Preparation method of nuclear pure grade thorium

A technology for the content of thorium nitrate and thorium, which is applied in the field of thorium purification to achieve the effects of high purity, reduced impurity elements, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

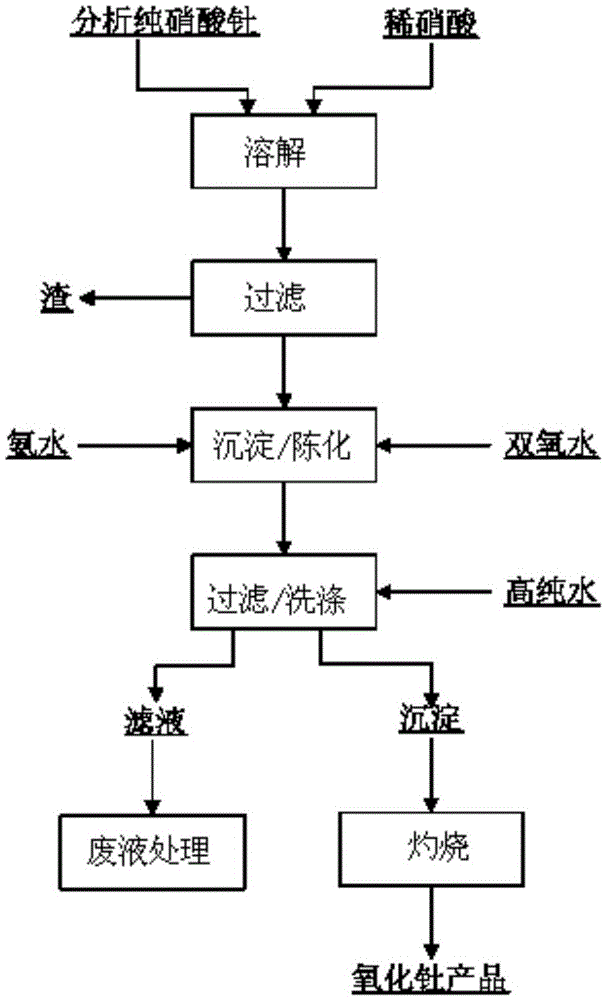

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0018] The steps of this embodiment are as follows figure 1 shown, including the following steps:

[0019] Step 1, dissolving and filtering: after dissolving the analytically pure thorium nitrate with deionized water until the thorium content is 80g / L, adjust the pH value of the thorium nitrate solution to a range of 2.0 with a 10% by volume nitric acid solution, and then filter the solution ;

[0020] Step 2, precipitation and aging: control the solution filtered in step 1 at about 50°C, add a 30% hydrogen peroxide solution dropwise in the solution and stir, wherein the amount of hydrogen peroxide depends on the thorium in the solution The consumption amount is calculated and added, the molar ratio of hydrogen peroxide to thorium is 3:2, and the excess concentration of hydrogen peroxide is maintained at 0.1-0.5mol / L; The pH value of solution is in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com