Patents

Literature

53results about How to "Maintain productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wet crepe throughdry process for making absorbent sheet and novel fibrous products

InactiveUS20020148584A1Big cost advantageReduce air permeabilityNon-fibrous pulp additionNatural cellulose pulp/paperFiberEngineering

An improved process for making sheet from a fibrous furnish includes: depositing the furnish on a foraminous support; compactively dewatering the furnish to form a nascent web; drying the web on a heated cylinder; creping the web therefrom and throughdrying the web to a finished product. The microstructure of the web is controlled so as to facilitate throughdrying. The product exhibits a characteristic throughdrying coefficient of from 4 to 10 when the airflow through the sheet is characterized by a Reynolds Number of less than about 1. The novel products of the invention are characterized by wet springback ratio, hydraulic diameter and an internal bond strength parameter.

Owner:GPCP IP HLDG LLC

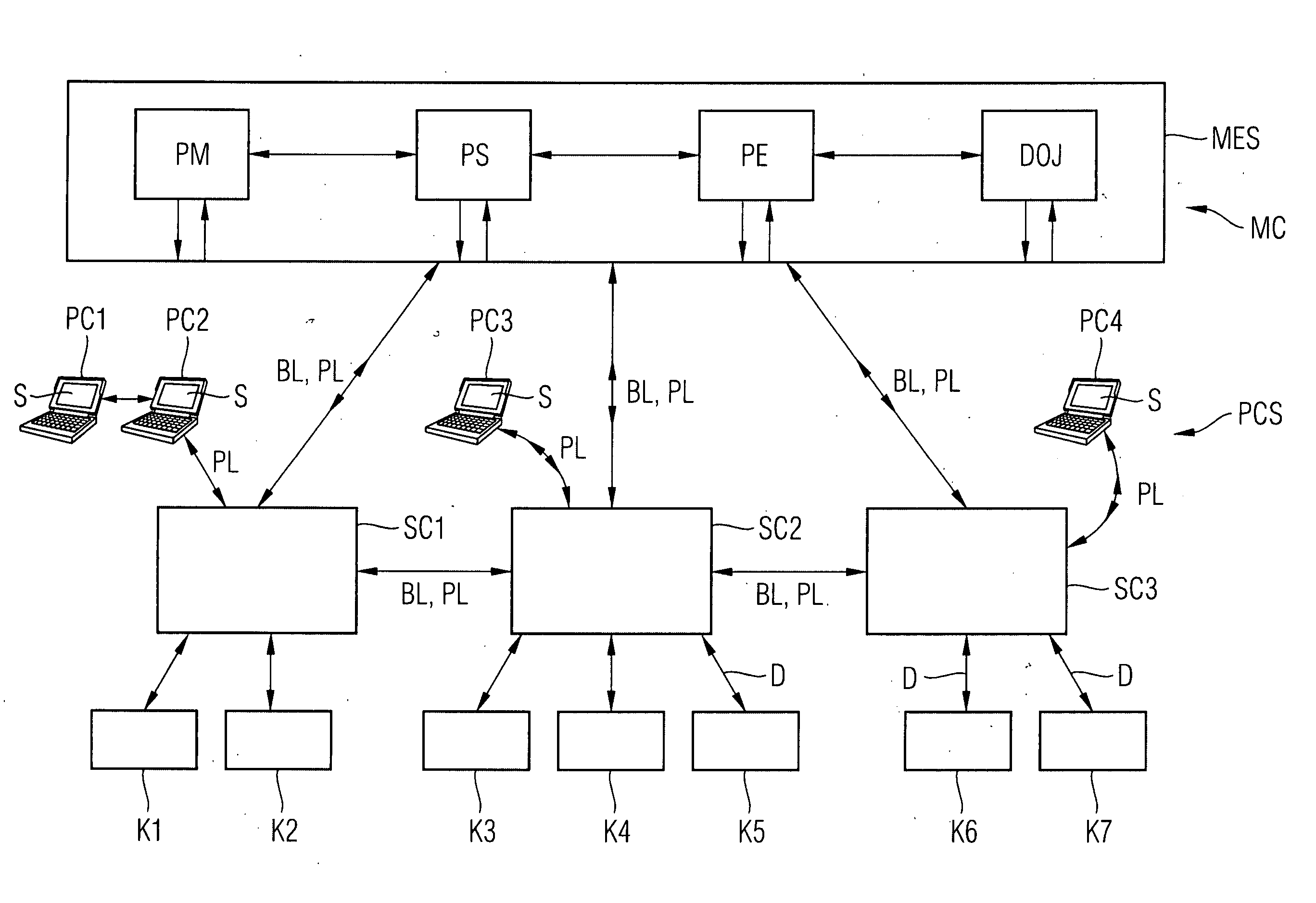

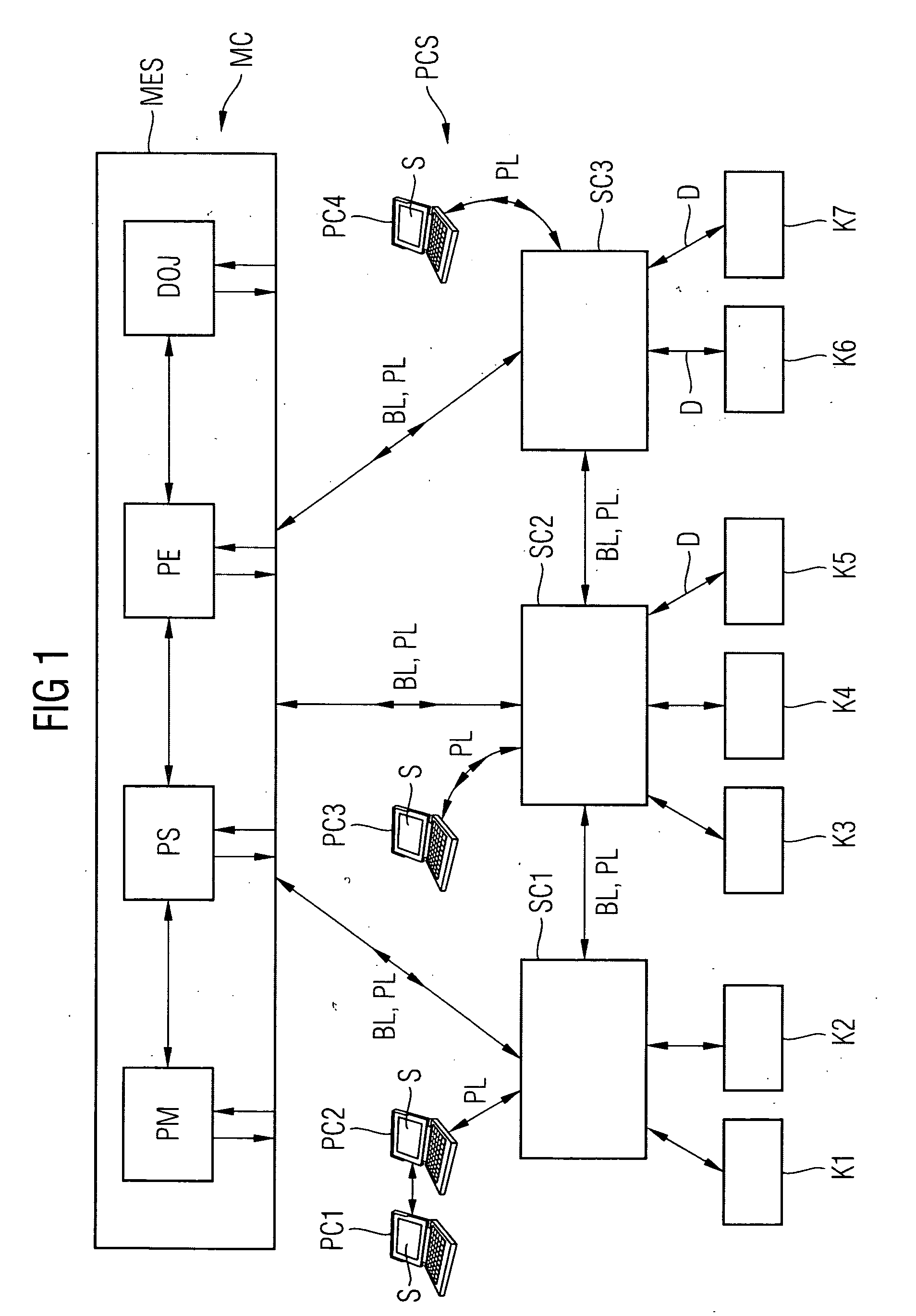

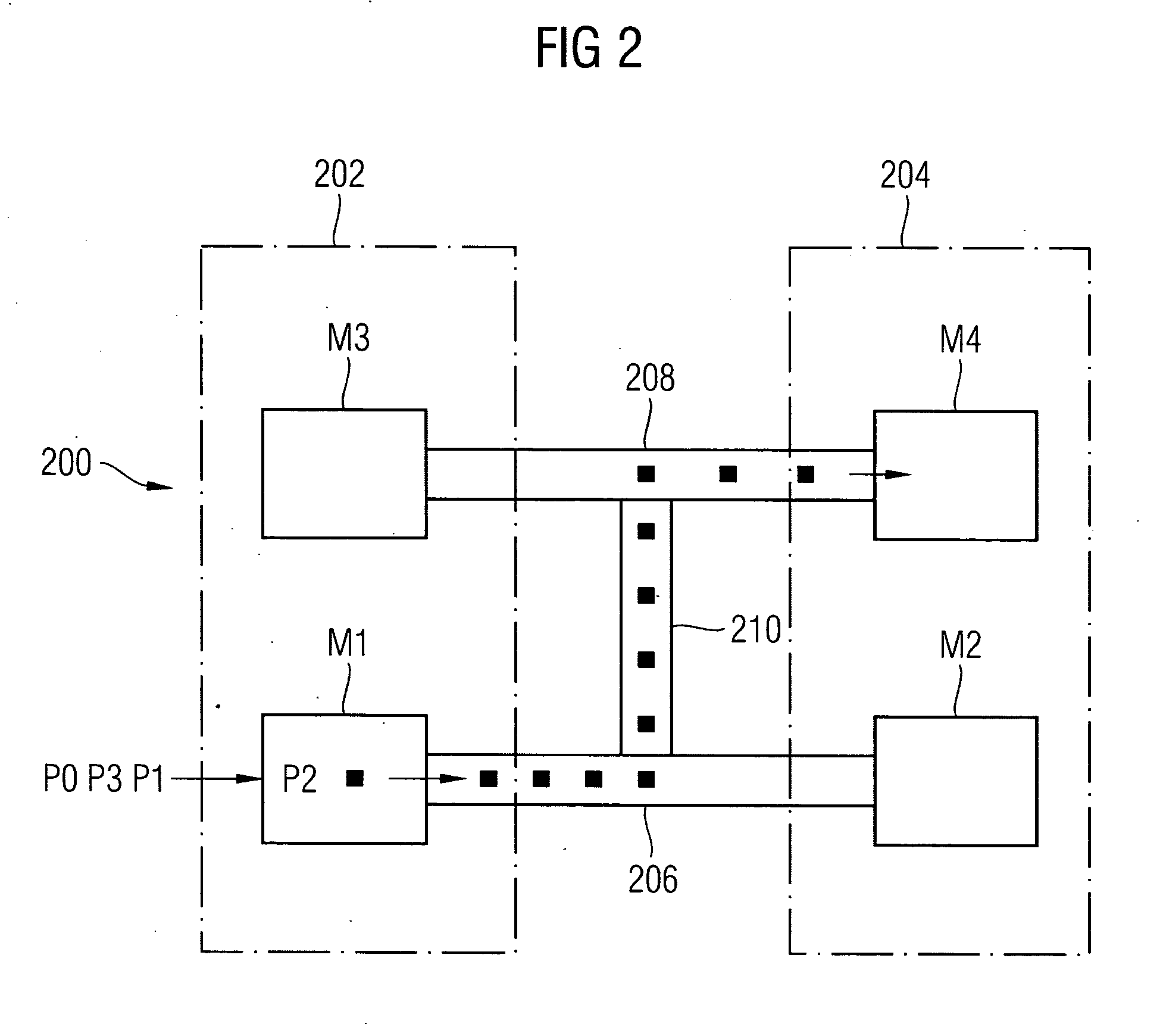

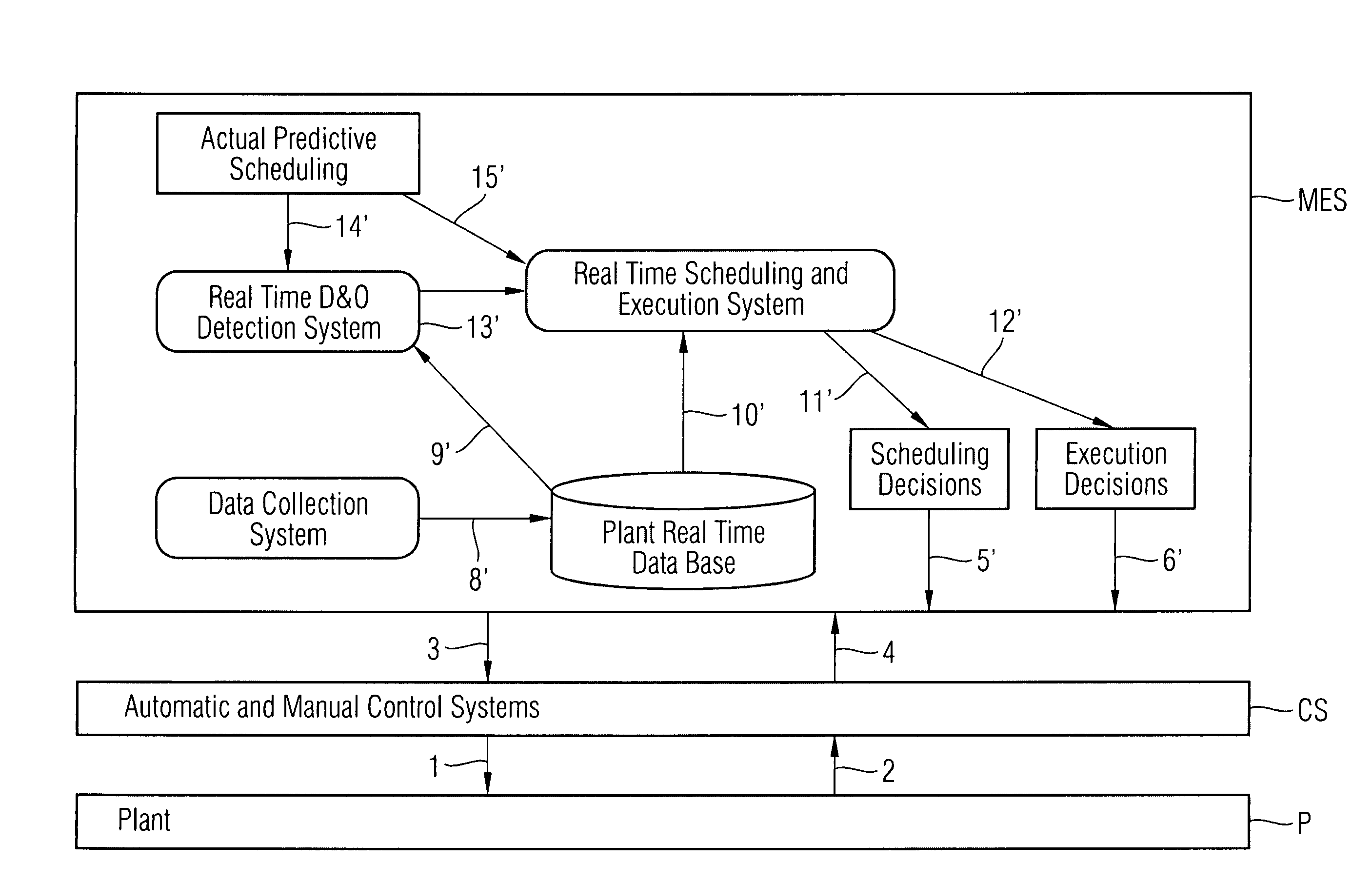

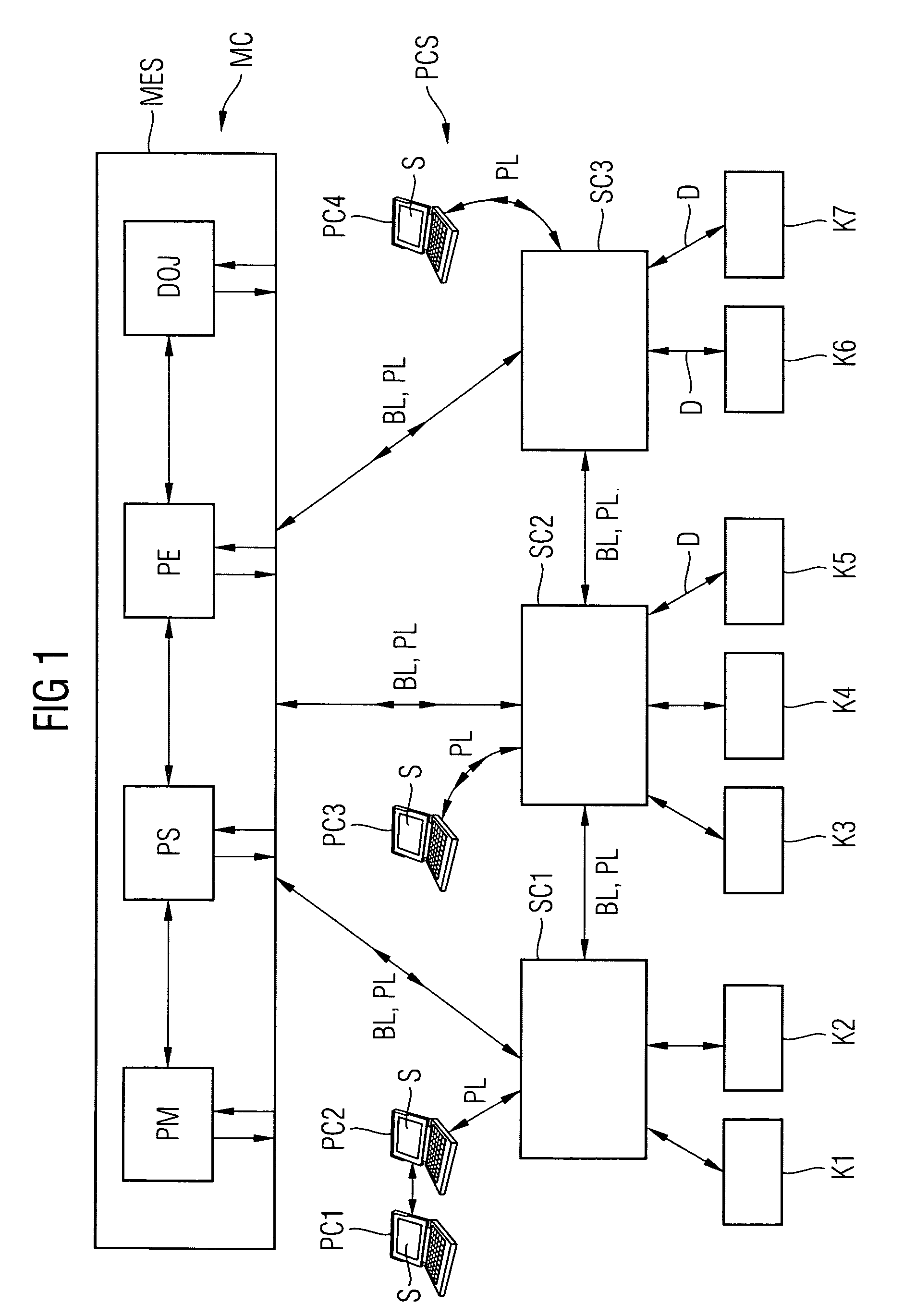

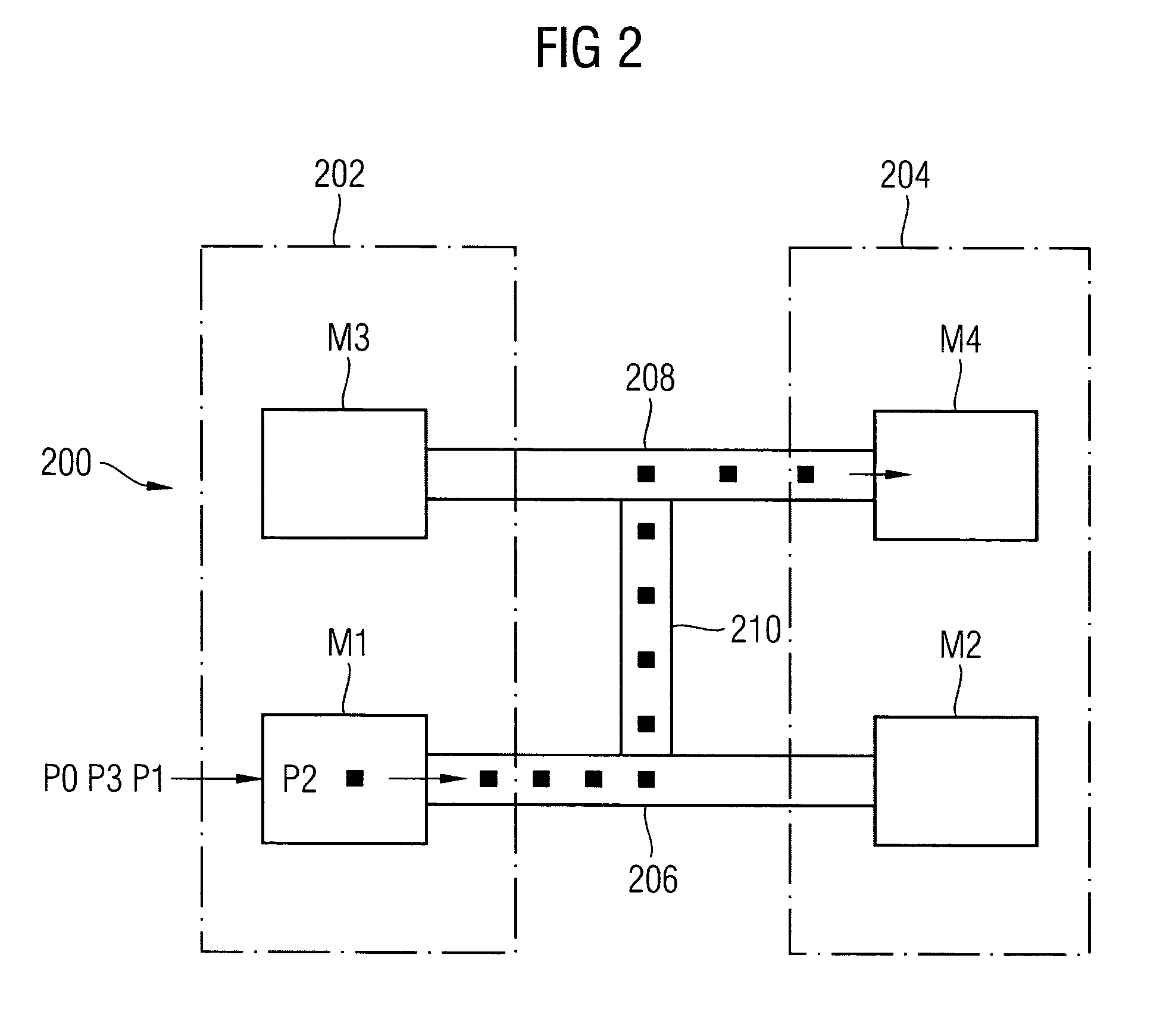

System and method for handling a production disturbance/opportunity event in a production execution system

InactiveUS20080294279A1Quickly reconfiguredMinimize impactProgramme controlResourcesProduction scheduleActuator

A system for handling a production disturbance / opportunity event includes a network having data processing units running a MES software for controlling / monitoring a production process operating production components. A production modeler defines a plant model of the production process, and a production scheduler generates an executable production schedule for the execution of operating procedures for the production components. A production executor executes the production process following the generated executable production schedule, and a production disturbance / opportunity event identifier detects a production disturbance event and identifies a production opportunity event which allows to maintain an efficiency of the production process at least as close as possible to an efficiency given by the executable production schedule as originally generated by the production scheduler. The production scheduler re-calculates an amended executable production schedule incorporating the identified production opportunity event, and the production executor executes the production process now following the re-calculated executable production schedule.

Owner:SIEMENS AG

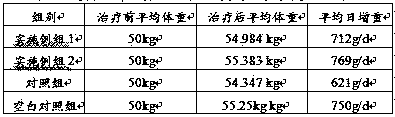

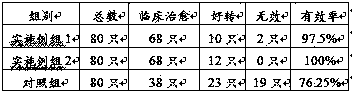

Pig functional feed and preparation method thereof

ActiveCN104256168AQuick effectDefinite curative effectAnimal feeding stuffVegetable oilAnimal science

The invention discloses a pig functional feed, which is characterized by comprising the following raw materials: corn, sticky rice, bean pulp, peanut meal, lotus root starch, fish meal, seaweed meal, honey, boiled egg white, vegetable oil, salt and vitamin premix. The pig functional feed disclosed by the invention is applied to pigs suffering from contagious pleuropneumonia, and is capable of treating contagious pleuropneumonia and also capable of satisfying nutritional requirements of pigs and keeping normal production performance.

Owner:江门市六和饲料有限公司

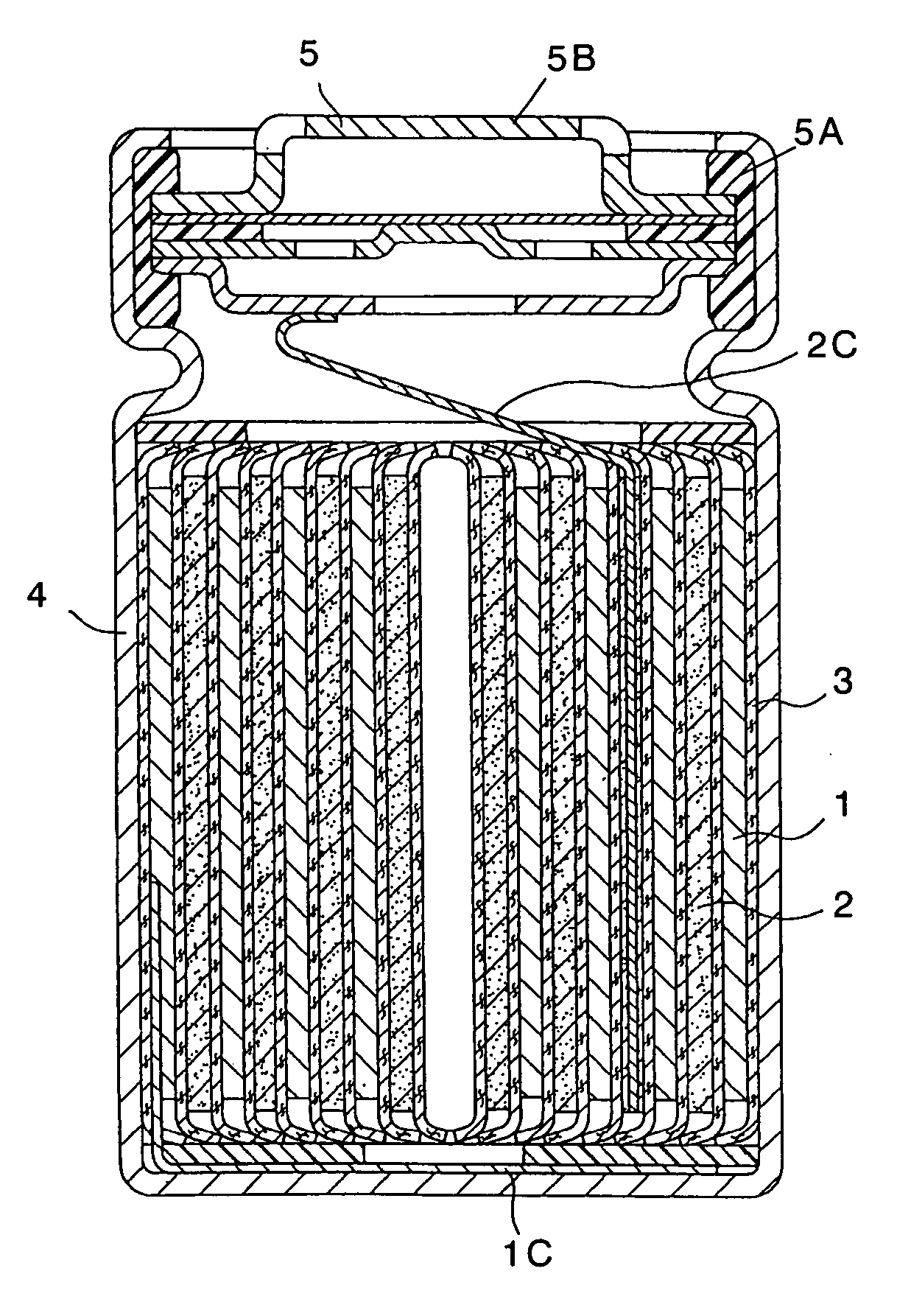

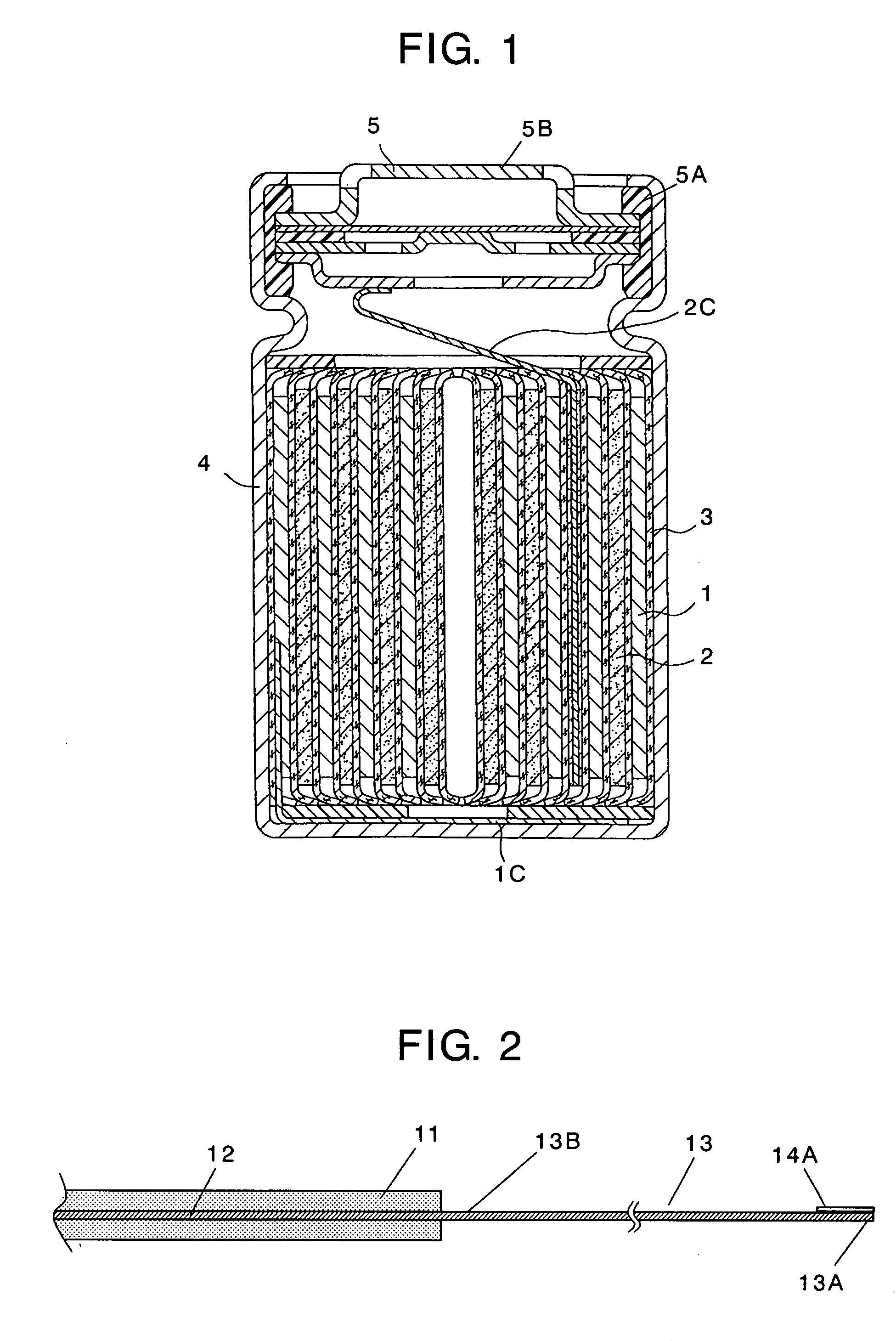

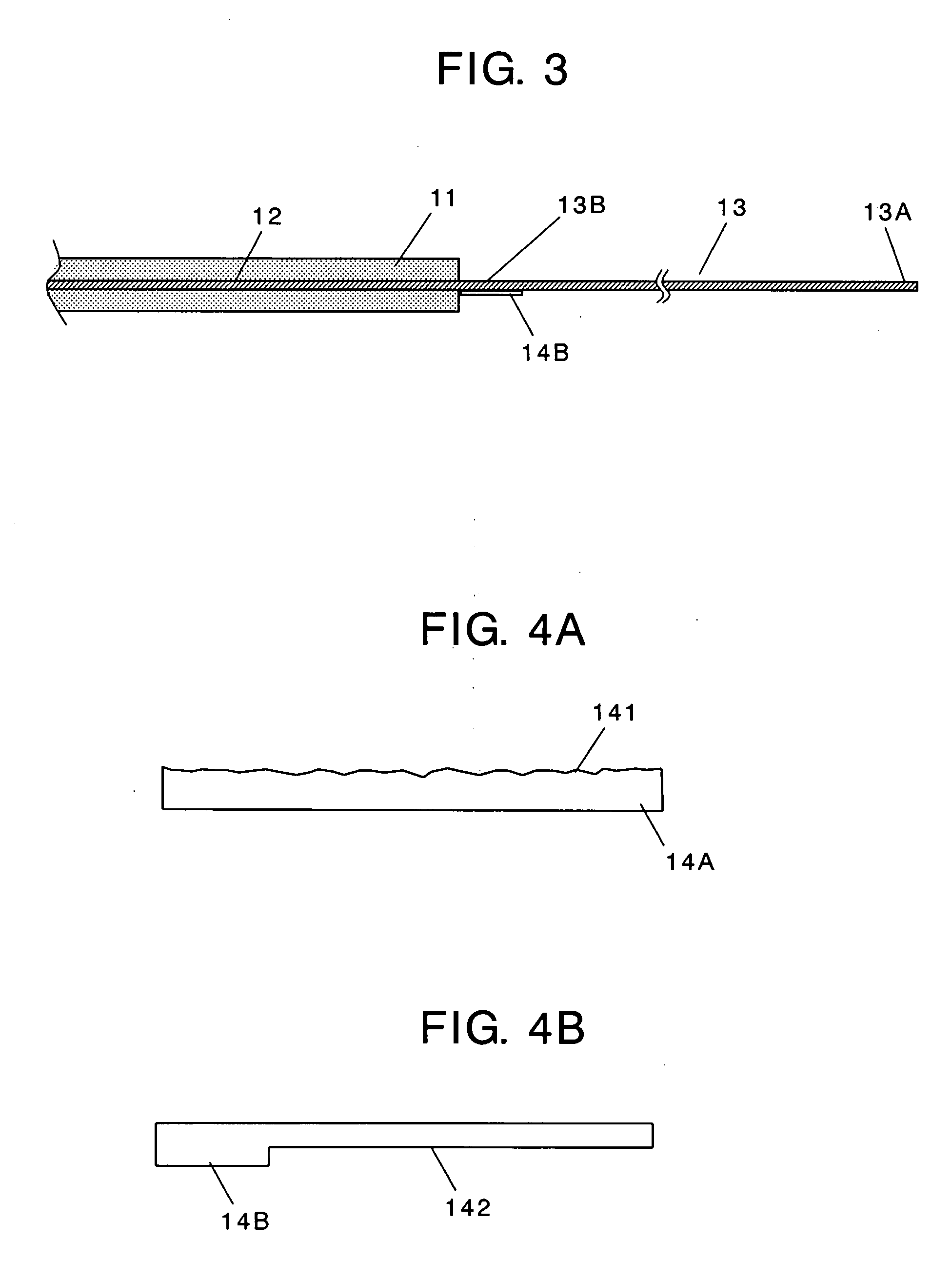

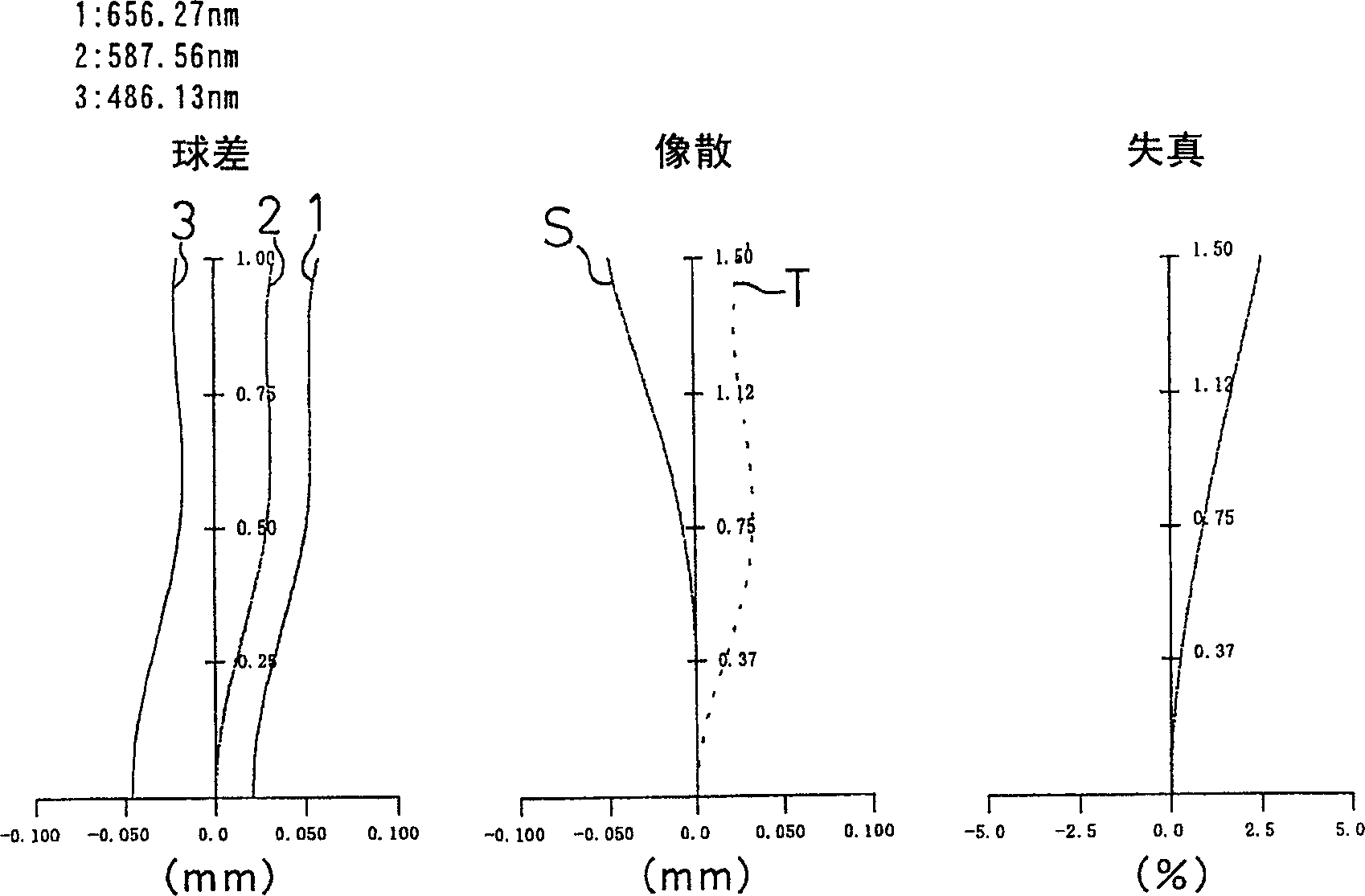

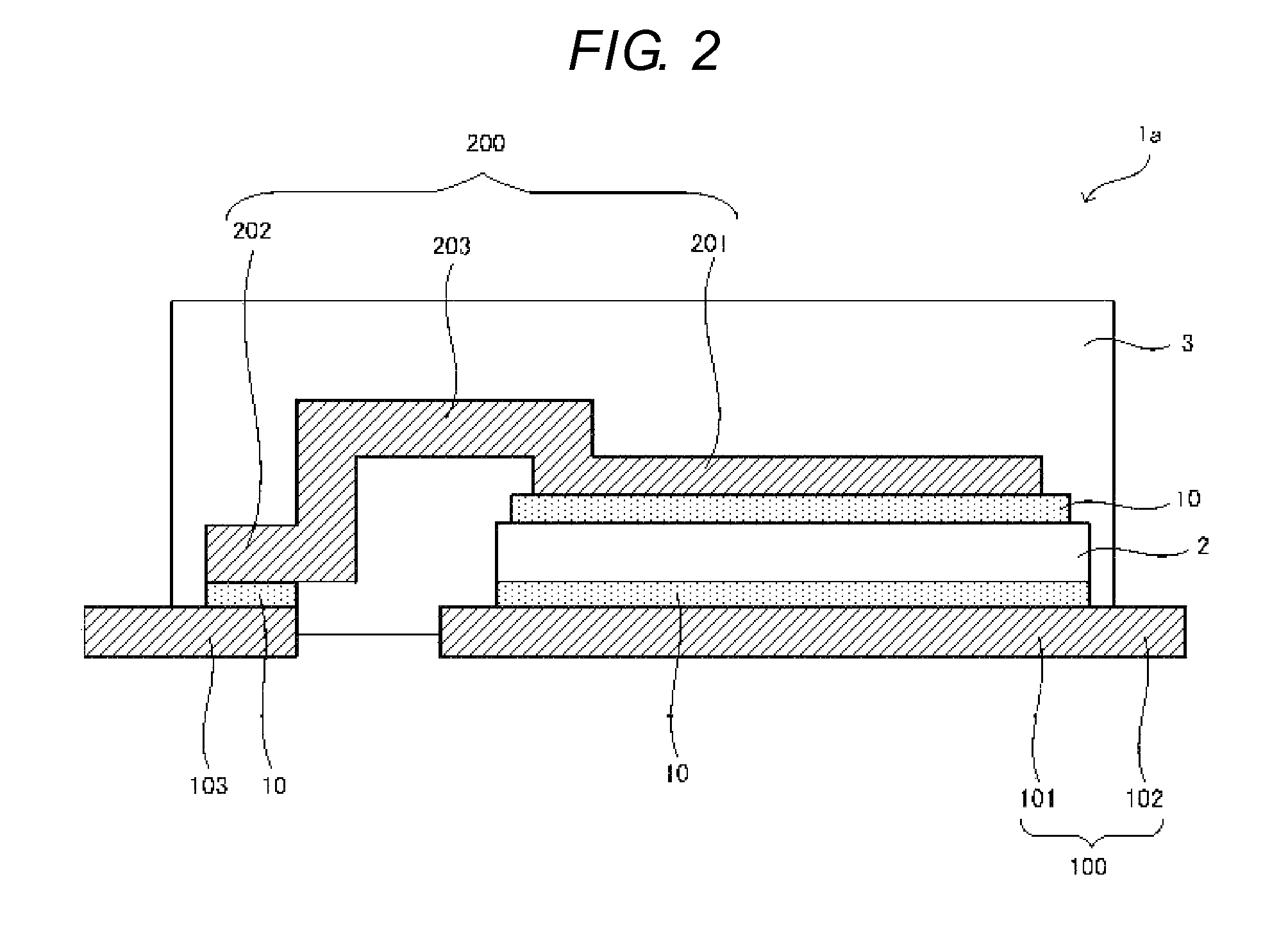

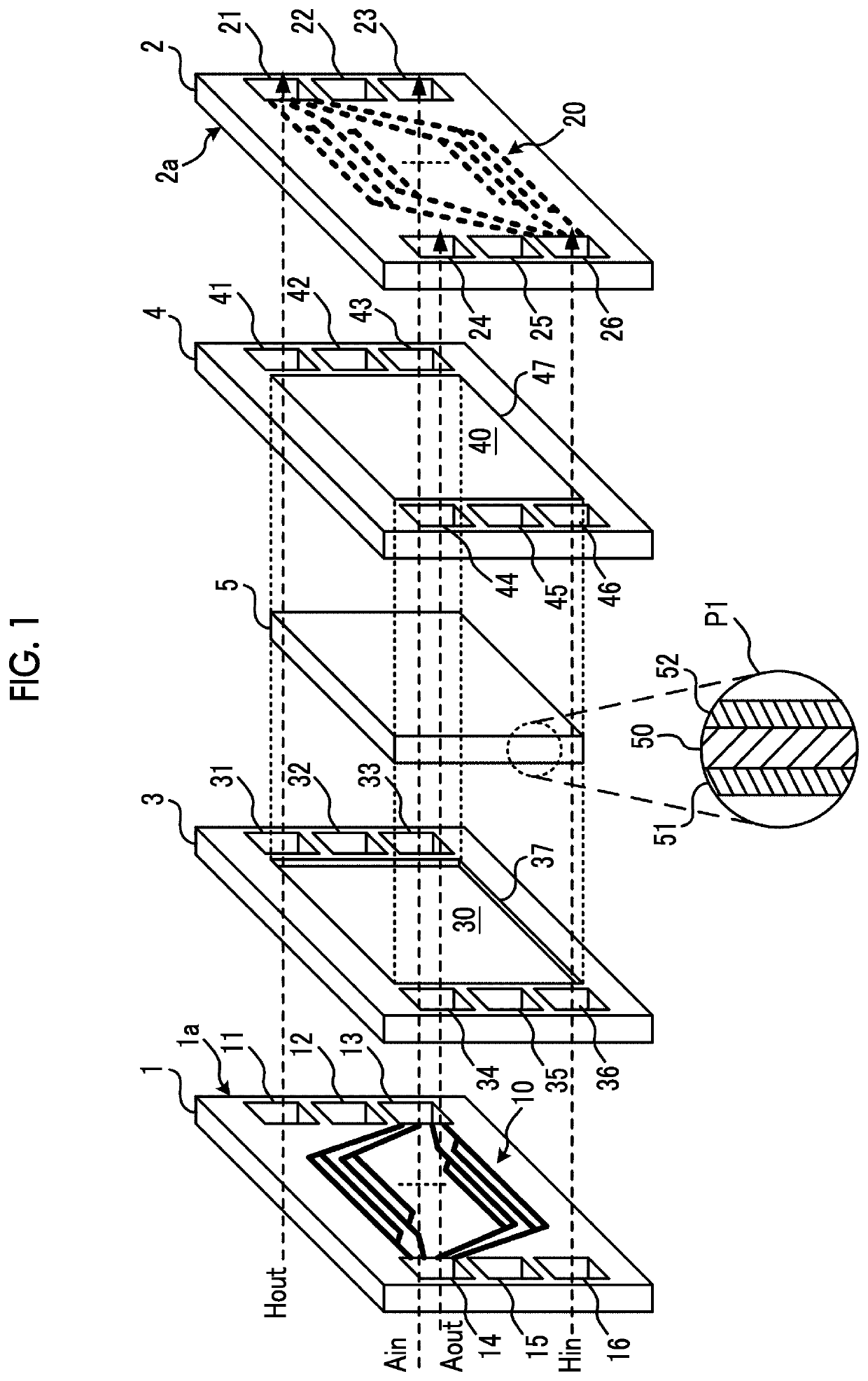

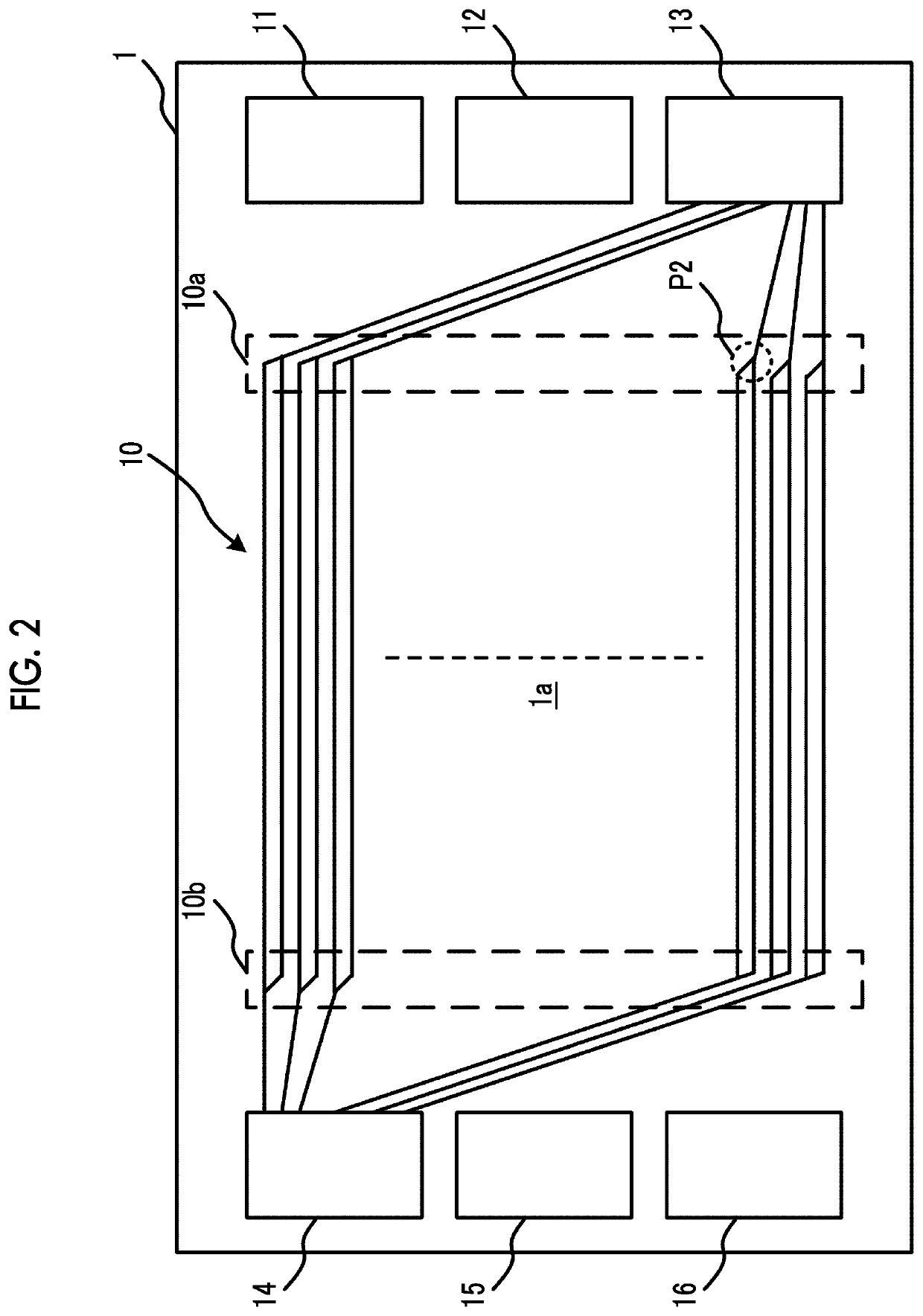

Non-aqueous electrolyte secondary battery and manufacturing method of the same

InactiveUS20080102353A1Avoid unwindingBuckling suppressionFinal product manufactureElectrode carriers/collectorsMetallic lithiumConductor Coil

In a method for manufacturing a non-aqueous electrolyte secondary battery, a negative electrode having a current collector exposed portion in a portion corresponding to an outer winding end of an electrode body, metallic lithium piece is allowed to precipitate or be deposited on this current collector exposed portion, and this metallic lithium piece is joined to the other portion of the current collector exposed portion or one metallic lithium piece is joined to the other metallic lithium piece so as to fix two points of the negative electrode.

Owner:PANASONIC CORP

System and method for handling a production disturbance/opportunity event in a production execution system

InactiveUS7962233B2Minimize impactQuickly reconfiguredProgramme controlMultiprogramming arrangementsActuatorComputer science

Owner:SIEMENS AG

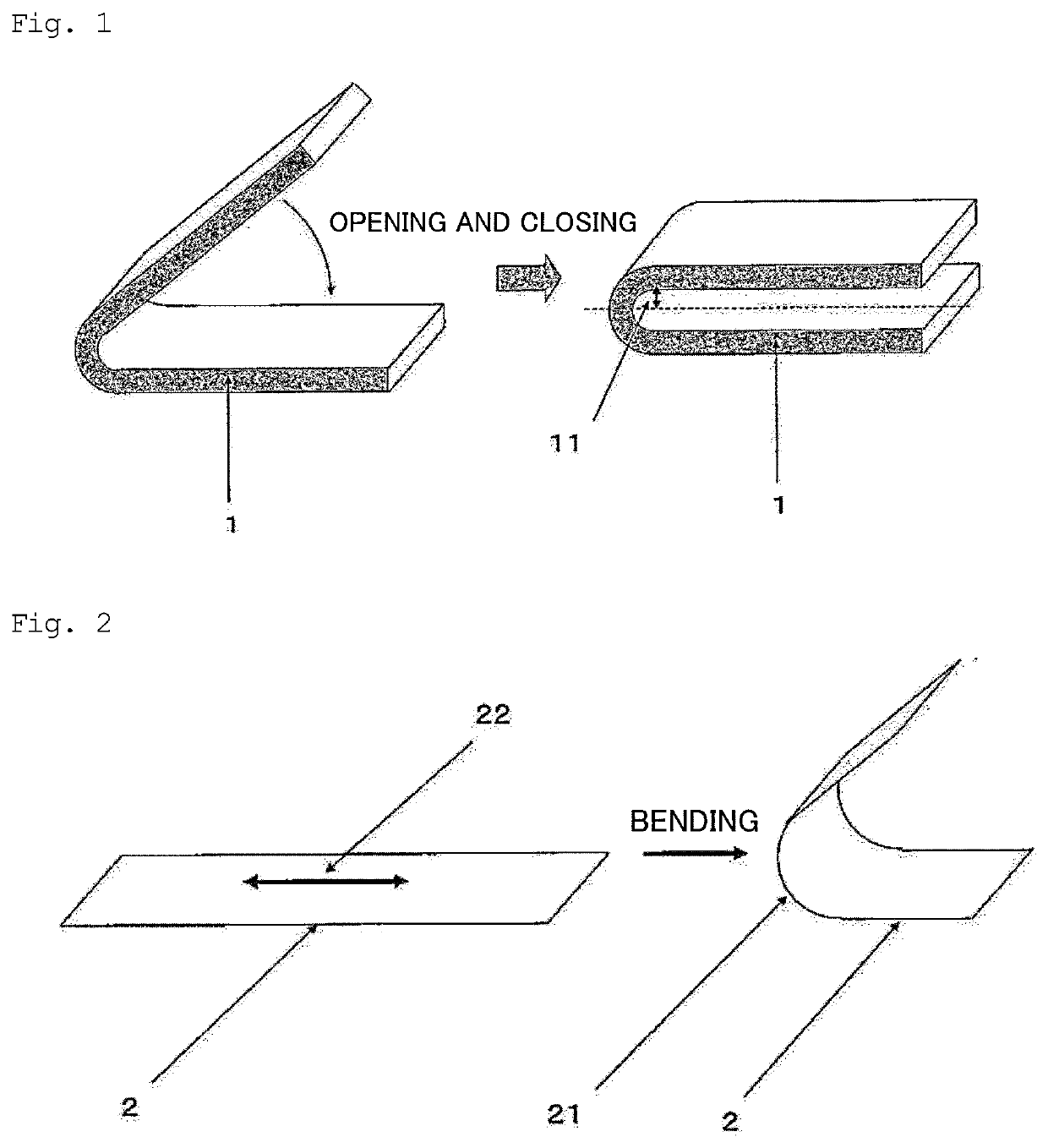

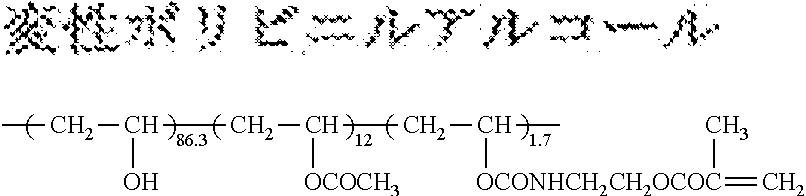

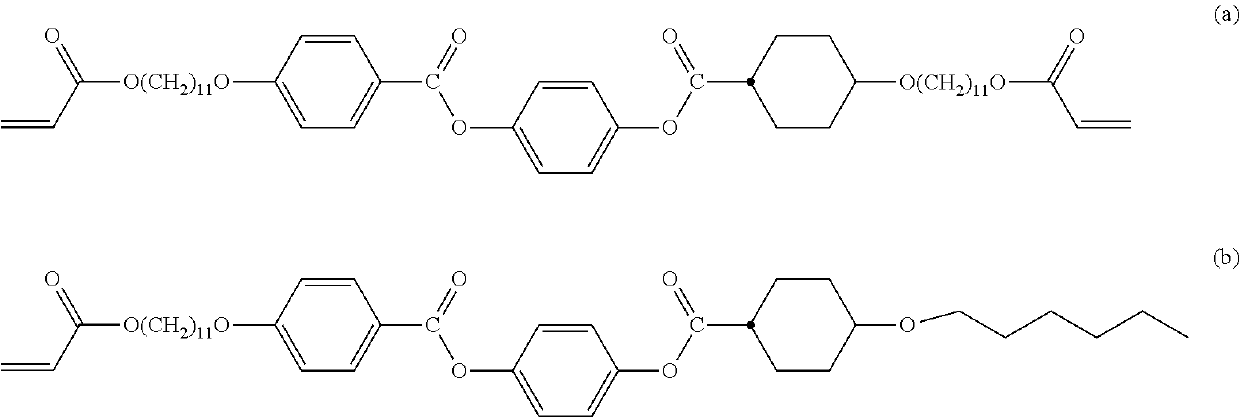

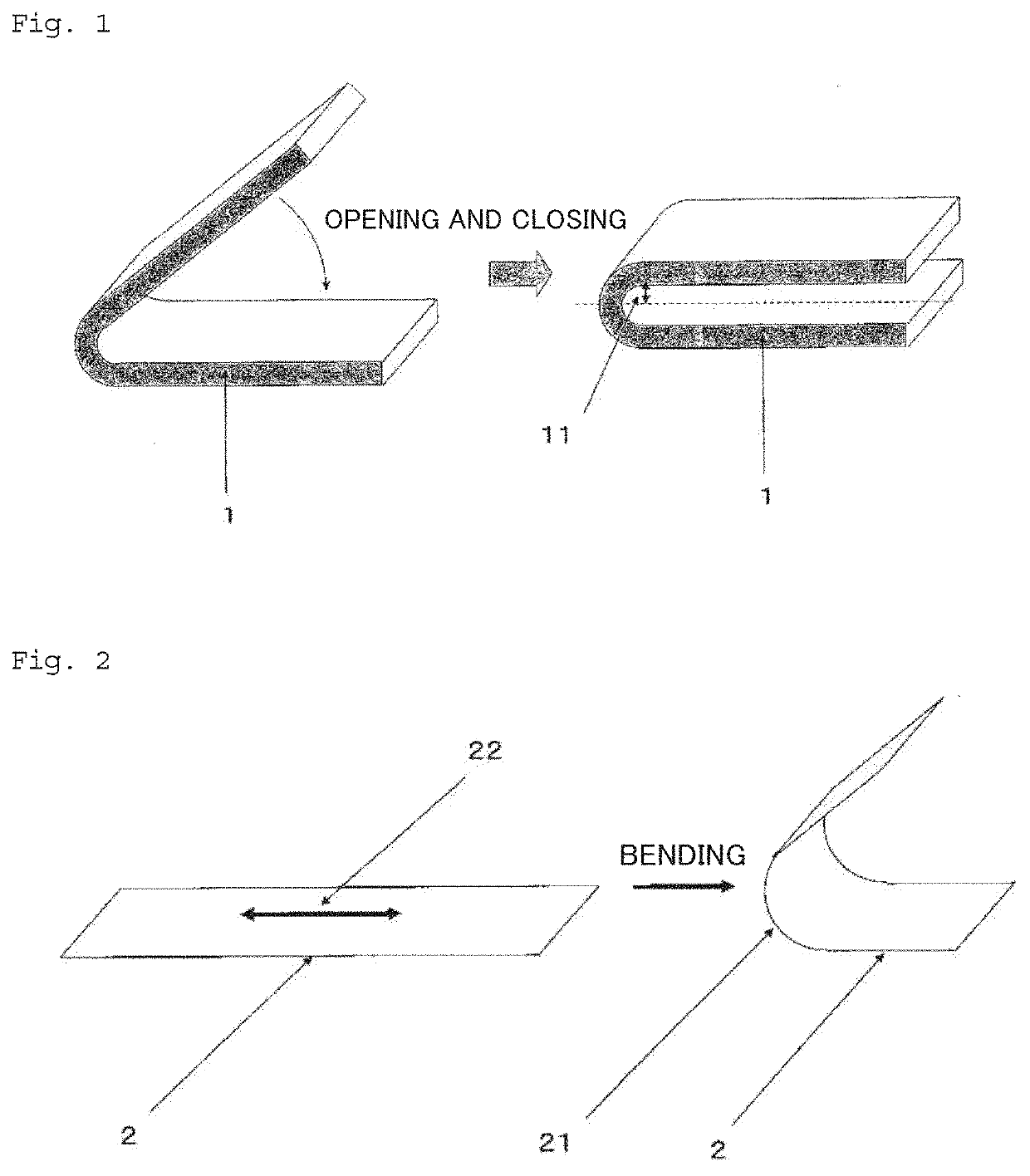

Foldable display

PendingUS20220236468A1Function increaseEasy to optimizeElectrical apparatusElectroluminescent light sourcesPolyesterDisplay device

Provided is a foldable display excellent in mass productivity, and free of a risk of causing distortion in an image displayed at a folding portion thereof after being repeatedly folded. The foldable display includes at least: a surface protective film; a polarizer; and a retardation layer, wherein the surface protective film is a polyester film satisfying the following conditions and having a thickness of from 10 μm to 80 (1) a refractive index in a bending direction is from 1.590 to 1.620; (2) a refractive index in a folding portion direction is from 1.670 to 1.700; (3) a refractive index in a thickness direction is 1.520 or less; and (4) a density is 1.380 g / cm3 or more, wherein the bending direction refers to a direction orthogonal to a folding portion of the polyester film at a time when the polyester film is folded.

Owner:TOYO TOYOBO CO LTD

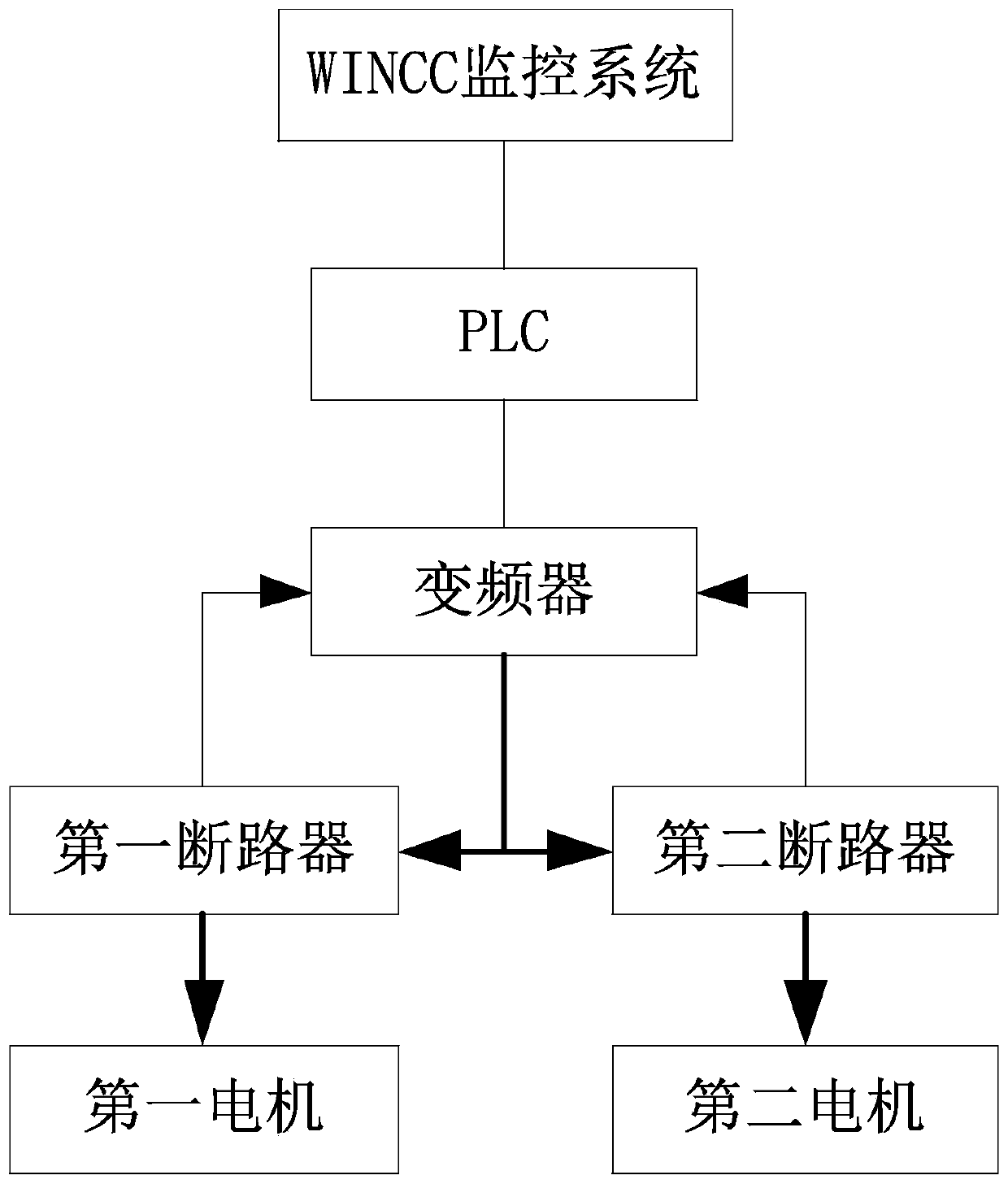

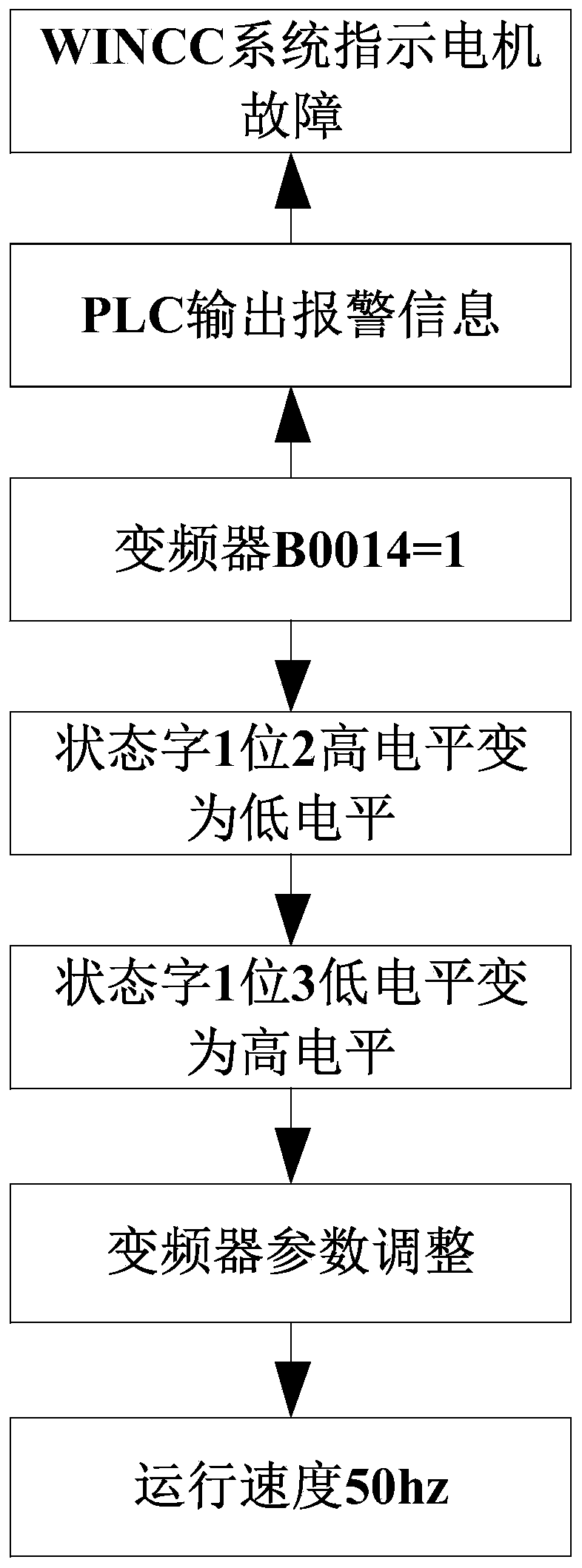

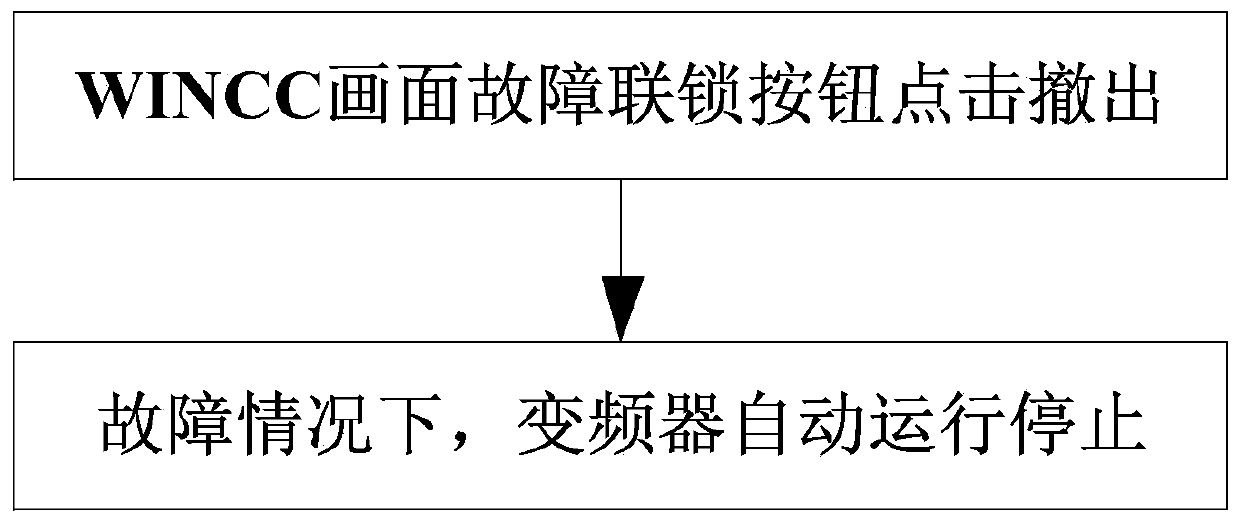

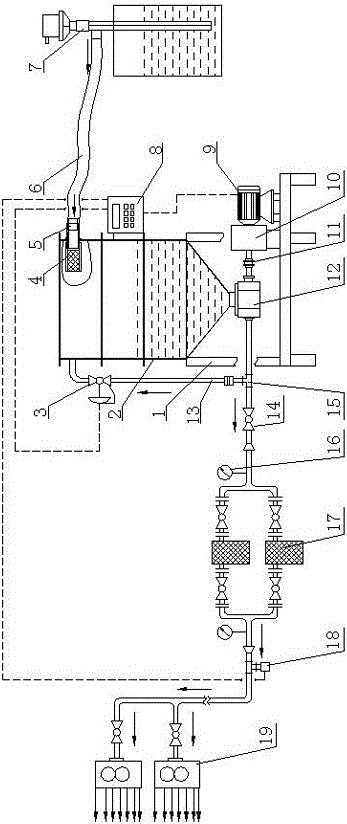

Automatic switching control system for alloy electric vibration fault behind converter

ActiveCN111077842AAvoid autorunImprove troubleshooting efficiencyManufacturing convertersIncreasing energy efficiencyFrequency changerElectric machine

The invention, which belongs to the technical field of metallurgical equipment, discloses an automatic switching control system for an alloy electric vibration fault behind a converter. The system comprises a WINCC, a PLC, a frequency converter, a first motor, a second motor, a first circuit breaker and a second circuit breaker. The WINCC is connected with the frequency converter through the PLC;a control panel of the frequency converter is connected with an auxiliary contact of the first circuit breaker and the second circuit breaker; a power supply terminal of the frequency converter is connected with a main contact of the first circuit breaker and the second circuit breaker; the first circuit breaker is connected with the first motor, and the second circuit breaker is connected with the second motor. A fault parameter scheme and a normal parameter scheme are set in the frequency converter; and when the frequency converter detects that the level signal of the auxiliary contact of the first circuit breaker or the second circuit breaker changes, the working parameters of the frequency converter are switched from the normal parameter scheme to the fault switching scheme. The frequency converter automatically judges whether a fault occurs during operation or not, and then controls to make a decision that whether to operate after automatic reset or to be in a standby state. According to the system provided by the invention, high-timeliness fault switching can be realized, and stable operation of electric vibration is maintained.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Cathode slurry for improving overbaking defect of high areal density cathode pole plate of lithium battery

InactiveCN109524669AImprove overbaking defectsMaintain productivityCell electrodesSecondary cells servicing/maintenanceSolid componentMetallurgy

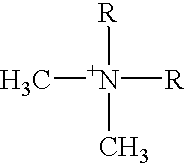

The invention discloses cathode slurry for improving overbaking defect of a high areal density cathode pole plate of a lithium battery. The cathode slurry comprises basic slurry and a surface tensionadjustor. The basic slurry comprises a solid component and a liquid component. The solid component comprises a cathode active substance, a conducting agent, a binder and a thickener. The surface tension adjustor is one of or any combination of Cathode slurry for improving overbaking defect of high areal density cathode pole plate of lithium battery, diethyl carbonate and ethyl methyl carbonate. The adding amount of the surface tension adjustor is 1-10% by mass of the solid component. By improving the cathode slurry, the surface tension adjustor is added to adjust the interfacial tension in a homogenating process to improve the overbaking defect of the high areal density cathode pole plate of the lithium battery. The cathode slurry is still suitable for a process of raising the drying temperature in a high areal density cathode pole plate coating process, and the original production efficiency and coating speed are kept. The selected surface tension adjustor is stable in property, low in boiling point and small in residue amount. The yield of the pole plate is improved greatly and the electrochemical performance of a product battery cell is improved greatly.

Owner:上海力信能源科技有限责任公司

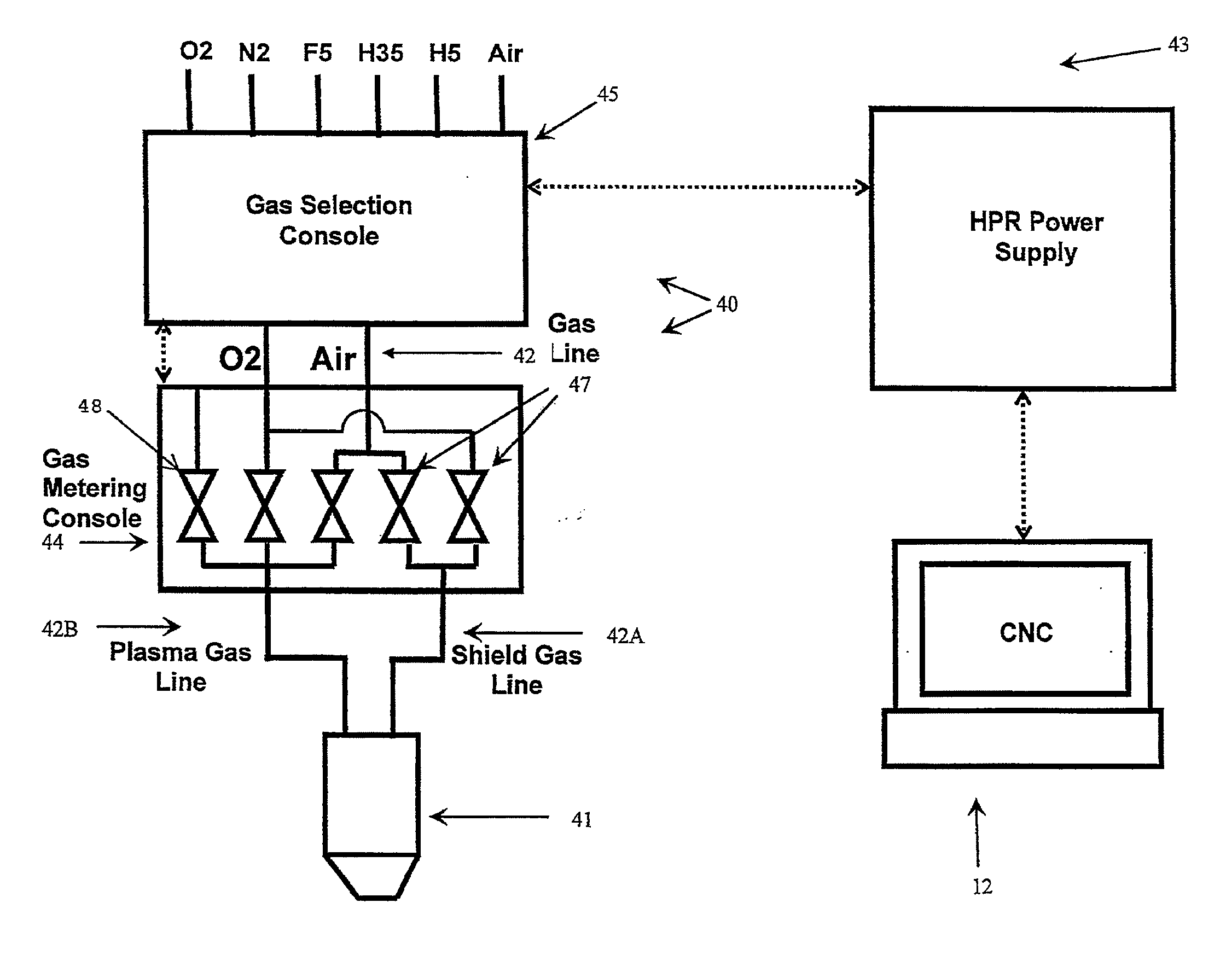

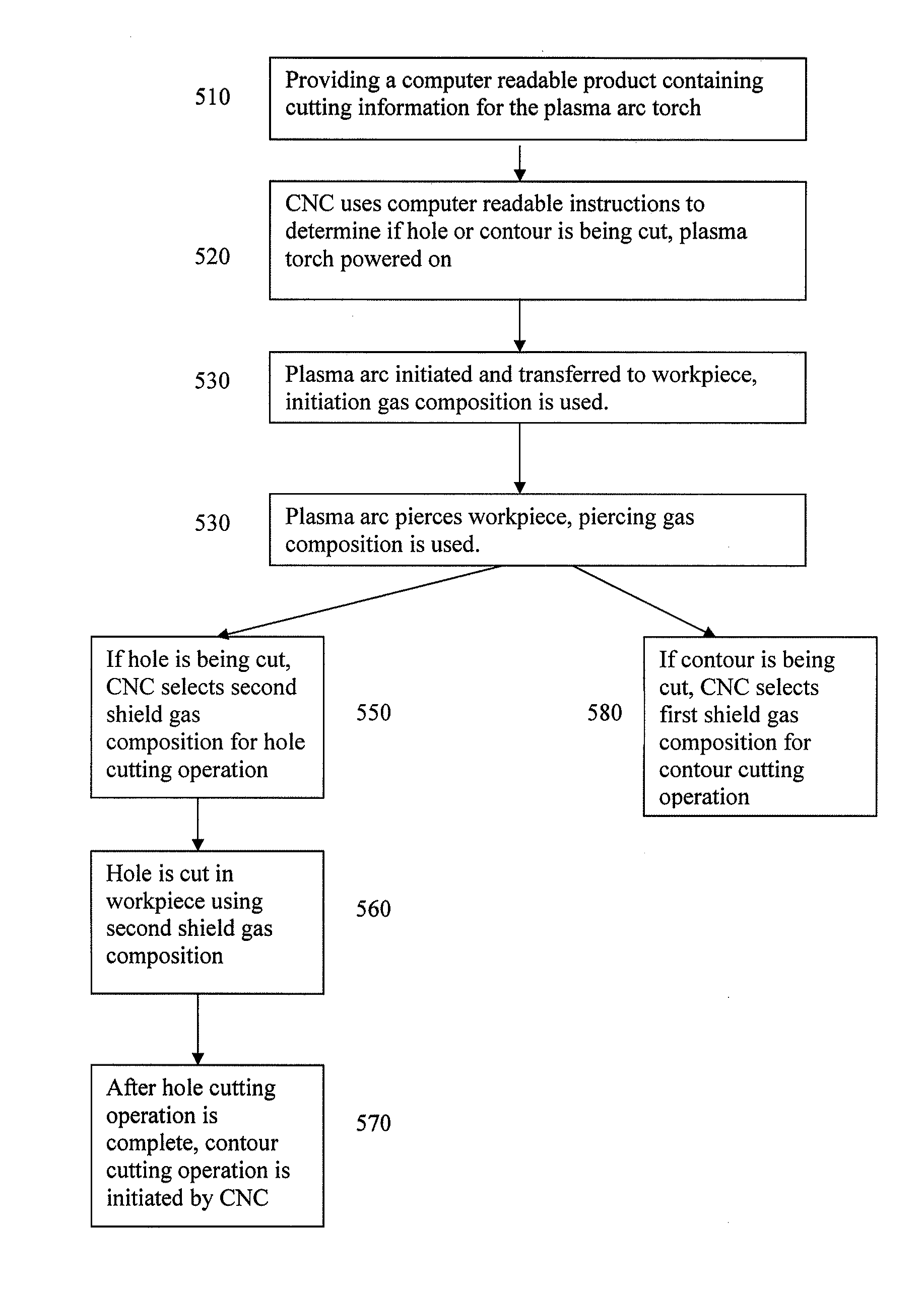

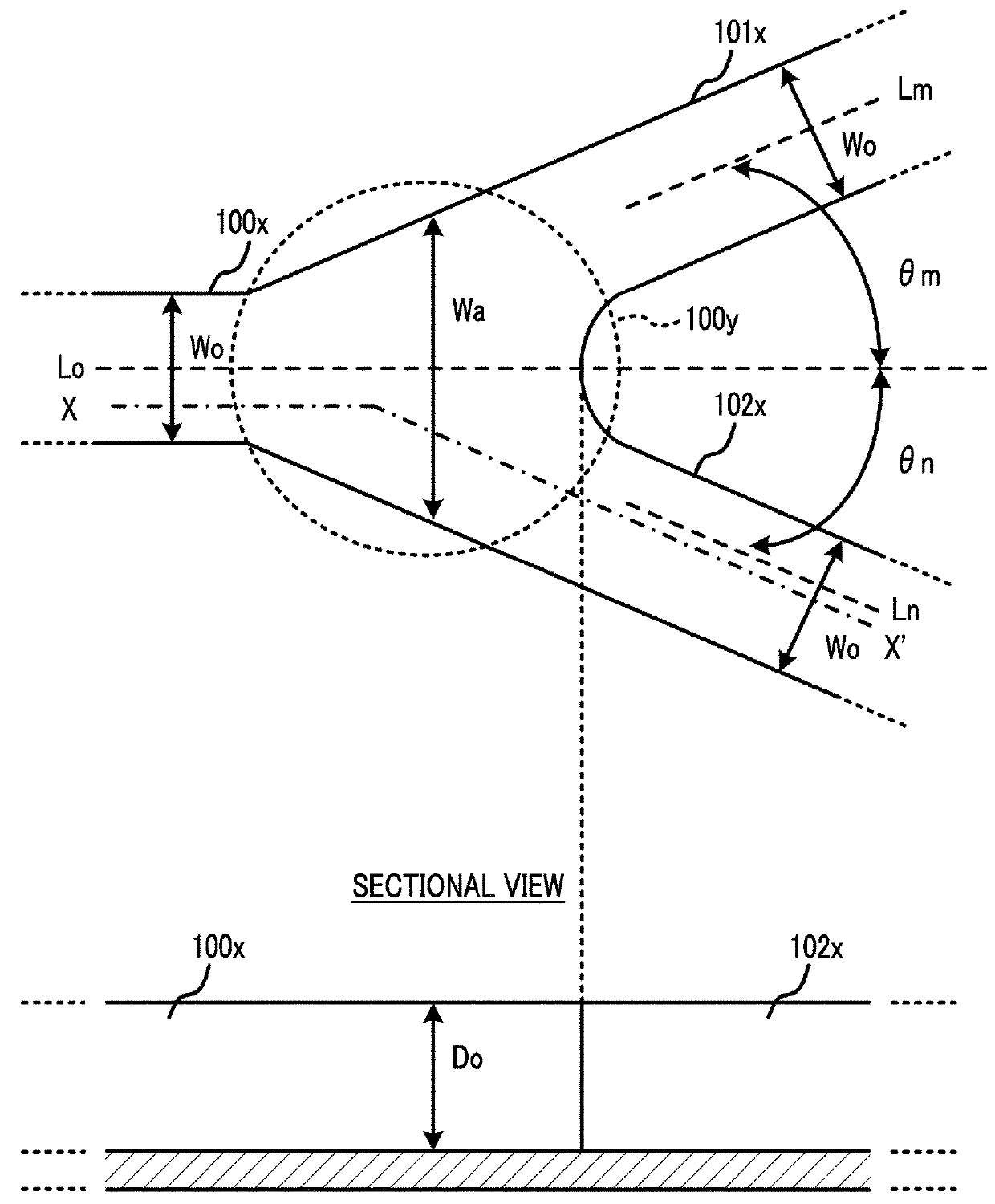

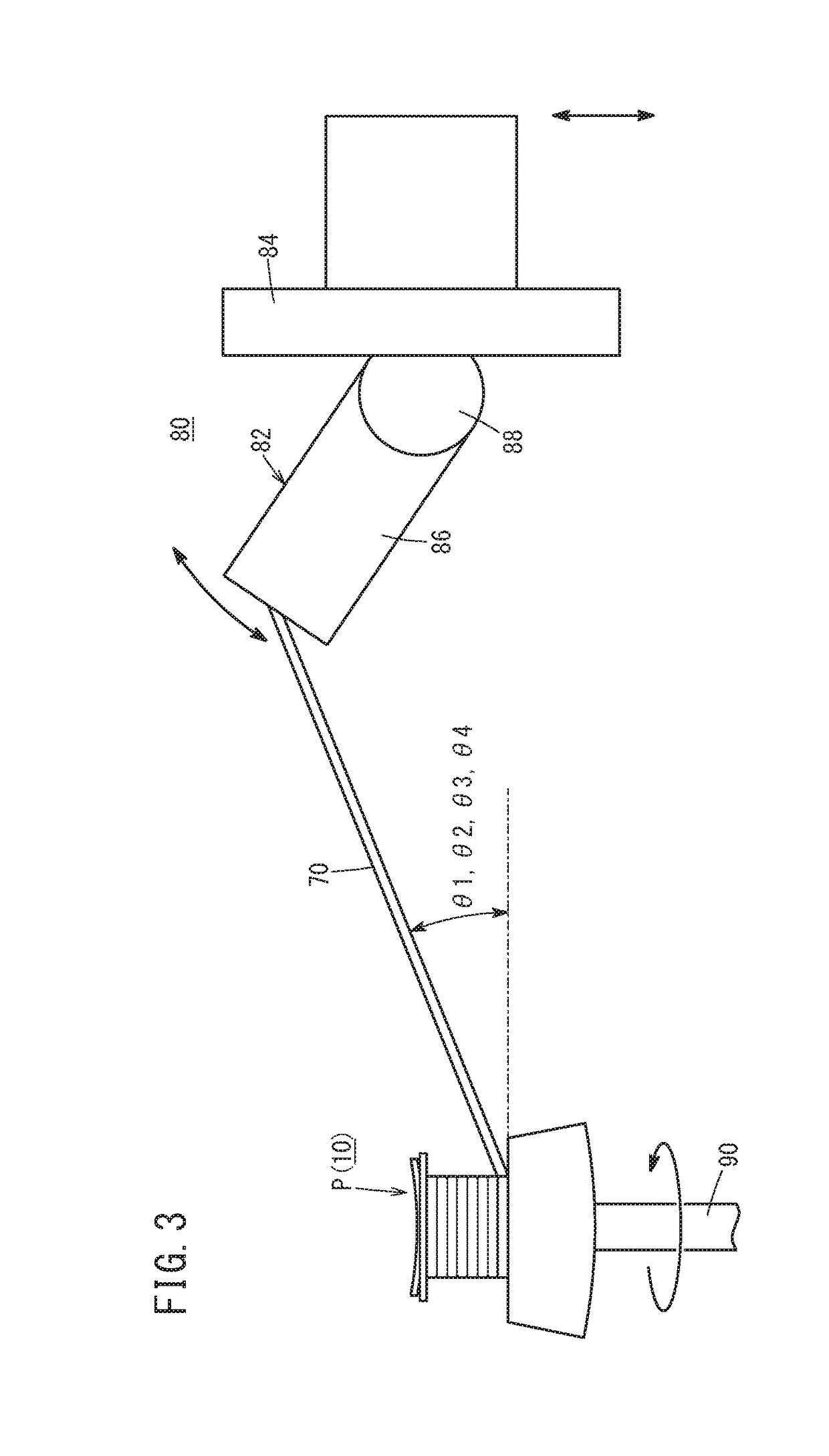

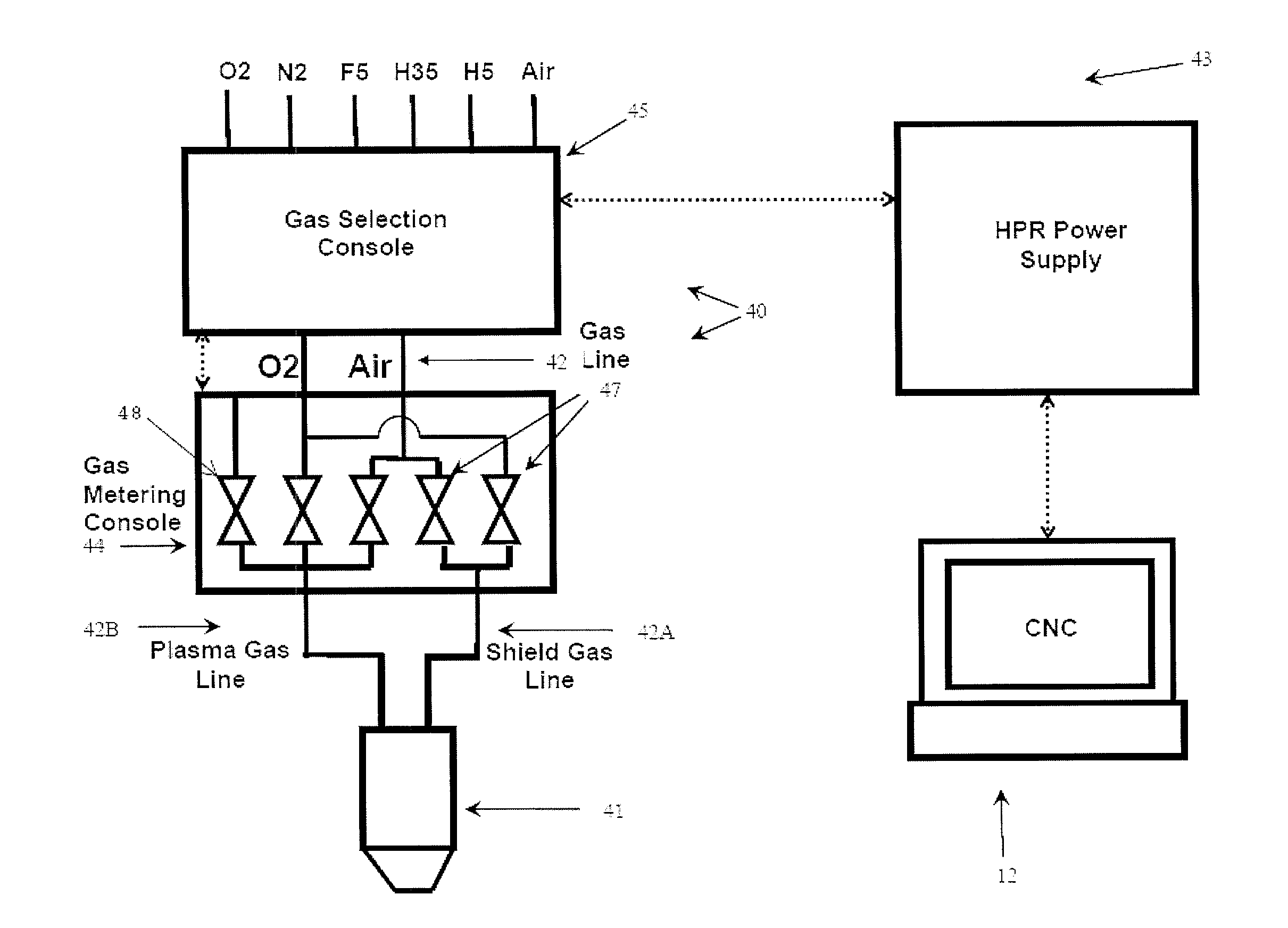

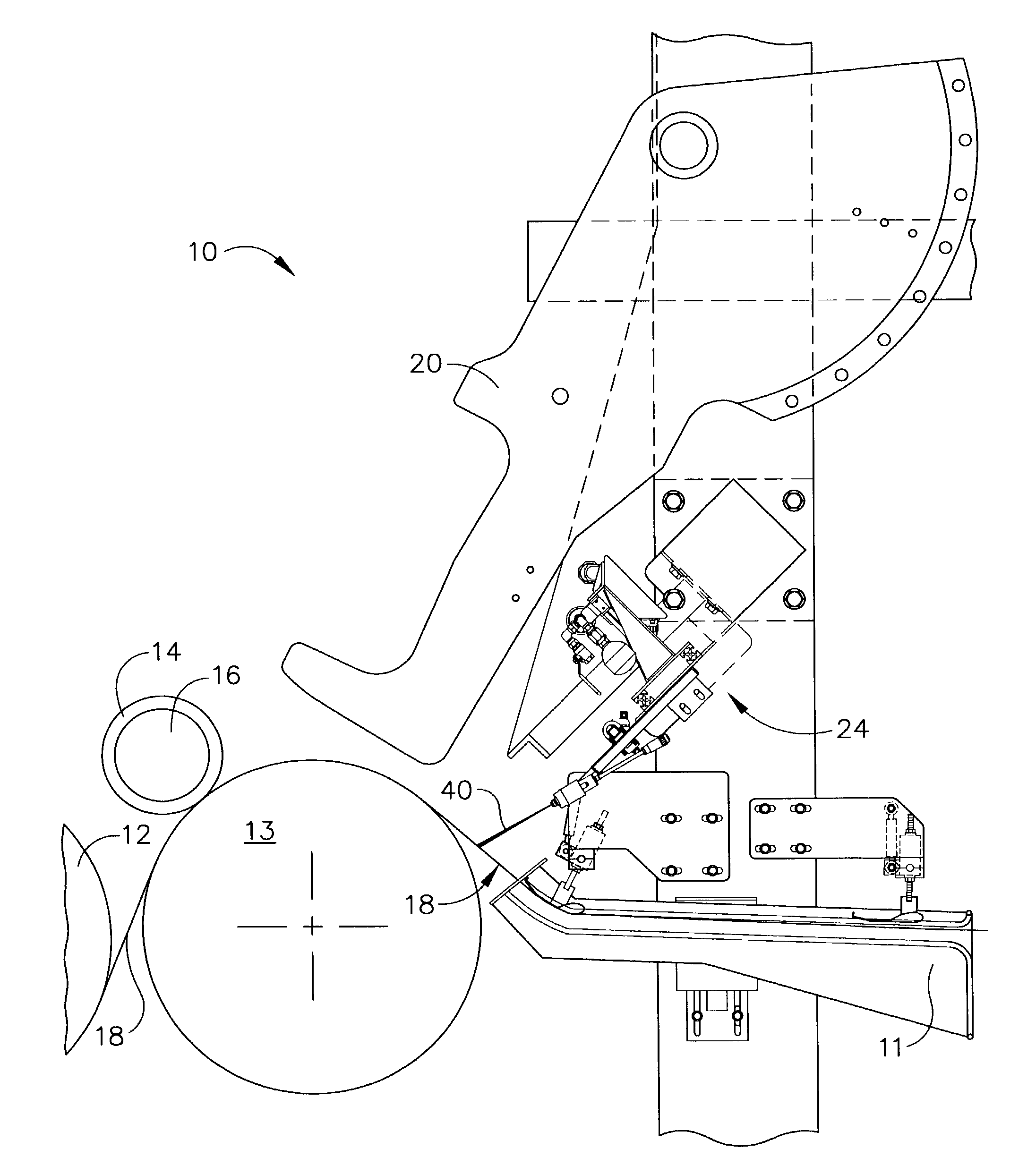

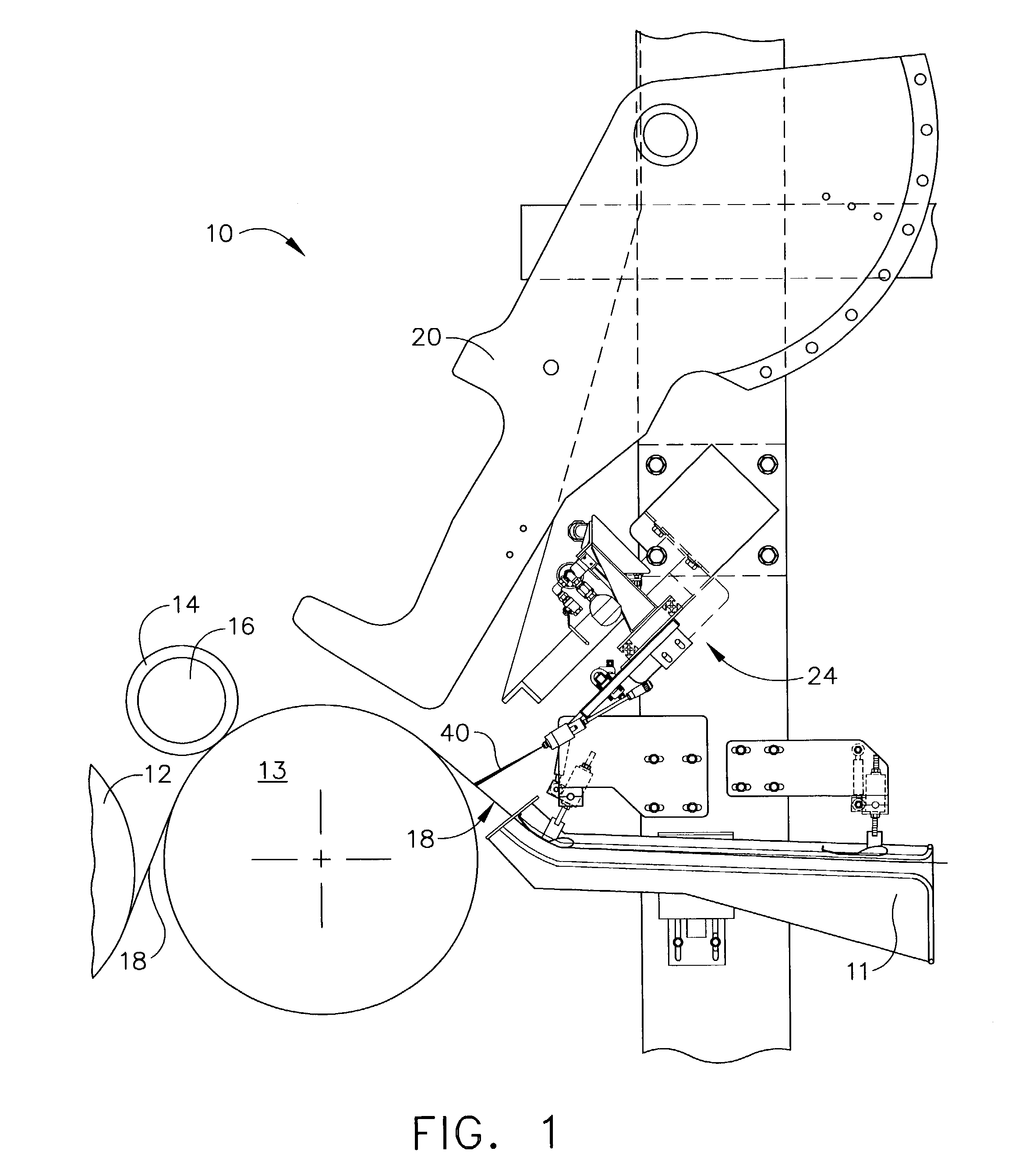

High quality hole cutting using variable shield gas compositions

ActiveUS20120018409A1Quality improvementMaintain levelArc welding apparatusPlasma welding apparatusShielding gasCarbon Dioxide / Helium

A method and apparatus for a plasma torch system having a plasma torch tip configuration that includes a nozzle, an electrode, and a control unit for controlling a composition of the shield gas flow, such that while cutting the contour the shield gas flow comprises a first shield gas composition and while cutting the hole the shield gas flow comprises a second shield gas composition.

Owner:HYPERTHERM INC

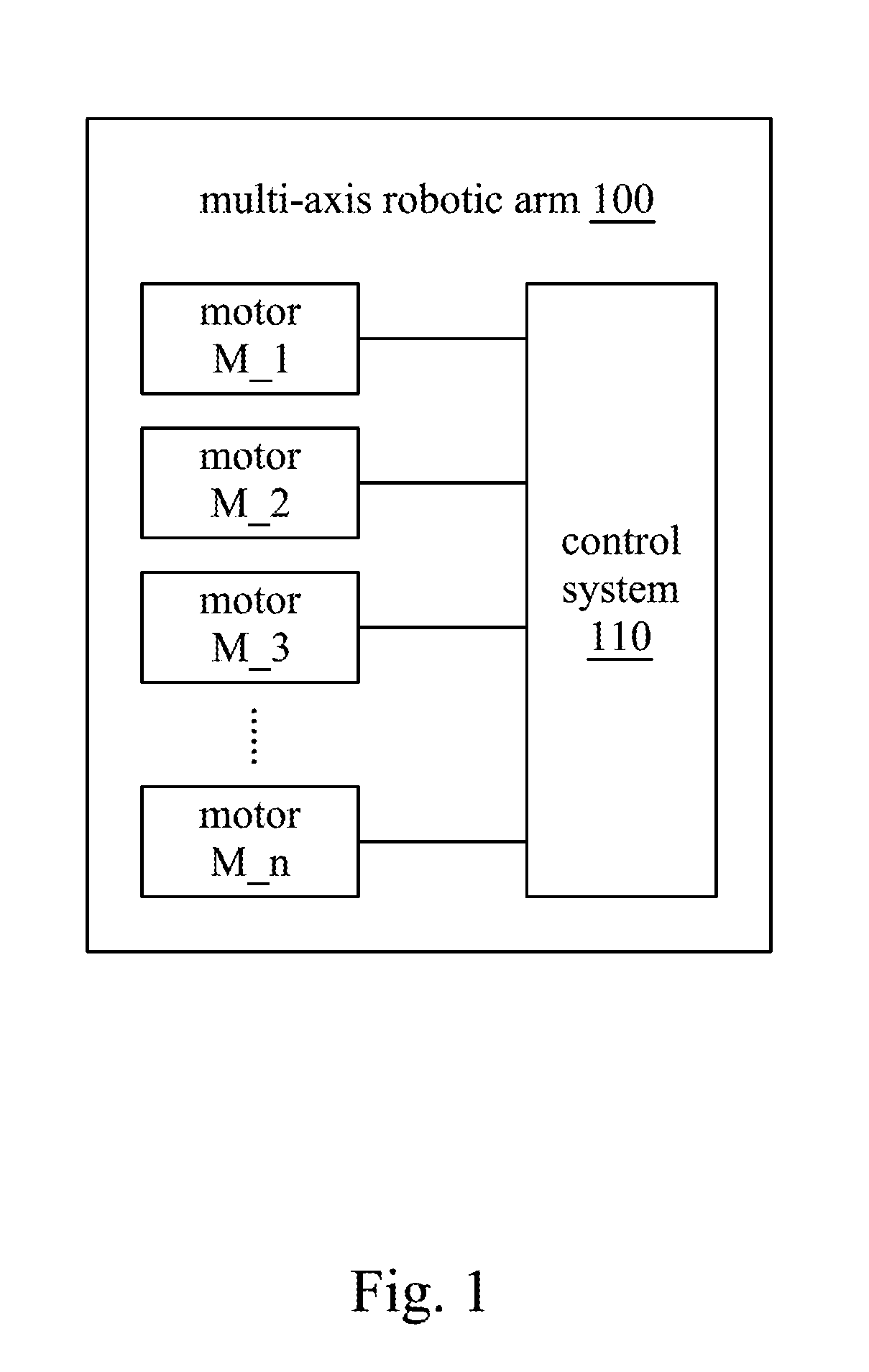

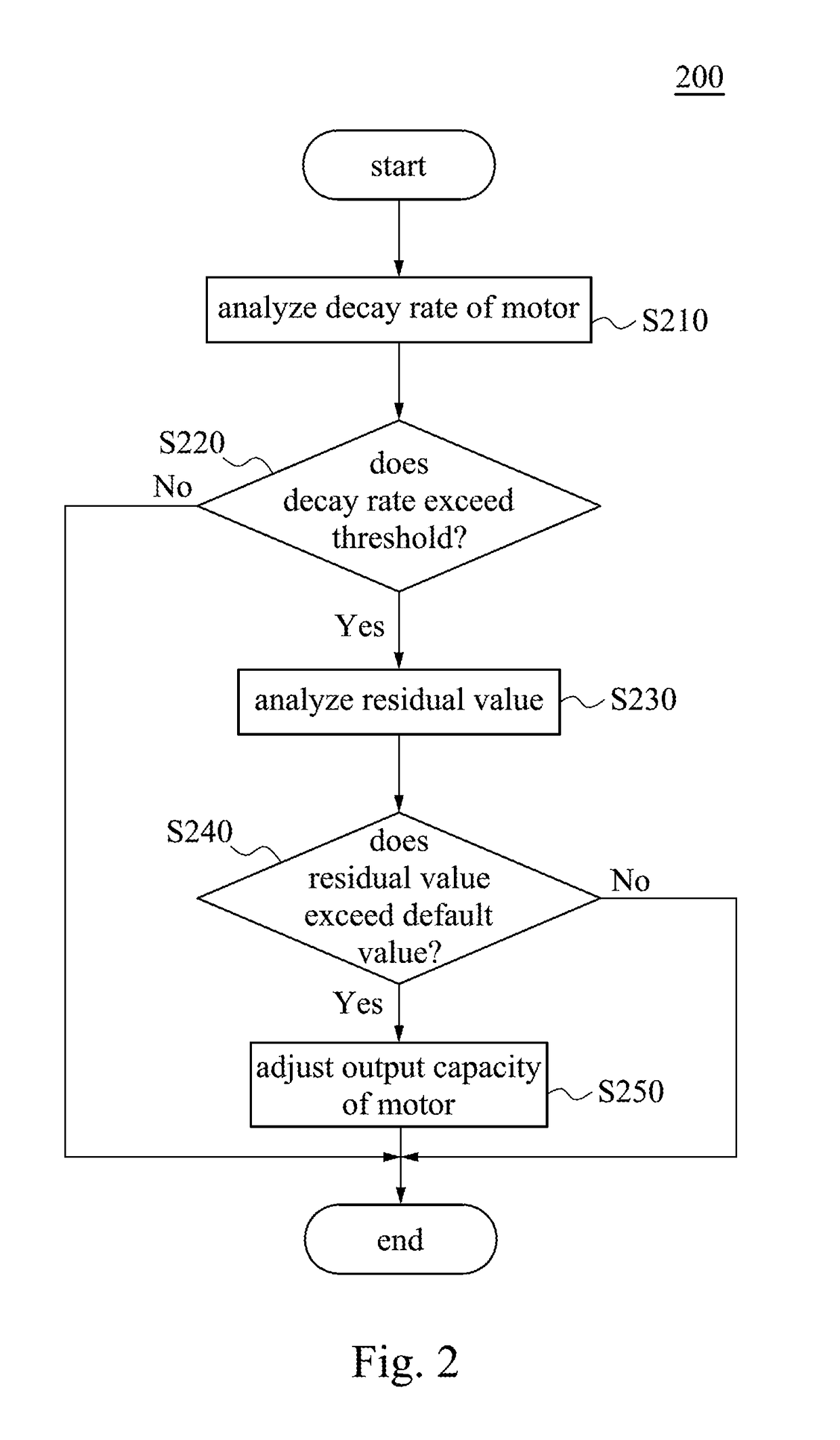

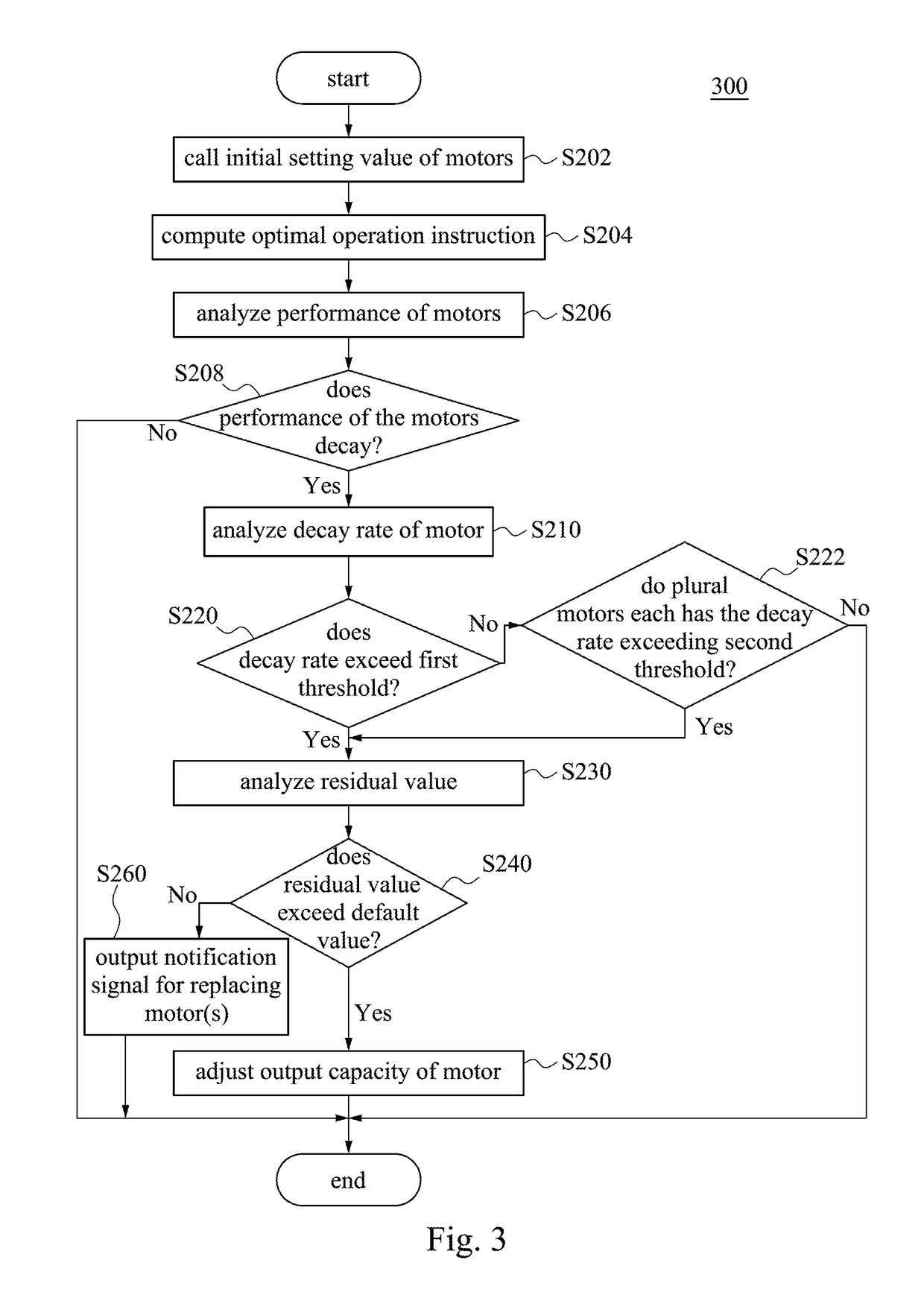

Multi-axis robotic arm and adjusting method thereof

ActiveUS20180154516A1Minimize costMaintain productivityProgramme-controlled manipulatorDynamo-electric converter controlResidual valueMulti axis

An adjusting method is implemented by a control system and is used to adjust a multi-axis robotic arm including a plurality of motors. The adjusting method includes following operations. A decay rate of each motor is analyzed by the control system. When the decay rate of one of the motors exceeds a corresponding first threshold, a residual value of the one of the motors is further analyzed by the control system. When the residual value exceeds a first default value, an output capacity of at least one of the motors is adjusted by the control system.

Owner:INSTITUTE FOR INFORMATION INDUSTRY

High quality hole cutting using variable shield gas compositions

ActiveUS8354609B2Quality improvementMaintain levelArc welding apparatusPlasma welding apparatusShielding gasCarbon Dioxide / Helium

A method and apparatus for a plasma torch system having a plasma torch tip configuration that includes a nozzle, an electrode, and a control unit for controlling a composition of the shield gas flow, such that while cutting the contour the shield gas flow comprises a first shield gas composition and while cutting the hole the shield gas flow comprises a second shield gas composition.

Owner:HYPERTHERM INC

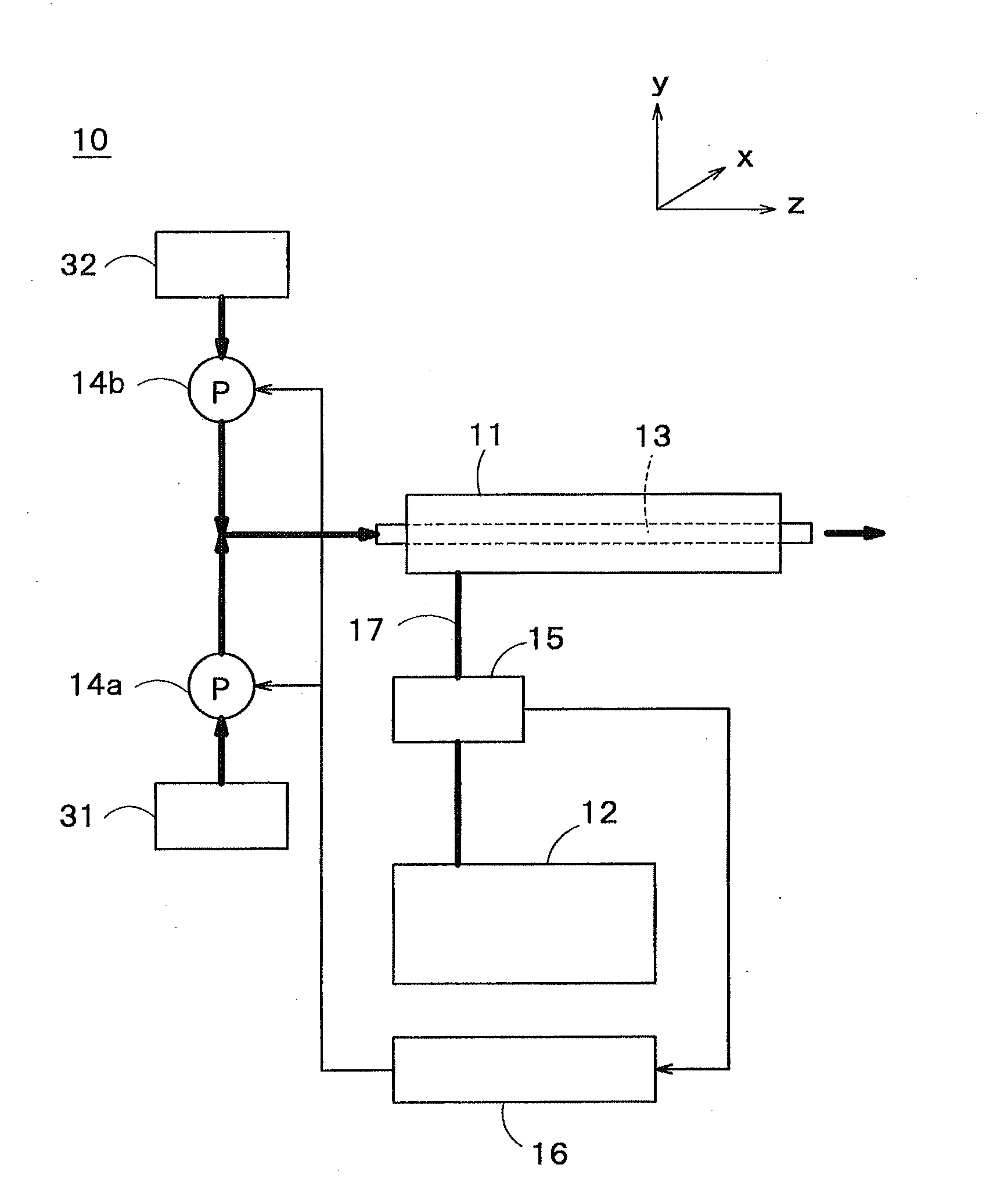

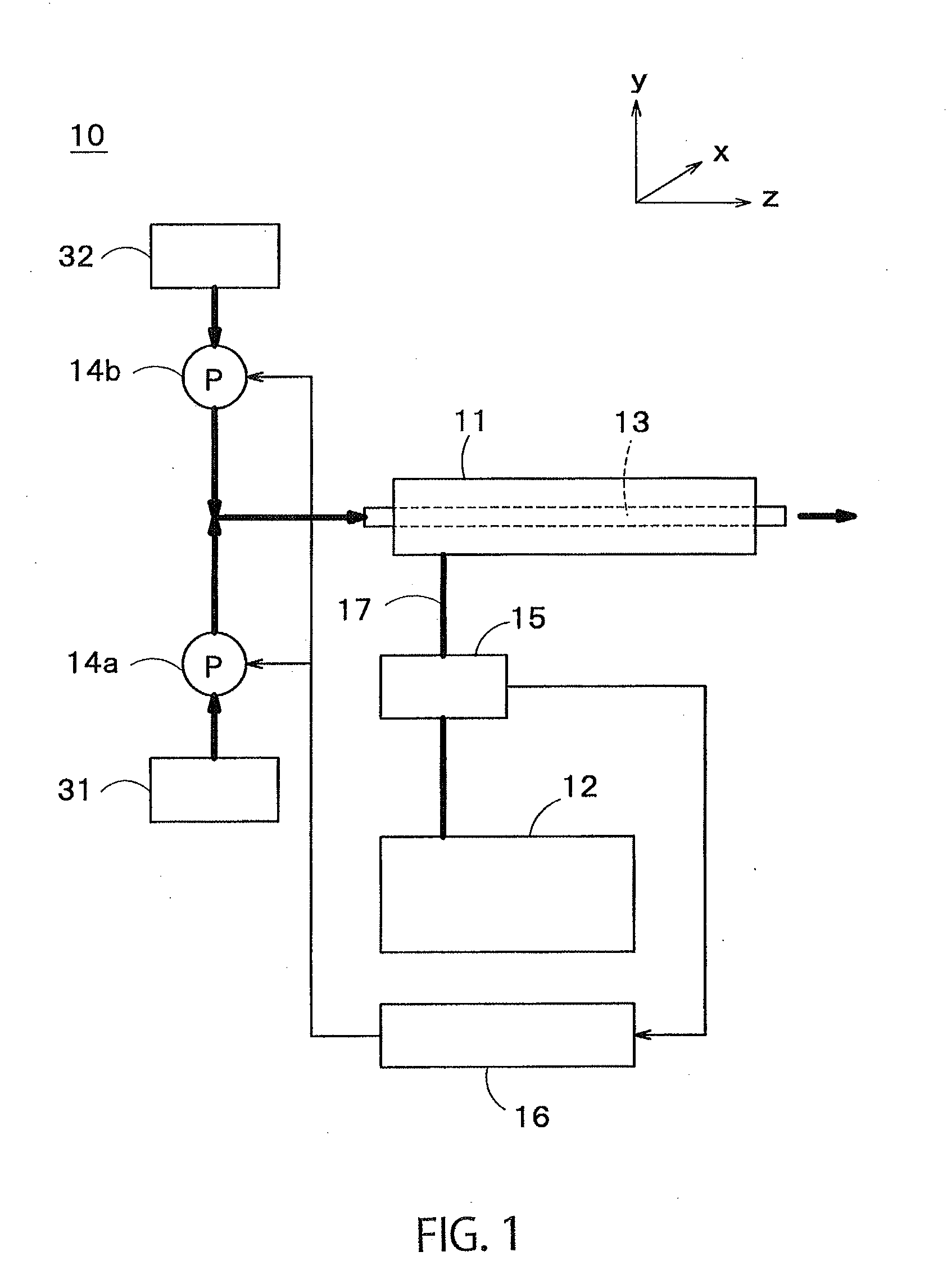

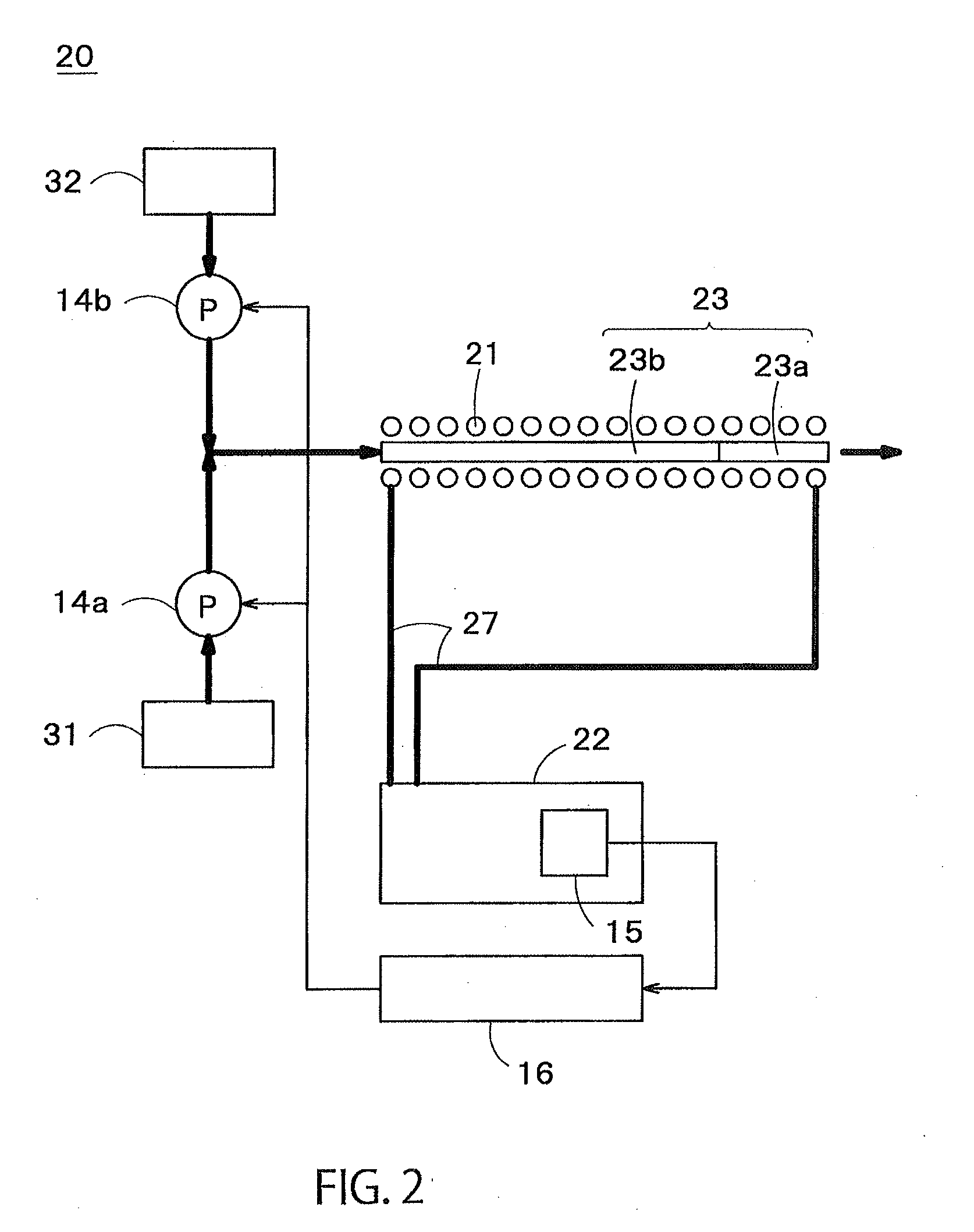

Ferromagnetic-particle manufacturing apparatus

InactiveUS20160296906A1Efficient solutionEfficient preparationTransportation and packagingMetal-working apparatusElectricityManufactured apparatus

A ferromagnetic-particle manufacturing apparatus includes: a single mode cavity that resonates with a microwave of a predetermined wavelength; a microwave oscillator electrically connected to the single mode cavity and configured to introduce the microwave of a predetermined wavelength into the single mode cavity; a pipe disposed to pass through an inside of the single mode cavity, the pipe being formed of a dielectric material; a pump configured to introduce, from one end of the pipe, an alkaline reaction liquid containing metal ions of a ferromagnetic metal; an impedance measuring device configured to measure an impedance of the single mode cavity; and a pump-flowrate deciding unit configured to decide, based on a measurement result of the impedance measuring device, a pump flowrate by which the impedance of the single mode cavity becomes a predetermined value or more; wherein the pump is configured to introduce the reaction liquid at the pump flowrate decided by the pump-flowrate deciding unit; and wherein ferromagnetic particles are generated by reacting the reaction liquid.

Owner:DAI ICHI HIGH FREQUENCY

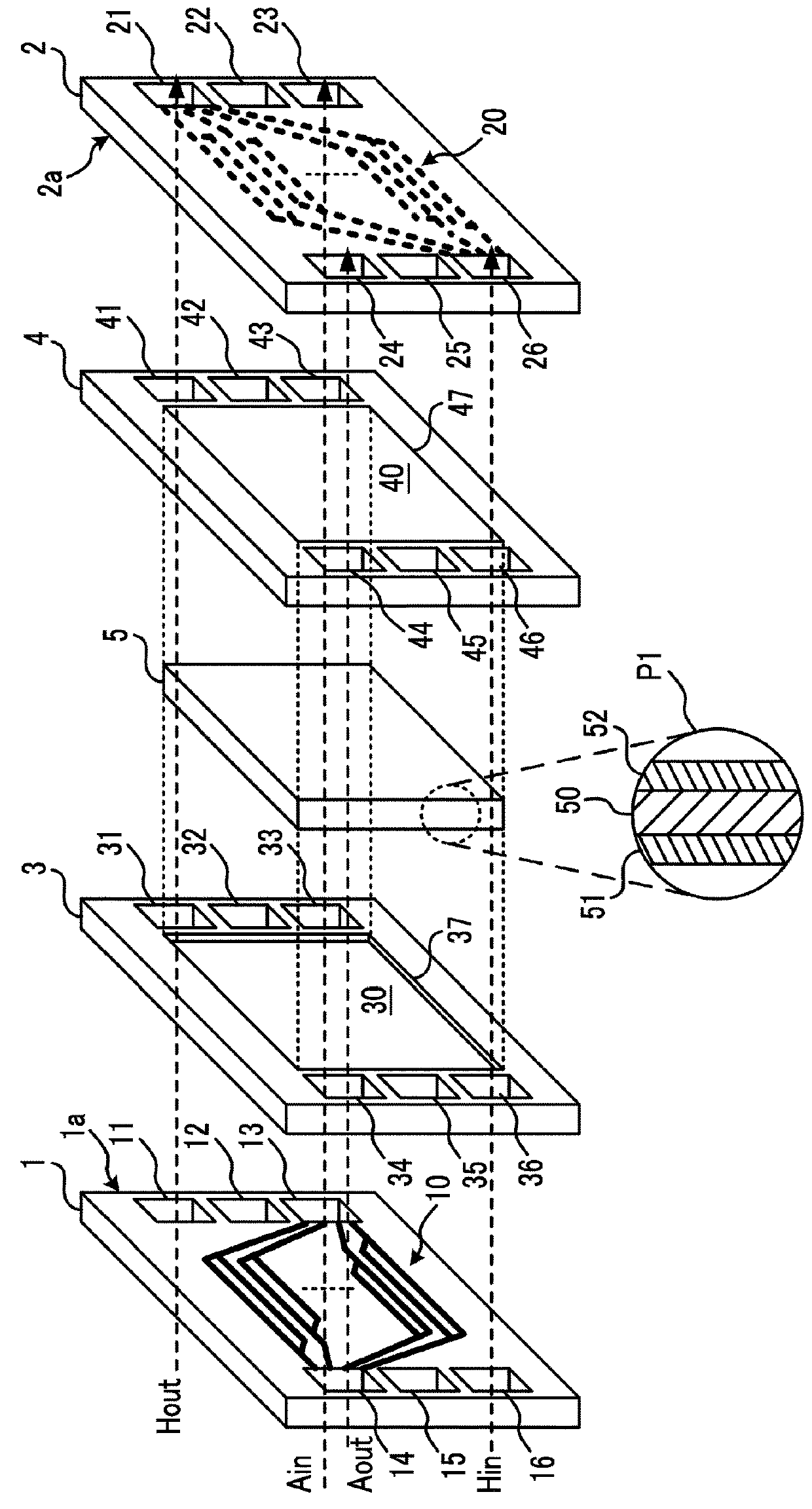

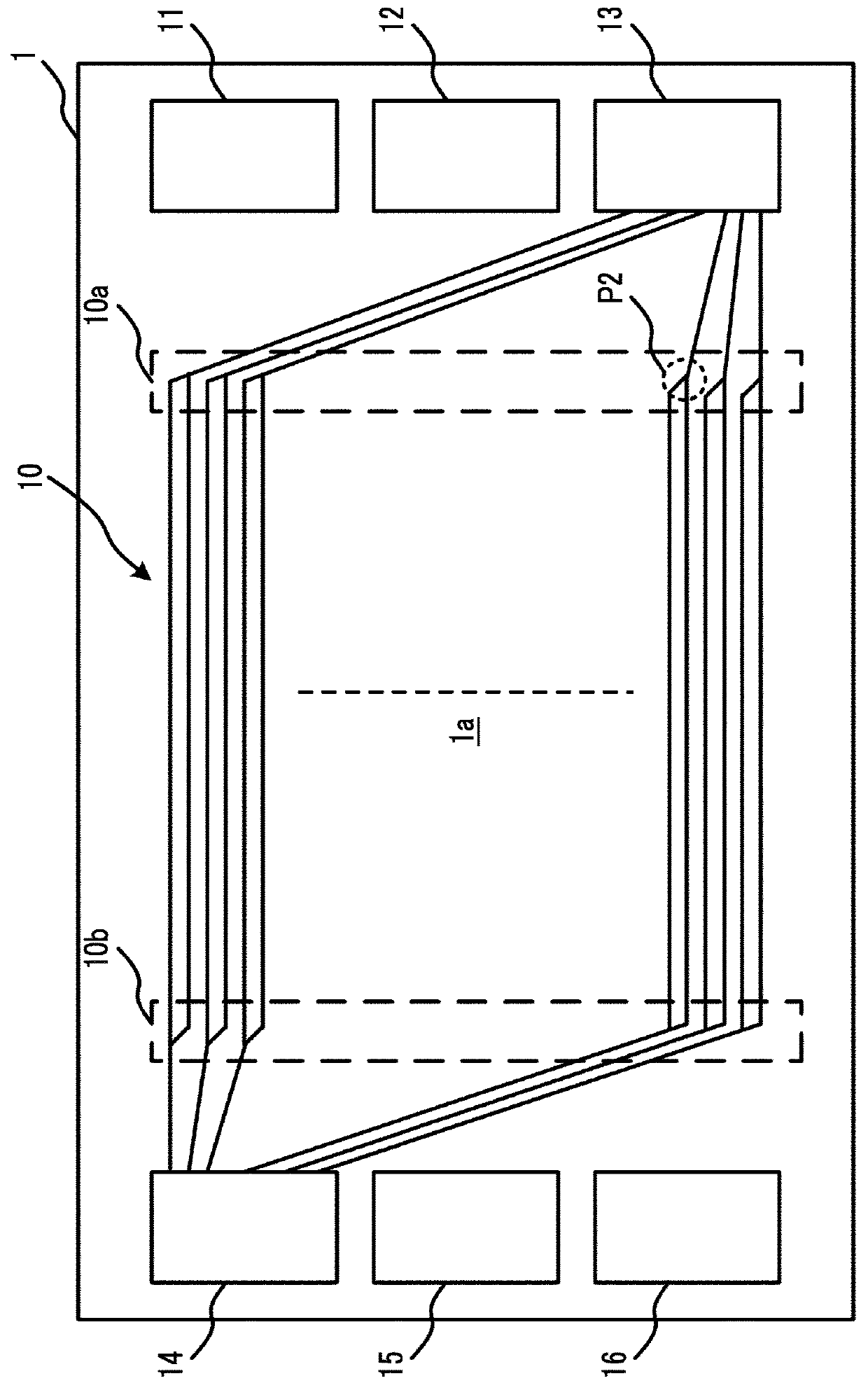

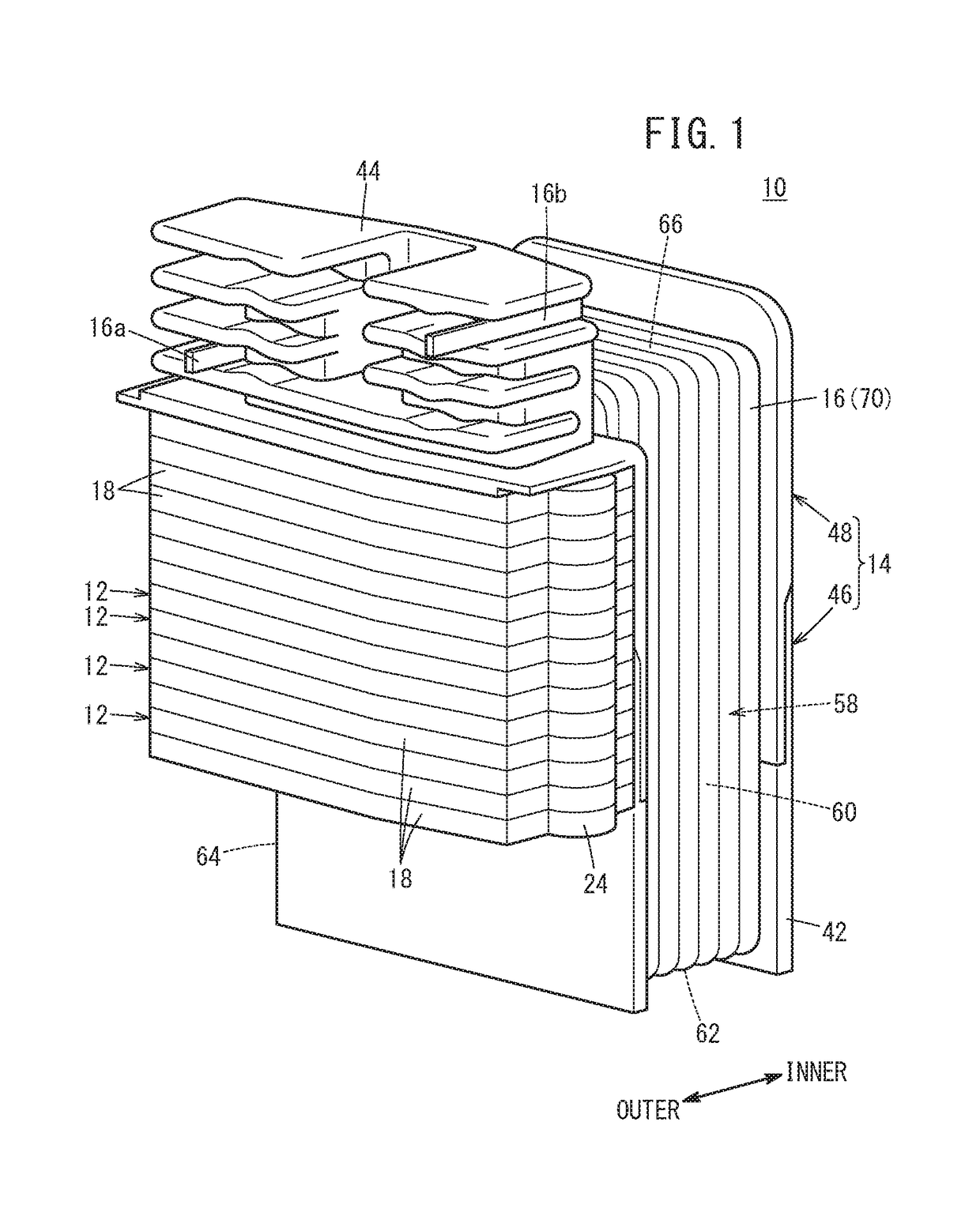

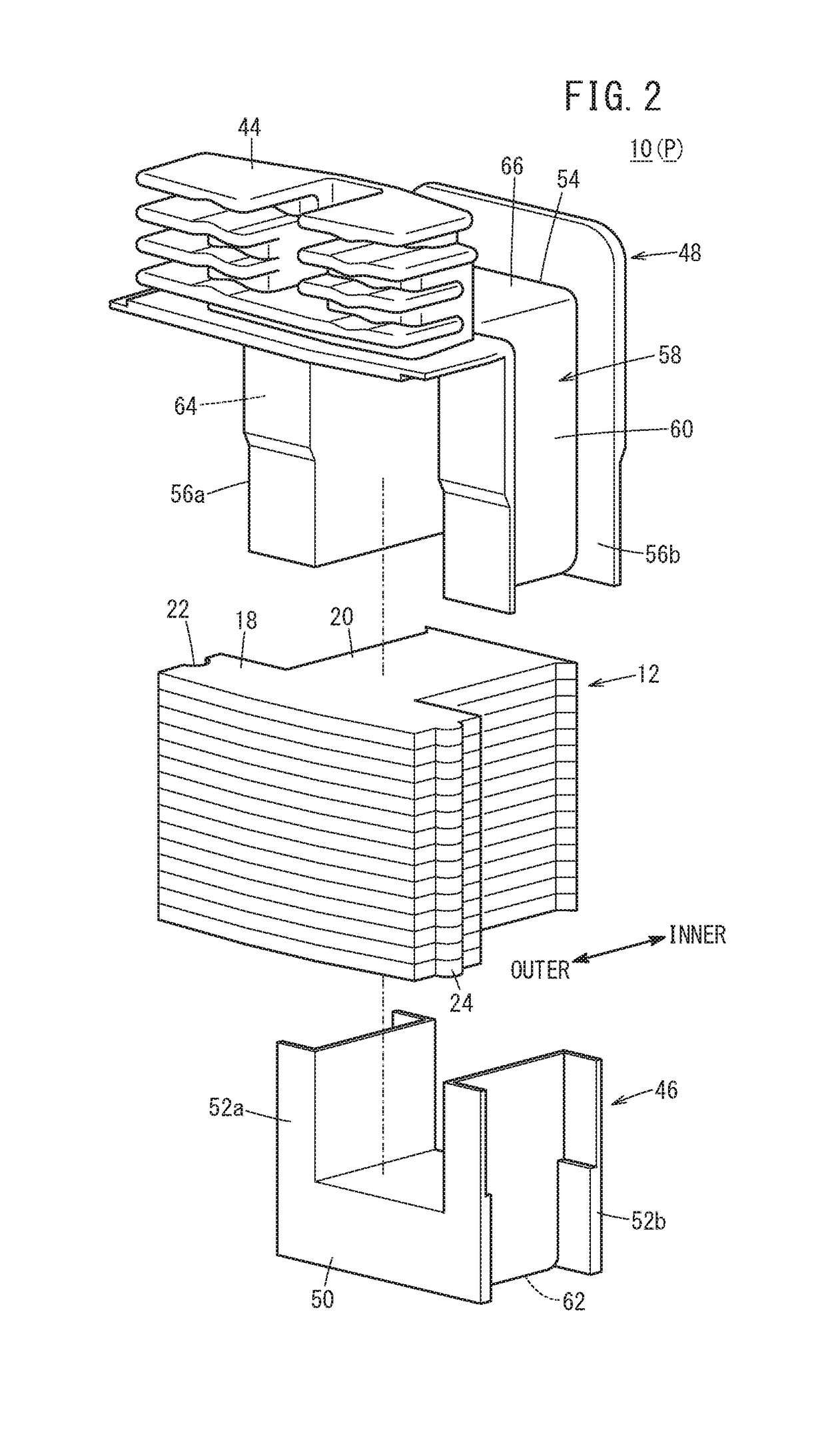

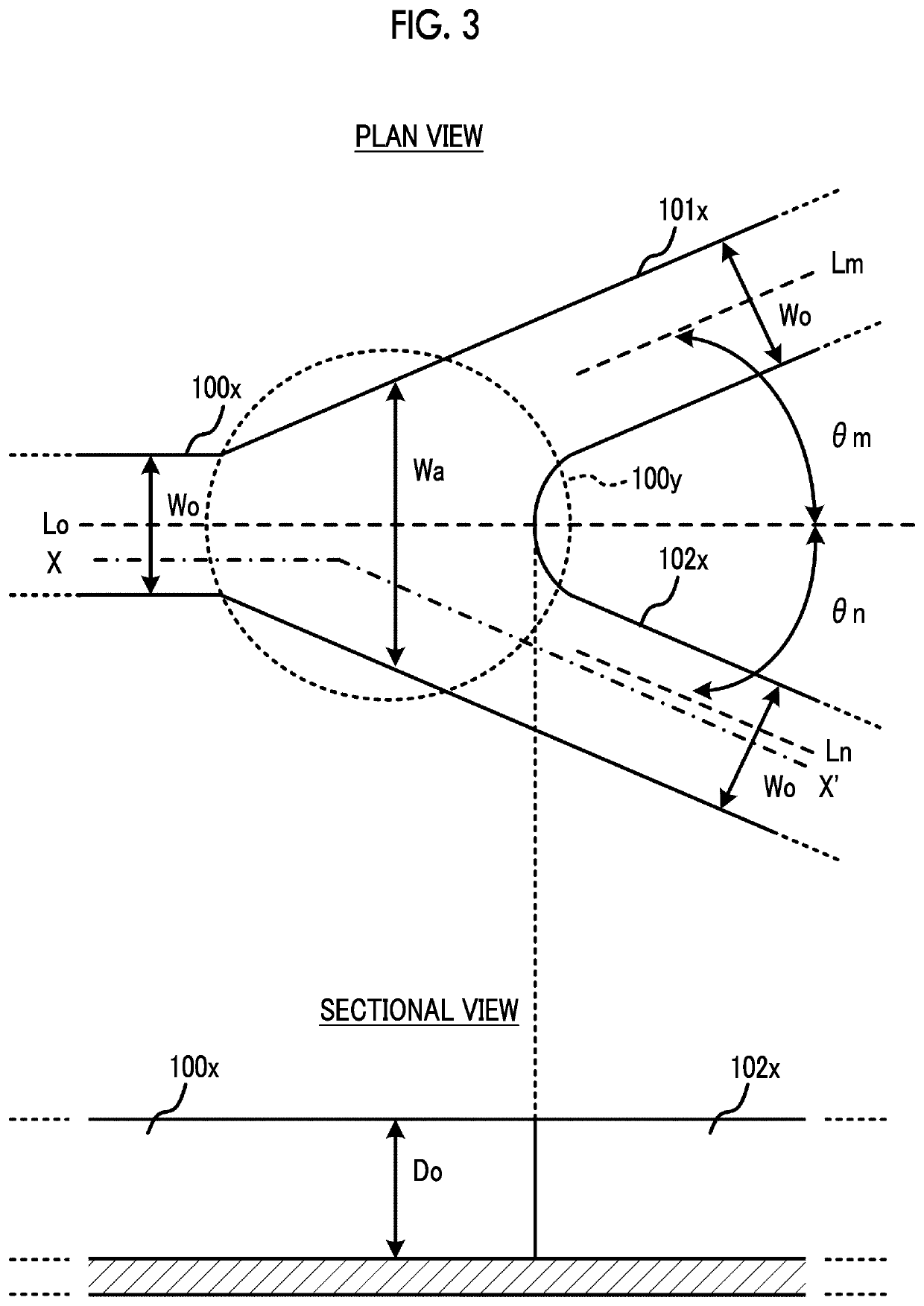

Separator for fuel cell and fuel cell

ActiveUS20180166702A1Maintain productivityDeterioration in a membrane electrode assembly is suppressedFinal product manufactureMotive system fuel cellsGroove widthFuel cells

A separator for a fuel cell, includes a separator plate provided with a flow path groove group through which the reaction gas flows. The flow path groove group includes a single first flow path groove, a plurality of second flow path grooves, and a branch portion that connects an end portion of the first flow path groove to end portions of the second flow path grooves. The branch portion includes a narrow portion having a narrower groove width than a groove width of a remaining portion of the branch portion. A groove depth of the narrow portion is shallower than a groove depth of the remaining portion of the branch portion.

Owner:TOYOTA JIDOSHA KK

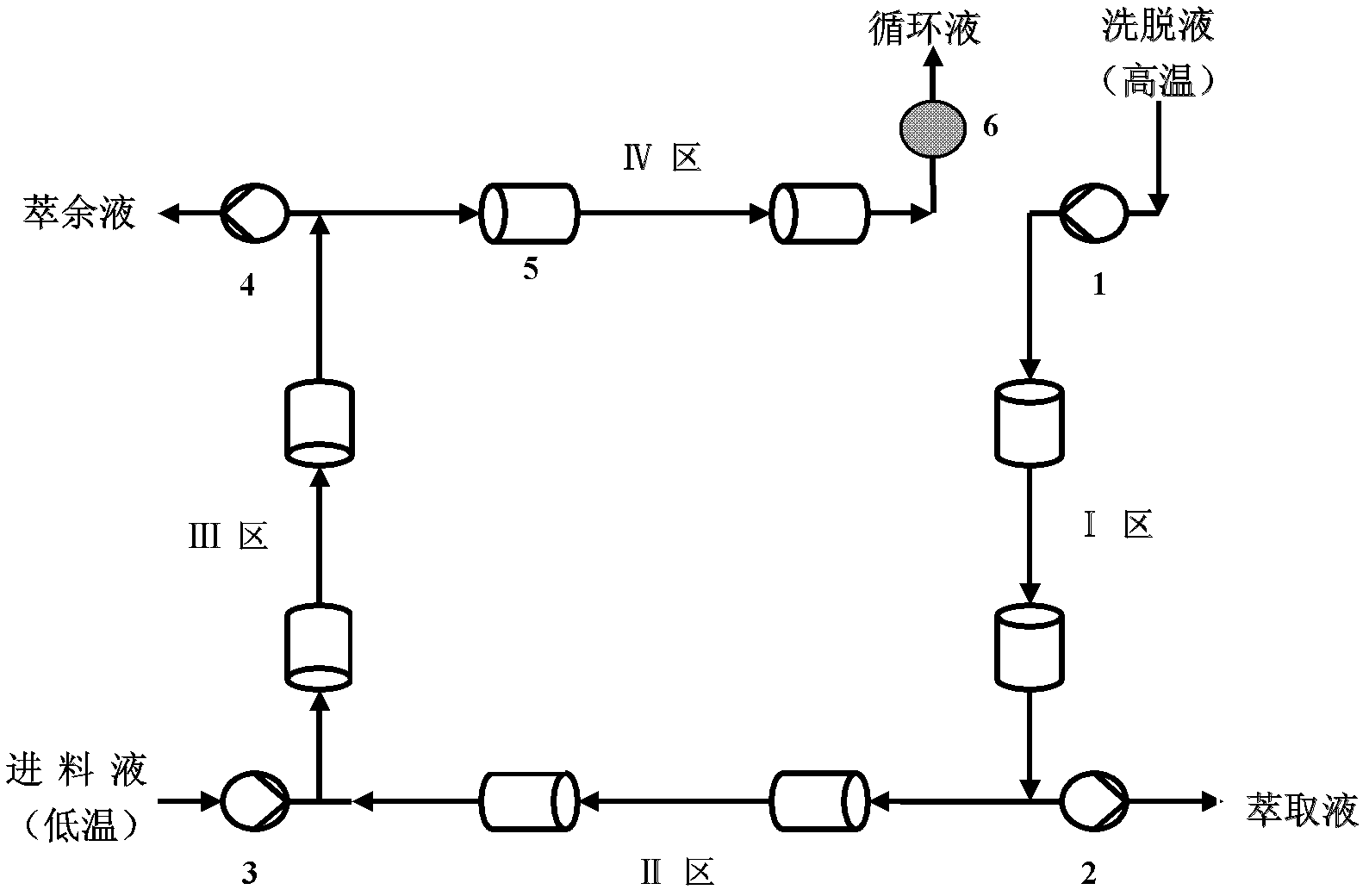

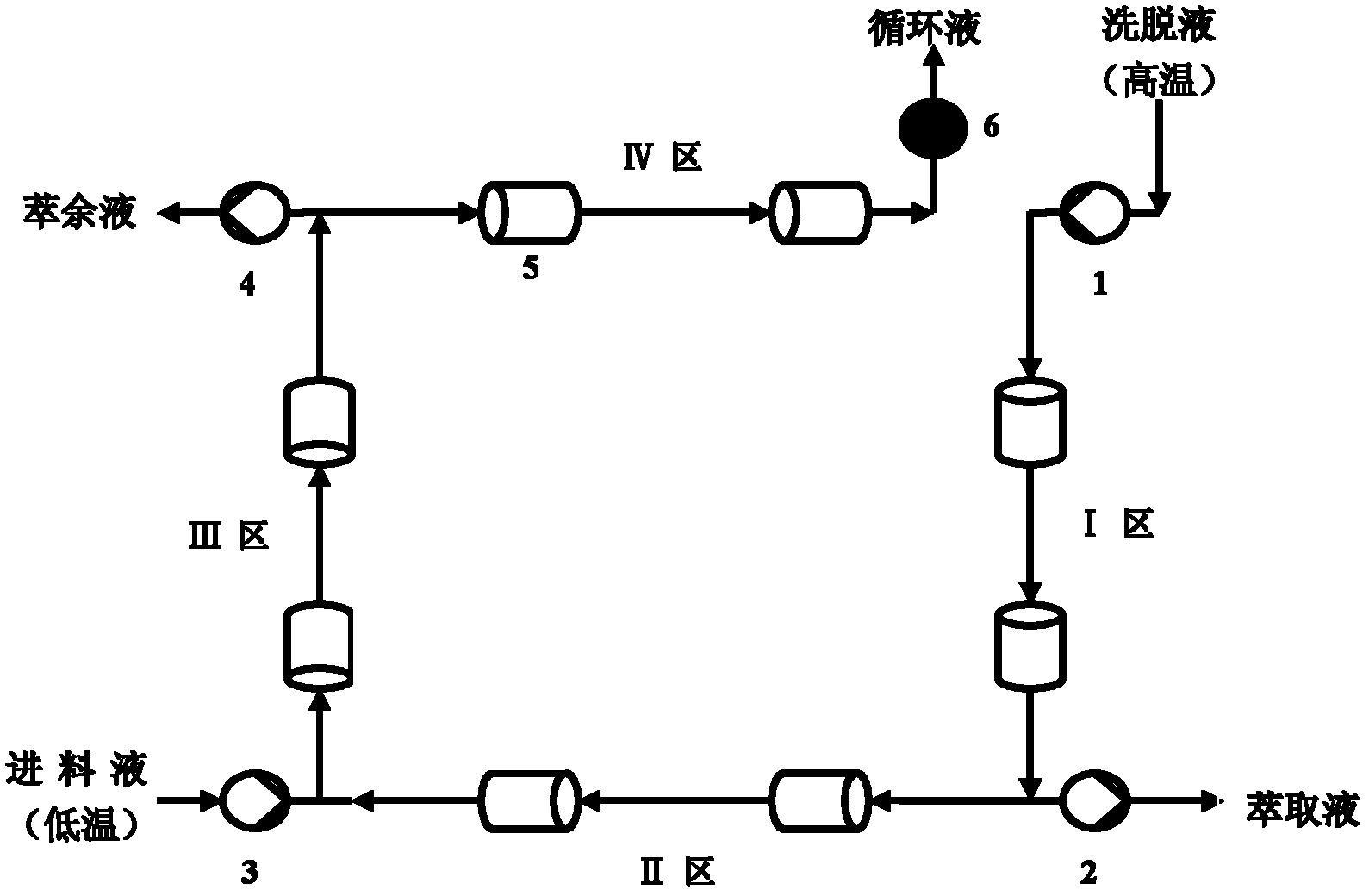

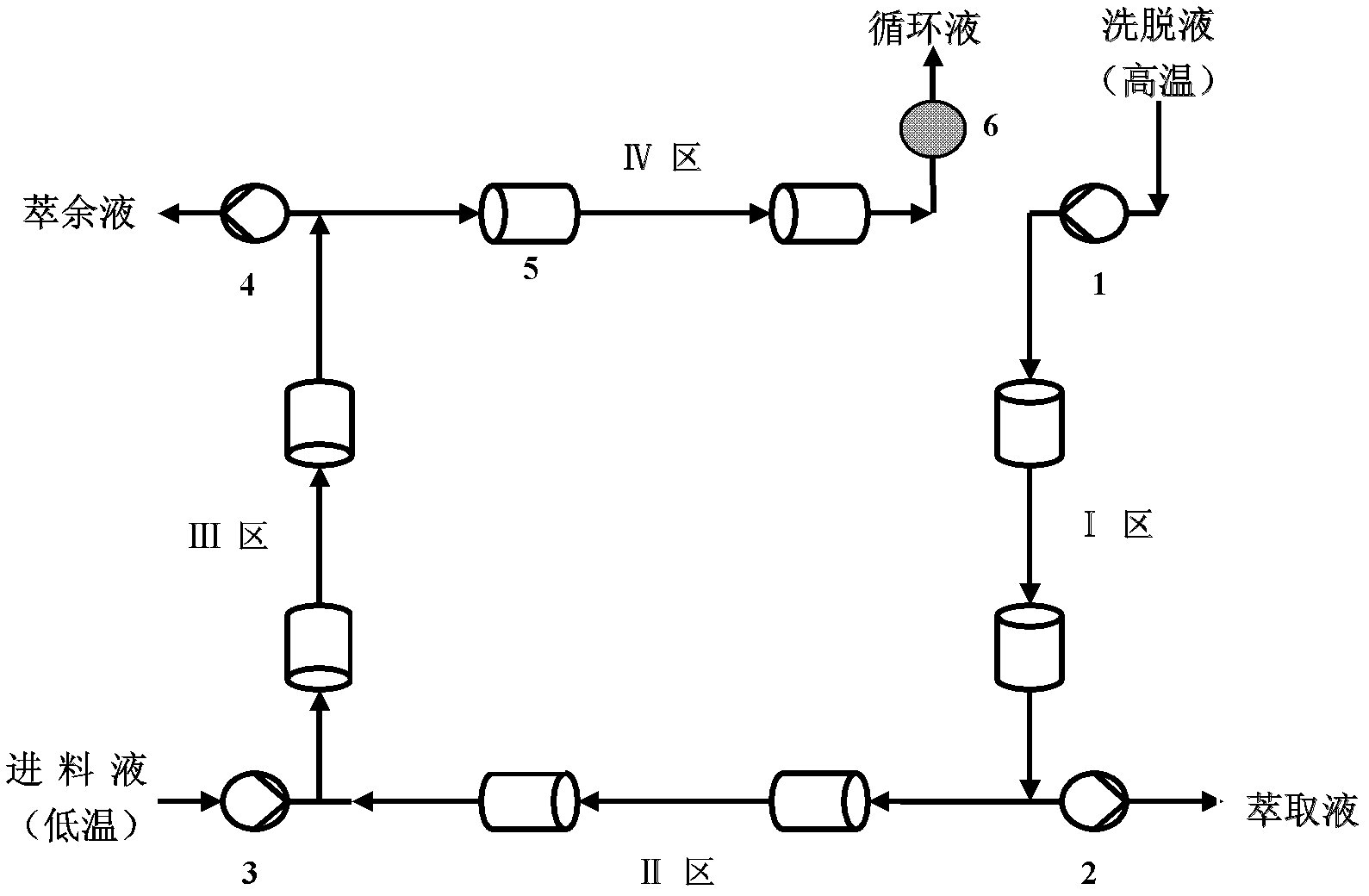

Method for splitting ketoprofen enantiomer by temperature gradient simulated moving bed chromatogram

InactiveCN102516068AAchieve separationHigh purityOptically-active compound separationCarboxylic compound separation/purificationDistillationSimulated moving bed

The invention discloses a method for splitting ketoprofen enantiomer by temperature gradient simulated moving bed chromatogram. The method comprises the following steps of: preparing a mobile phase as an eluate; using the eluate as a solvent to prepare a ketoprofen racemate solution as a charging liquid; introducing the charging liquid and the eluate with a temperature difference or with a same temperature into an open-loop simulated moving bed chromatogram to split the ketoprofen racemate and obtain levorotatory ketoprofen solution with a purity higher than 98% and a dextrorotatory ketoprofen solution; collecting the obtained levorotatory ketoprofen solution and the dextrorotatory ketoprofen solution; and carrying out distillation, recrystallization and drying respectively to obtain levorotatory ketoprofen enantiomer crystal and dextrorotatory ketoprofen enantiomer crystal with purity higher than 98%. The method has advantages of high separation efficiency, small solvent amount, continuous production and large operation elasticity, and has good commercialized application prospect.

Owner:WENZHOU UNIVERSITY

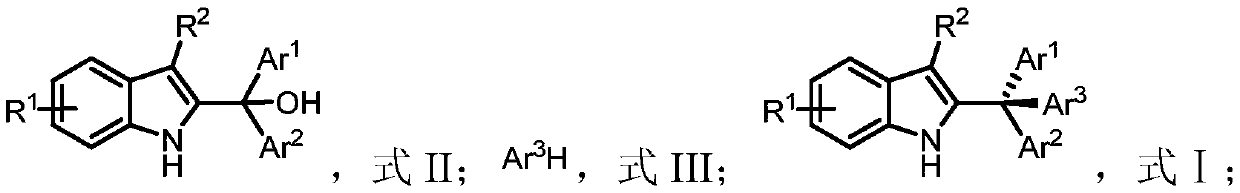

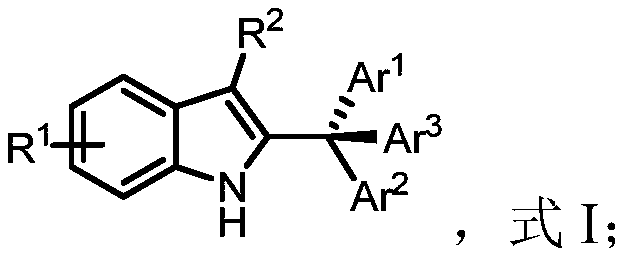

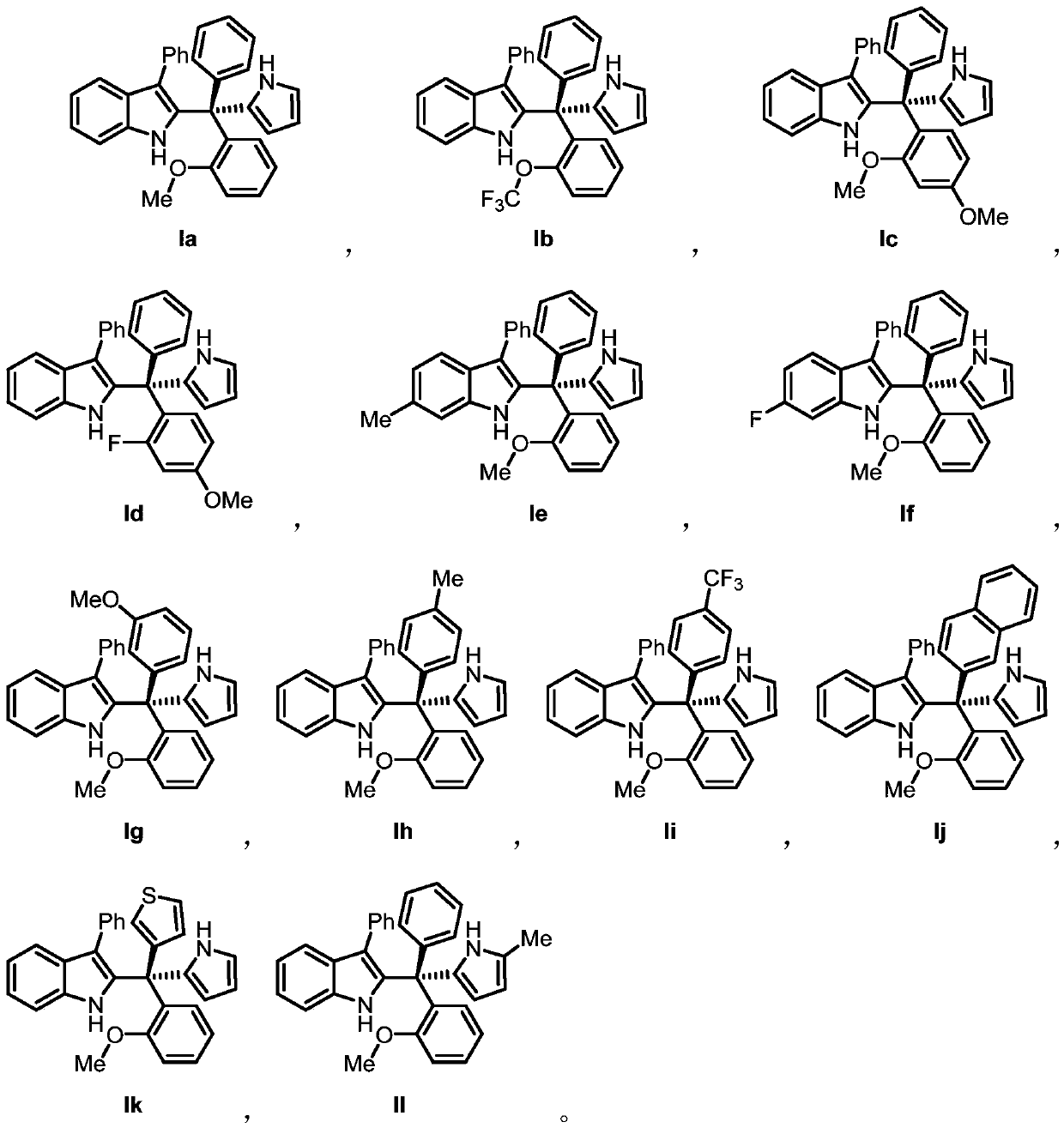

Preparation method of anti-tumor indole compound, indole compound and application

ActiveCN110804041AGood antitumor activityInterfering with metabolic pathwaysOrganic active ingredientsOrganic chemistry methodsChemical synthesisAryl

The invention belongs to the technical field of chemical synthesis, and particularly relates to a preparation method of an anti-tumor indole compound. The preparation method comprises the following steps: obtaining a compound shown in a formula II and a compound shown in a formula III, dissolving the compound shown in the formula II and the compound shown in the formula III in an organic solvent,and carrying out a synthetic reaction under a condition that the temperature is 0-40 DEG C and a catalyst is chiral phosphoric acid to obtain the anti-tumor indole compound shown in a formula I, wherein R<1> and R<2> are ones separately selected from alkyl, aryl, heteroaryl, substituted aryl and substituted heteroaryl; Ar<1>, Ar<2> and Ar<3> are ones separately selected from aryl, heteroaryl and substituted heteroaryl; and the Ar<1>, the Ar<2> and the Ar<3>differ from each other. The preparation method provided by the invention has the characteristics of simple and practical operation, high yield, greenness and economy, environmental friendliness and easy industrialization. The formula II the formula III and the formula I are represented as in the description.

Owner:HKUST SHENZHEN RES INST

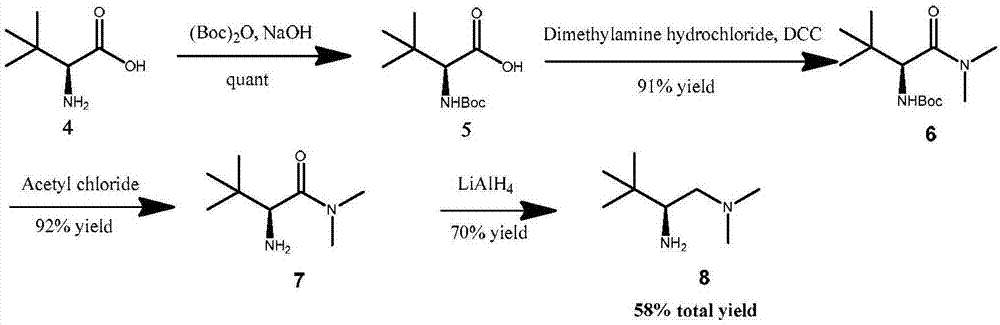

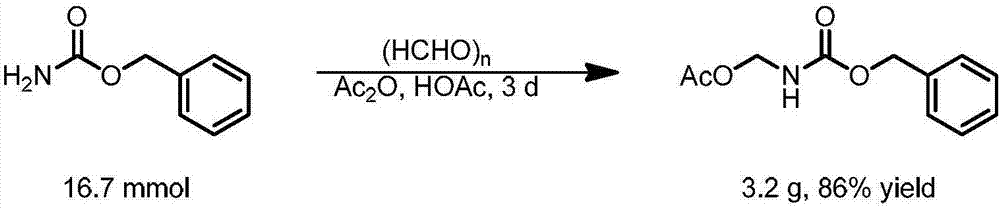

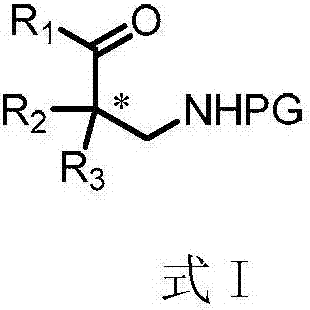

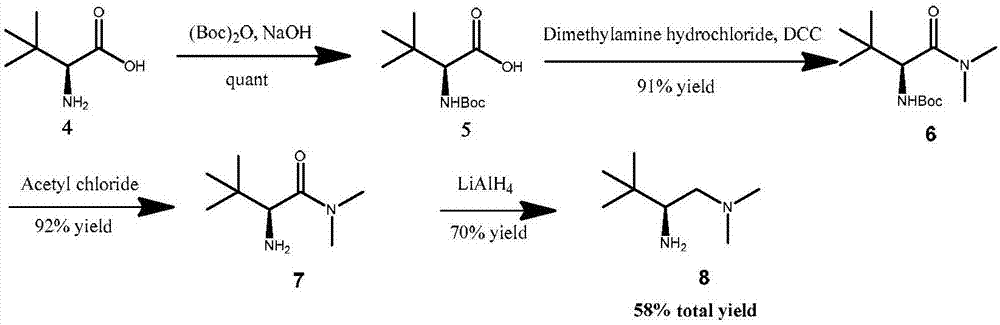

Chiral beta-amino acid derivative and preparation method thereof

ActiveCN107382783ASimple structureShort synthetic routeCarbamic acid derivatives preparationCarboxylic acid nitrile preparationStrong acidsSolvent free

The invention discloses a chiral beta-amino acid derivative and a preparation method thereof. The structural formula of the chiral beta-amino acid derivative is represented by a formula I (shown in the description). The preparation method comprises the steps of mixing a mixture of a carbonyl compound and N,O-acetal with chiral primary-tertiary diamine organic small-molecule catalyst, strong acid and weak acid to react, so as to obtain the chiral beta-amino acid derivative, wherein the carbonyl compound includes aldehyde and / or ketone. The chiral beta-amino acid derivative is catalyzed by virtue of the chiral primary-tertiary diamine organic small-molecule catalyst with a simple structure, is synthesized through a one-step method, and is solvent-free, simple and efficient.

Owner:INST OF CHEM CHINESE ACAD OF SCI

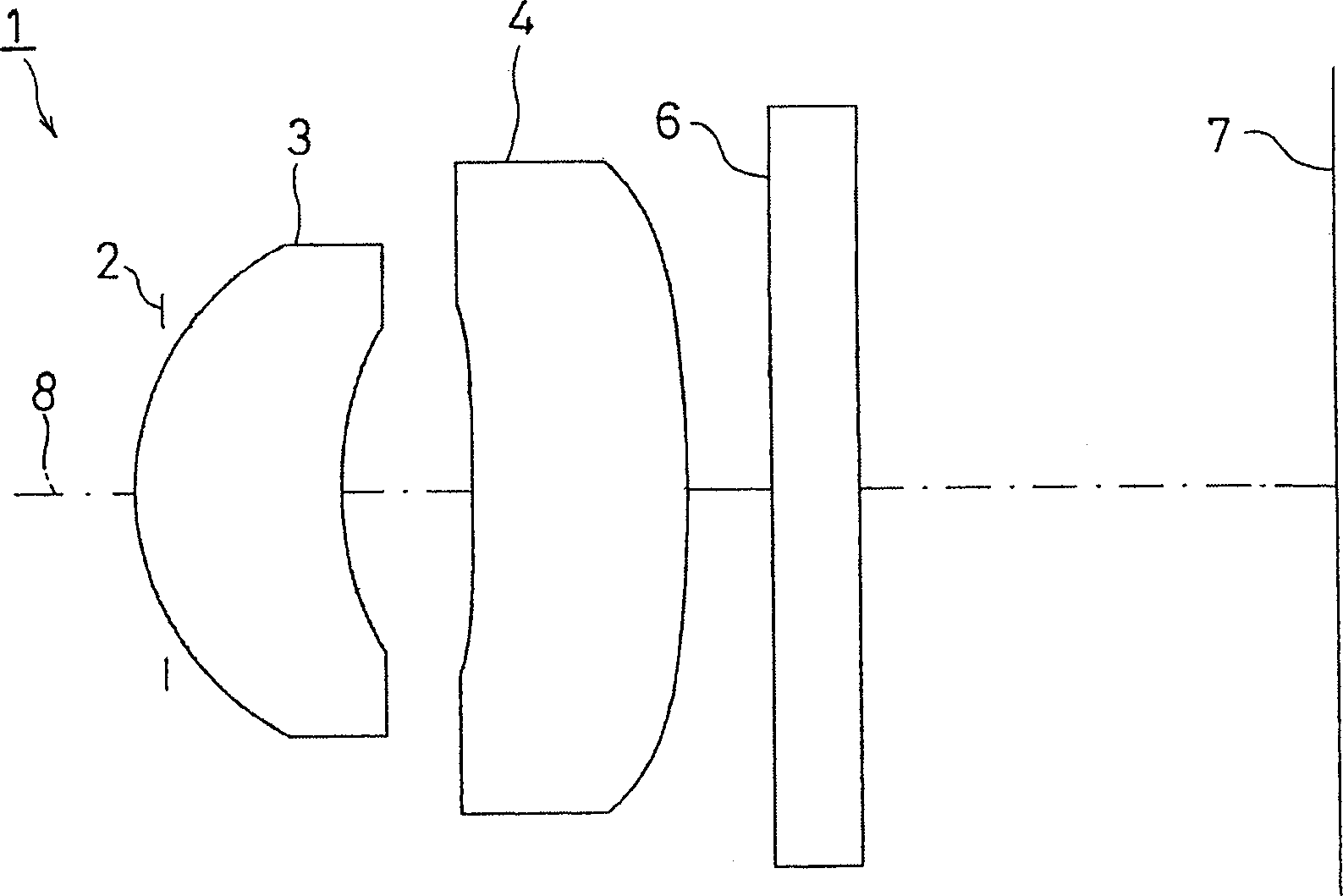

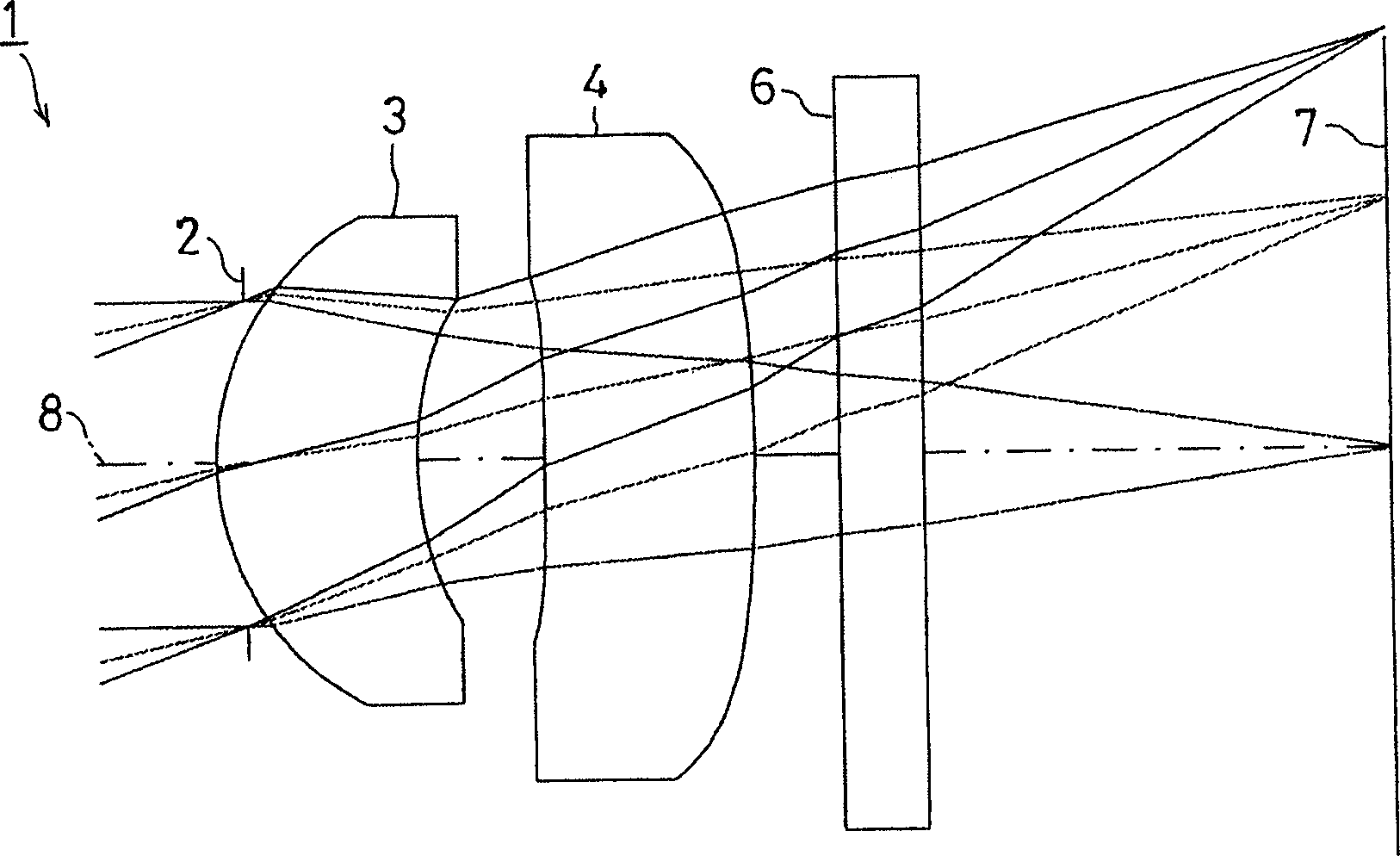

Imaging lens system

The present invention provides a compact imaging lens. The compact imaging lens comprises, from the object side to the image side, a diaphragm (2), a first positive meniscus lens (3) with a positive focal crescent shape which the convex surface of which facing the object side, and a second positive lens (4) the convex surface of which facing the image surface side, wherein following inequalities are satisfied 1.25>=L / fl>=0.8, 0.55>=f1 / f2>=0.2, 1.8>=f1 / fl>=1, 4>=f2 / fl>=1.5, 1>=d2 / d1>=0.5, 0.27>=d1 / fl>=0.1, 0.27 >=d3 / fl>=0.1 where, L: entire length of the lens system, Fl: focal distance of entire lens system, f1: focal distance of the first lens, f2: focal distance of the second lens, d1: center thickness of the first lens, d2: distance between the first lens and second lens on the optical axis, d3: center thickness of the second lens.

Owner:ENPLAS CORP

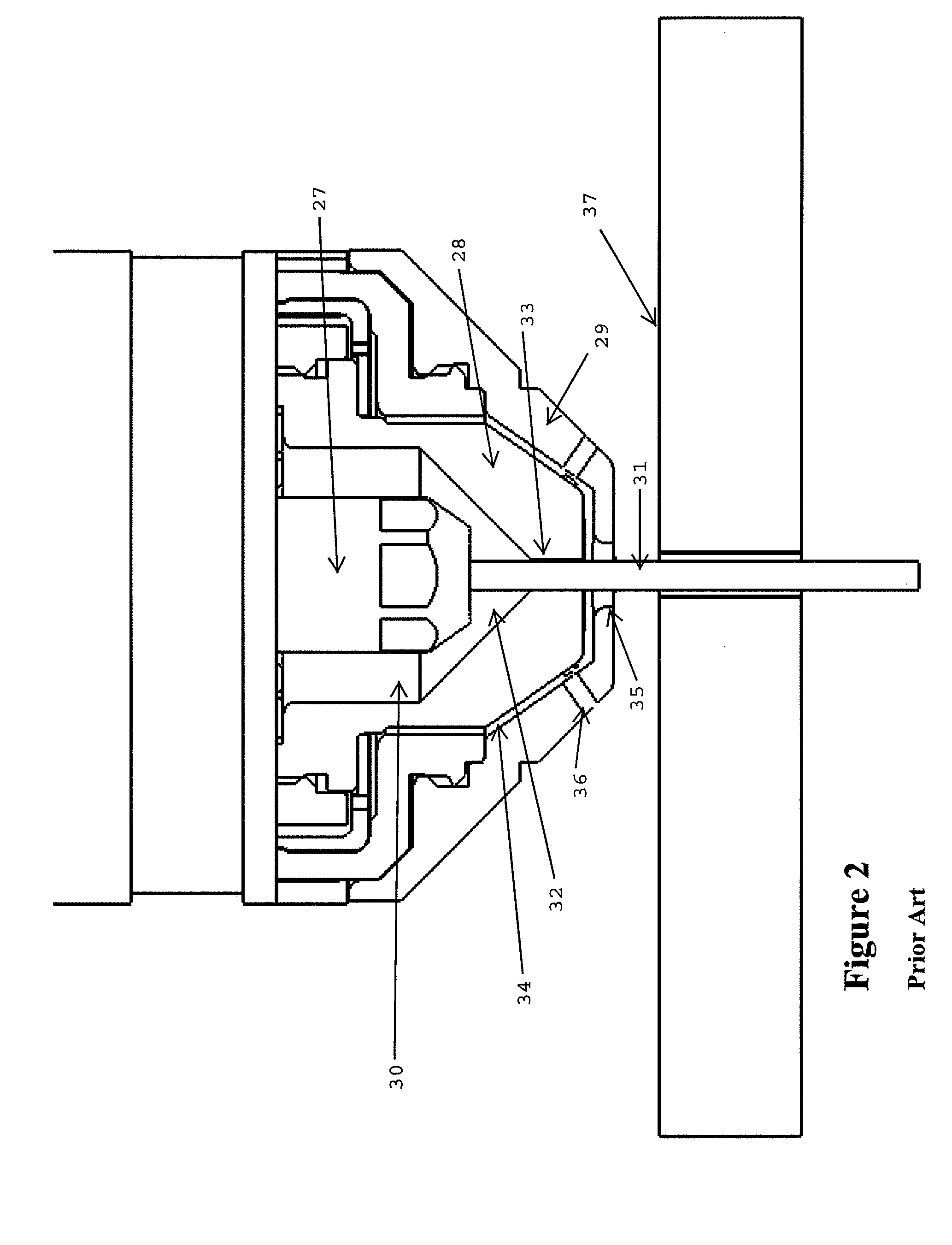

Method of manufacturing divided cores for a stator

ActiveUS20190020251A1Amount of movementWinding efficiency of the wire, and henceWindings insulation materialWindings insulation shape/form/constructionEngineeringMechanical engineering

An electromagnetic coil is formed by winding a wire around a winding member of an insulator. The winding member is configured with a substantially polygonal shape. Further, in a winding step of winding the wire, which is supplied from a wire supply unit, around the winding member, when the wire reaches a corner portion of the winding member, a residual stress toward an outer side in the diametrical direction of the stator is imparted to the wire. Thereafter, portions of the insulative coating of the wire are subjected to fusion bonding.

Owner:HONDA MOTOR CO LTD

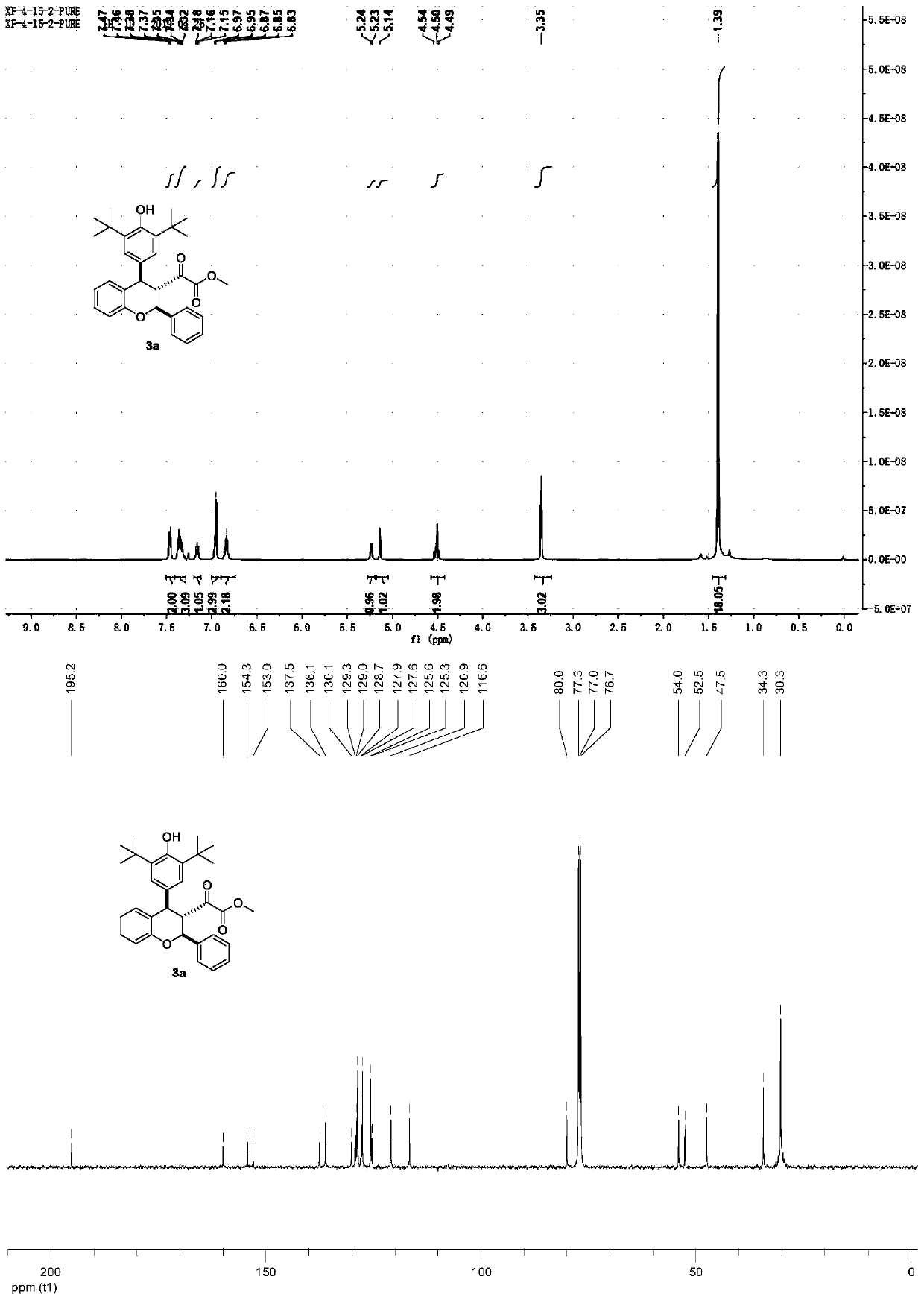

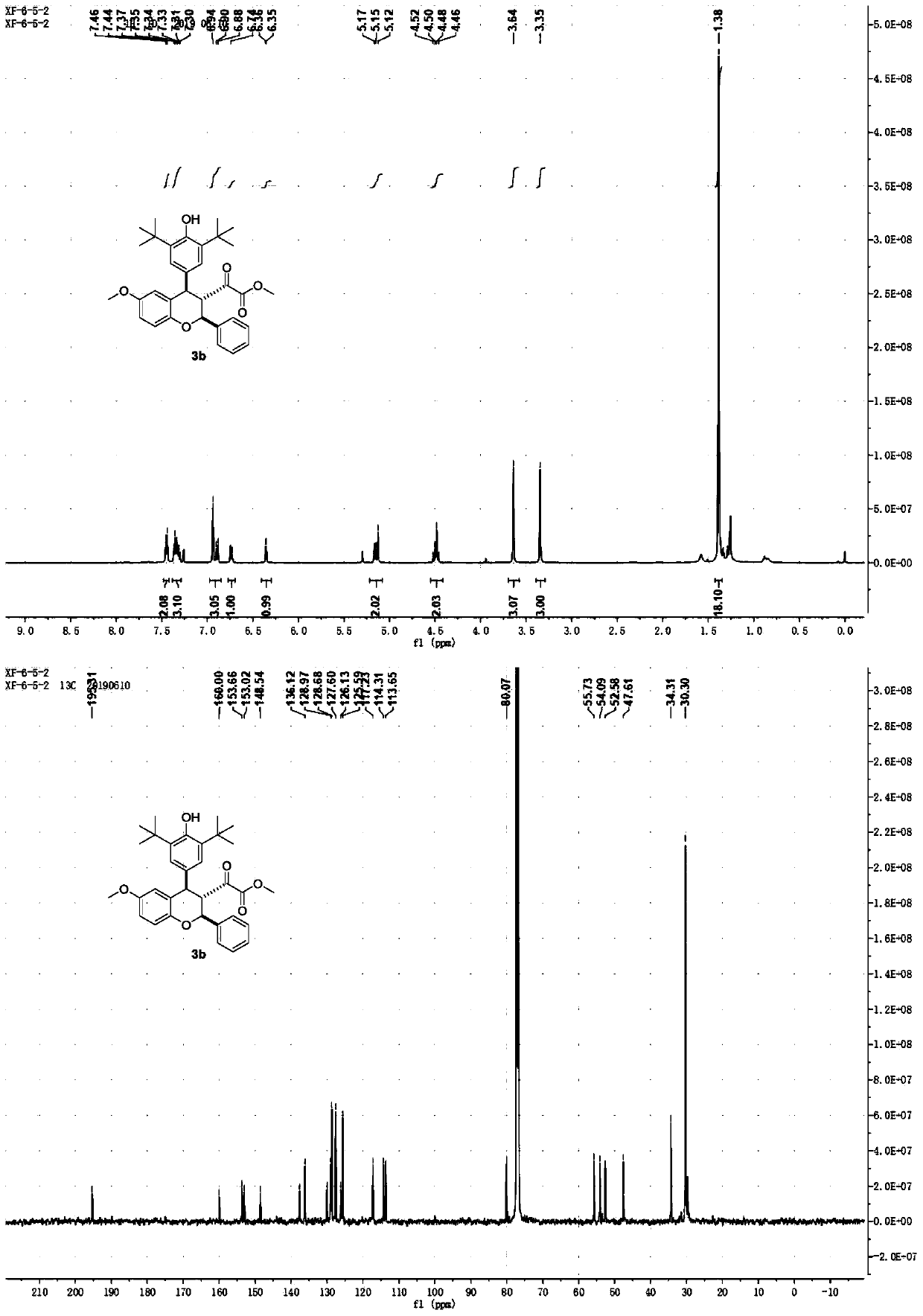

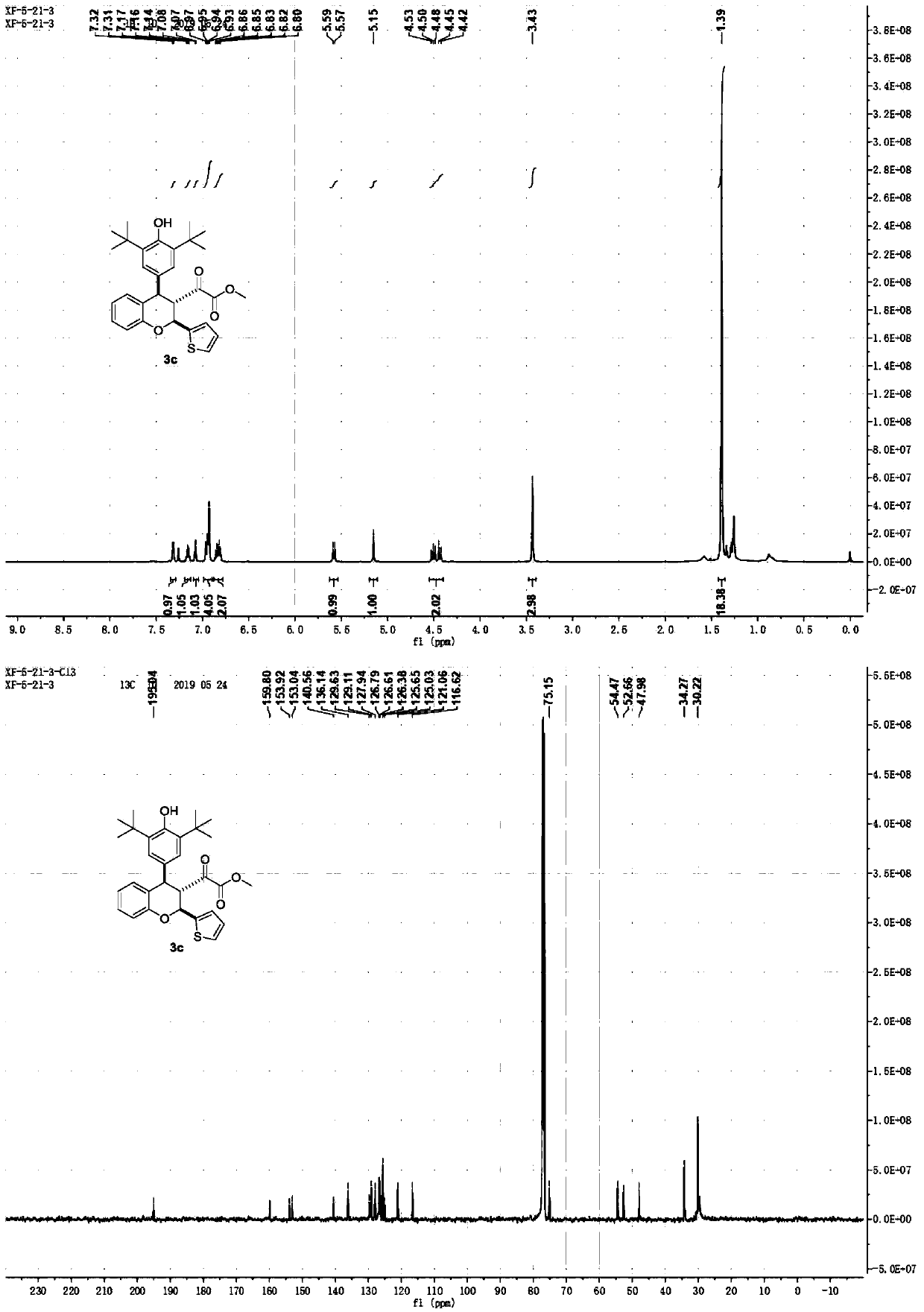

Synthesis method of polysubstituted 4-phenyl chroman compounds

The invention belongs to the technical field of organic synthesis and discloses a synthesis method of polysubstituted 4-phenyl chroman compounds. The structural formula of polysubstituted 4-phenyl chroman compounds is shown by formula I. The method involves non-metal catalyzed oxamichael addition and 1,6-tandem reaction conjugated addition under mild condition. The catalyst used in the invention is a commercial nonmetallic alkali, has low cost, is environmentally friendly and is easy to operate; the method disclosed in the invention has high yield, excellent diastereoselectivity, mild conditions, convenient post-treatment and easy separation and purification of products; the method of the invention is easy to produce on a large scale, and the amplified yield and diastereoselectivity can bemaintained.

Owner:QINGDAO UNIV OF SCI & TECH

Method for splitting ketoprofen enantiomer by temperature gradient simulated moving bed chromatogram

InactiveCN102516068BAchieve separationHigh purityOptically-active compound separationCarboxylic compound separation/purificationDistillationSimulated moving bed

The invention discloses a method for splitting ketoprofen enantiomer by temperature gradient simulated moving bed chromatogram. The method comprises the following steps of: preparing a mobile phase as an eluate; using the eluate as a solvent to prepare a ketoprofen racemate solution as a charging liquid; introducing the charging liquid and the eluate with a temperature difference or with a same temperature into an open-loop simulated moving bed chromatogram to split the ketoprofen racemate and obtain levorotatory ketoprofen solution with a purity higher than 98% and a dextrorotatory ketoprofen solution; collecting the obtained levorotatory ketoprofen solution and the dextrorotatory ketoprofen solution; and carrying out distillation, recrystallization and drying respectively to obtain levorotatory ketoprofen enantiomer crystal and dextrorotatory ketoprofen enantiomer crystal with purity higher than 98%. The method has advantages of high separation efficiency, small solvent amount, continuous production and large operation elasticity, and has good commercialized application prospect.

Owner:WENZHOU UNIV

Transparent conductive polyester film and use of same

PendingUS20220246069A1Maintains mass productivityFunction increaseInput/output processes for data processingIdentification meansPolyesterPolymer science

Provided is a transparent conductive polyester film for a foldable display which is free of occurrence of a fold mark or a tear at a folding portion thereof to be used in a foldable display excellent in mass productivity, and free of a risk of causing distortion in an image displayed at a folding portion thereof, and a mobile device. The transparent conductive polyester film for a foldable display includes: a polyester film; and a transparent conductive layer laminated on at least one surface of the polyester film, wherein the polyester film satisfies the following conditions: (1) a refractive index in a bending direction is from 1.590 to 1.620; (2) a refractive index in a folding portion direction is from 1.670 to 1.700; (3) a refractive index in a thickness direction is 1.520 or less; and (4) a density is 1.380 g / cm3 or more, wherein the bending direction refers to a direction orthogonal to a folding portion of the polyester film at a time when the polyester film is folded.

Owner:TOYO TOYOBO CO LTD

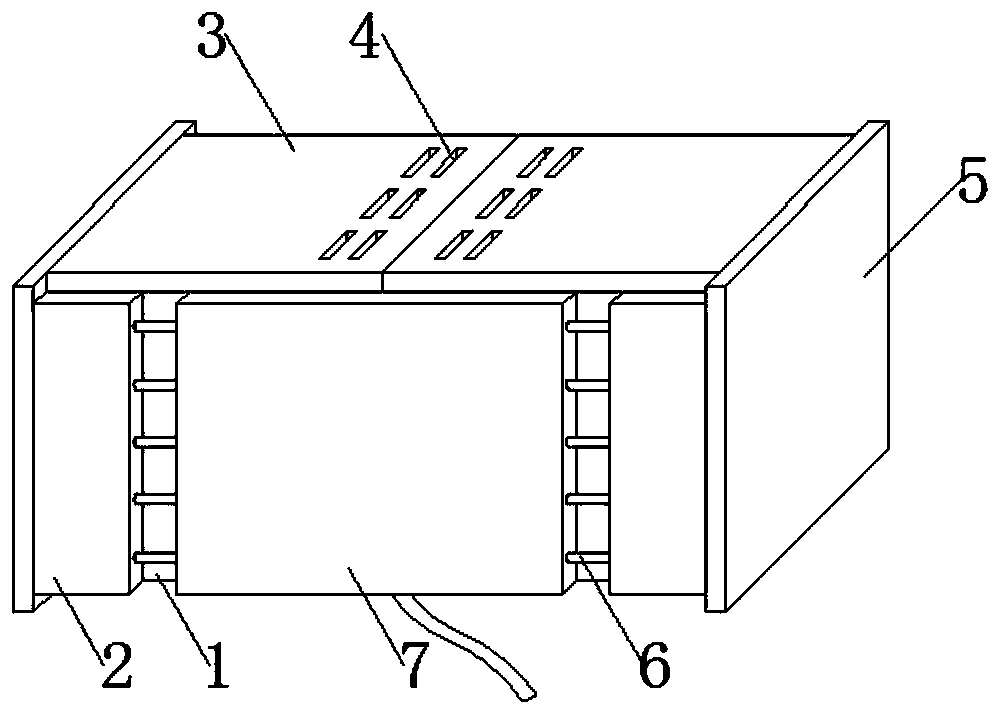

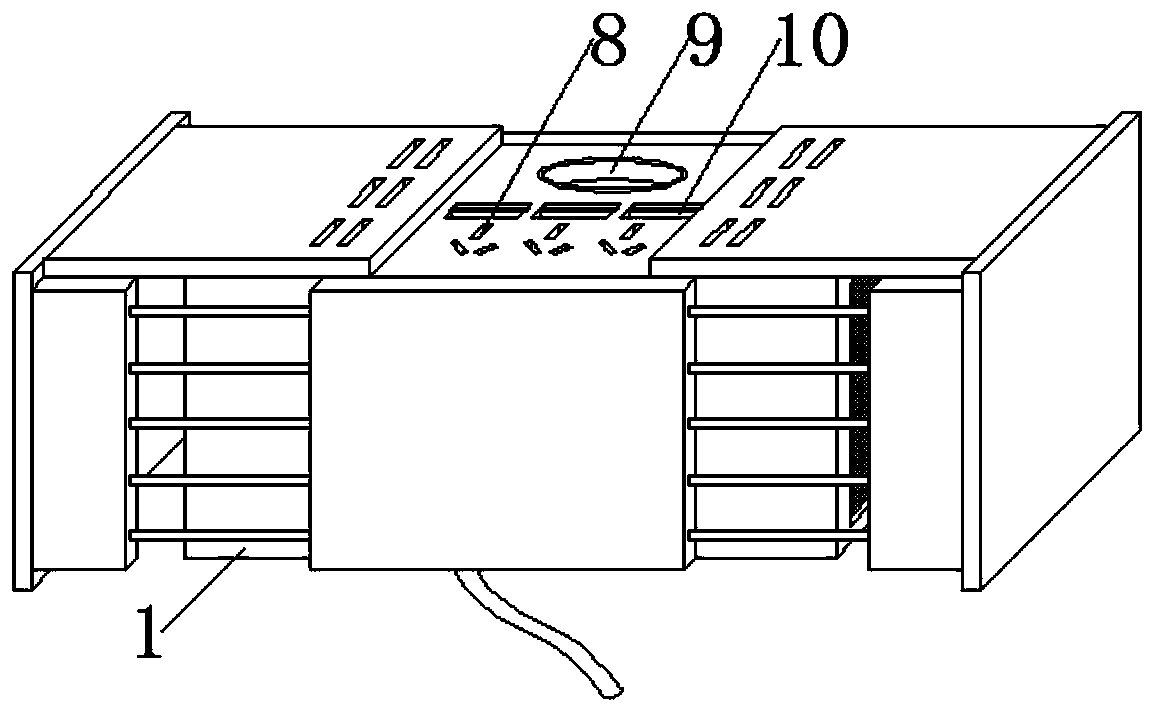

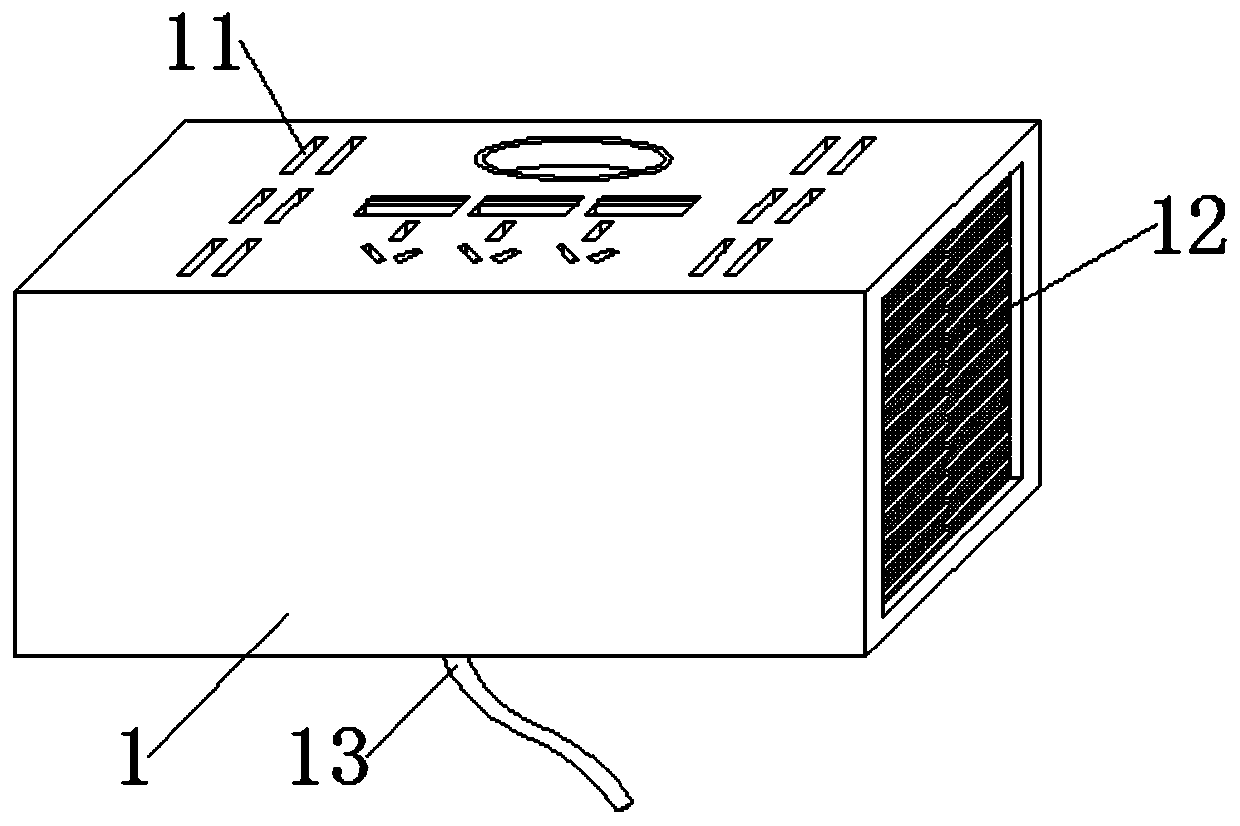

Vehicle-mounted inverter with convection heat dissipation and heat dissipation and dust prevention method

ActiveCN110149058AEfficient heat dissipationImprove environmental adaptabilityConversion constructional detailsModifications for power electronicsEngineeringConvection heat

The invention discloses a vehicle-mounted inverter with convection heat dissipation and a heat dissipation and dust prevention method. The method includes a housing, an inverter circuit board mountedon the lower wall in the shell and heat dissipation openings formed in the two ends of the shell. When a device works, two fans directly facing the inversion circuit board can rapidly and efficientlydissipate heat of the inversion circuit board and the working heat can be discharged out of the device through the heat dissipation openings; through second ventilation holes formed in the top plate of the shell, air convection inside the shell can be accelerated, so that the device has better environment adaptability; the heat dissipation capacity of the device can be effectively improved throughtwo groups of convection heat removal systems, and the problem that the working efficiency and the service life of the device are influenced by excessive heat collection inside the device is solved.

Owner:CHANGZHOU WUJIN HGPOWER

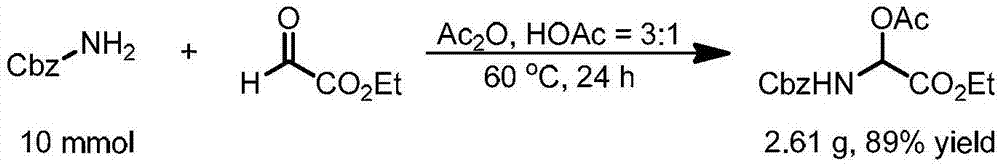

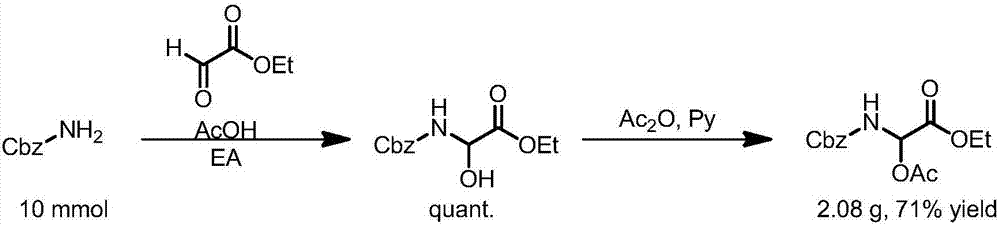

Chiral alpha-amino acid derivative and preparation method thereof

ActiveCN107325025ASimple structureShort synthetic routeCarbamic acid derivatives preparationOrganic compound preparationSolventDiamine

The invention discloses a chiral alpha-amino acid derivative and a preparation method thereof. The structural formula of the chiral alpha-amino acid derivative disclosed by the invention is of formula I shown in the specification. The preparation method of the derivative comprises the following steps: mixing a carbonyl compound with a N,O-acetal mixture, a chiral primary tert-diamine organic small molecule catalyst, strong acid and weak acid, and performing a reaction, thereby obtaining the chiral alpha-amino acid derivative. The chiral alpha-amino acid derivative comprises aldehyde and / or ketone. The chiral alpha-amino acid derivative disclosed by the invention is prepared under catalysis of the chiral primary tert-diamine organic small molecule catalyst of a simple structure via one-step synthesis without solvent, thus being simple and efficient.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Small batch spandex spinning test device

ActiveCN104088020BReduce cleaningImprove cleanlinessSpinning head liquid feederInternal pressureElectrical control

Owner:LIANYUNGANG DUZHONG NEW AOSHEN SPANDEX

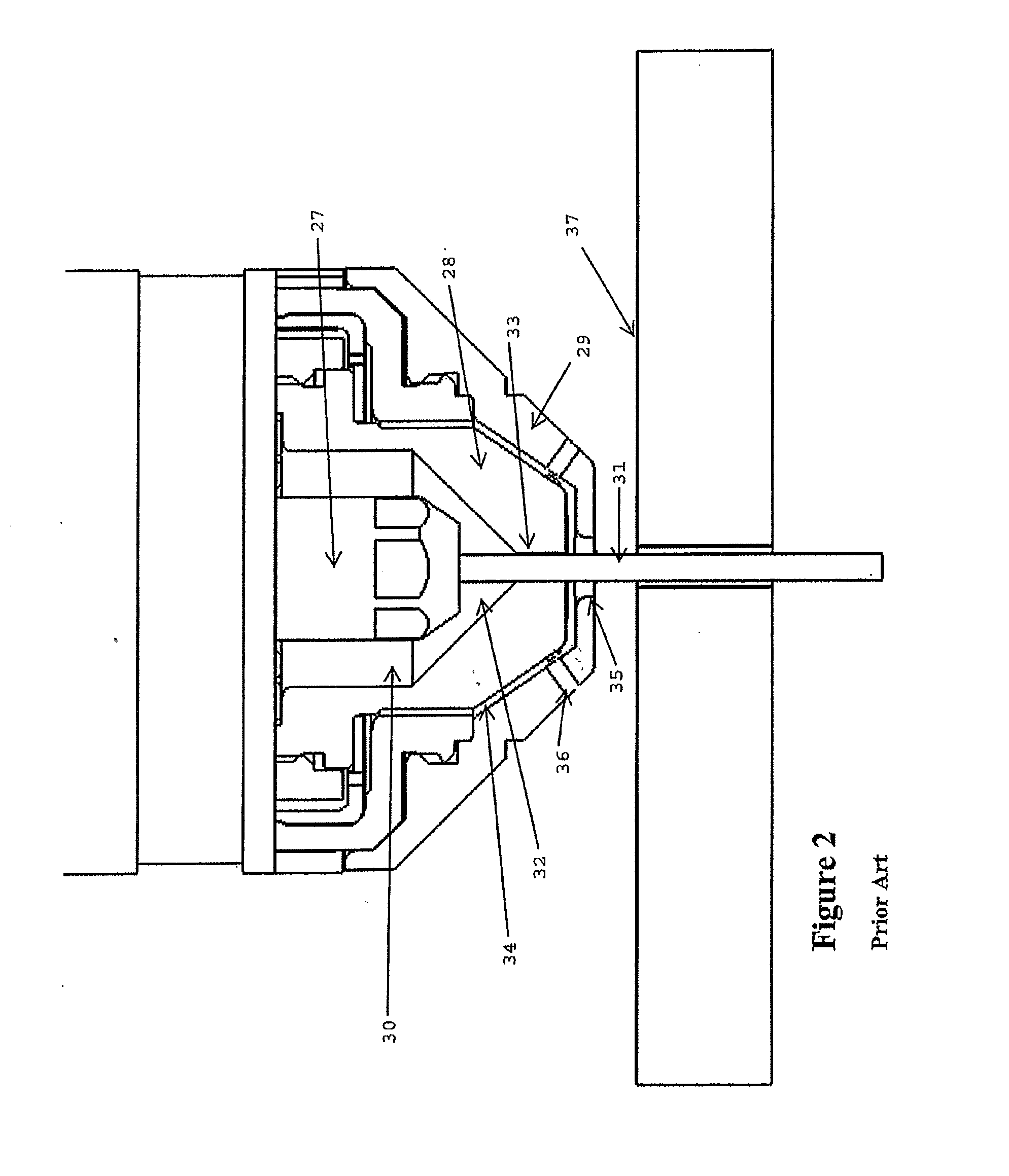

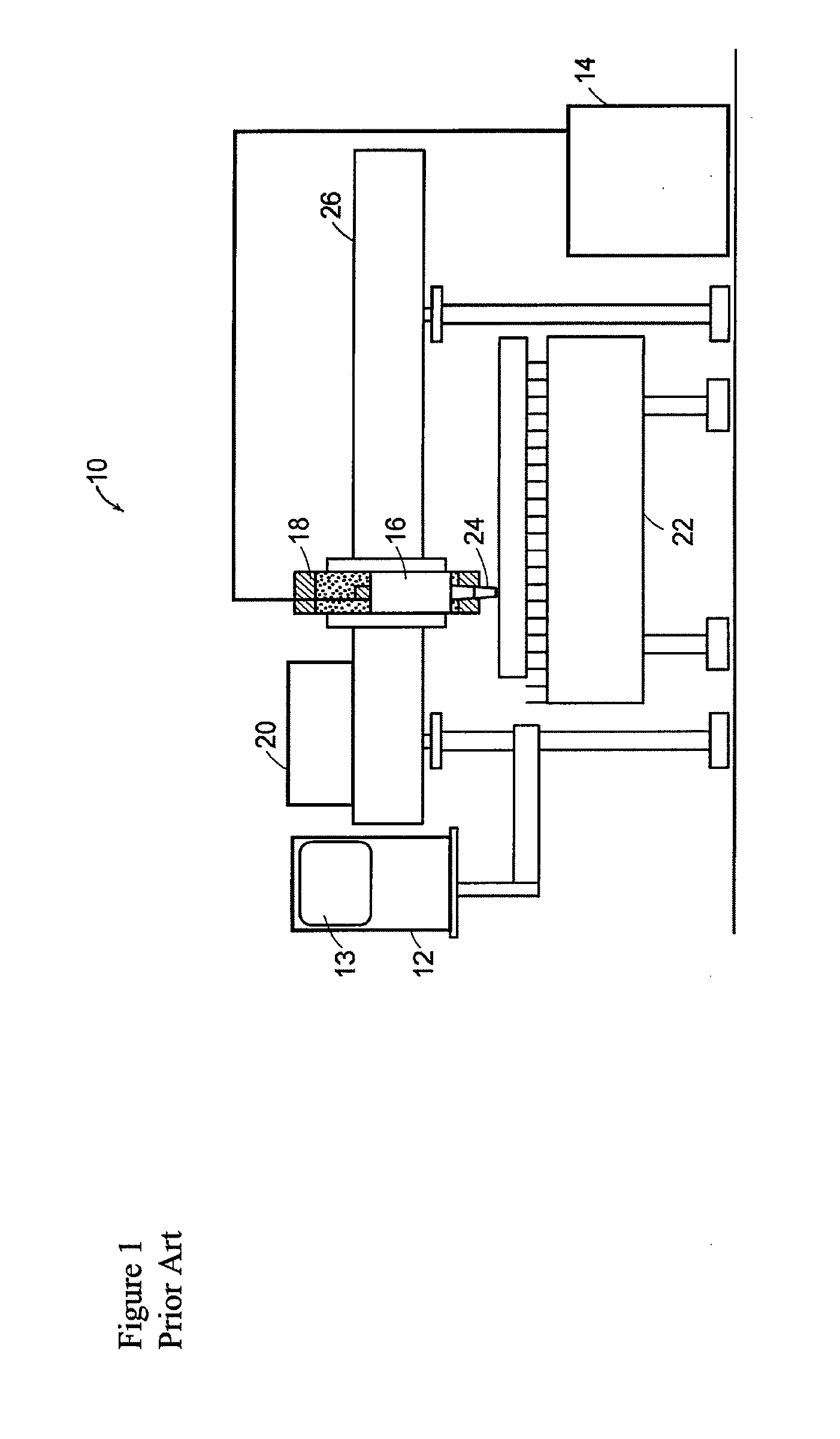

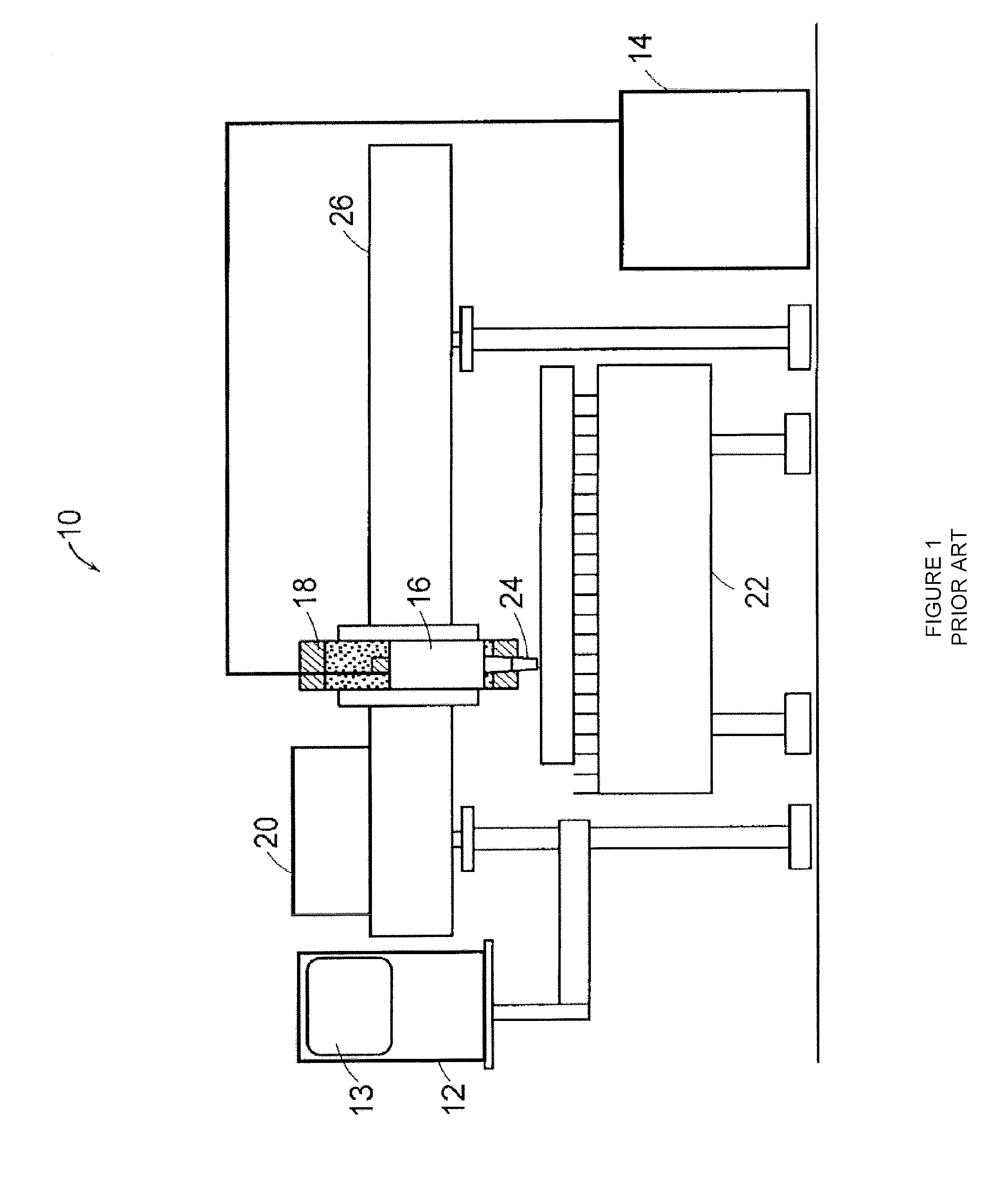

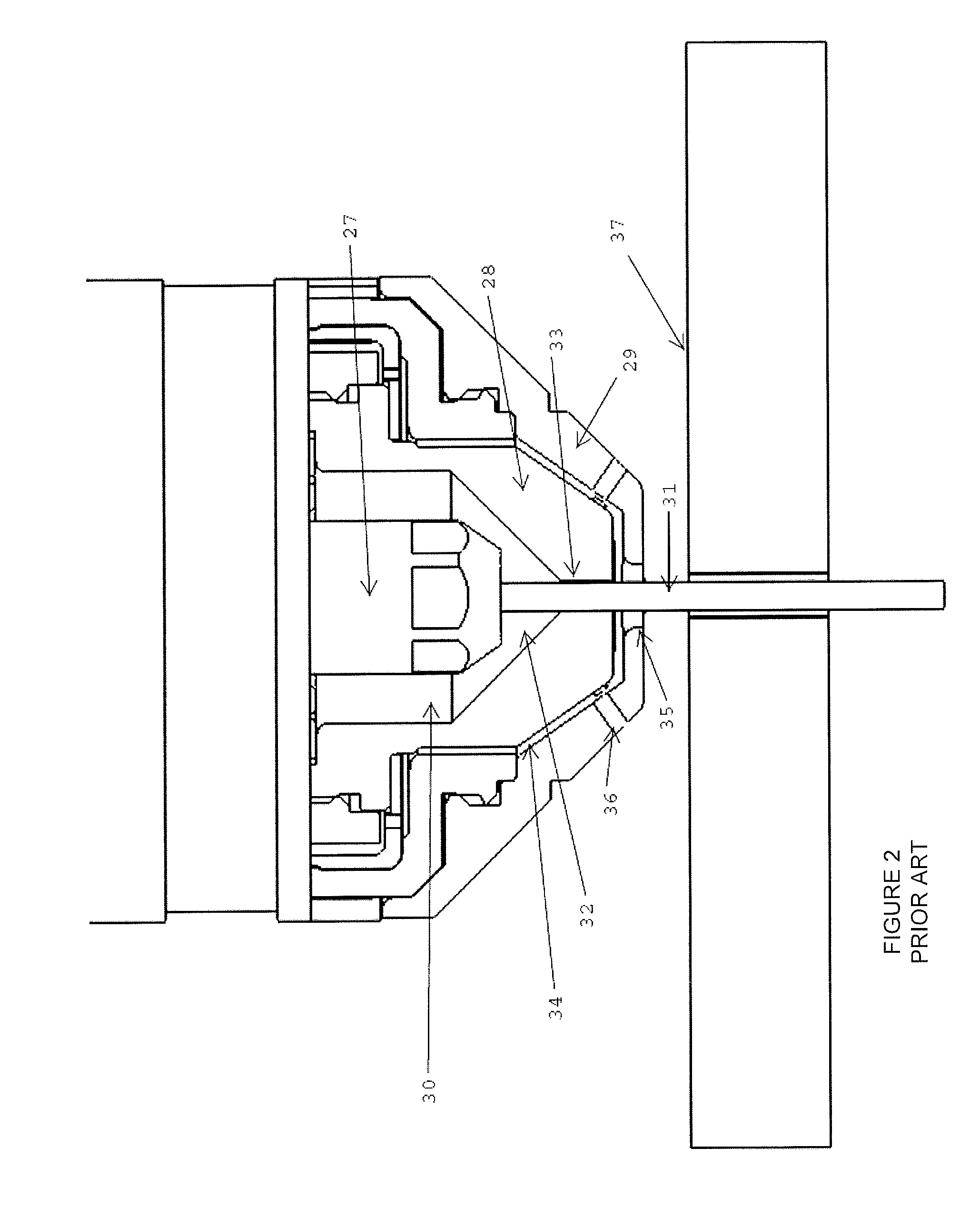

Method and Apparatus for Cutting High Quality Internal Features and Contours

ActiveUS20120048835A1Improve cut qualityMaintain productivityArc welding apparatusPlasma welding apparatusEngineeringTorch

An automated method for cutting a plurality of hole features using a plasma arc torch system can be implemented on a computer numerical controller. The automated method can include the steps of: a) cutting a lead-in for a hole feature using a lead-in command speed based on a diameter of that hole feature and b) cutting a perimeter for the hole feature using a perimeter command speed greater than the corresponding lead-in command speed for the hole feature. The automated method can also include the step c) of repeating steps a) and b) for each additional hole feature having a same diameter or a different diameter.

Owner:HYPERTHERM INC

Tissue reel transfer device and method

InactiveUS6976651B2Eliminates lost productionEliminate wasteWebs handlingAdhesiveBiomedical engineering

The present invention relates to a system and method for transferring tissue reels. The system preferably incorporates nozzles that spray an adhesive directly onto moving tissue paper substrate, as opposed to applying adhesive directly to the reel, independent of machine speeds and basis weights of the substrate. Alternatively, the system of the present invention may also apply adhesive directly to the new reel as opposed to the tissue paper substrate. In the preferred embodiment, the new core or reel is brought up to substantially equivalent speed as the moving tissue paper substrate and placed into contact with the moving web of tissue. When the new reel is in place, the valves are activated thereby spraying adhesive across the width of moving tissue. The newly coated substrate sticks substantially immediately to the new core and cleanly tears away from the completed roll.

Owner:VALCO CINCINNATI

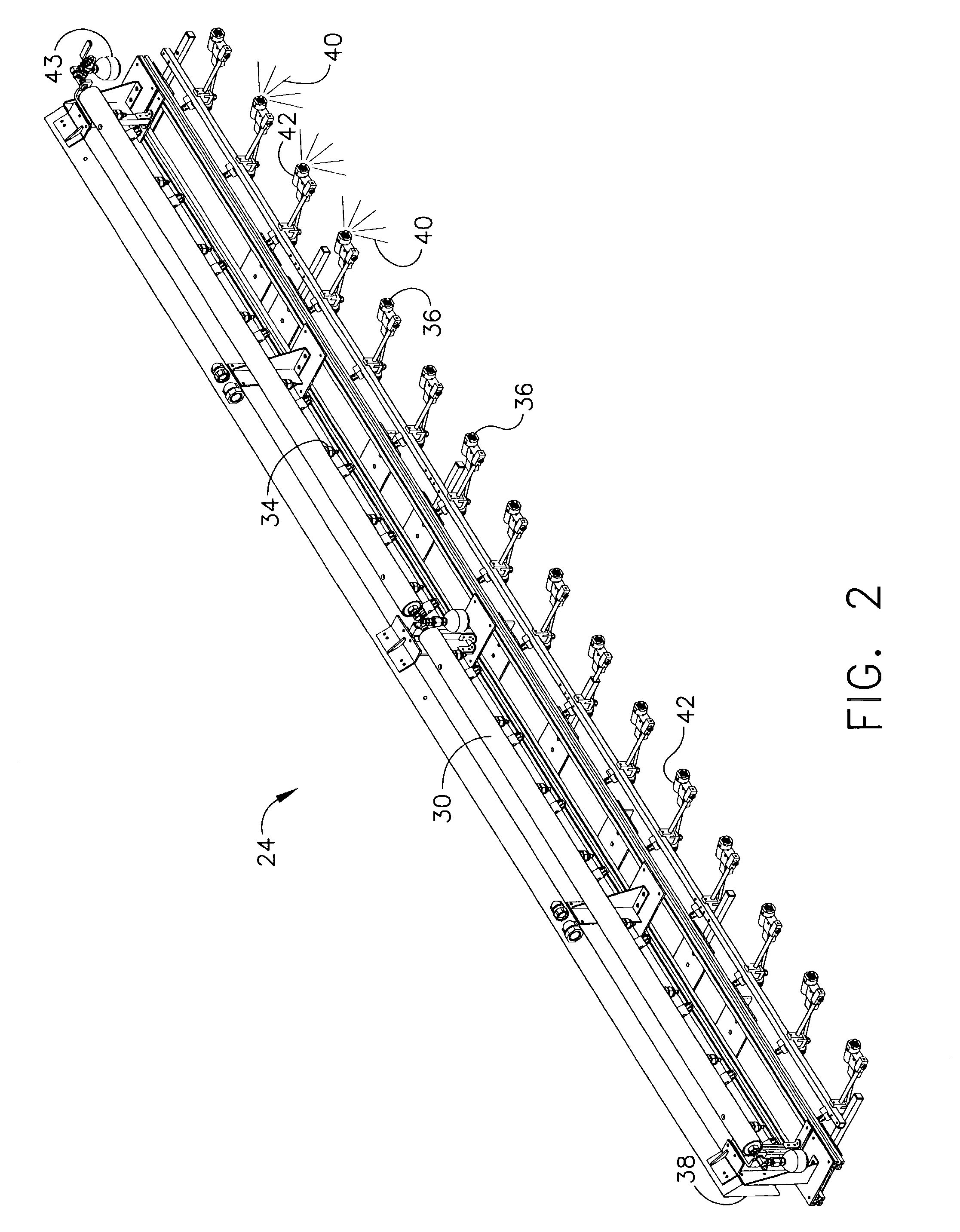

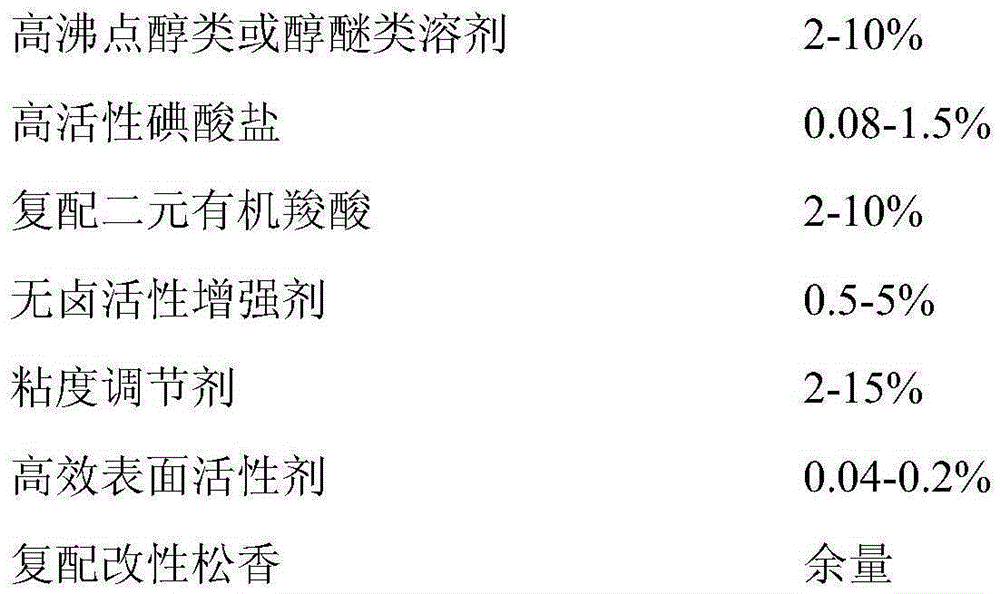

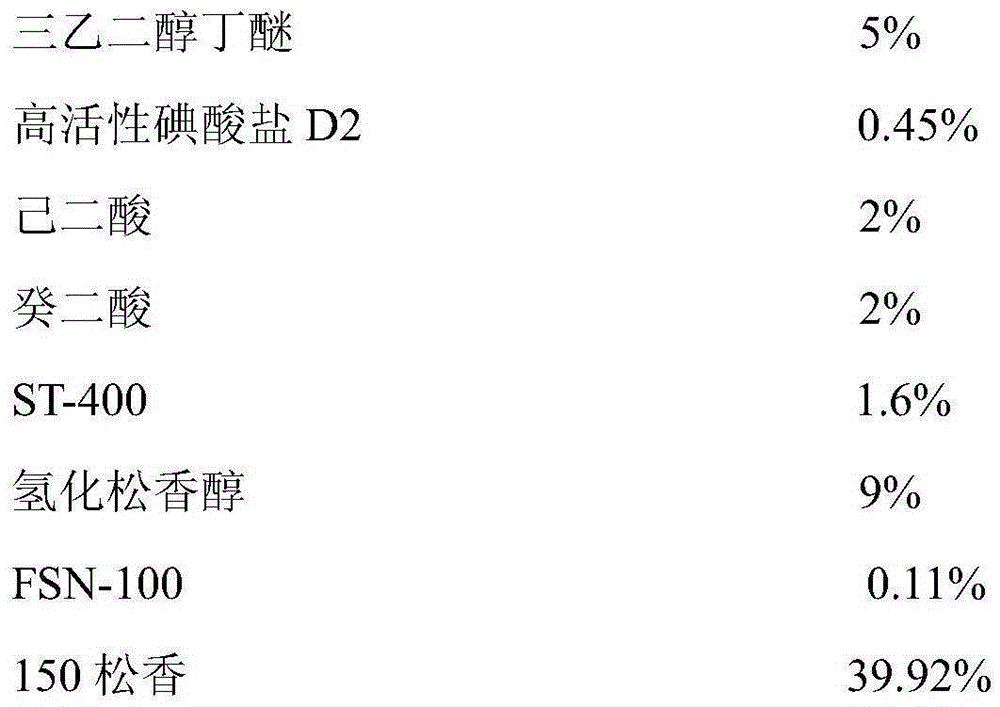

A halogen-free high-activity low-spatter solder wire flux and preparation method thereof

InactiveCN104191108BHalogenatedFast tinningWelding/cutting media/materialsSoldering mediaSurface-active agentsSolvent

The invention discloses halogen-free high-activity low-splatter solder wire soldering flux and a preparing method thereof. The halogen-free high-activity low-splatter solder wire soldering flux comprises, by mass, 2-10 percent of alcohol or alcohol ether high-boiling-point solvent, 0.08-1.5 percent of high-activity iodate, 2-10 percent of compound binary organic acid, 0.5-5 percent of halogen-free activity enhancer, 2-15 percent of viscosity modifier, 0.04-0.2 percent of efficient surface active agent and the balance modified rosin and rosin derivatives. The preparing method includes the steps that the compound rosin and the viscosity modifier are added into a container to be heated and stirred until the compound rosin and the viscosity modifier are completely melted down, the organic acid, the novel high-activity iodate, the efficient surface active agent and the high-boiling-point solvent are added to be stirred continuously, and therefore the soldering flux is prepared. The prepared halogen-free soldering flux for solder wires is free of halogen compounds, tin is easy to apply in the soldering process, splatter is little, smells are light, soldering spots are bright and full, damage to the health and the environment is avoided, and the post-soldering reliability effect of an electronic product is ensured.

Owner:SOUTH CHINA UNIV OF TECH +1

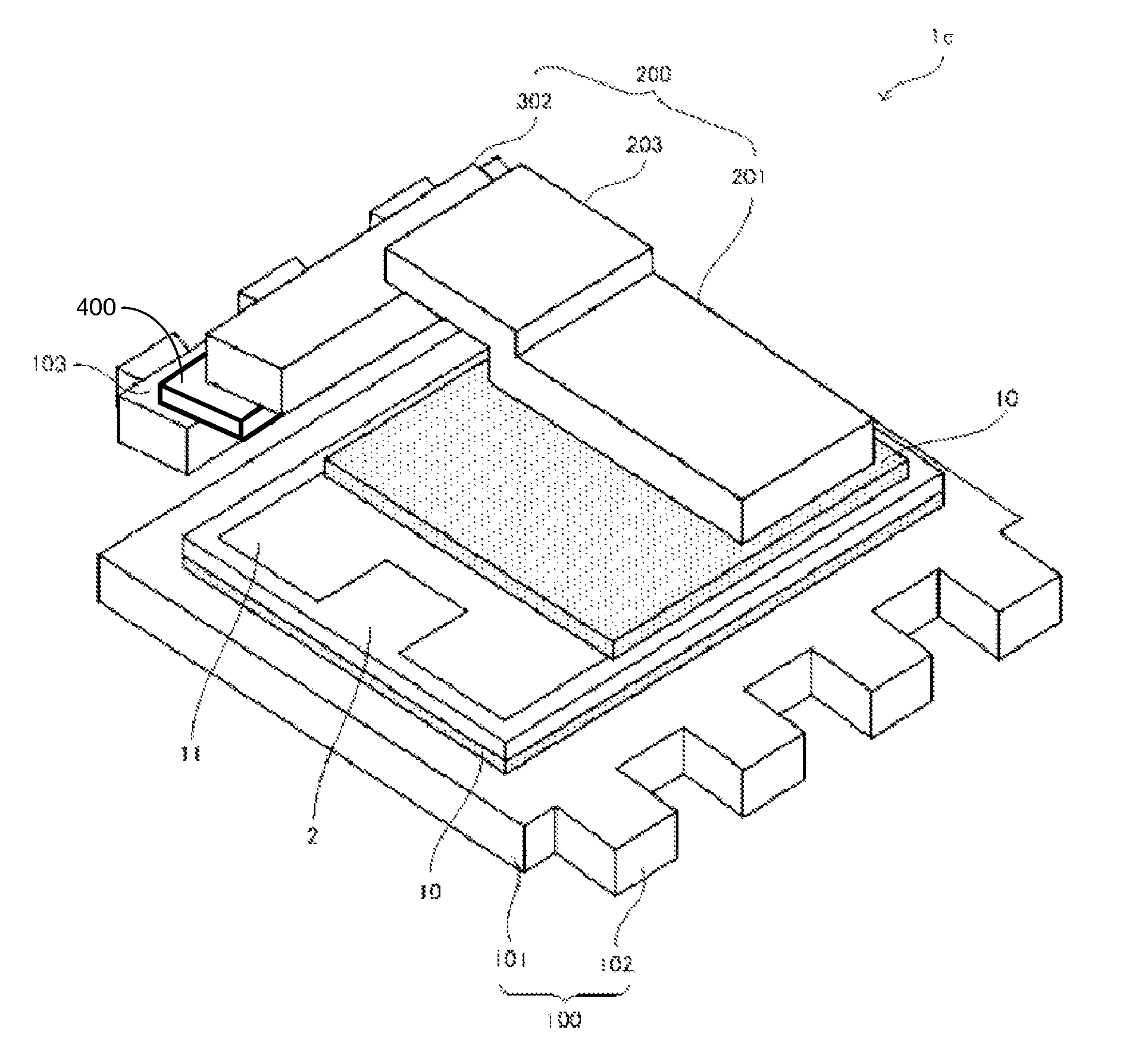

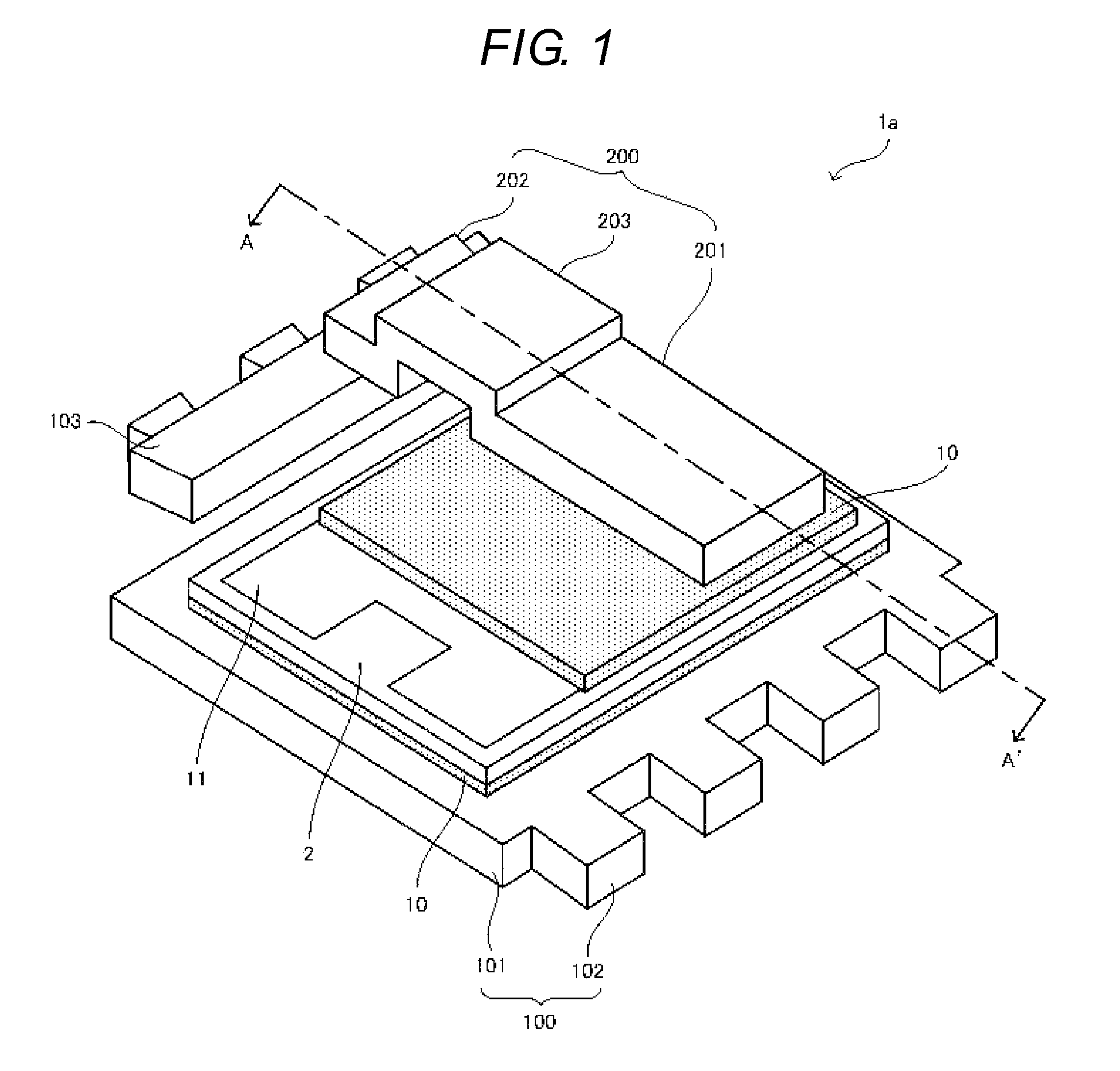

Semiconductor device

InactiveUS9171817B2Inhibition of thermal degradationReduce resistanceSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

A semiconductor device includes a semiconductor chip having an electrode, a connector having a chip contact surface, an interconnecting portion, and an external electrode terminal contact surface, the chip contact surface being electrically connected to the electrode, and a first connection material disposed between the chip contact surface and the electrode, the first connecting material having a surface area that is greater than a surface area of the chip contact surface.

Owner:KK TOSHIBA

Separator for fuel cell and fuel cell

ActiveUS11450862B2Maintain productivityDeterioration in a membrane electrode assembly is suppressedFinal product manufactureMotive system fuel cellsFuel cellsEngineering

A separator for a fuel cell, includes a separator plate provided with a flow path groove group through which the reaction gas flows. The flow path groove group includes a single first flow path groove, a plurality of second flow path grooves, and a branch portion that connects an end portion of the first flow path groove to end portions of the second flow path grooves. The branch portion includes a narrow portion having a narrower groove width than a groove width of a remaining portion of the branch portion. A groove depth of the narrow portion is shallower than a groove depth of the remaining portion of the branch portion.

Owner:TOYOTA JIDOSHA KK

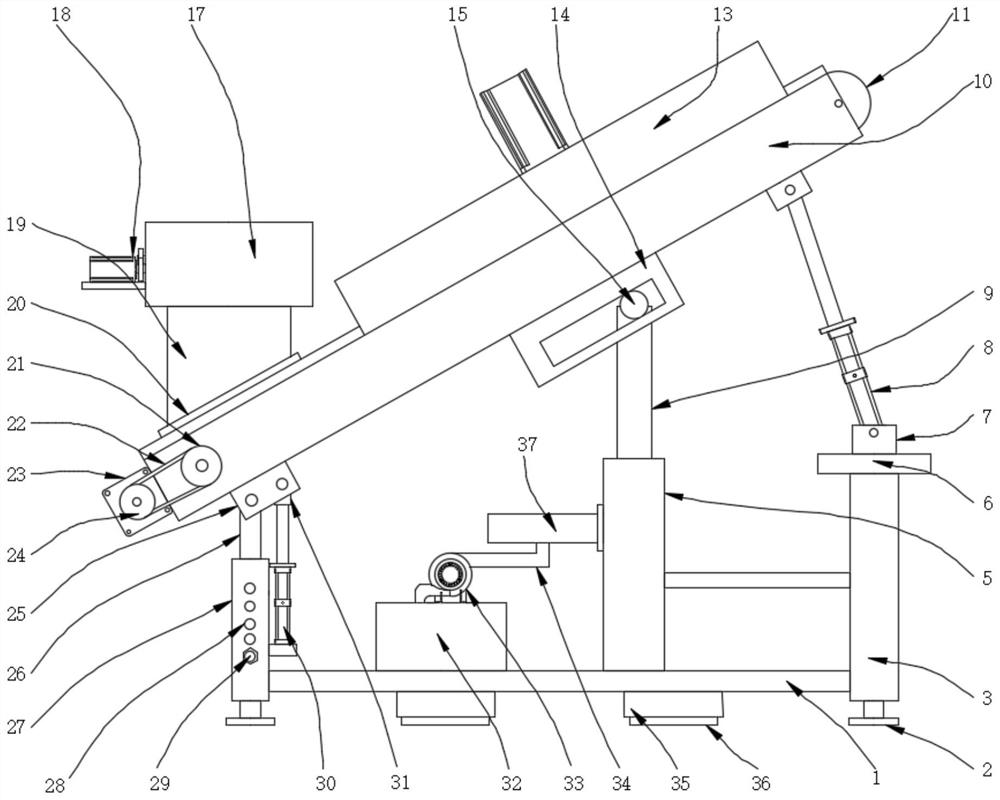

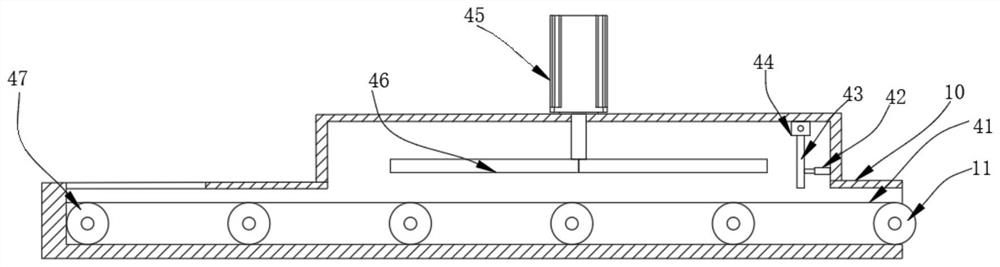

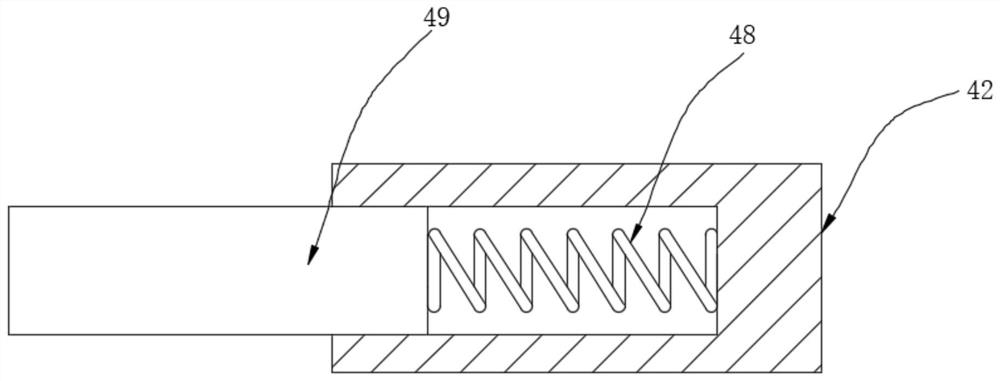

Mixed conveying equipment for mineral powder production

InactiveCN112642519AHeight increase and decreaseEasy to adjustDirt cleaningGrain treatmentsEngineeringStructural engineering

The invention discloses mixed conveying equipment for mineral powder production. The equipment comprises a base and a first shell, wherein two second supporting legs are symmetrically welded to the outer side wall of the base, second electric push rods are mounted on the outer side walls of the two second supporting legs, second column bodies are slidably connected to the inner side walls of the second supporting legs, a second fixed block is welded to the lower surface of the first shell, one end of the second column body is hinged to the inner side wall of the second fixed block, a piston rod of each second electric push rod is welded to a connecting block, and a third rod body and a fourth rod body drive a crushing roller to crush a mineral powder raw material preliminarily. By adjusting the heights of the first and second electric push rods, the heights of a feeding pipe and a first rotating roll can be increased and decreased. It is convenient to adjust the height of mixing equipment correspondingly and raw materials which are large in size in the entering raw materials are treated, so that normal production and work is ensured and the production efficiency is maintained.

Owner:武汉青铜科技信息咨询有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com