Piling anti-jamming sinking pipe of cast-in-situ pile and its construction technology

A technology of cast-in-place piles and pile tips, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as low construction efficiency, increased construction cost, and increased construction difficulty, so as to improve construction efficiency and enhance shear resistance , The effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

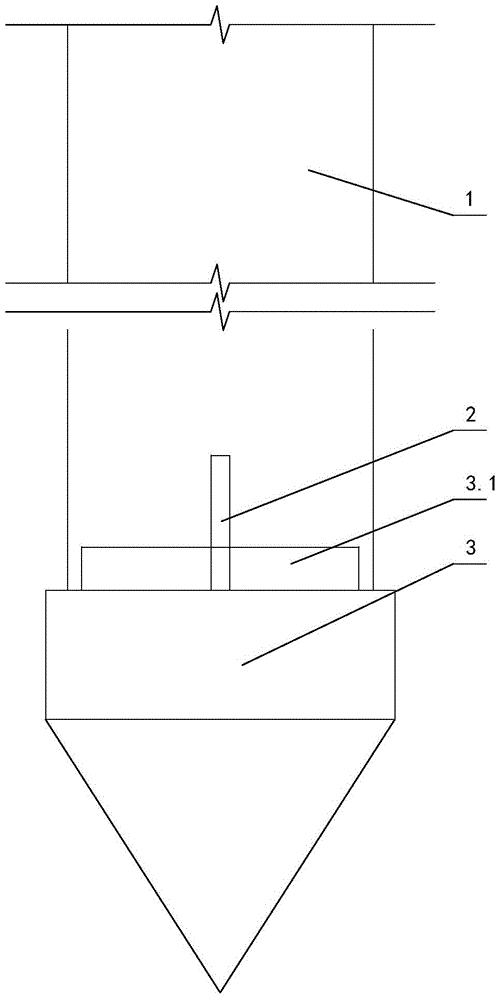

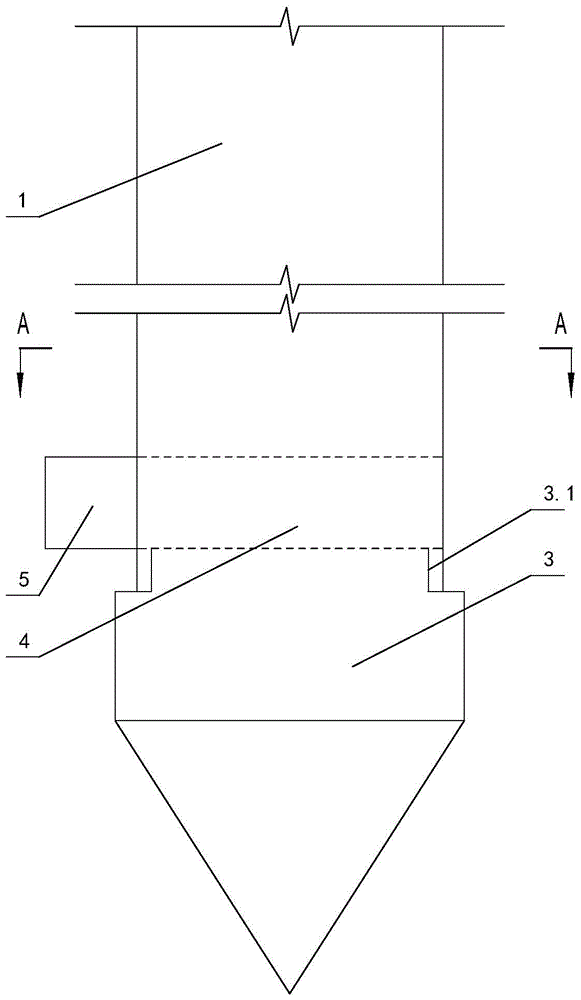

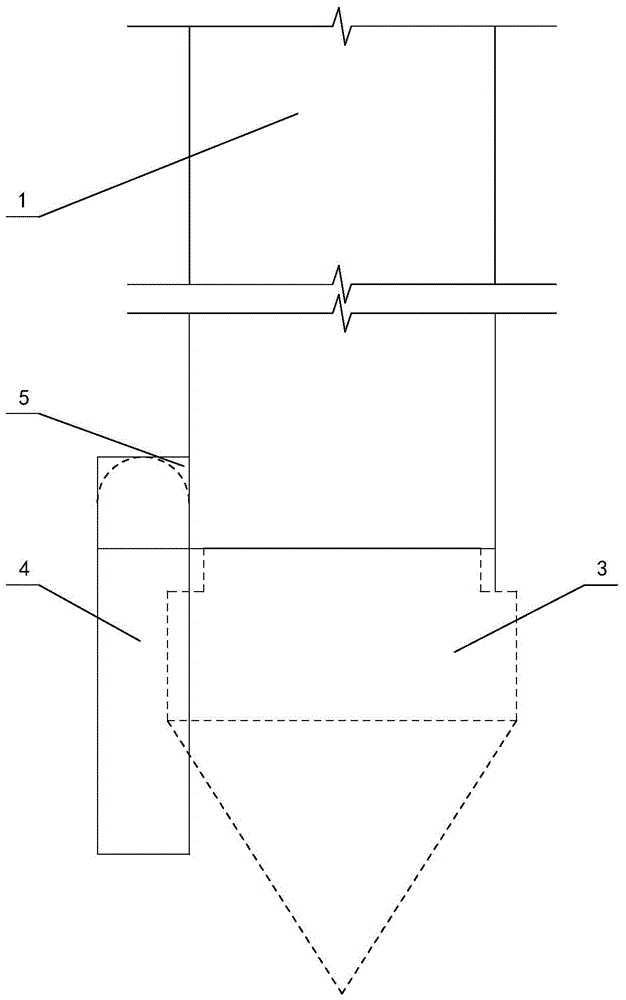

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0038] Depend on Figure 1 to Figure 9 It can be seen from the structural schematic diagram of the anti-jamming sinking tube of the pile tip of the cast-in-situ pile shown in the present invention that it includes the immersed tube body 1 and the reinforced concrete pile tip 3, and the upper end of the reinforced concrete pile tip 3 is socketed on the immersed tube body 1. bottom end. It also includes a steel clip 4, the bottom end of the immersed tube body 1 is provided with a radially through opening groove 2, the steel clip 4 is clamped in the open groove 2 and the lower side of the steel clip 4 is connected to the The upper end surface of the reinforced concrete pile point 3 contacts, and one end of the steel clip 4 is rotationally connected with the immersed tube body 1 through the connection assembly along the up and down direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com