Preparation method for spherical thorium dioxide nano material with sheet-shaped surface structure and spherical thorium dioxide particles obtained from preparation method

A thorium dioxide, surface structure technology, applied in chemical instruments and methods, nanotechnology, inorganic chemistry and other directions, to achieve the effects of good reproducibility, low cost, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]A preparation method of a spherical thorium dioxide nanomaterial with a sheet-like surface structure is carried out according to the following steps:

[0036] S1, add 2mmol Th(NO 3 ) 4 ·6H 2 O was dissolved in 10ml of deionized water under stirring at room temperature or under ultrasound, and stirred to form a uniform and transparent solution;

[0037] S2, 3mmol of urea (CO(NH 2 ) 2 ) was dissolved in 10ml of deionized water under stirring at room temperature or under ultrasonic, and stirred to form a uniform and transparent solution;

[0038] S3, transfer the thorium nitrate solution in step S1 and the urea solution in step S2 to a clean 100mL polytetrafluoro reactor, tighten the lid, and put on the outer tank;

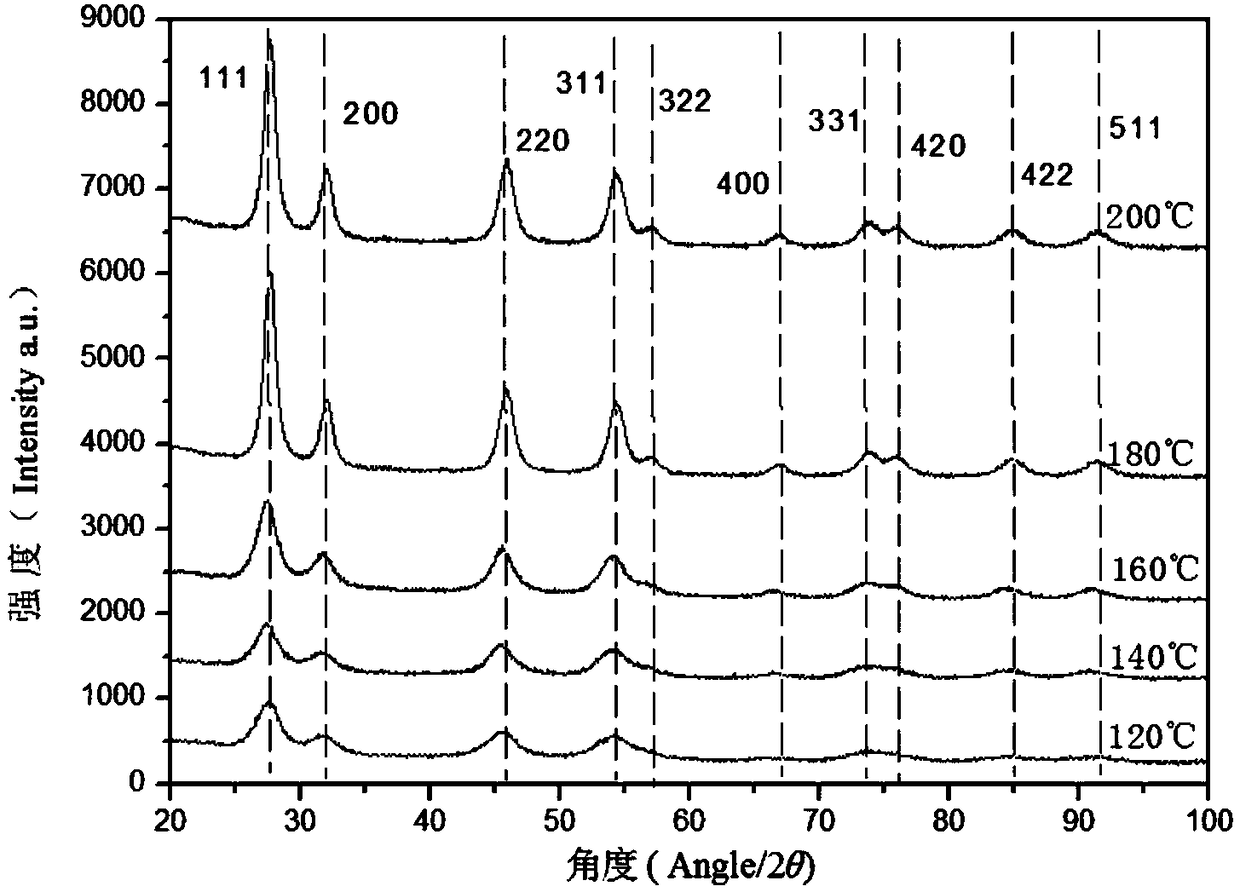

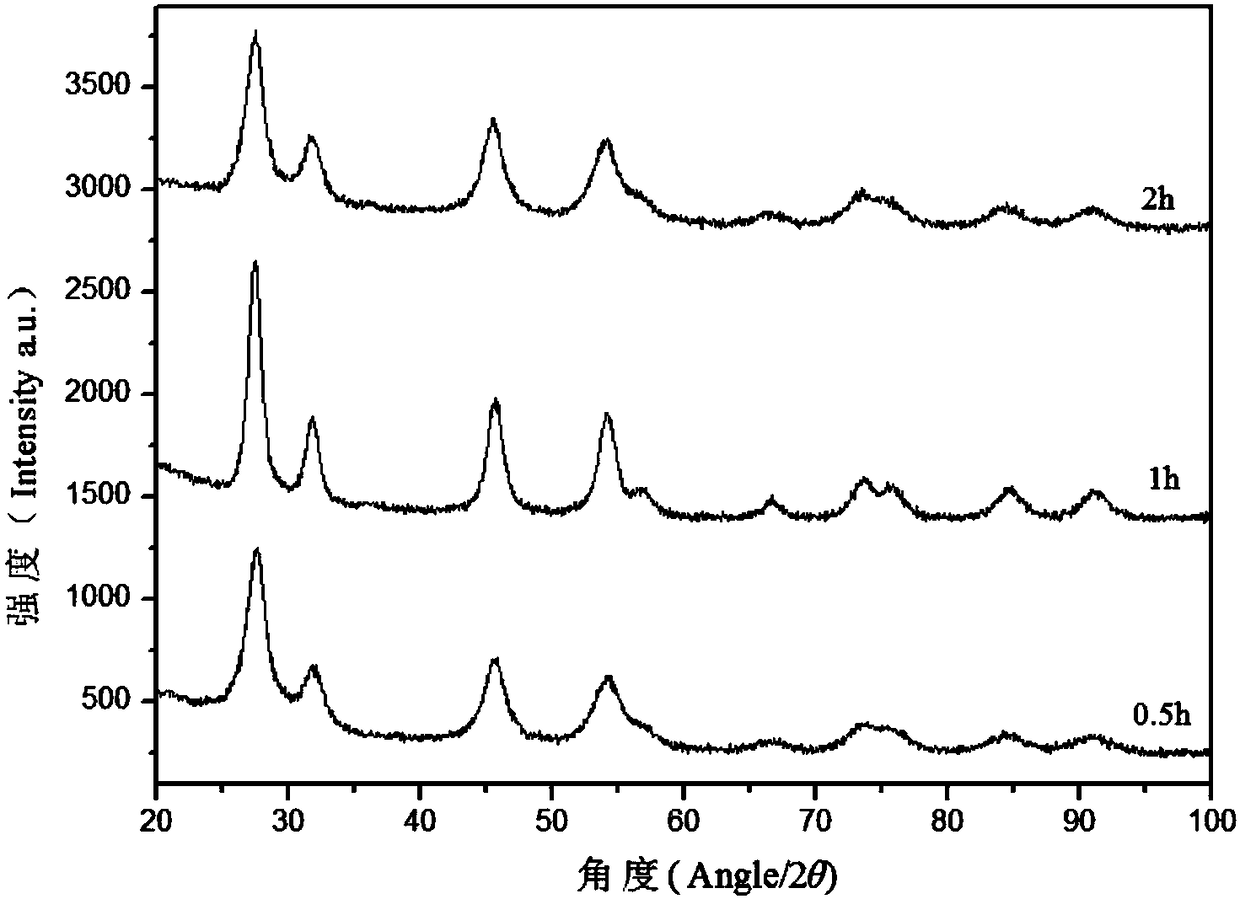

[0039] S4, the reactor in step S3 is placed in a microwave reactor, the reaction temperature is selected to be 180°C, the microwave power is 600W, and the reaction is heated for 60min; Washed twice with water and ethanol;

[0040] S5, drying the precipit...

Embodiment 2

[0043] A preparation method of a spherical thorium dioxide nanomaterial with a sheet-like surface structure is carried out according to the following steps:

[0044] S1, add 2mmol Th(NO 3 ) 4 ·6H 2 O was dissolved in 10ml of deionized water under stirring at room temperature or under ultrasound, and stirred to form a uniform and transparent solution;

[0045] S2, 3mmol of urea (CO(NH 2 ) 2 ) was dissolved in 10ml of deionized water under stirring at room temperature or under ultrasonic, and stirred to form a uniform and transparent solution;

[0046] S3, transfer the thorium nitrate solution in step S1 and the urea solution in step S2 to a clean 100mL polytetrafluoro reactor, tighten the lid, and put on the outer tank;

[0047] S4, the reactor in step S3 is placed in a microwave reactor, the reaction temperature is selected to be 200°C, the microwave power is 400W, and the reaction is heated for 60 minutes; after the reaction is completed, cool down, collect the microwave...

Embodiment 3

[0050] A preparation method of a spherical thorium dioxide nanomaterial with a sheet-like surface structure is carried out according to the following steps:

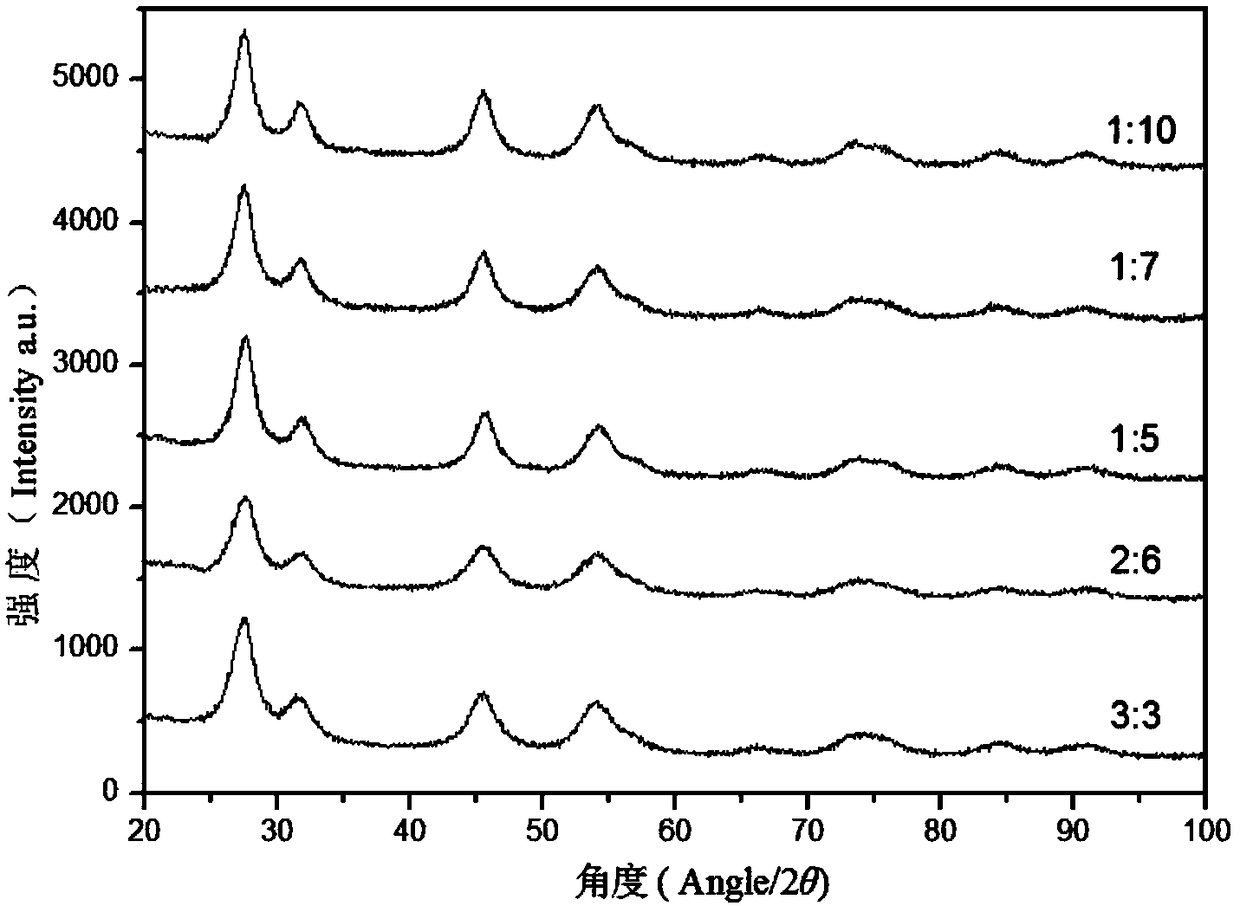

[0051] S1, add 3mmol Th(NO 3 ) 4 ·6H 2 O was dissolved in 10ml of deionized water under stirring at room temperature or under ultrasound, and stirred to form a uniform and transparent solution;

[0052] S2, 3mmol of urea (CO(NH 2 ) 2 ) was dissolved in 10ml of deionized water under stirring at room temperature or under ultrasonic, and stirred to form a uniform and transparent solution;

[0053] S3, transfer the thorium nitrate solution in step S1 and the urea solution in step S2 to a clean 100mL polytetrafluoro reactor, tighten the lid, and put on the outer tank;

[0054] S4, the reactor in step S3 is placed in a microwave reactor, the reaction temperature is selected to be 180°C, the microwave power is 800W, and the reaction is heated for 60min; Washed 3 times with water and ethanol;

[0055] S5, the precipitate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com