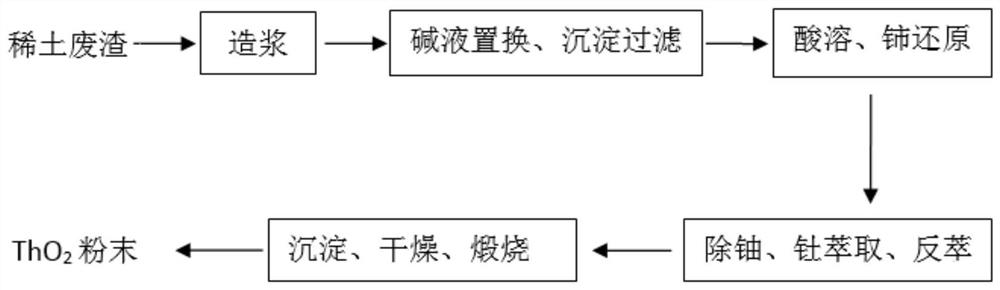

Method for extracting and preparing nuclear-grade ThO2 powder from rare earth waste residues

A technology for rare earth waste residue and powder, which is applied in the field of extracting and preparing nuclear pure ThO2 powder, can solve the problems of low utilization rate of thorium resources, many radioactive waste water, low recovery efficiency, etc., and achieves good extraction and stripping effect and simple process flow. , the effect of less corrosive equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Step 1. Pretreat the rare earth waste residue, measure its components, add 5-12L deionized water to each kilogram of waste residue to make slurry, and control the temperature of the waste residue slurry at 60-90°C.

[0072] Step 2: adding 2.5-4 mol / L lye to carry out alkaline displacement reaction, the amount of lye added is 120-180% of the normal reaction amount, and the displacement reaction is not less than 3 hours. The generated thorium hydroxide filter cake is subjected to washing operation, the washing temperature is 50-70°C, and the washing times are not less than 3-5 times.

[0073] Step 3, using nitric acid to dissolve the thorium hydroxide filter cake, the dissolution temperature is controlled at 60-90° C., the concentration of thorium ions in the solution is adjusted to 50-300 g / L, and the acidity is adjusted to 1-4 mol / L. Add 3% to 12% H in volume to the thorium nitrate solution 2 o 2 Carry out cerium ion reduction conversion, and use it as an extraction s...

Embodiment 2

[0077] Step 1. Pretreat the rare earth waste residue, measure its components, and make slurry according to the ratio of adding 7L deionized water per kilogram of waste residue.

[0078] Step 2: Control the temperature of the waste residue slurry at 70° C., add 3 mol / L sodium hydroxide solution to carry out alkaline displacement reaction, and carry out the reaction for 2 hours to obtain a thorium hydroxide filter cake. The thorium hydroxide filter cake was washed 4 times with deionized water at 60°C.

[0079] Step 3, add nitric acid to dissolve the thorium hydroxide filter cake, control the dissolution temperature at 80°C, adjust the concentration of thorium ions to 150g / L, adjust the acidity to 2mol / L, and add 5% H 2 o 2 Carry out cerium ion reduction conversion, and use it as an extraction stock solution for later use.

[0080] Step 4: first prepare TBP-kerosene with a volume ratio of 5%, and carry out the operation of removing uranium from the solution, and then prepare TB...

Embodiment 3

[0083] Step 1. Pretreat the rare earth waste residue, measure its components, make slurry according to the ratio of adding 10L deionized water per kilogram of waste residue, and control the temperature of the waste residue slurry at 80°C.

[0084] Step 2: adding 2.5 mol / L sodium hydroxide solution to carry out alkaline displacement reaction, and the reaction was carried out for 3 hours to obtain a thorium hydroxide filter cake. The thorium hydroxide filter cake was washed three times with deionized water at 70°C.

[0085] Step 3, add nitric acid to dissolve the thorium hydroxide filter cake, control the dissolution temperature at 75°C, adjust the concentration of thorium ions to 200g / L, adjust the acidity to 2.5mol / L, and add 8% H 2 o 2 Carry out cerium ion reduction conversion, and use it as an extraction stock solution for later use.

[0086] Step 4: first prepare TBP-kerosene with a volume ratio of 9%, and perform the solution deuranium operation, and then prepare TBP-ker...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com