Mixed conveying equipment for mineral powder production

A technology for conveying equipment and mineral powder, which is applied in the field of mixed conveying equipment for mineral powder production, which can solve the problems of affecting production efficiency, reducing production, troublesome adjustment of conveying equipment, etc., and achieves the effect of high-level corresponding adjustment and convenient maintenance of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

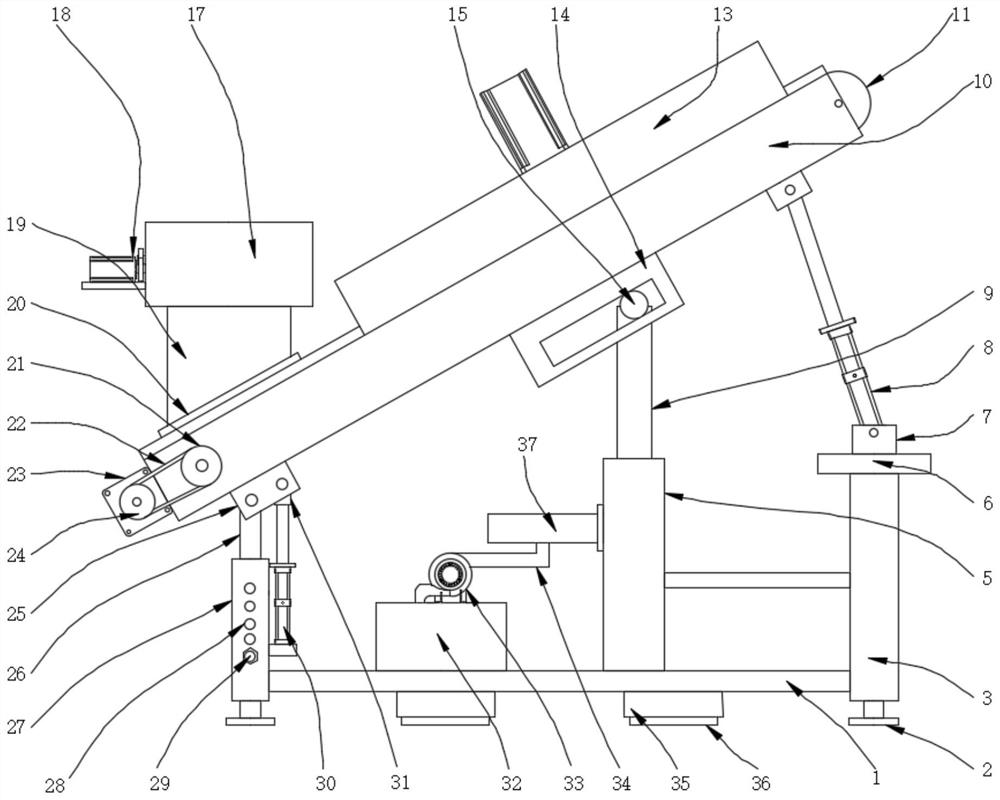

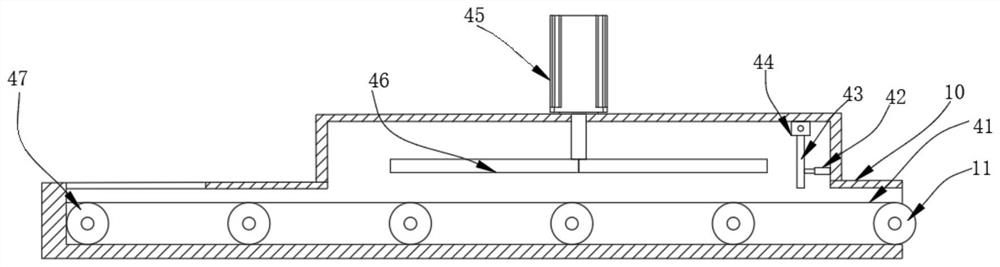

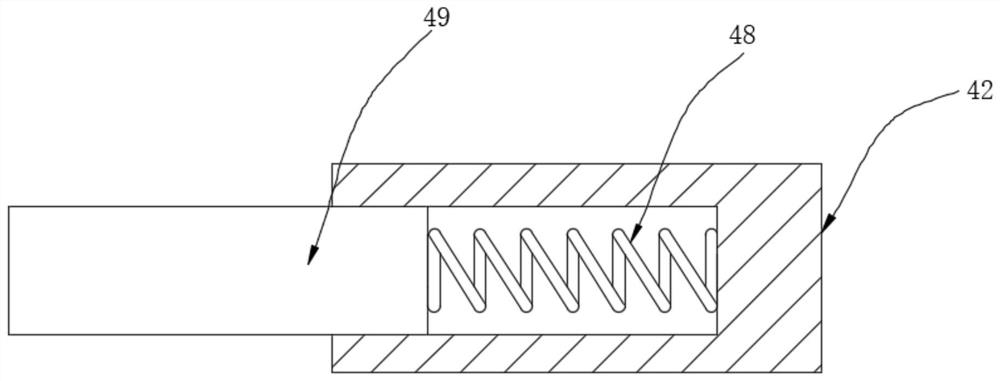

[0022] see Figure 1-6 , the present invention provides a technical solution: a mixing and conveying equipment for mineral powder production, including a base 1 and a first shell 10, the outer wall of the base 1 is symmetrically welded with two second support legs 27, and the two second support legs The outer side walls of the legs 27 are equipped with a second electric push rod 30, the inner side walls of the second supporting legs 27 are slidably connected with the second cylinder 26, the lower surface of the first housing 10 is welded with the second fixed block 25, the second One end of the cylinder 26 is hinged with the inner side wall of the second fixed block 25, the piston rod of the second electric push rod 30 is welded with a connecting block 31, the outer side wall of the connecting block 31 is hinged with the inner side wall of the second fixed block 25, and the base 1 Two first support legs 3 are welded symmetrically on the outer side wall of the two first support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com