Small batch spandex spinning test device

A technology of spandex spinning and testing equipment, which is applied in filament forming treatment, textile and papermaking, feeding solution to spinnerets, etc., which can solve the problems of unsuitable automatic transfer of polymers, high labor intensity and long labor time, etc., and achieve The effect of shortening the R&D cycle, reducing the scrap rate and reducing the R&D cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

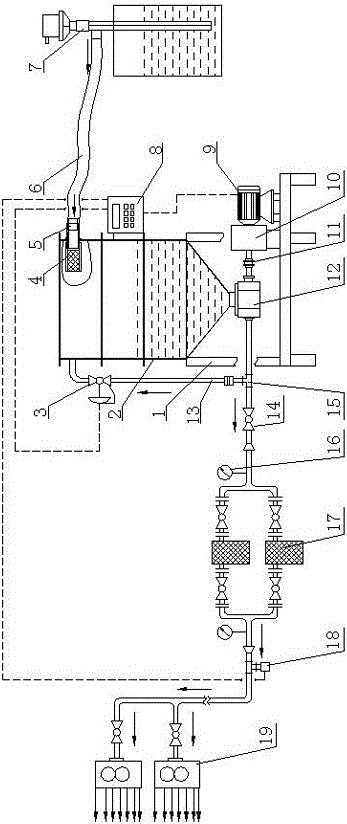

[0016] Embodiment 1, with reference to figure 1 , a small-batch spandex spinning test device, comprising a support 1, a storage tank 2 located on the support 1 and a spinning metering pump 19 leading to the spinneret, the upper part of the storage tank 2 is provided with an inlet with a filter screen 4 The material pipe 5 and the bottom of the storage tank 2 are provided with a discharge pipe, and a gear booster pump 12 is installed on the discharge pipe, and one end of the gear booster pump 12 is connected with the spinning metering pump 19 through a delivery pipeline, and The other end links to each other with motor 9 through shaft coupling 11, speed reducer 10, is provided with filter 17 on the delivery pipeline between described gear booster pump 12 and spinning metering pump 19, filter 17 and gear booster pump There is a tee 15 on the delivery pipeline between 12, and the tee 15 is connected with the upper part of the storage tank 2 through a bypass line 13, and a bypass ...

Embodiment 2

[0017] Embodiment 2, in the small-batch spandex spinning test device described in Embodiment 1: a pressure sensor 18 is arranged on the delivery pipeline between the filter 17 and the spinning metering pump 19, the pressure sensor 18, the motor 9, the side The through valves 3 are all connected with the electric controller 8 arranged on the storage tank 2 .

Embodiment 3

[0018] Example 3, in the small-batch spandex spinning test device described in Example 2: the electrical controller 8 is a PLC, and the pressure sensor 18, the motor 9, and the bypass valve 3 are all connected to the controller in the PLC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com