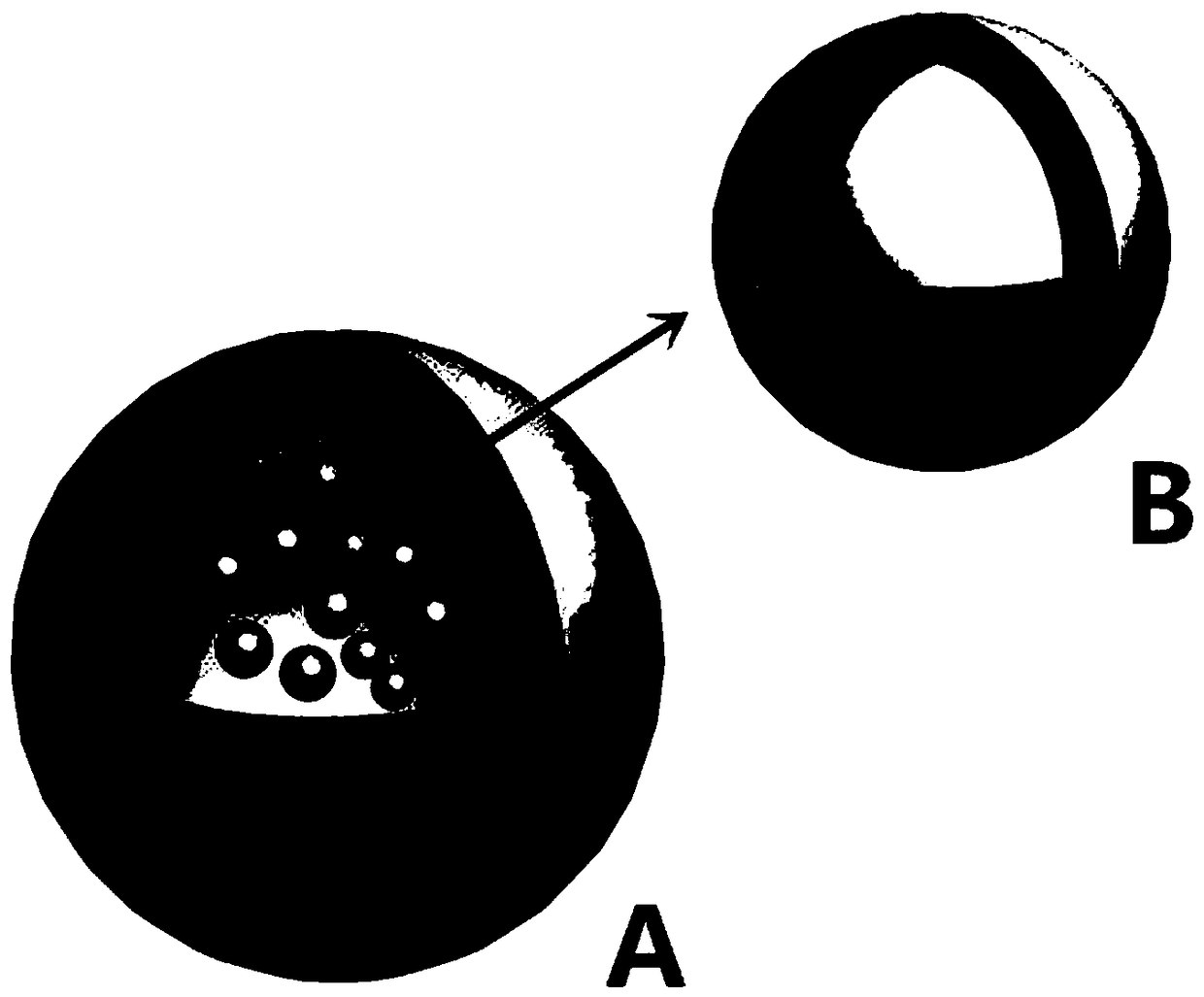

Outer-repairing and inner-curing type graphene functionalization self-repairing microcapsule with cellular structure and preparation method of self-repairing microcapsule

A technology of self-healing microcapsules and cellular structures, which can be applied in the direction of microcapsule preparation, microsphere preparation, coating, etc., and can solve the problems of narrow application range of self-healing systems, poor thermochemical stability of microcapsules, and expensive graphene oxide, etc. , to improve the self-repair efficiency, the modification method is simple and easy to operate, and the effect of improving the repair efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

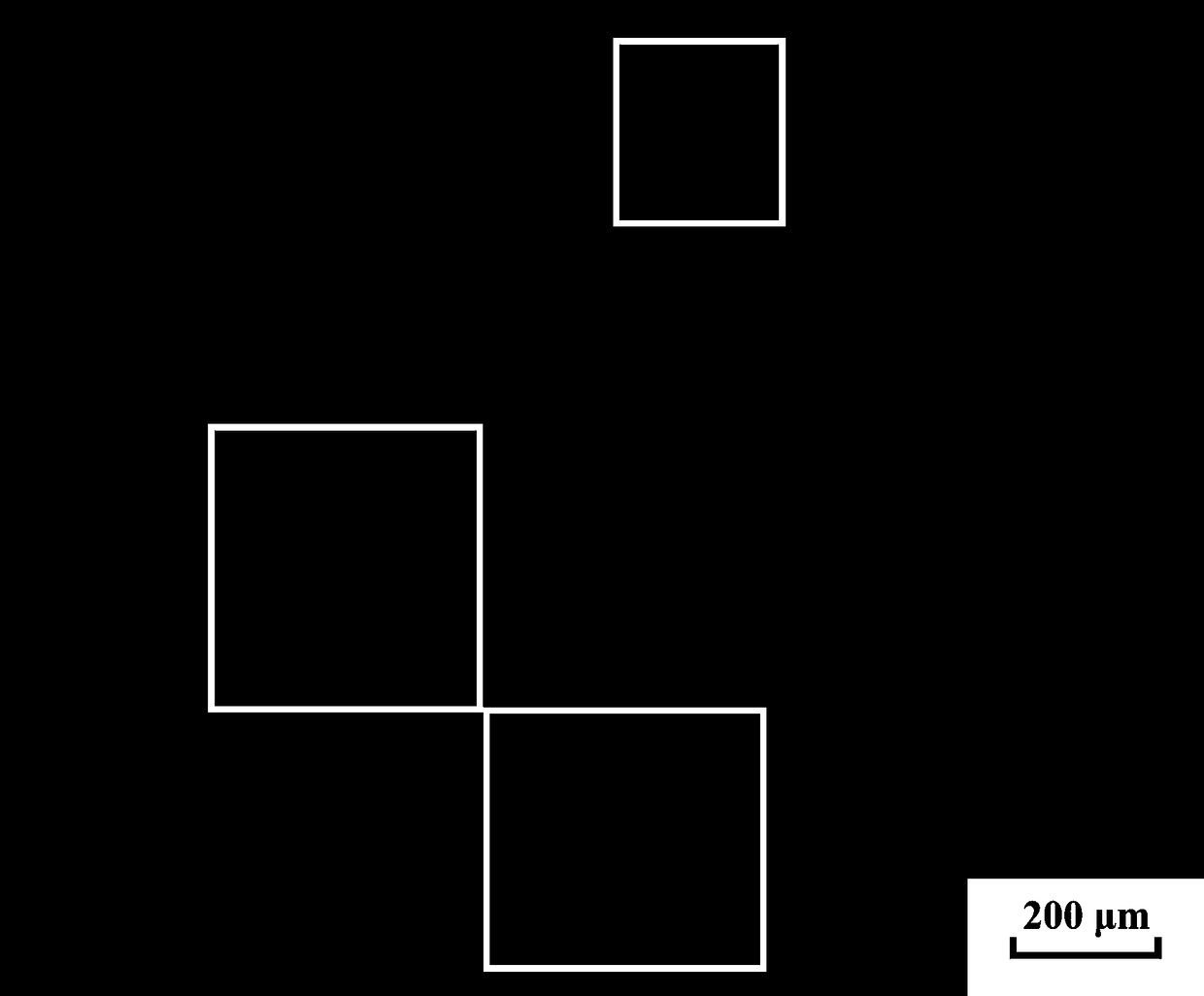

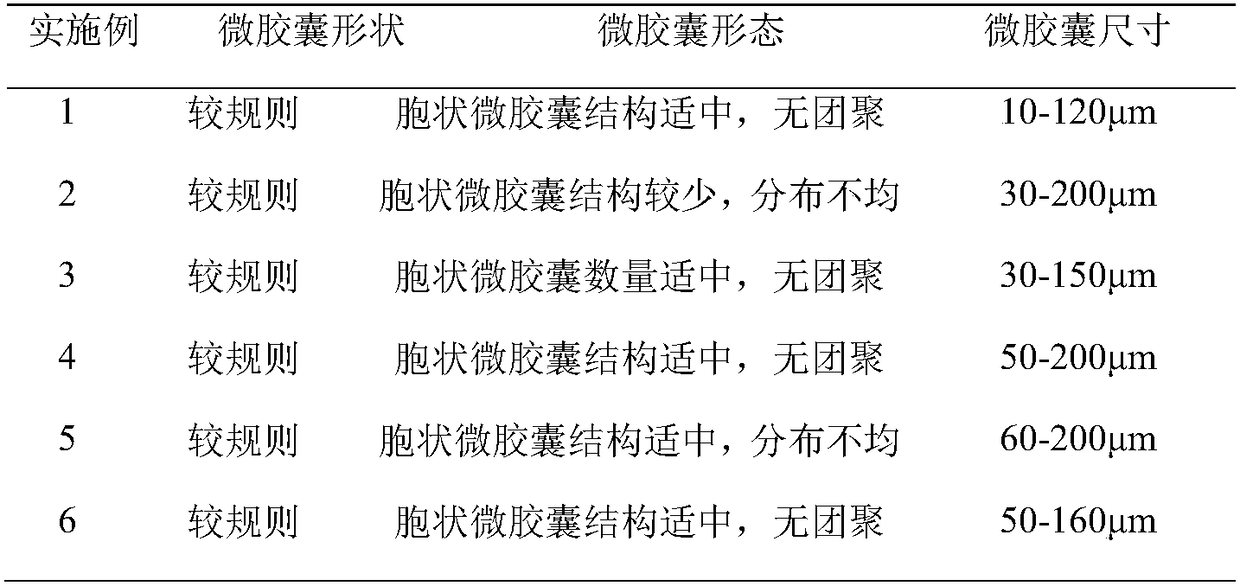

Examples

Embodiment 1

[0040] The preparation method of the externally repaired and internally solidified graphene functionalized self-repairing microcapsules with a cellular structure comprises the following steps:

[0041] (1) Preparation of oil-in-water silane emulsion 1:

[0042] (1a) Weigh an appropriate amount of silane, emulsifier and dispersant, the weight ratio of silane, emulsifier and dispersant is 80:1:1, stir at room temperature at a speed of 2000rpm for 30min to obtain a uniformly dispersed oil phase; the silane It is vinyltriethoxysilane, the emulsifier is Op-10, and the dispersant is polyethylene glycol.

[0043] (1b) Weigh an appropriate amount of emulsifier Op-10 and water, the weight ratio of emulsifier and water is 1:110, and stir at 1400rpm at room temperature for 26min to obtain a composite water phase;

[0044] (1c) Gradually drop the oil phase into the water phase, the weight ratio of the oil phase to the water phase is 1:1.2, and stir at 7000rpm at 44°C for 4h to obtain a u...

Embodiment 2

[0057] Different from Example 1, the preparation method of the externally repaired and internally solidified graphene functionalized self-repairing microcapsules with a cellular structure comprises the following steps:

[0058] (1) Preparation of oil-in-water silane emulsion 1:

[0059] (1a) Weigh an appropriate amount of silane, emulsifier and dispersant, the weight ratio of silane, emulsifier and dispersant is 100:2:1, and stir at room temperature for 26min at a speed of 2400rpm to obtain a uniformly dispersed oil phase; the silane It is vinyltrimethoxysilane, the emulsifier is polyvinyl alcohol, and the dispersant is potassium citrate.

[0060] (1b) Weigh an appropriate amount of emulsifier polyvinyl alcohol and water, the weight ratio of emulsifier and water is 1:120, and stir at 1800rpm at room temperature for 22min to obtain a composite water phase;

[0061] (1c) Gradually drop the oil phase into the water phase, the weight ratio of the oil phase to the water phase is 1...

Embodiment 3

[0074] Different from Example 1, the preparation method of the externally repaired and internally solidified graphene functionalized self-repairing microcapsules with a cellular structure comprises the following steps:

[0075] (1) Preparation of oil-in-water silane emulsion 1:

[0076] (1a) Weigh an appropriate amount of silane, emulsifier and dispersant, the weight ratio of silane, emulsifier and dispersant is 120:2.5:1, and stir at room temperature for 22min at a speed of 2800rpm to obtain a uniformly dispersed oil phase; the silane It is isobutyltriethoxysilane, the emulsifier is sodium dodecylbenzenesulfonate, and the dispersant is sodium linoleate. .

[0077] (1b) Take an appropriate amount of emulsifier sodium dodecylbenzenesulfonate and water, the weight ratio of emulsifier and water is 1:105, and stir at 2200rpm at room temperature for 20min to obtain a composite water phase;

[0078] (1c) Gradually drop the oil phase into the water phase, the weight ratio of the oi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com