Ferromagnetic-particle manufacturing apparatus

a technology of ferromagnetic particles and manufacturing equipment, which is applied in the direction of electric/magnetic/electromagnetic heating, nickel oxides/hydroxides, and nickel compounds, etc., can solve the problems of small variation in composition and dimension of ferromagnetic particles generated, unlikely to vary, and reduce the generation efficiency of ferromagnetic particles, etc., to achieve efficient manufacturing and solve the effect of ferromagnetic particle generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

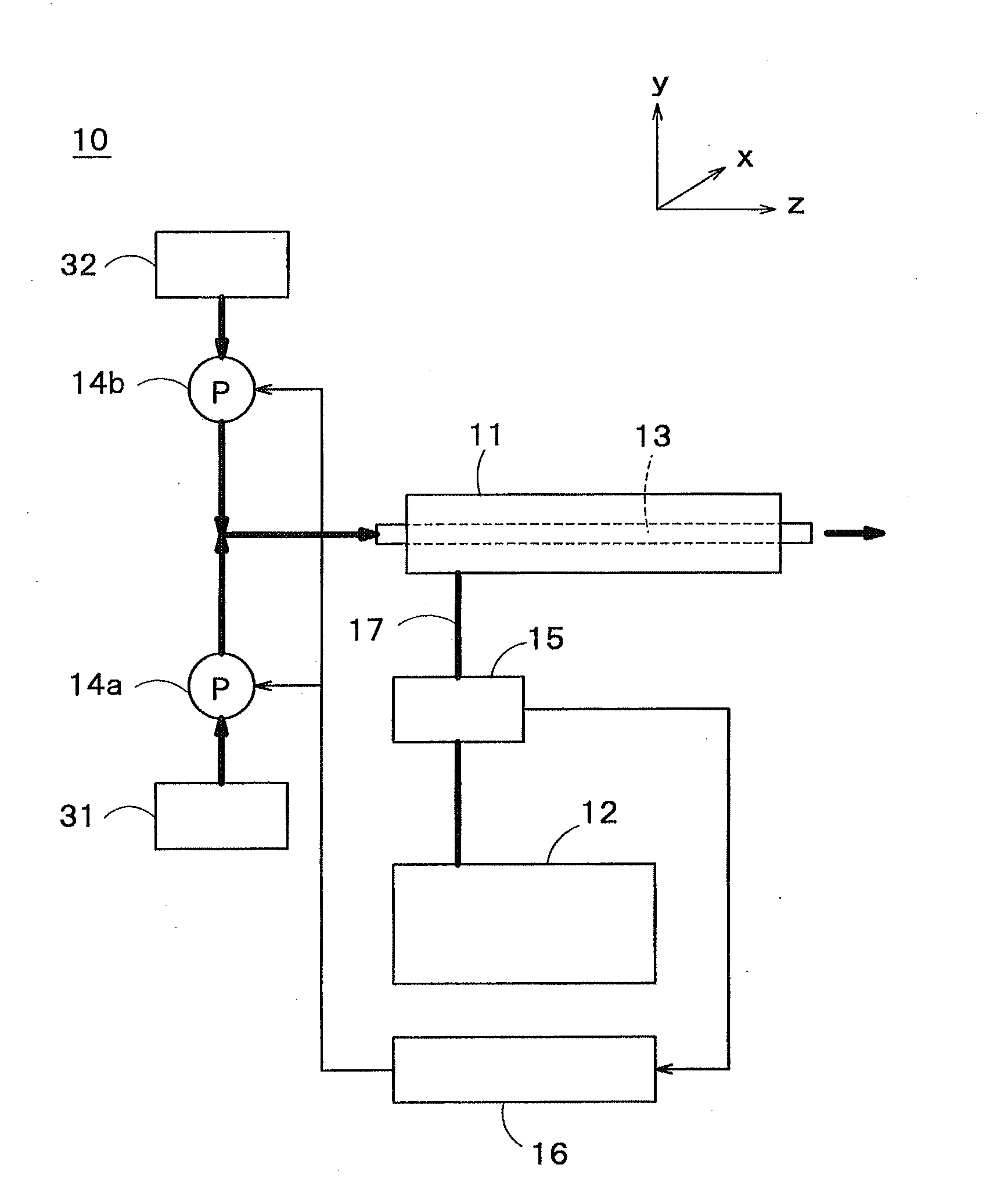

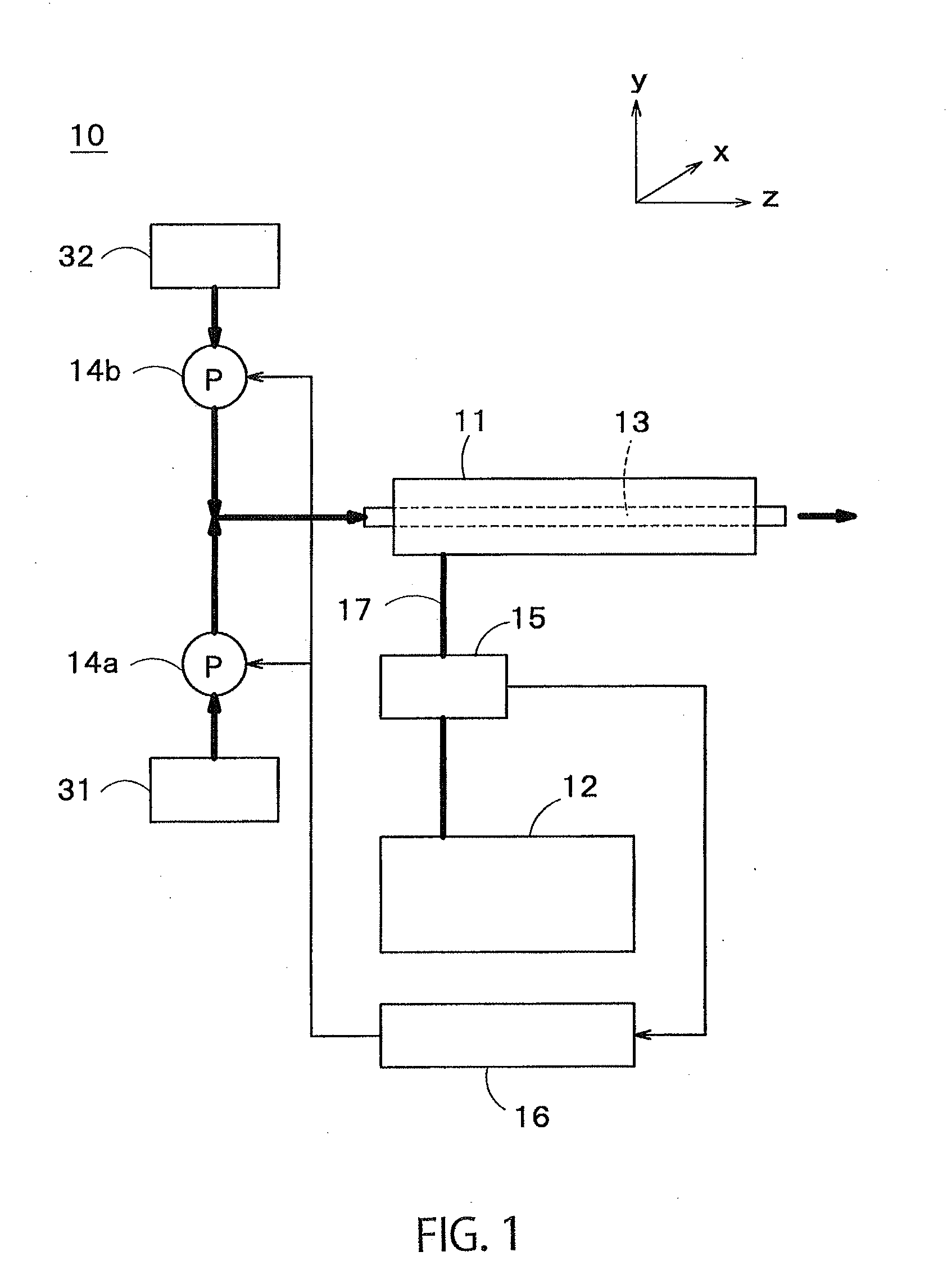

[0025]FIG. 1 is a schematic structural view showing a ferromagnetic-particle manufacturing apparatus in the present invention.

[0026]As shown in FIG. 1, a ferromagnetic-particle manufacturing apparatus 10 in this embodiment includes: a single mode cavity 11 that resonates with a microwave of a predetermined wavelength; a microwave oscillator 12 electrically connected to the single mode cavity 11 and configured to introduce the microwave of a predetermined wavelength into the single mode cavity 11; a pipe 13 disposed to pass through the inside of the single mode cavity 11, the pipe 13 being formed of a dielectric material; and pumps 14a and 14b configured to introduce, from one end of the pipe 13, an alkaline reaction liquid in which metal ions of a ferromagnetic metal and hydroxide ions are dissolved.

[0027]The single mode cavity 11 is a hollow container made of a conductive wall such as a metal, and is also referred to as cavity resonator. The single mode cavity 11 is configured to r...

second embodiment

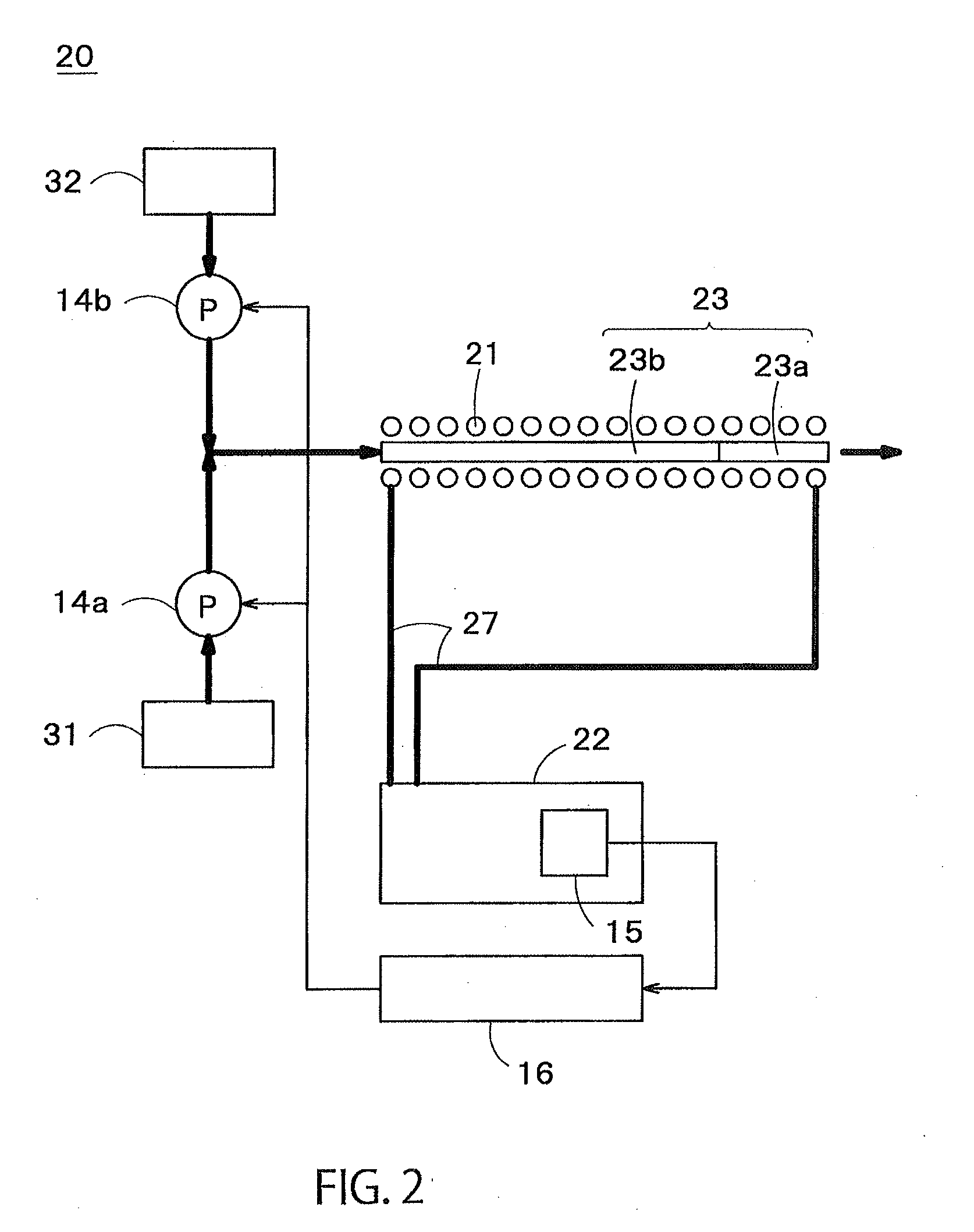

[0056]FIG. 2 is a schematic structural view showing a ferromagnetic-particle manufacturing apparatus in the present invention.

[0057]As shown in FIG. 2, in place of the single mode cavity 11, the microwave oscillator 12 and the pipe 13 formed of a dielectric material of the ferromagnetic-particle manufacturing apparatus 10 in the first embodiment, a ferromagnetic-particle manufacturing apparatus 20 in the second embodiment includes: an induction heating coil 21; a radiofrequency power source 22 electrically connected to the induction heating coil 21 and configured to form an alternating field inside the induction heating coil 21; and a pipe 23 disposed to pass through the inside of the induction heating coil 21. At least a partial area 23a of the pipe 23 in an axial direction thereof is formed of a dielectric material. An area 23b, which is nearer to one end of the pipe 2 than the area 23a formed of a dielectric material, is formed of a conductive material.

[0058]The induction heating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com