A kind of vortex type graphene stripping device, graphene production system and production method

A technology of a peeling device and a production system, applied in the field of graphene production, can solve the problems of insufficient powder shear force, increase the amount of pressurized powder, and uneven pressure applied by graphite, achieve less structural defects and burrs, expand the application range, The effect of expanding the practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

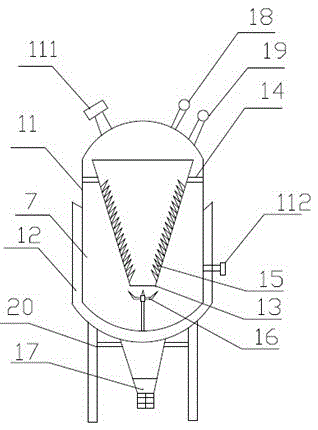

[0047] The invention relates to an eddy current graphene peeling device 1 and a graphene production system, and also relates to a graphene production method.

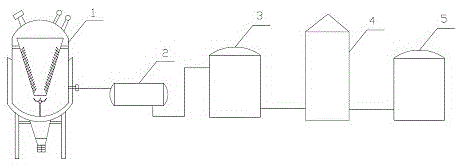

[0048] The graphene production system, such as figure 1 As shown, the vortex graphene peeling device 1, the storage tank 2, the centrifuge 3, the vacuum filtration device 4, and the freeze drying device 5 are included in sequence along the process sequence; the storage tank 2 is used to collect and stand the graphene peeling device 1 The product is discharged after processing, the centrifuge 3 is used to centrifuge the upper suspension in the storage tank 2 to separate exfoliated graphene and unexfoliated graphite, and the vacuum filtration device 4 is used to filter the supernatant obtained after the centrifuge 3 is centrifuged , Washing, freeze drying device 5 is used to dry the graphene after vacuum filtration. Here, the discharge port 112 of the vortex graphene peeling device 1 is connected with the feed port of the st...

Embodiment 2

[0056] One of the differences between this embodiment and Embodiment 1 lies in the structure of the shear blade 15 in the eddy current graphene peeling device 1.

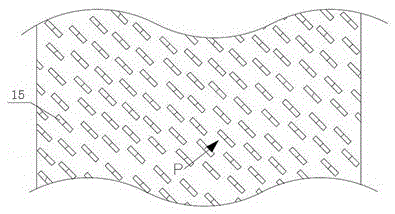

[0057] In this embodiment, in order to reduce the damage of the tooth tip of the shear blade 15 to the graphene structure, further reduce the defects of the produced graphene and increase the size of the graphene, such as Figure 4 with Figure 5 As shown, the cutting blade 15 is designed as a serrated hook knife: the end surfaces of each cutting blade 15 are perpendicular to the spiral line (P direction) where it is located, but the tooth tip of the cutting blade 15 is slightly facing away from the cutting The blade 15 is bent in the upward spiral direction to form the warped portion 150 of the hook knife. In the research, it is found that the angle α of the tooth tip of the shearing blade 15 slightly bent away from the spiral upward direction of the shearing blade 15 is 5-15°, which can maximize the balance between th...

Embodiment 3

[0059] The difference between this embodiment and the second embodiment lies in the design of the feed port 111 and the configuration of the outer cylinder 11 in the vortex graphene peeling device 1. In this embodiment, such as Image 6 As shown, the feed port 111 is directly facing the outside of the inner cylinder 13, so that when it enters the outer cylinder 11 from the feed port 111, it is dispersed first and then enters the inner cylinder 13, which can avoid blockage of the groove between the shear blades 15 to a certain extent , And the graphite passes through the inner cylinder 13 in a manner parallel or approximately parallel to the inner wall of the inner cylinder 13.

[0060] At the same time, an ultrasonic vibration box 22 is provided in the outer cylinder 11 close to the feeding port 111, and is connected to the ultrasonic generator 21 outside the outer cylinder 11 through a wire. In this way, the graphite fed from the feeding port 111 can break the agglomeration in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com