Drinking type normal-temperature yoghourt and preparation method thereof

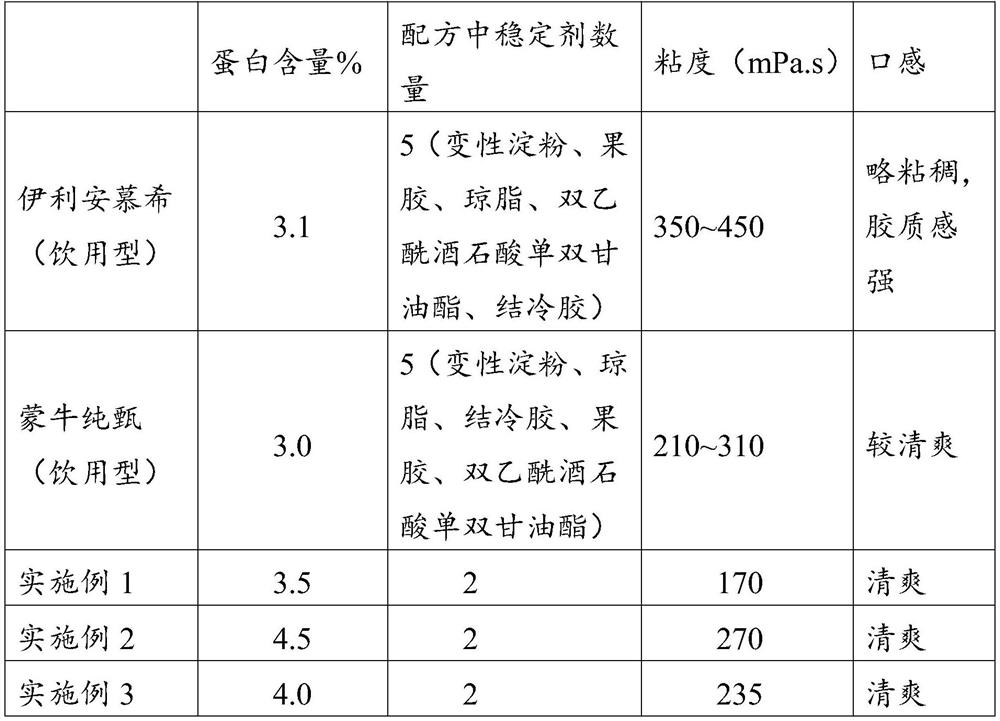

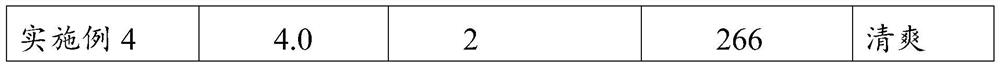

A drinking-type, room-temperature technology, which is applied to the bacteria and applications used in milk preparations and food preparation, can solve the problems of less protein content stabilizer, more stabilizer, sticky taste, etc., and achieves refreshing taste and system stability. , nutritionally high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A preparation method of drinkable normal temperature yoghurt, its raw materials include: concentrated milk 73%, partial sucrose 6%, remaining sucrose 3%, milk protein powder 0.9%, pectin (low-ester pectin: high-ester pectin=1: 3) 0.45%, gellan gum 0.02%, Lactobacillus bulgaricus 1×10 6 cfu / g, Streptococcus thermophilus 1×10 5 cfu / g, water 16.53%, wherein percentage is the mass percentage accounting for the total mass of raw materials, and its preparation method comprises the following steps:

[0044] ①. Concentrate raw milk at 2°C through reverse osmosis RO membrane to obtain concentrated milk, and concentrated milk: water = 8:2; the membrane pressure of the reverse osmosis RO membrane is 20bar, and the membrane pore size is 1nm;

[0045] ②. Sterilize the concentrated milk obtained in step ① at 135°C for 6 seconds. After it is cooled to 40°C, add milk protein powder and part of 6% sucrose, and mix for 30 minutes to obtain a mixed base material;

[0046] ③. After the m...

Embodiment 2

[0054] A preparation method of drinkable normal temperature yogurt, its raw materials include: 74.88% of concentrated milk, 3% of part of sucrose, 3% of remaining sucrose, 2.1% of milk protein powder, pectin (low-ester pectin: high-ester pectin=1: 4) 0.3%, gellan gum 0.01%, Lactococcus lactis subspecies lactic acid 1×10 6 cfu / g, Lactococcus lactis subsp. cremoris 4×10 6 cfu / g, water 16.69%, wherein percentage is the mass percentage accounting for the total mass of raw materials, and its preparation method comprises the following steps:

[0055] ①. Concentrate raw milk at 10°C through reverse osmosis RO membrane to obtain concentrated milk, and concentrated milk: water = 8:2; the membrane pressure of the reverse osmosis RO membrane is 20bar, and the membrane pore size is 1nm;

[0056] ②. Sterilize the concentrated milk obtained in step ① at 139°C for 4s. After cooling to 50°C, add milk protein powder and part of 3% sucrose, and mix for 15 minutes to obtain a mixed base materia...

Embodiment 3

[0065] A preparation method of drinkable normal temperature yoghurt, its raw materials include: concentrated milk 73.46%, partial sucrose 5%, remaining sucrose 3%, milk protein powder 1.5%, pectin (low-ester pectin: high-ester pectin=1: 3) 0.45%, modified starch 0.15%, Lactobacillus bulgaricus 1×10 6 cfu / g, Streptococcus thermophilus 2.5×10 5 cfu / g, water 16.4%, wherein percentage is the mass percentage accounting for the total mass of raw materials, and its preparation method comprises the following steps:

[0066] ①. The raw milk at 4°C is concentrated by reverse osmosis RO membrane to obtain concentrated milk, and concentrated milk: water = 8:2; the membrane pressure of the reverse osmosis RO membrane is 20bar, and the membrane pore size is 1nm;

[0067] ②. Sterilize the concentrated milk obtained in step ① at 137°C for 4 seconds. After cooling to 50°C, add milk protein powder and part of 5% sucrose, and mix for 20 minutes to obtain a mixed base material;

[0068] ③. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com