Aluminum wheel finishing process

A wheel and process technology, applied in the field of aluminum alloy wheel polishing and processing technology, can solve the problems of worker health injury, low labor efficiency, insufficient production capacity, etc. The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

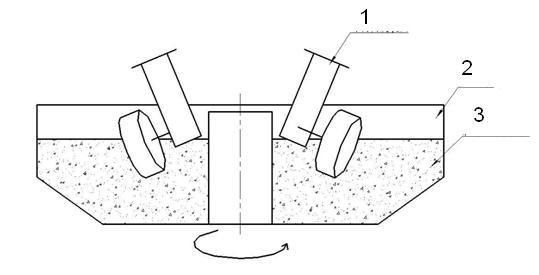

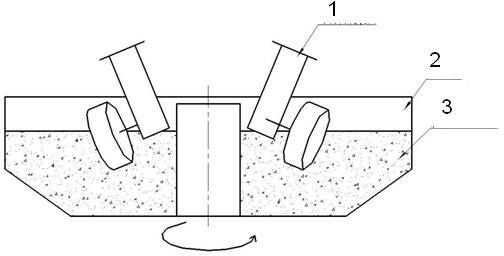

Image

Examples

Embodiment 1

[0015] According to the above-mentioned high-efficiency mirror finishing process of high-grade aluminum alloy wheels, take the processing process of aluminum alloy wheels (17-inch aluminum alloy blank) with surface roughness Ra 6.03 after heat treatment and shot peening as an example:

[0016] Step 1: Use 80-mesh brown corundum Φ5 grinding block, self-made 5% HYY type coarse grinding agent, adjust the inclination angle of the machine head to 45°, select other appropriate parameters, and finish processing for 20 minutes. The surface is clean and wavy, and the roughness is reduced. to Ra 1.45.

[0017] Step 2: Use a 100-mesh Φ7*7 resin grinding block, self-made 5% CA-type medium abrasive, adjust the inclination angle of the machine head to 45°, select other appropriate parameters, and finish processing for 20 minutes. The surface is clean, smooth and even, and the roughness is reduced. to Ra 0.15.

[0018] Step 3: Use 1200-mesh high-alumina Φ3 grinding block, self-made 5% HYA t...

Embodiment 2

[0020] According to the above-mentioned high-efficiency mirror finishing process of high-grade aluminum alloy wheels, take the processing process of aluminum alloy wheels (18-inch aluminum alloy blank) with surface roughness Ra 6.42 after heat treatment and shot peening as an example:

[0021] Step 1: Use 240-mesh brown corundum Φ6 grinding block, self-made 4% HYY type coarse grinding agent, adjust the inclination angle of the machine head to 55°, select other appropriate parameters, and finish processing for 15 minutes. The surface is clean and wavy, and the roughness is reduced. to Ra 1.71.

[0022] Step 2: Use a 150-mesh Φ8*8 resin grinding block, self-made 5% CA-type medium abrasive, adjust the inclination angle of the machine head to 60°, select other appropriate parameters, and finish processing for 20 minutes. The surface is clean, smooth and even, and the roughness is reduced. to Ra 0.19.

[0023] Step 3: Use 1500-mesh ceramic Φ3 grinding block, self-made 5% HYA fine ...

Embodiment 3

[0025] According to the above-mentioned high-efficiency mirror finishing process of high-grade aluminum alloy wheels, take the processing process of aluminum alloy wheels (18-inch aluminum alloy blank) with surface roughness Ra 7.32 after heat treatment and shot peening as an example:

[0026] Step 1: Use 240-mesh resin Φ10 grinding block, self-made 5% HYY type coarse grinding agent, adjust the inclination angle of the machine head to 65°, select other appropriate parameters, finish processing for 30 minutes, the surface is clean and even, and the roughness is reduced to Ra 1.06 .

[0027] Step 2: Use a 200-mesh Φ5*5 resin grinding block, self-made 5% CA-type medium abrasive, adjust the inclination angle of the machine head to 65°, select other appropriate parameters, and finish processing for 15 minutes. The surface is clean, smooth and even, and the roughness is reduced. to Ra 0.09.

[0028] Step 3: Use 2500-mesh ceramic Φ2 grinding block, self-made 5% HYA type fine grindin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com