Nano modified material contained plant oil based lubricating oil preparation method

A nano-modified material, vegetable oil-based technology, applied in lubricating compositions, petroleum industry, etc., can solve the problems of ecological environment pollution, poor biodegradability, etc., to improve anti-oxidation, high temperature, wear resistance, and wear resistance Effect, the effect of improving the anti-wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

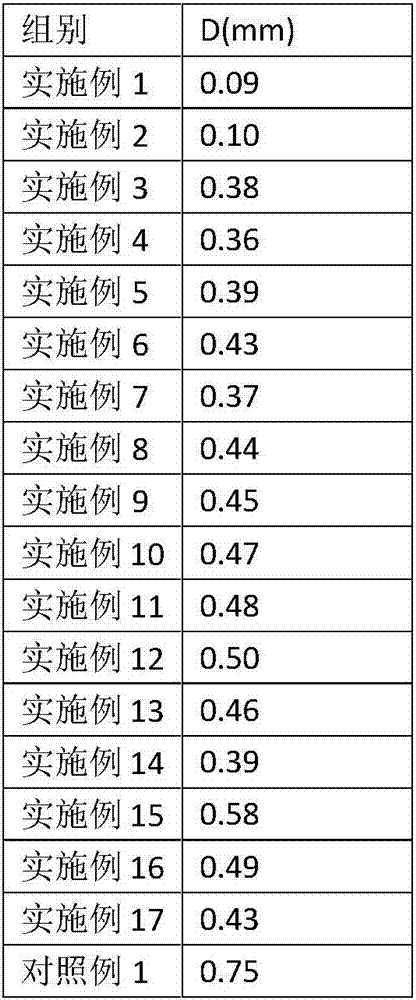

Examples

Embodiment 1

[0016] Example 1 Prepare a sample of nanometer thorium oxide and nanometer zinc oxide 5:3. 5 parts of nano-thorium oxide and 3 parts of nano-zinc oxide. 100 parts of castor oil, 20ml of acetic acid, 6 parts of ion exchange resin, 30ml of hydrogen peroxide, 5 parts of activated silica powder, 1 part of p-diphenylamine, 0.4 parts of DL171 coupling agent, sodium alkylbenzenesulfonate (LAS) surface active 0.3 parts of agent, 0.2 parts of polyisobutylene (PIB) viscosity index modifier.

[0017] Step 1. Add 100 parts of castor oil, 20ml of acetic acid, and 6 parts of cation exchange resin into a 1000mL three-neck flask, raise the temperature of the oil bath and start magnetic stirring (weigh 30ml of hydrogen peroxide in a separatory funnel). Raise the temperature to a constant temperature of 80°C, slowly add hydrogen peroxide dropwise during the heating process, control the dropping speed so that the addition is completed in about 3 hours, react for about 7 hours, stop the magnetic...

Embodiment 2

[0027] Example 2 Prepare a sample of nanometer thorium oxide and nanometer zinc oxide 2:5. 2 parts of nano-thorium oxide, 5 parts of nano-zinc oxide. Other raw material consumption, operation steps are the same with embodiment 1.

Embodiment 3

[0028] Example 3 Prepare nano-thorium oxide, nano-zinc oxide 1:1 sample. 1 part of nano-thorium oxide, 1 part of nano-zinc oxide. Other raw material consumption, operation steps are the same with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com