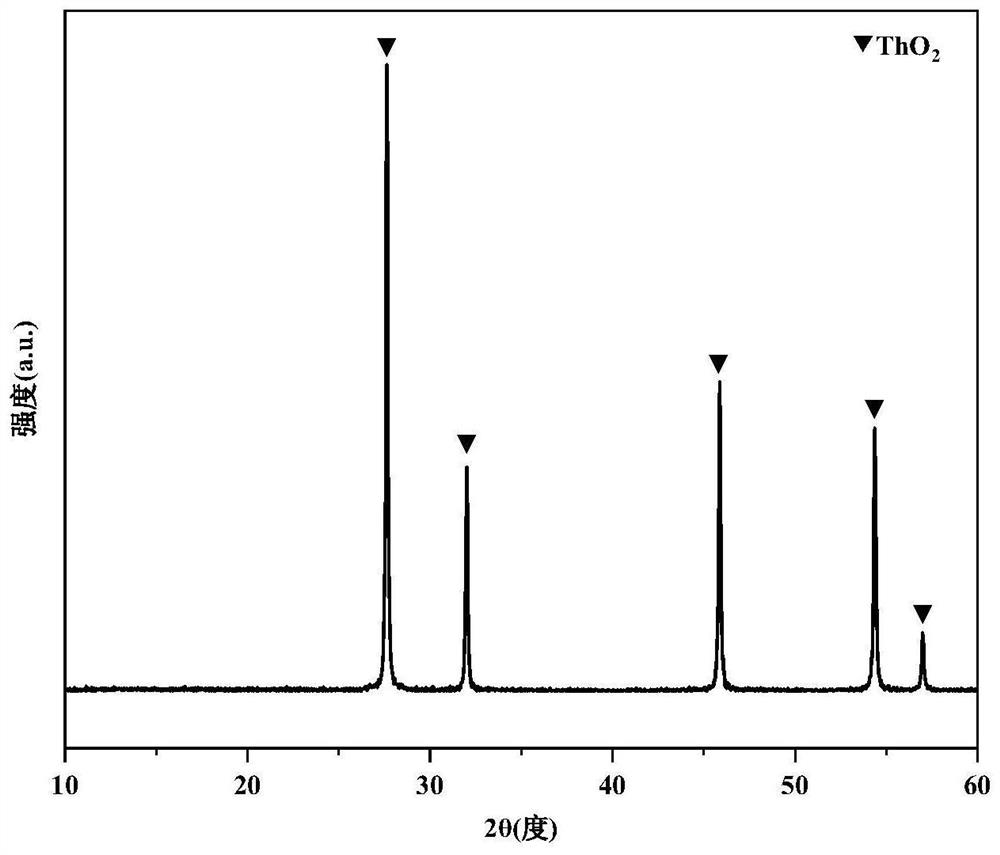

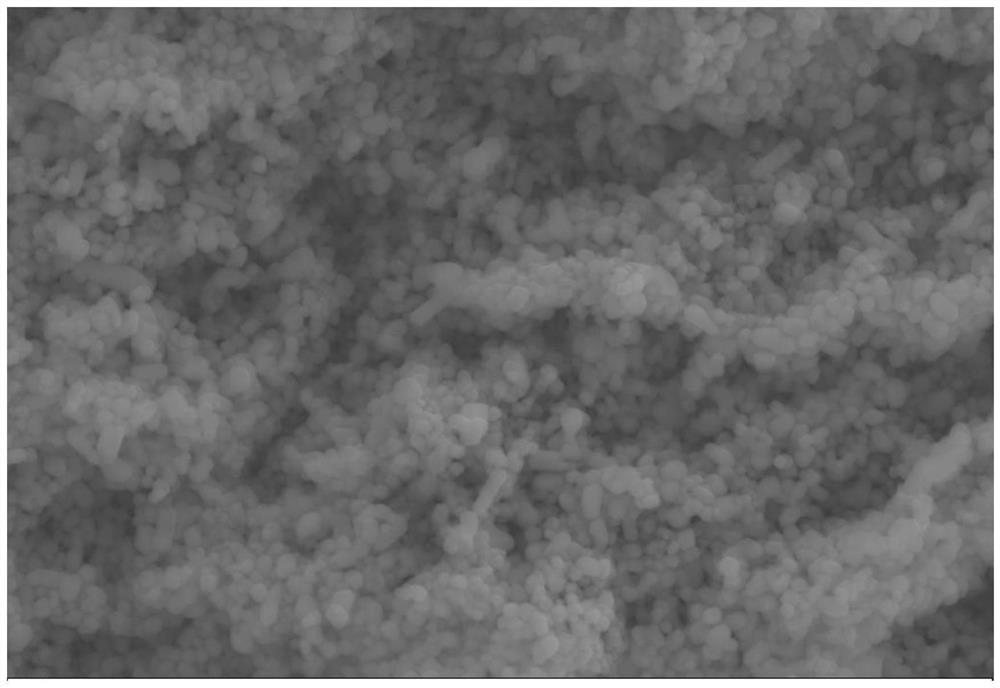

Method for preparing thorium dioxide nano material based on molten salt method and thorium dioxide nano material obtained by method

A thorium dioxide and nanomaterial technology, applied in the field of materials, can solve the problems of uneven particles, cumbersome processes, etc., and achieve the effects of uniform morphology, simple process, and promoting effective ion diffusion and chemical reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1: 59 mol% lithium chloride, 41 mol% potassium chloride are used as molten salt, and the molar ratio of thorium nitrate hexahydrate to molten salt is 1:5 to form raw material ingredients.

[0027] Step 2, placing the raw materials in an alumina crucible and stirring and mixing evenly to obtain a mixture.

[0028] Step 3: Put the mixture into a box-type resistance furnace, raise the temperature to 500° C. at a rate of 10° C. / min, and calcinate for 4 hours. After the sample is completely cooled, a reaction product is obtained.

[0029] Step 4. Transfer the reaction product from the crucible to a beaker, add sufficient water to the beaker for ultrasonic dissolution, and obtain a milky white suspension.

[0030] Step 5. Suction filter the milky white suspension with a suction filtration device, then repeatedly wash it with pure water for eight times, and then dry it at 100°C to obtain thorium dioxide nanomaterials based on the molten salt method. .

Embodiment 2

[0032] This example is the same as Example 1 except that the molar ratio of thorium nitrate hexahydrate to molten salt is 1:10.

Embodiment 3

[0034] This example is the same as Example 1 except that the molar ratio of thorium nitrate hexahydrate to molten salt is 1:20.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com