Extraction method for rubidium ions and cesium ions

A technology of cesium ion and rubidium ion, which is applied in the extraction field of rubidium ion and cesium ion, can solve the problems of low extraction efficiency of Rb and Cs, and achieve the effect of avoiding difficulty in phase separation, reducing the demand for basicity, and improving extraction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The process of preparing composite extractant is not limited to the above-mentioned preferred embodiment, when composite extractant includes phenolic extractant, acidic extractant, neutral organic matter and hydrocarbon solvent, above-mentioned preparation method can also comprise: extracting phenol Mixing agent, hydrocarbon solvent and neutral organic matter to form a premix, and adding acidic extractant to the premix to form a composite extractant; or mixing acidic extractant, hydrocarbon solvent and neutral organic to form a premix, and The phenolic extractant is added to the premix to form a composite extractant; or the neutral organic matter is divided into the first neutral organic part and the second neutral organic part, and the hydrocarbon solvent is divided into the first hydrocarbon solvent part and the second part. Two hydrocarbon solvent parts, the phenolic extractant, the first neutral organic part and the first hydrocarbon solvent part are mixed to form th...

Embodiment 1

[0048] The extraction method of rubidium ion and cesium ion provided by the present embodiment comprises the following steps:

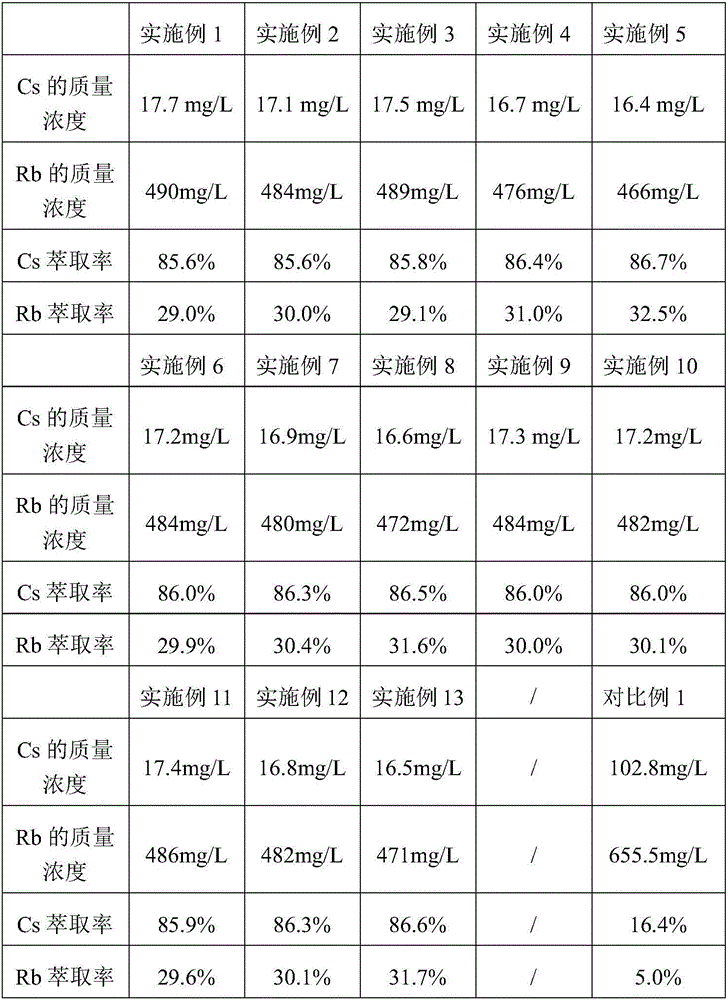

[0049] At first, provide a kind of sulfate solution that contains 123mg / L Cs ion, 690mg / L Rb ion as mixed solution, its pH=9.0, utilize compound extractant to carry out the first extraction treatment to this mixed solution, compound extractant and mixed solution The volume ratio is 1:11, extract at room temperature for 15 minutes, and obtain the first organic phase and the first raffinate; then, use the compound extractant to carry out the second extraction treatment on the first raffinate, the compound extractant and the mixed solution The volume ratio is 1:1, and the extraction time is 20min to obtain the second organic phase and the second raffinate; finally, using stripping agent H 2 SO 4 A solution with a mass concentration of 10% is used for stripping the first organic phase, and the volume ratio of the stripping agent used to the first organic...

Embodiment 2

[0052] The difference between the extraction method provided by the present embodiment and embodiment 1 is:

[0053] The molar ratio of phenolic extractant to acidic extractant is 1:0.1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com