Preparation method of thorium dioxide nano material

A technology of nanomaterials and thorium dioxide, which is applied in the field of nanomaterials to achieve the effects of controllable morphology, good catalytic activity and light agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Add 5 mL of 0.5 mol / L thorium nitrate solution dropwise to 75 mL of 5 mol / L sodium hydroxide solution, and stir the mixed solution at room temperature for 30 min. Subsequently, the mixed solution was transferred into a 100mL polytetrafluoroethylene-lined stainless steel reactor, and placed in an oven at 80°C and 0.6MPa for 48h. After cooling to room temperature, wash with ultrapure water to pH = 7.5, dry and grind at 60°C to obtain ThO 2 White powder.

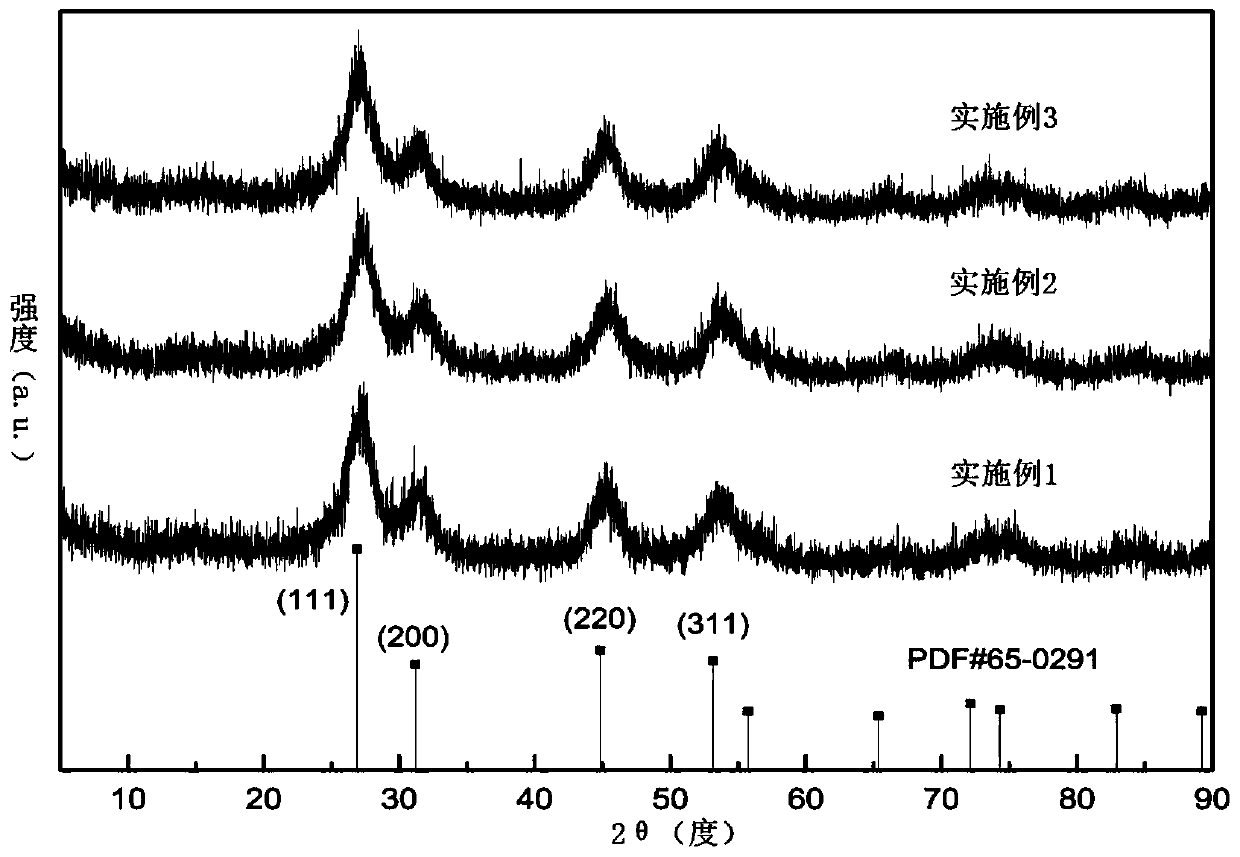

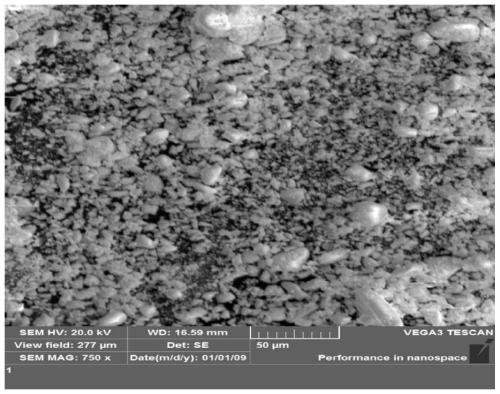

[0020] Produced ThO 2 The white powder was determined, XRD pattern and ThO 2 Corresponding to standard PDF card 65-0291 (see figure 1 ); the results of scanning electron microscopy showed that (see figure 2 ), the particle size is relatively uniform, the average grain size is 8.7nm, and the dispersion is good.

Embodiment 2

[0022] Add 5 mL of 0.8 mol / L thorium nitrate solution dropwise into 75 mL of 6.4 mol / L sodium hydroxide solution, and stir the mixed solution at room temperature for 30 min. Subsequently, the mixed solution was transferred into a 100mL polytetrafluoroethylene-lined stainless steel reactor, and placed in an oven at 90°C and 0.7MPa for 30h. After cooling to room temperature, wash with ultrapure water to pH = 8.0, dry and grind at 60°C to obtain ThO 2 White powder.

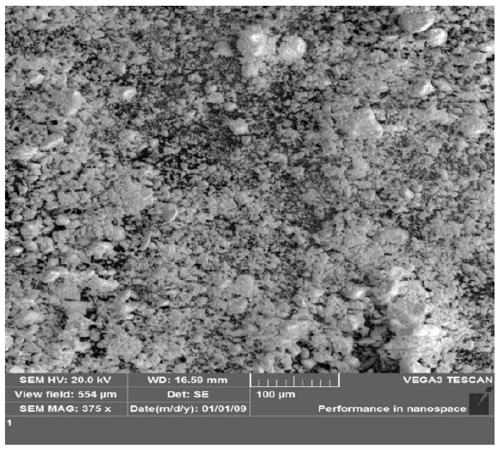

[0023] Produced ThO 2 The white powder was determined, XRD pattern and ThO 2 Corresponding to standard PDF card 65-0291 (see figure 1 ); the results of scanning electron microscopy showed that (see image 3 ), the particle size is relatively uniform, the average grain size is 8.9nm, and the dispersion is good.

Embodiment 3

[0025] Add 5 mL of 1.0 mol / L thorium nitrate solution dropwise into 75 mL of 8 mol / L sodium hydroxide solution, and stir the mixed solution at room temperature for 30 min. Subsequently, the mixed solution was transferred into a 100mL polytetrafluoroethylene-lined stainless steel reactor, and placed in an oven at 100°C and 0.8MPa for 18h. After cooling to room temperature, wash with ultrapure water to pH = 8.5, dry and grind at 60°C to obtain ThO 2 White powder.

[0026] Produced ThO 2 The white powder was determined, XRD pattern and ThO 2 Corresponding to standard PDF card 65-0291 (see figure 1 ); the results of scanning electron microscopy showed that (see Figure 4 ), the particle size is relatively uniform, the average grain size is 9.6nm, and the dispersion is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com