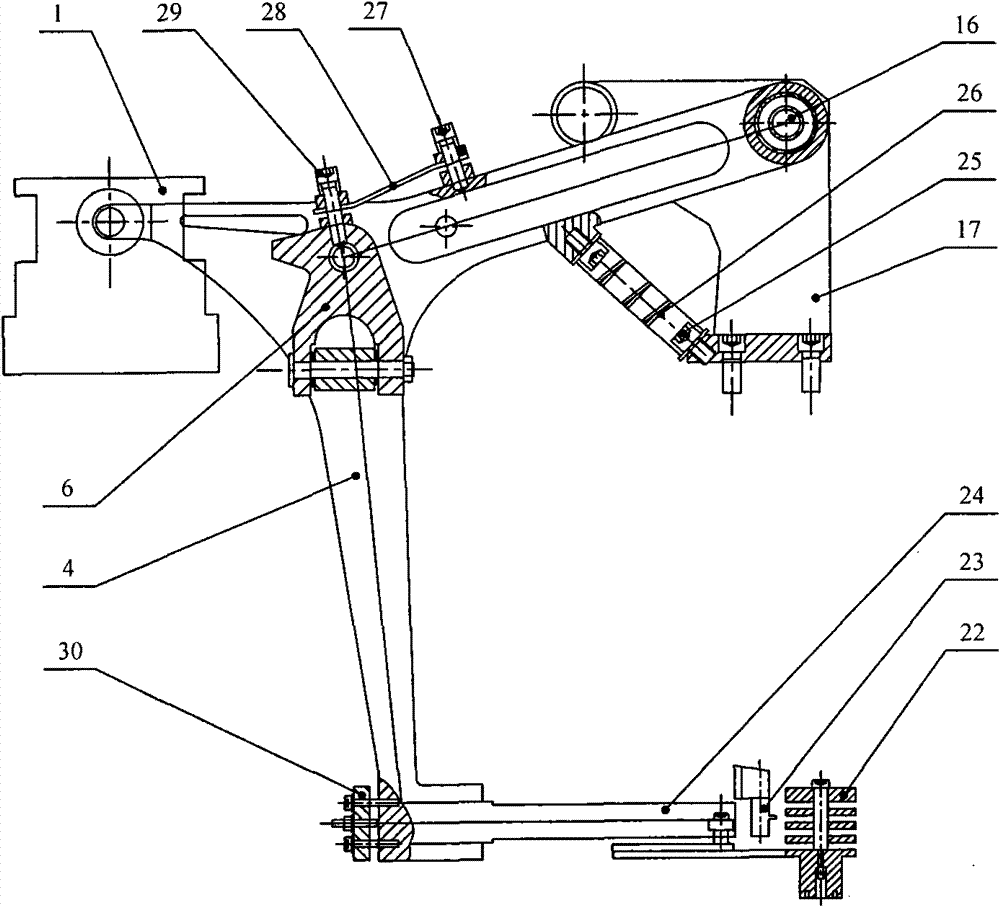

[0042] A bottle-picking mechanism for an online visual inspection robot for visible foreign matter in bottled liquids, characterized in that it includes a rotatable cam 1, a swing rod seat 17, a C-shaped long swing rod 4, a C-shaped short swing rod 21, and a clutch mechanism; The C-shaped long swing rod 4 and the C-shaped short swing rod 21 are all installed on the swing rod seat 17; the C-shaped long swing rod 4 is embedded in the groove of the rotatable cam 1 through a deep groove ball bearing 2, so that it can rotate The cam drives the C-shaped long swing rod to periodically swing with the rotation of the rotatable cam; the free end of the C-shaped short swing rod 21 is provided with a C-shaped short swing rod push plate 39 for removing bottles;

[0043] The clutch mechanism includes a cylindrical pin 9 arranged on a C-shaped long fork, a frame-type electromagnet 18 arranged on a C-shaped short fork, a limit support block 37, a claw 5 and a clutch plate 6; The limit support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com