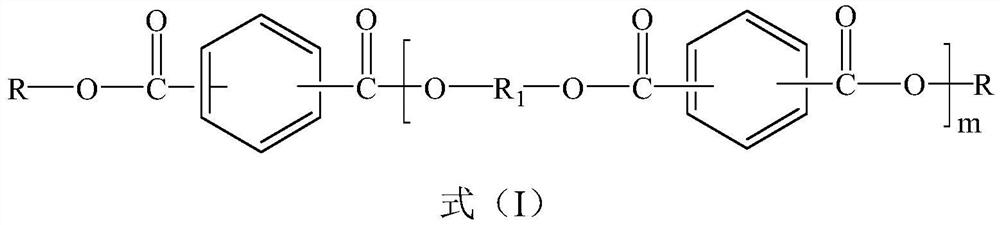

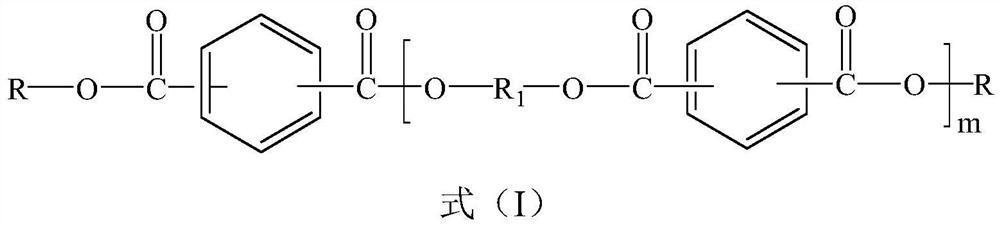

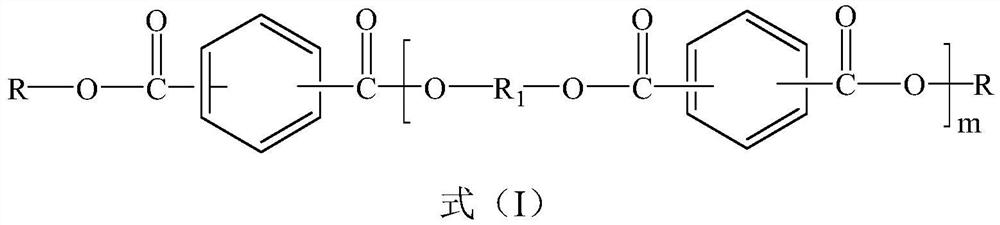

A kind of phosphorus-containing active ester and its halogen-free composition and copper clad substrate

A technology of active ester and resin composition, applied in the fields of prepreg, phosphorus-containing active ester and its halogen-free resin composition, laminate and printed circuit board, can solve the problem of poor dielectric properties, affect the performance of the sheet, It can reduce the dielectric loss factor, improve the electrical properties of the system, and meet the effect of halogen-free flame retardant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0048] Heat 0.3mol DOPO to 160°C to melt, add 0.1mol 4,4'-dihydroxybenzophenone to the molten DOPO, water will be generated during the reaction, and the generated water will be evaporated under reduced pressure to promote the forward movement of the reaction . After reacting for 4 hours, the temperature was lowered to 100°C, and 100ml of toluene was added. The excess DOPO was dissolved in toluene, and the product was precipitated as a white powder. The product was filtered and purified by washing with tetrahydrofuran to obtain 2DOPO-2PhOH.

[0049] Add 628.5g (1mol) 2DOPO-2PhOH and 816g methyl isobutyl ketone (MIBK) in the flask that thermometer, dropping funnel, condensing tube, fractionating tube, stirrer are installed, nitrogen replacement under reduced pressure in the system, make It dissolves. Then, 182.7g (0.9mol) of terephthaloyl chloride was put into the reaction for 2h, and the temperature in the system was controlled below 60°C; then, 114g (1.2mol) of phenol was add...

Synthetic example 2

[0051] Heat 0.3mol DOPO to 160°C to melt, add 0.1mol 4,4'-dihydroxybenzophenone to the molten DOPO, water will be generated during the reaction, and the generated water will be evaporated under reduced pressure to promote the forward movement of the reaction . After reacting for 4 hours, the temperature was lowered to 100°C, and 100ml of toluene was added. The excess DOPO was dissolved in toluene, and the product was precipitated as a white powder. The product was filtered and purified by washing with tetrahydrofuran to obtain 2DOPO-2PhOH.

[0052] Add 628.5g (1mol) 2DOPO-2PhOH and 816g methyl isobutyl ketone (MIBK) in the flask that thermometer, dropping funnel, condensing tube, fractionating tube, stirrer are installed, nitrogen replacement under reduced pressure in the system, make It dissolves. Then, 182.7g (0.9mol) of terephthaloyl chloride was put into the reaction for 2 hours, and the temperature in the system was controlled below 60°C; then, 172.8g (1.2mol) of naphtho...

Embodiment 1

[0065] Take a container, add 60 parts by weight of 627, add an equivalent amount of A1 active ester and continue to stir, add an appropriate amount of curing accelerator 4-dimethylaminopyridine, continue to stir evenly, and finally adjust the liquid solid content to 60% to 80% with a solvent And make glue. Soak the above glue with glass fiber cloth to form the glue. Immerse the above glue with glass fiber cloth and control it to an appropriate thickness, then dry to remove the solvent to obtain a prepreg. Using several prepared prepregs to stack each other, press a piece of copper foil on both sides, put them into a hot press and cure them to form the epoxy resin copper-clad laminate. The physical data are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com