Low-hardness high-damping rubber composition and preparation method thereof

A rubber composition and high damping technology, applied in the field of rubber, can solve the problems of poor ozone resistance and brittleness, and achieve the effects of improving roll wrapping, increasing intermolecular friction, and avoiding unmixed uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Example 1 A kind of low hardness high damping rubber composition and preparation method thereof

[0063] A low-hardness high-damping rubber composition, which comprises the following components:

[0064] 90g of polynorbornene rubber, 10g of butyl rubber, 5.0g of zinc oxide, 0.8g of stearic acid, 40g of Subofer S503 lamellar modified clay;

[0065] High viscosity naphthenic oil 120g, coumarone resin 40g, phenolic resin 20g;

[0066] Accelerator CBS 4.5g, Accelerator EZ 1.0g, Sulfur 2.0g;

[0067] Wherein, the molecular weight of the polynorbornene rubber is 3,000,000 g / mol.

[0068] The preparation method of described polynorbornene rubber is carried out according to the following sequence of steps:

[0069] ① Raise the temperature of the mill to 100°C;

[0070] ②Preheat 100 parts of polynorbornene rubber preheated to 140°C for 20 minutes, mix in an open mill at 100°C, set the temperature at 120°C, and adjust the roller distance to 0.3mm;

[0071] ③ Add 150 parts o...

Embodiment 2-6

[0089] Embodiment 2-6 Low hardness and high damping rubber composition and preparation method thereof

[0090] Examples 2-6 are respectively a low-hardness and high-damping rubber composition and a preparation method thereof.

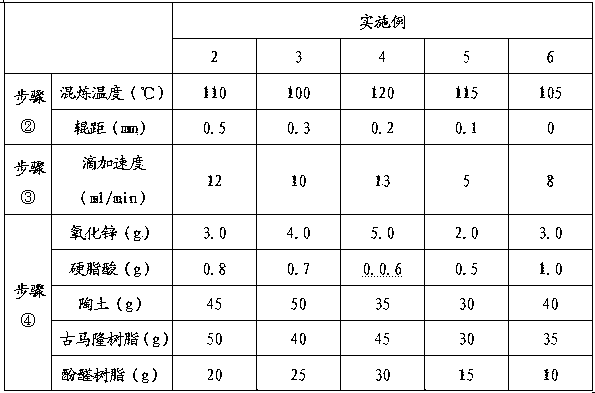

[0091] The difference between embodiment 2-6 and embodiment 1 is only that its component content is different, specifically as shown in the following table:

[0092]

[0093] Embodiment 2-6 polynorbornene rubber preparation parameter table

[0094]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com