A prefabricated bridge pile assembly structure and connection method thereof

A prefabricated, pile technology, applied in bridges, bridge construction, bridge parts, etc., can solve the problems of increased construction cost and construction difficulty, heavy component weight, large structure size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

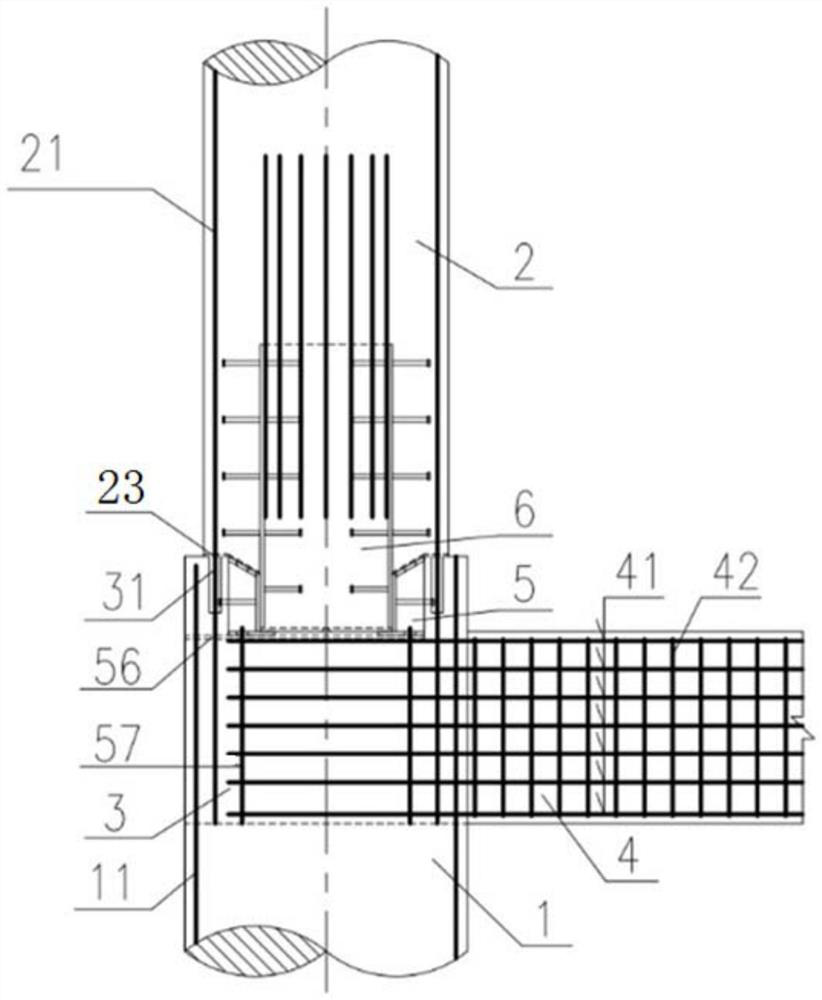

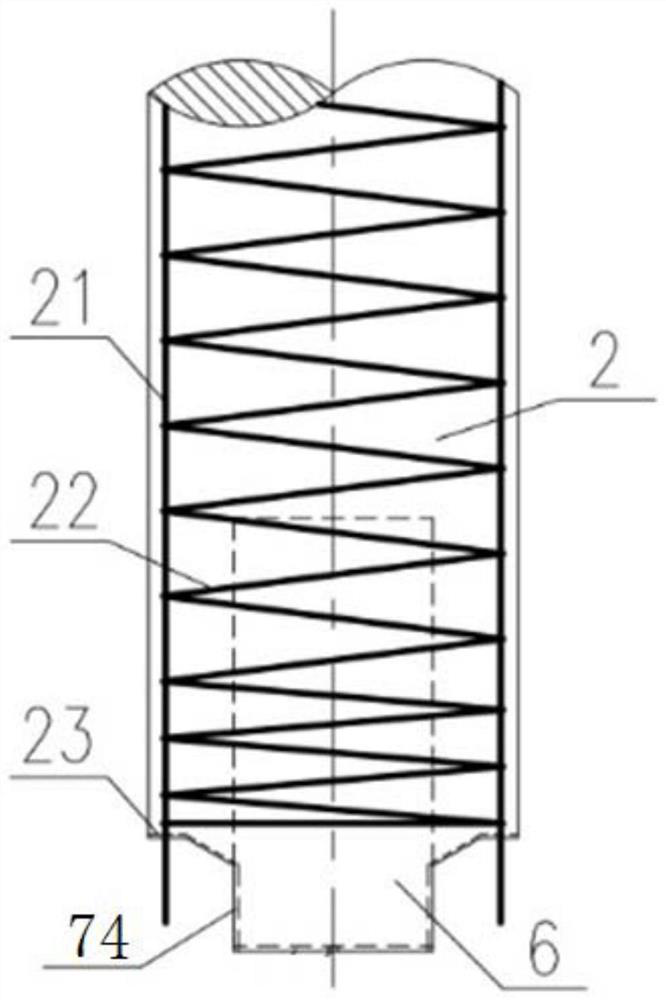

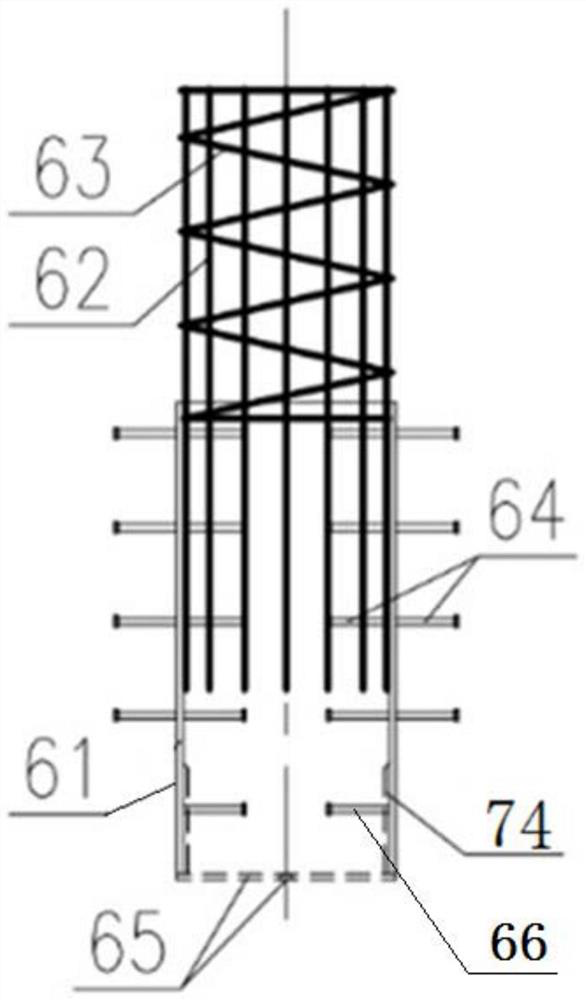

[0085] like Figure 1-11 shown.

[0086]A prefabricated bridge pile assembly structure, including a pile foundation 1, a pier column 2, a first steel pipe column 51, and a second steel pipe column 6, the top of the pile foundation is provided with a socket, the first steel pipe column 51 is arranged in the socket, and the second The top part of the second steel pipe column 6 is located in the pier column 2, the part exposed from the bottom of the second steel pipe column 6 is the socket part 61, the top of the first steel pipe column 51 is open, and the inside is a hollow structure, and the second steel pipe column 6 is a solid structure , the shape of the first steel pipe column 51 and the second steel pipe column 6 are the same, the socket part 61 of the second steel pipe column 6 is inserted into the inside of the first steel pipe column 51, and the side wall of the first steel pipe column 51 forms an outward protrusion at several set positions 73, the side wall of the sec...

Embodiment 2

[0118] like Figure 12 As shown, the difference between this embodiment and Embodiment 1 is: the grouting sleeve is arranged at the bottom of the pier column, the first anchoring steel bar extends out of the top of the pile connecting section 3 for a certain length, and the bottom of the main reinforcement 21 of the first pier column extends into the grouting In the sleeve, when the pier column and the pile foundation are connected, the grouting sleeve is aligned with the first anchoring steel bar, and then each grouting sleeve is grouted one by one.

[0119] Compared with Embodiment 1, the advantages of this embodiment are: the grouting sleeve is set on the top of the pile foundation, and when the prefabricated pier column 2 is poured with concrete, the retracted main reinforcement of the pier column is beneficial to the quality control of the concrete at the bottom of the pier column, which is beneficial to the quality control of the pier column. The protection of the bottom...

Embodiment 3

[0121] A method for connecting a prefabricated bridge pile assembly structure, the specific steps are as follows:

[0122] The second steel pipe column 6 is connected with several second studs 64, the second pier column main reinforcement 62, and the fifth stirrup 63, and the concrete in the second steel pipe column 6 should be poured synchronously with the concrete of the pier column 2;

[0123] Binding and fixing the main reinforcement 21 of several first pier columns and the fourth stirrup 22, inserting one end of the second steel pipe column 6 into the reinforcement cage surrounded by the main reinforcement 21 of several first pier columns, and pouring the pier column 2;

[0124] The pile foundation 1 is arranged below the ground, and the pile foundation main reinforcement 11, some first anchor reinforcement bars 32, and some second anchor reinforcement reinforcement bars 57 are arranged at predetermined positions of the pile foundation, and are connected with the first stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com