Method for embedding chips into cavities in front and back sides of adapter plate

An adapter plate and cavity technology, which is applied to the field of embedding chips on the front and back sides of the adapter plate, can solve the problems of complex process and high cost, and achieve the effects of large economic benefits, large cost advantages and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] include:

[0058] A: TSV (Through Silicon Via) is made on a silicon wafer with a double-layer SOI (Silicon-On-Insulator, silicon on insulating substrate) layer, and the TSV stops on the surface of the second layer of SOI, and the TSV is filled with electroplating metal;

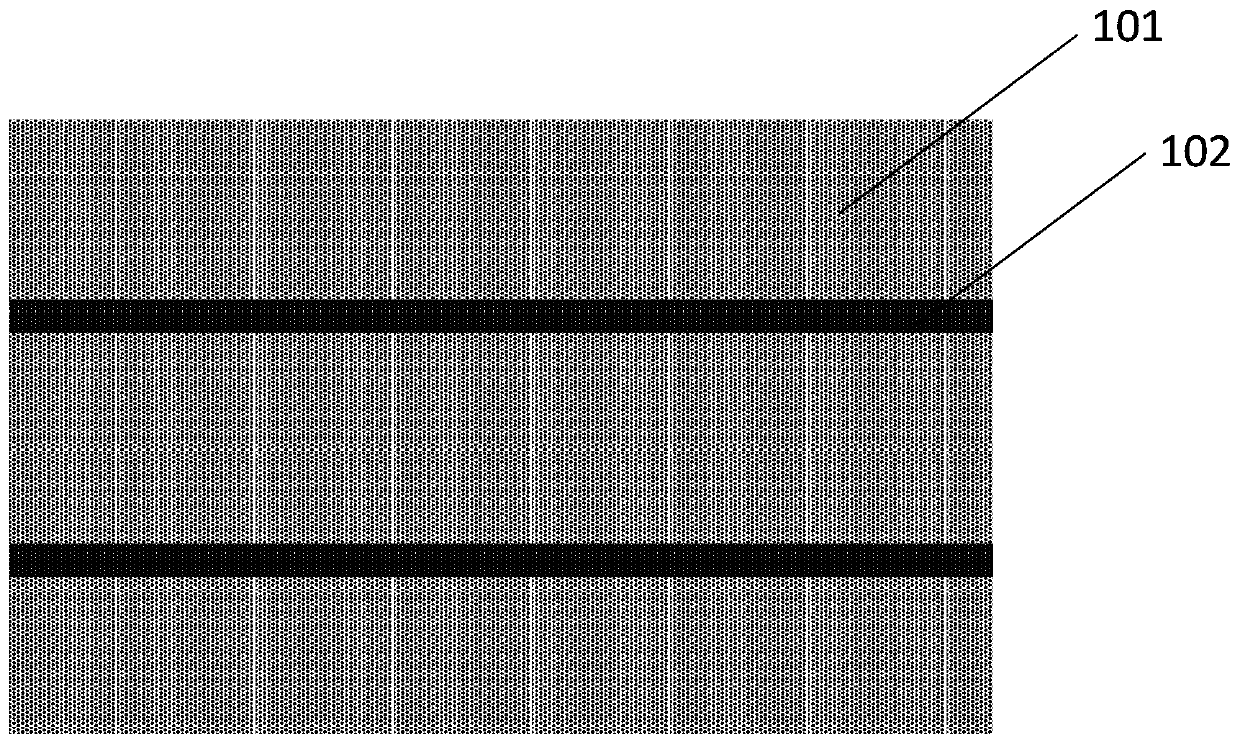

[0059] like figure 1 As shown, an SOI silicon wafer 101 is selected, wherein 102 is an SOI layer. This silicon wafer has two layers of SOI, from top to bottom, which are the first SOI layer 102 and the second SOI layer;

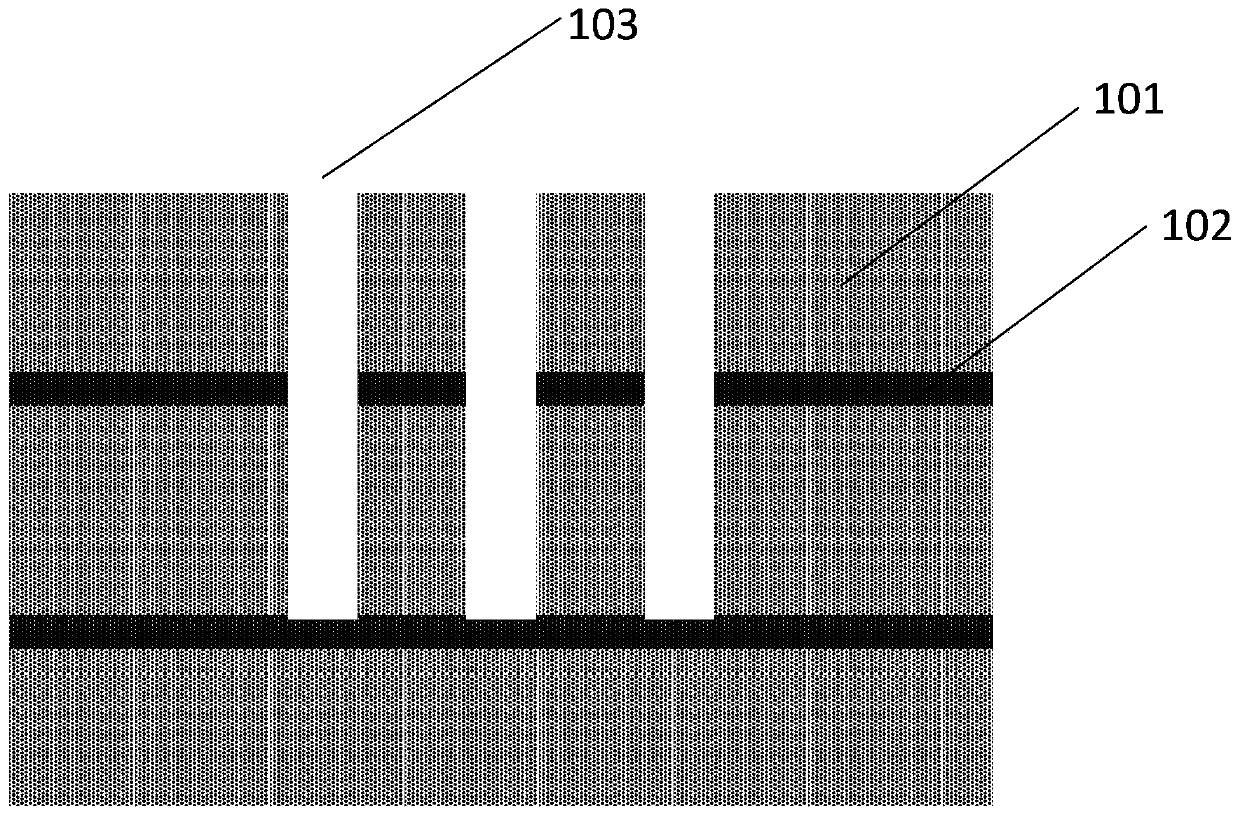

[0060] like figure 2 As shown, TSV holes 103 are fabricated on the surface of the SOI silicon wafer by photolithography and etching processes, the hole diameter ranges from 1um to 1000um, and the depth ranges from 10um to 1000um;

[0061] Etching stops on the second SOI layer;

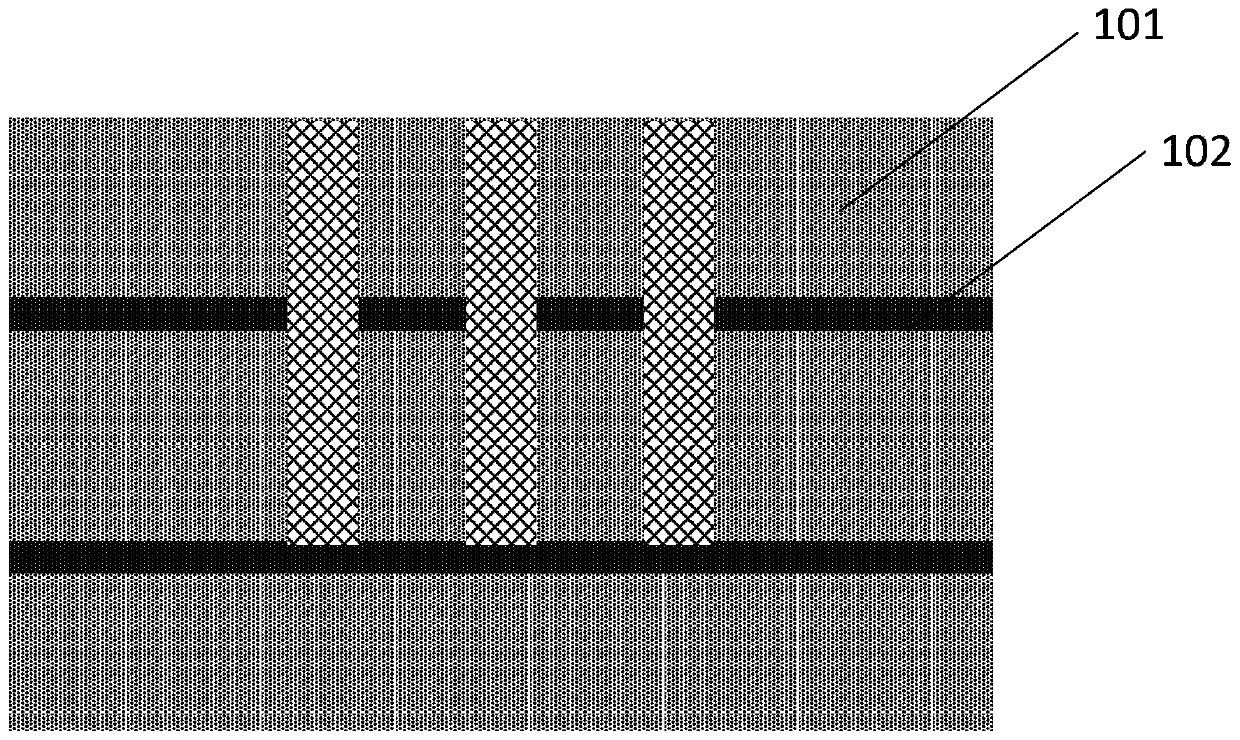

[0062] like image 3 As shown, an insulating layer such as silicon oxide or silicon nitride is deposited on the silicon wafer, or directly thermally oxidized, and the thickness of the insulating layer ran...

Embodiment 2

[0074] include:

[0075] A: Make TSV on the silicon wafer with double-layer SOI layer, TSV stops on the surface of the second layer of SOI, continue to etch the TSV to the lower surface of the SOI, and fill the TSV with metal plating;

[0076] like Figure 11 As shown, the SOI silicon wafer is selected. This silicon wafer has two layers of SOI; TSV holes are made on the surface of the SOI silicon wafer through photolithography and etching processes. The diameter of the hole ranges from 1um to 1000um, and the depth ranges from 10um to 1000um;

[0077] Etching the TSV stops at the surface of the second layer of SOI, and continues to etch the TSV to the lower surface of the SOI;

[0078] Deposit insulating layers such as silicon oxide or silicon nitride on the silicon wafer, or direct thermal oxidation, the thickness of the insulating layer ranges from 10nm to 100um; make seeds on the insulating layer by physical sputtering, magnetron sputtering or evaporation process Layer, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com