Preparation method of phosphorous-containing phenol formaldehyde resin and resin prepared

A technology of phenolic resin and formaldehyde, which is applied in the field of preparation methods and prepared products, can solve the problems of affecting crosslinking density, affecting heat resistance, and impossibility to improve impact strength, etc., and achieves the effect of simple preparation method and low pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

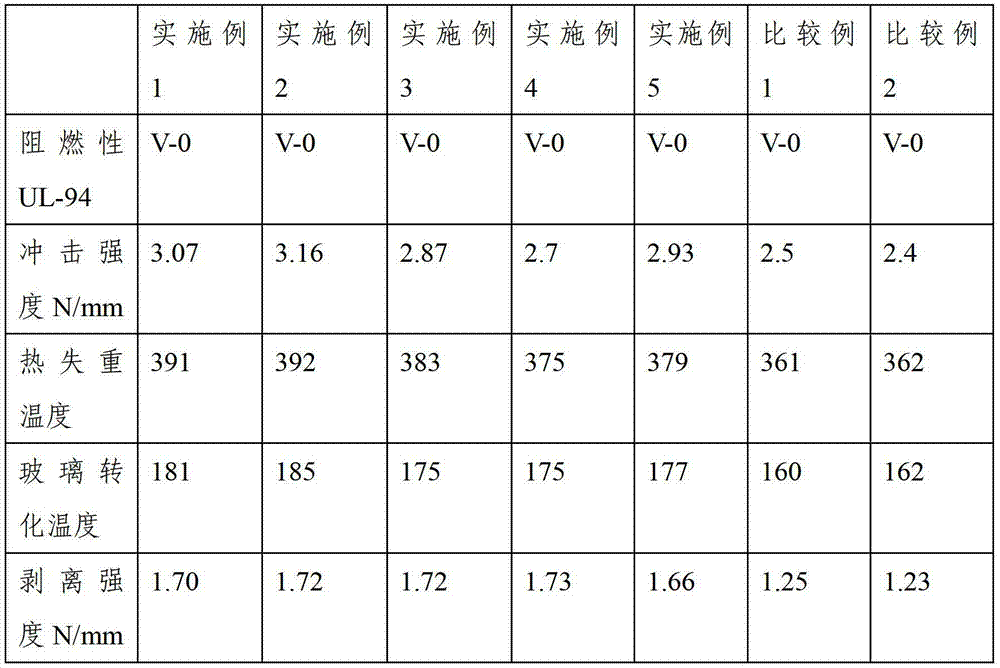

Examples

Embodiment 1

[0025] Add 10 parts by weight of phenol, 2 parts of nonylphenol, 8 parts of formaldehyde (38wt% solution), and 0.2 part of oxalic acid into a four-necked flask equipped with a stirrer, a condenser tube, a thermometer and a nitrogen port, and stir (stir The speed is 300rpm) and nitrogen gas is passed through, and the temperature is raised to 100°C for reflux reaction for 6 hours.

[0026] Add 14 parts of n-butanol to carry out etherification reaction. The etherification temperature is controlled at 110°C. The solvent reflux method is used to remove water. The condensation reflux device is connected to a water separator, and the liquid produced by condensation is layered in the water separator. The lower layer is water, and the upper organic layer was returned to the reaction system. The etherification reaction stopped until no water was separated out, and the etherification reaction time was 10 hours, and then added 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO ) 8 ...

Embodiment 2

[0028] Add 10 parts by weight of bisphenol A, 2 parts of nonylphenol, 8 parts of formaldehyde (38wt%), and 0.2 parts of oxalic acid into a four-necked flask equipped with a stirrer, a condenser, a thermometer and a nitrogen port and stir (the stirring speed is 300rpm) and nitrogen gas was introduced, and the temperature was raised to 100°C for reflux reaction for 6 hours. Add 13. parts of n-butanol to carry out etherification reaction. The etherification temperature is controlled at 110°C, and the water is removed by solvent reflux until no more water is produced. The etherification reaction time is 8 hours, and then 9,10-dihydro-9-oxa-10-phospha Heat 8 parts of phenanthrene-10-oxide (DOPO) to 160°C and continue to react for 4 hours, add 8 parts of solvent methyl isobutyl ketone to adjust the viscosity, and obtain a high-performance phenolic formaldehyde with a viscosity of 650cp / 25°C and a phosphorus content of 9.5%. resin.

Embodiment 3

[0030] Add 10 parts by weight of phenol, 1 part of nonylphenol, 8 parts of formaldehyde (38wt%), and 0.2 parts of oxalic acid into a four-necked flask equipped with a stirrer, a condenser tube, a thermometer and a nitrogen port, and stir (the stirring speed is 300rpm) and nitrogen gas, heated to 100°C and refluxed for 6 hours, added 15 parts of n-butanol to control the etherification temperature at 110°C, and used the solvent reflux method to remove moisture until no more moisture was produced. The etherification reaction time was 12 hours, then add 8 parts of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO), raise the temperature to 160°C, continue the reaction for 4 hours, add the solvent ethylene glycol Adjust the viscosity with 8 parts of ether to obtain a high-performance phenolic resin with a phosphorus content of 9.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com