Fuel additive for increasing fuel oil efficiency and manufacturing method thereof

A technology of fuel efficiency and manufacturing method, applied in the field of fuel additive and its manufacturing, can solve the problems of reduced willingness of consumers to use, complicated manufacturing and high cost, and achieve the effects of improving fuel efficiency, reducing air pollution and economic cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

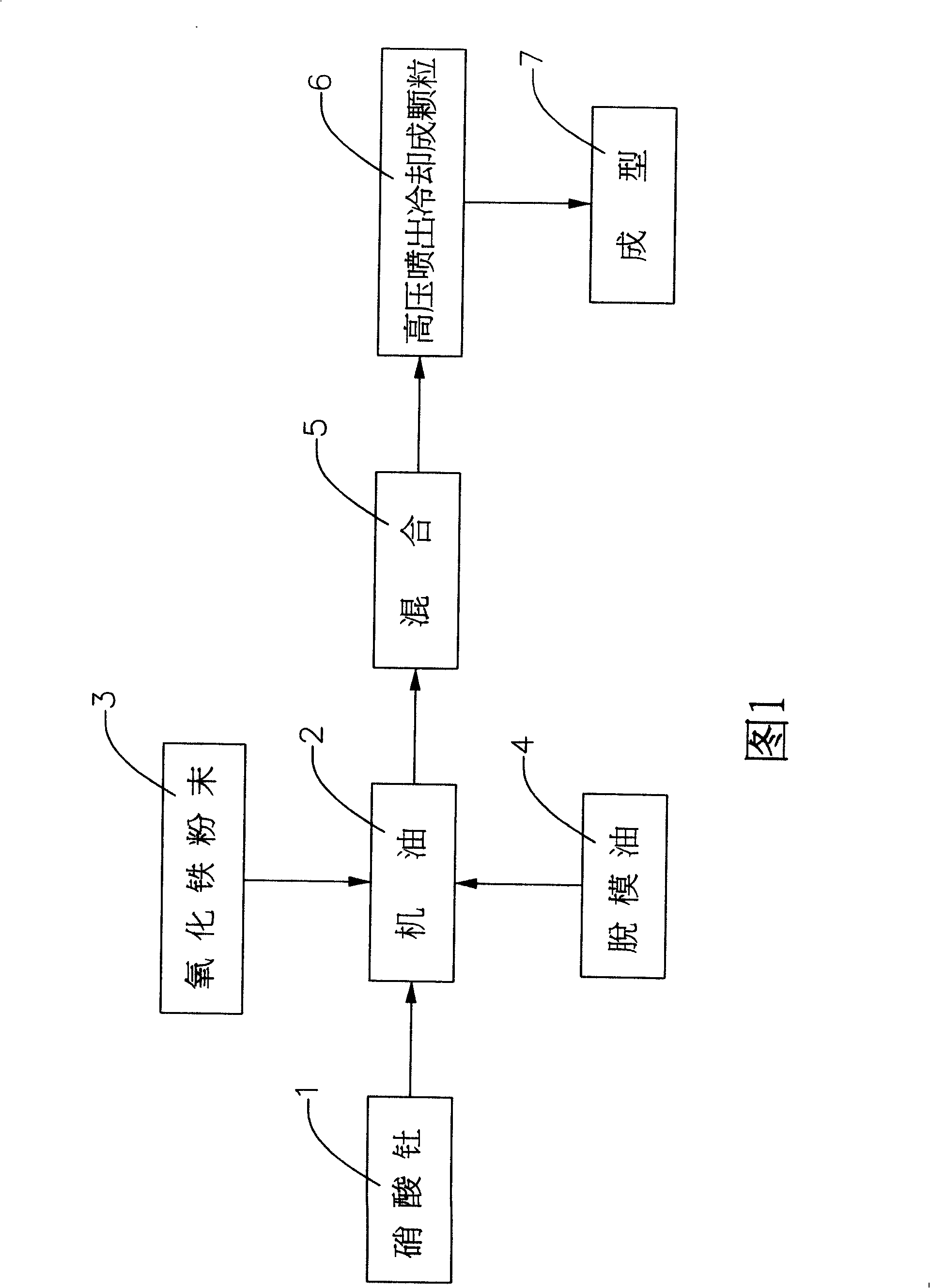

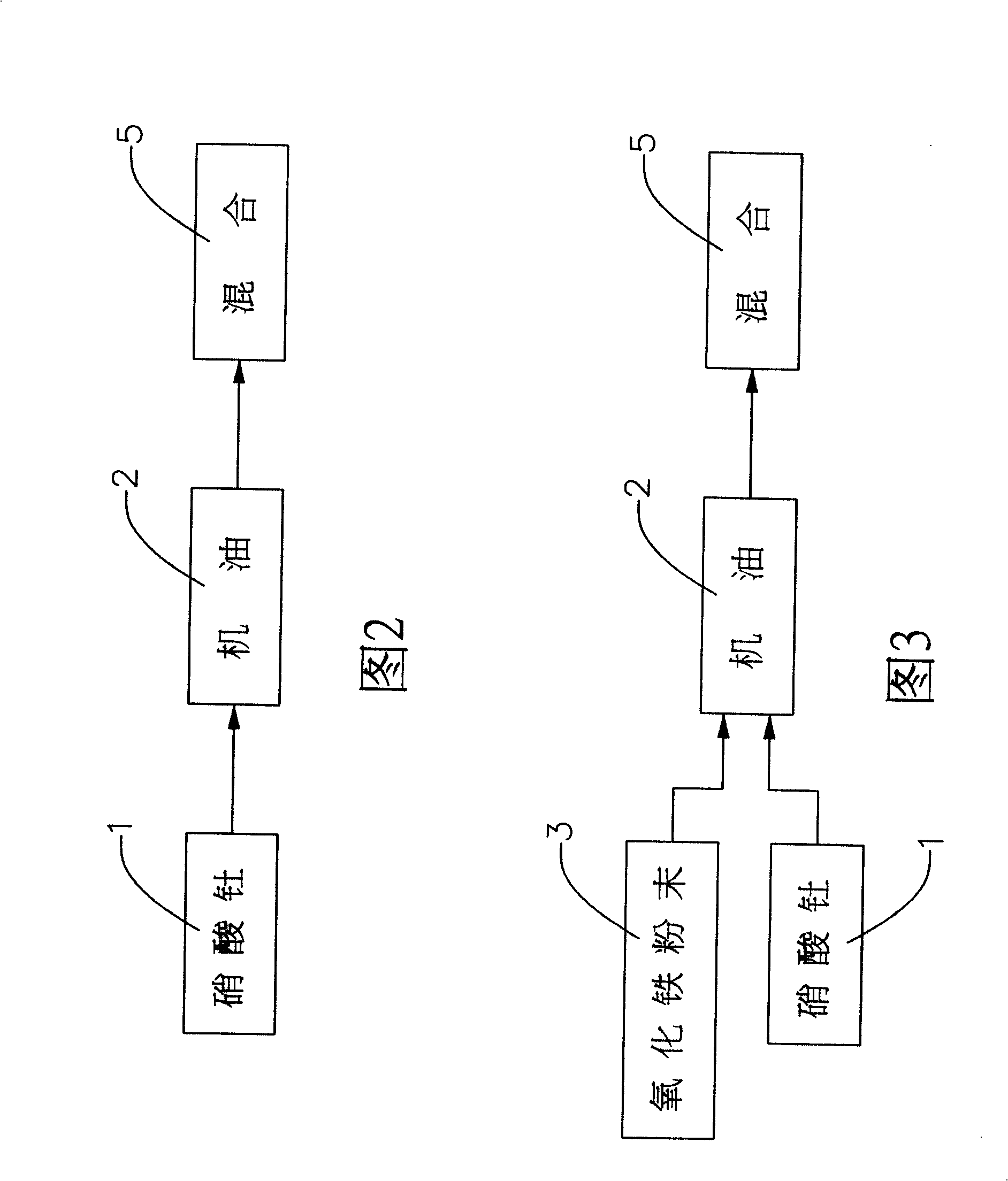

[0020] Please refer to Fig. 1, the composition and manufacturing method of the fuel additive for improving fuel efficiency of the present invention is mainly to mix 500 grams of thorium nitrate 1 with 1000 grams of engine oil 2, and at the same time, add 200 grams of gram release oil 4 and mix uniformly, then add 10000 gram iron oxide powder 3 (iron powder) and mix to homogeneous state, then carry out the program of high-pressure spraying and cooling into granule 6, produce instant cooling and form granule, the formed The small granular material is put into the molding machine and pressurized7 to form particles of the required size, and then form the required fuel additive, and the far-infrared radiation energy generated by the thorium nitrate1 can catalyze the fuel, And make the fuel molecules smaller to increase octane quality, and achieve the purpose of improving fuel efficiency.

[0021] Wherein the machine oil 2 is used as the mixing of the aforementioned thorium nitrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com