Method for preparing thorium nitrate by utilizing monazite excellent molten slag

A technology of thorium nitrate and slag melting, which is applied in the field of preparing thorium nitrate by using monazite excellent slag melting, can solve the problems such as not being used, and achieve the effect of reducing the extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

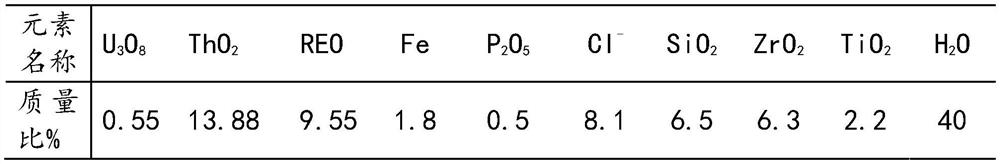

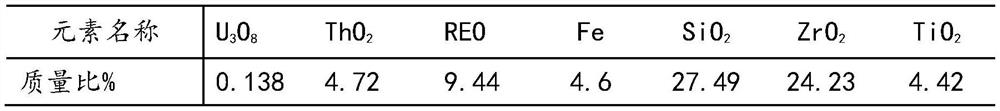

[0052] (1) Pretreatment and titanium removal treatment: Take 3000Kg of monazite excellent molten slag of the above composition and pour it into 10m 3 In the PPH tank with stirring, add 3000L of water according to S:L=1:1, add 1050L of 98% fuming nitric acid under stirring state, turn on the heating to boil, stir and keep warm for 1h. After keeping warm for 1 hour, add tap water to S:L=1:2, and measure the concentration of residual acid to be 3.27mol / L; when the solution temperature is 60°C, add 50L of hydrogen peroxide and 0.4L of polyether, stir well and use a 100m2 diaphragm filter press Press filtration, the feed liquid is aged for 12 hours, filtered with a 5 μm precision filter, and the filtrate is used to obtain a clarified feed liquid B-5.19m 3 . NO in feed liquid 3 - 3.91mol / L, REO 43.10g / L, ThO 2 70.82g / L, U 3 0 8 3.02g / L, Fe 5.06g / L, TiO 2 6.11g / L, ZrO 2 0.11g / L, Cl - 40.31g / L, the direct recovery rate of thorium is 88.27%, the direct recovery rate of rar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com