Process for preparing microcrystalline cellulose by cotton noils

A technology of microcrystalline cellulose and process, which is applied in the field of microcrystalline cellulose preparation from combed noil, can solve the problems of not being able to comb the yarn and reduce the value of combed cotton, and achieve the goal of increasing the reaction rate and saving the amount of additives Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

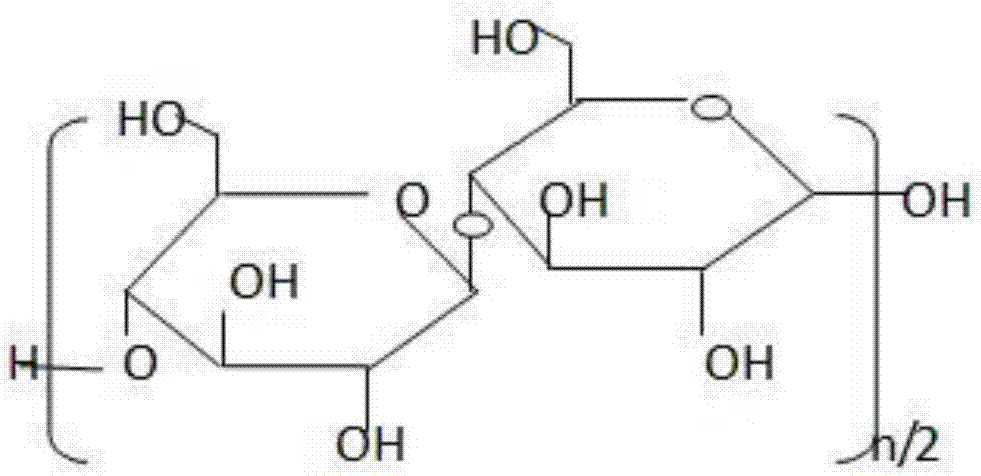

[0057] The technical scheme for preparing microcrystalline cellulose from combed noil of the present invention is that the combed noil is sequentially subjected to pretreatment, drying, acid hydrolysis, water washing, centrifugation, and drying processes to obtain high-purity microcrystalline cellulose .

[0058] The pretreatment process sequentially includes scouring, oxygen bleaching, soaping, and water washing processes.

[0059] The scouring process uses scouring agent including caustic soda 3g / L, refining agent TF-1871 (Transchem Chemical) dosage 0.5g / L, chelating agent PCA (Shanghai Kekai) dosage 0.2g / L, and the balance is water , Treated at 100℃ for 40min, every 20L of scouring agent aqueous solution can treat 1kg of combed cotton waste.

[0060] In the oxygen bleaching process, the treatment agent used includes H 2 O 2 5g / L, TF-1871 (Transchem Chemical) dosage 0.5g / L, chelating agent PCA (Shanghai Kekai) dosage 0.2g / L, hydrogen peroxide stabilizer P (Shanghai Kekai) dosage ...

experiment example 1

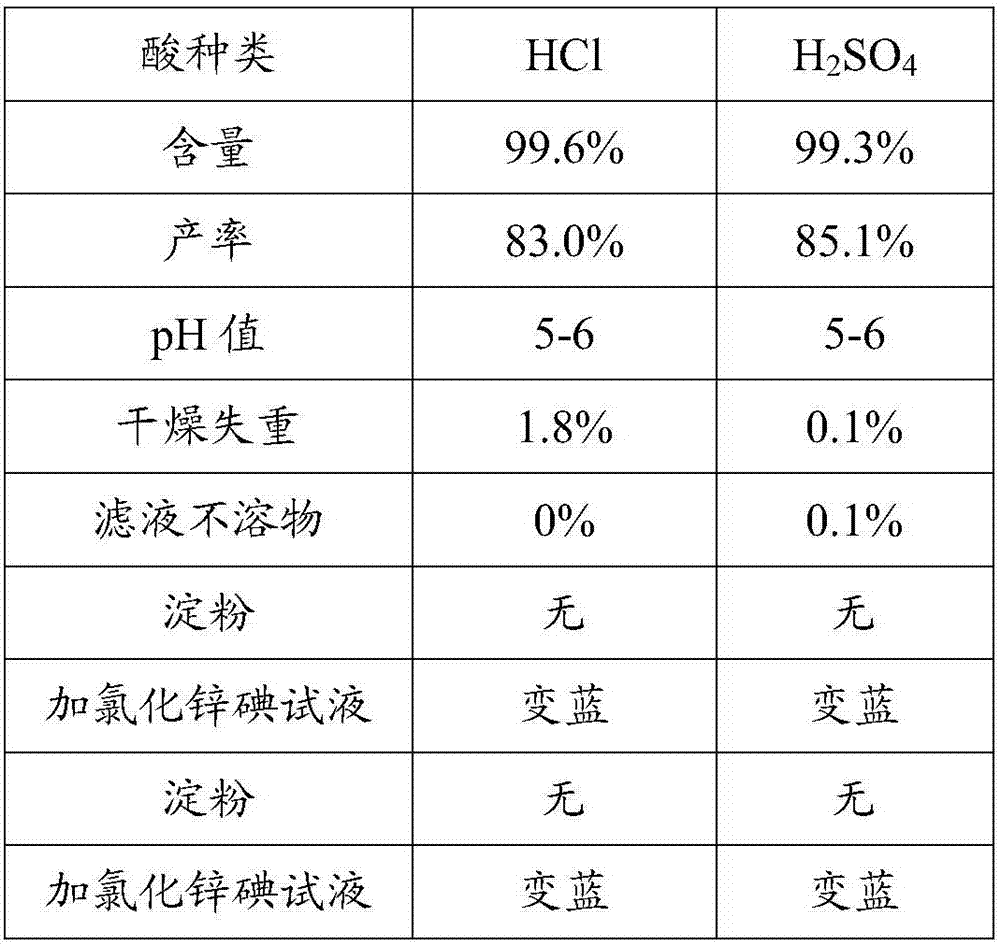

[0066] Effects of different acids on the quality of microcrystalline cellulose

[0067] The type of acid has a certain difference in the properties of the prepared MCC, mainly because the type of acid has a different ability to dissolve the cellulose molecular chain in the amorphous region, and the type of acid is also related to the chemical properties of the surface of the prepared MCC. . In this experiment, the concentration of hydrochloric acid is 6-8% and the concentration of sulfuric acid is 6-10% to prepare microcrystalline cellulose. In order to compare the effects of two acid hydrolysis, two acid solutions with the same concentration of 8% were used to hydrolyze cotton staple fiber at 80°C for 4 hours. The results are shown in Table 1:

[0068] Table 1 Test results of microcrystalline cellulose prepared by hydrochloric acid and sulfuric acid

[0069]

[0070]

[0071] Comparing the two finished products, it is found that the microcrystalline cellulose treated with hydrochl...

experiment example 2

[0073] The effect of acid hydrolysis time on the quality of microcrystalline cellulose

[0074] Hydrochloric acid was selected for the preparation of MCC, and 8% hydrochloric acid was used for 2h, 3h, and 4h treatments at 80°C. The specific index tests of the prepared microcrystalline cellulose are shown in Table 2:

[0075] Table 2 Test results of microcrystalline cellulose prepared by acid hydrolysis at different times

[0076] Processing time2h3h4h content99.3%99.5%99.6% Yield82.6%83.0%83.0% pH value5-65-65-6 Loss on drying0%2.6%1.8% Filtrate insoluble matter0%0%0% starch no no no Add zinc chloride iodine test solution Turn blue Turn blue Turn blue

[0077] According to the above results, the basic indicators of the products obtained by treating 8% hydrochloric acid at 80°C for 2-4h meet the requirements, but in terms of content and yield, the yield obtained from hydrochloric acid treatment time of 3h or 4h is slightly higher, and 8% hydrochloric acid treatment at 80°C A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com