A halogen-free high-activity low-spatter solder wire flux and preparation method thereof

A high-activity, solder wire technology, applied in welding equipment, welding media, manufacturing tools, etc., can solve the problems of large spatter and insufficient activity, achieve less spatter, strong ability to remove oxides, and reduce surface tension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

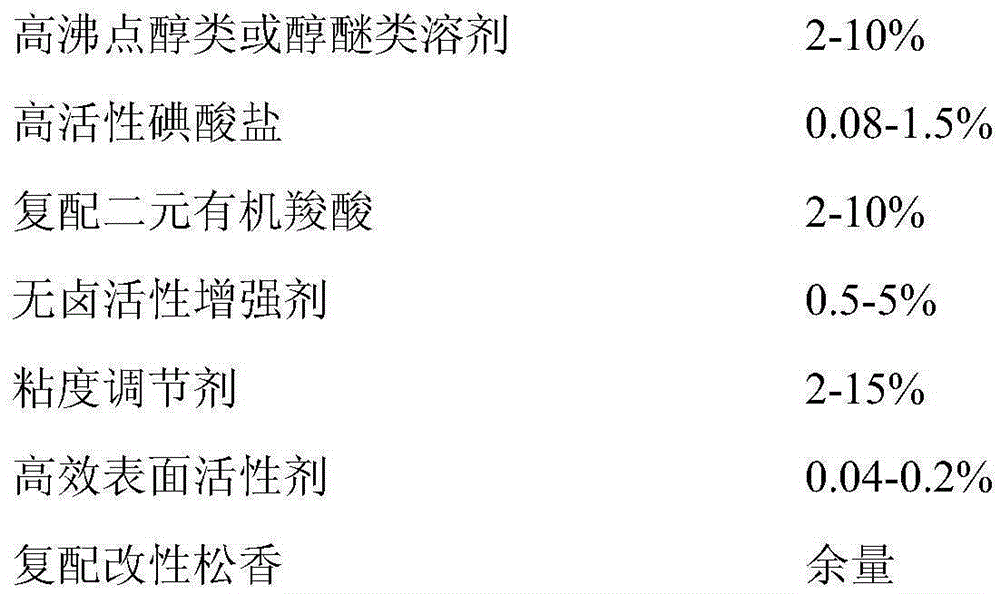

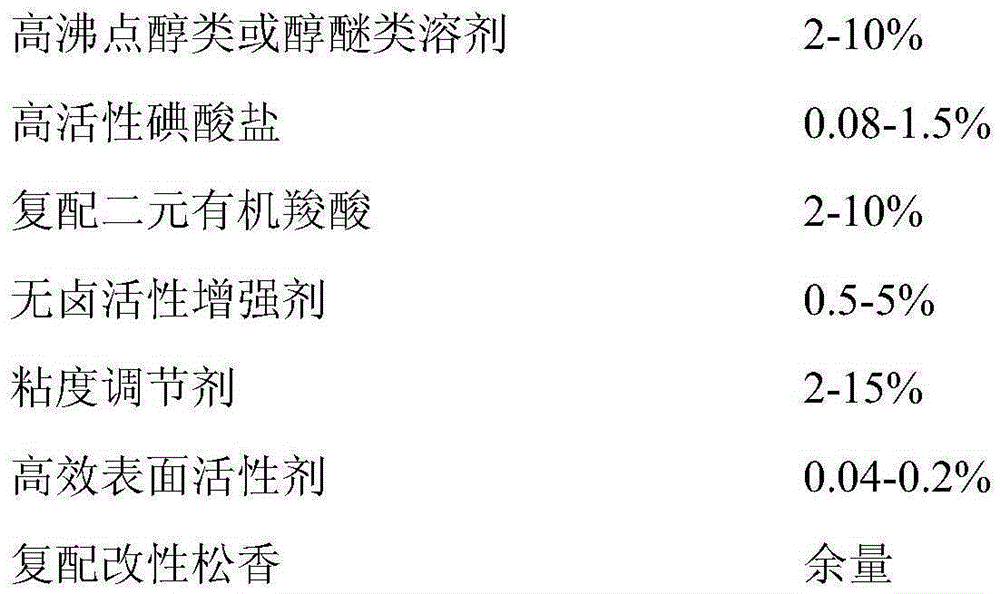

[0030] The flux for the halogen-free high-activity low-spatter solder wire of this embodiment has the following components and mass percentages:

[0031]

[0032]

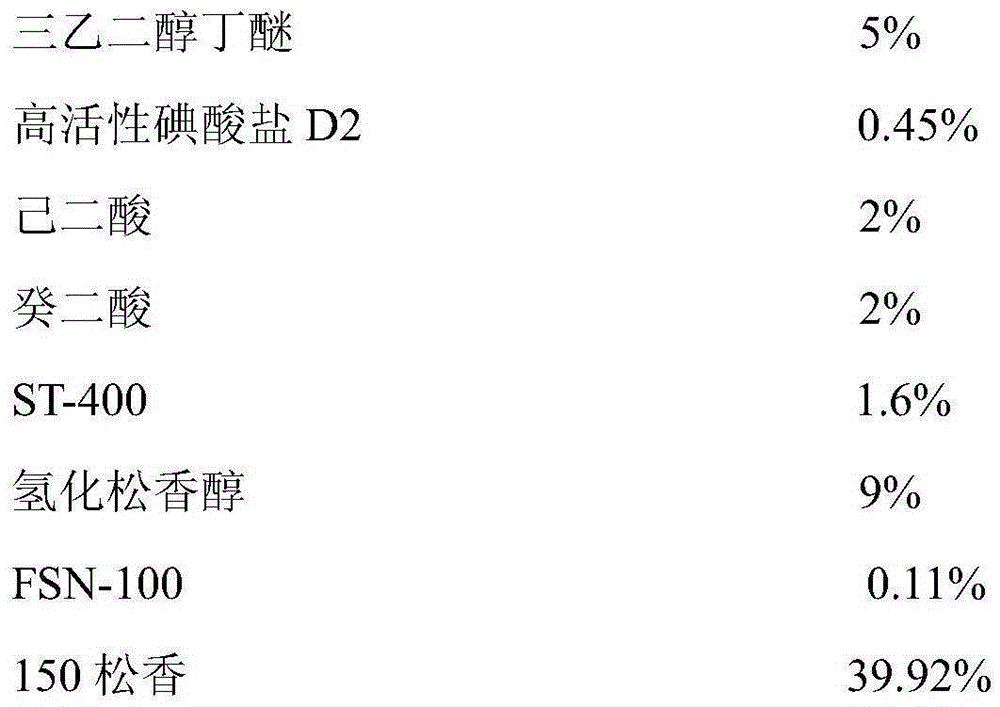

[0033] Specific preparation method:

[0034] Add 39.92% rosin 150, 39.92% polymerized rosin 115 and 9% hydrogenated abietyl alcohol into the container, heat to 140°C and stir until completely melted. At this temperature, add 2% adipic acid and 2% sebacic acid, 1.6% halogen-free activity enhancer ST-400, 0.45% periodate D2, 0.11% fluorocarbon surfactant FSN-100 , 5% high-boiling-point organic solvent triethylene glycol butyl ether, continue to stir for 20 minutes until all components are completely dissolved, and then the halogen-free high-activity low-spatter solder wire flux can be made.

[0035] The expansion rate, surface insulation resistance after welding, and welding tests were respectively carried out on this embodiment, and the test results are shown in Table 1 below.

Embodiment 2

[0037] The flux for the halogen-free high-activity low-spatter solder wire of this embodiment has the following components and mass percentages:

[0038]

[0039] Specific preparation method:

[0040] Add 27.66% Brazilian rosin, 55.32% 125 rosin and 3% hydrogenated rosin methyl ester into the container, heat to 140°C and stir until completely melted. At this temperature, add 2.5% hexadecanic acid, 1.5% sebacic acid and 1.5% dodecanoic acid, 1.8% halogen-free activity enhancer ST-400, 0.54% highly active iodate D2, 0.18% fluorocarbon Surfactant FC-4430, 6% high-boiling point organic solvent diethylene glycol monobutyl ether, continue to stir for 30 minutes until all components are completely dissolved, and then you can make halogen-free high-activity low-spatter solder wire flux.

[0041] The expansion rate, surface insulation resistance after welding, and welding tests were carried out on the examples respectively, and the test results are shown in Table 1 below.

Embodiment 3

[0043] The flux for the halogen-free high-activity low-spatter solder wire of this embodiment has the following components and mass percentages:

[0044]

[0045]

[0046] Specific preparation method:

[0047] Add 64.17% water white rosin, 21.39% 685 rosin and 2% pentaerythritol tetrabenzoate into the container, heat to 140°C and stir until completely melted. At this temperature, add 1.5% adipic acid, 3% sebacic acid and 1.5% myristic acid, 1.2% halogen-free activity enhancer ST-400, 0.58% highly active iodate D2, and 0.16% fluorocarbon Surfactant FSO-100, 6% high-boiling point organic solvent 2-ethyl-1,3-hexanediol, continue to stir for 25 minutes until all components are completely dissolved, and then you can make halogen-free high-activity low-splash solder wire flux.

[0048] The expansion rate, surface insulation resistance after welding, and welding tests were respectively carried out on this embodiment, and the test results are shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com