Mixed rare earth concentrate decomposition method

A mixed rare earth and concentrate technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of waste gas and waste residue polluting the environment, reduce lime consumption, reduce storage costs, and achieve high decomposition rates. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

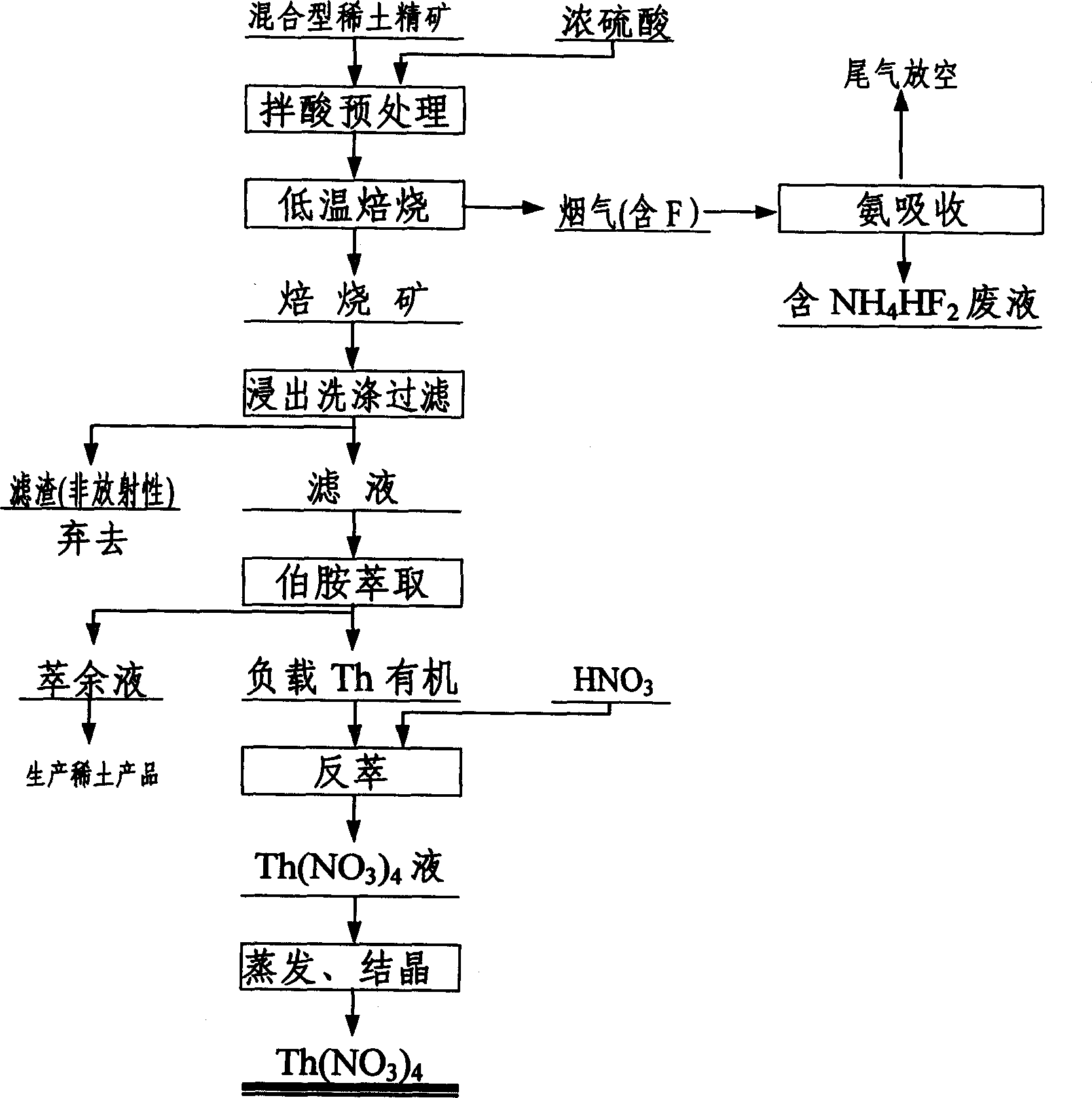

Method used

Image

Examples

Embodiment 1

[0030] Get 100g mixed type rare earth concentrate, the main components of the concentrate are as follows (percentage by weight):

[0031] REO ThO 2 F P 2 o 5

[0032] 55% 0.20% 7.5% 6.5%

[0033] Get 165g concentration and be that the concentrated sulfuric acid of 98% is mixed with above-mentioned concentrate, and mixture is placed in the incubator immediately, and the temperature of measured concentrate is 70 ℃. After aging for 8 hours, take it out and put it into a muffle furnace, and bake it at 250° C. for 2 hours. Then take it out, add 800ml of water, and leaching for 1 hour at 30°C. Analysis of RE on leach residue 2 o 3 (Determined by the content of Ce in the slag) and the content of thorium, and detect the radioactivity of the slag. The leaching rate of RE is greater than 95%, the leaching rate of thorium is 96%, the thorium content in the leaching residue is less than 0.05%, and the total specific activity of radioactivity is less than 1×10 4 Bq...

Embodiment 2~10

[0039] Examples 2-10 all take 100g of the mixed rare earth concentrate described in Example 1, and then mix each with 165g of concentrated sulfuric acid, and after aging for a period of time, put them into a muffle furnace for roasting. The produced calcine was leached with 800ml of water, and the leaching solution and slag were analyzed for REO, ThO content, and slag specific activity of radioactivity. The aging temperature, roasting temperature and time and calcine leaching results are shown in Table 1.

[0040] Numbering

Embodiment 11

[0042] Take 5 kg of the rare earth concentrate described in Example 1, add concentrated sulfuric acid according to the mass ratio of the concentrate to concentrated sulfuric acid 1:1.5, stir and mix and then mature, the curing temperature is 60°C. Then take it out and add it to the rotary kiln for roasting. The concentrate goes in and out of the rotary kiln continuously, and the residence time in the kiln is 1.5 hours. The inlet temperature of the rotary kiln is 200°C, the outlet temperature is 210°C, and the maximum temperature in the kiln is 250°C. The calcined sand produced by roasting automatically enters the collecting hopper at the outlet of the rotary kiln, and then soaked in water to analyze the rare earth and thorium content in the slag and liquid. The rare earth leaching rate is greater than 95%, the thorium leaching rate is greater than 95%. 4 Bq / Kg; the flue gas enters the vertical flue, and liquid ammonia is sprayed into the flue, and the fluorine content of the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific activity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com