Soybean filament drawing protein vegetarian ham and preparation method thereof

A technology for soybean drawing protein and vegetarian ham, which is applied in the field of food and food processing, can solve the problems of product quality decline, increase production process, reduce ductility, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

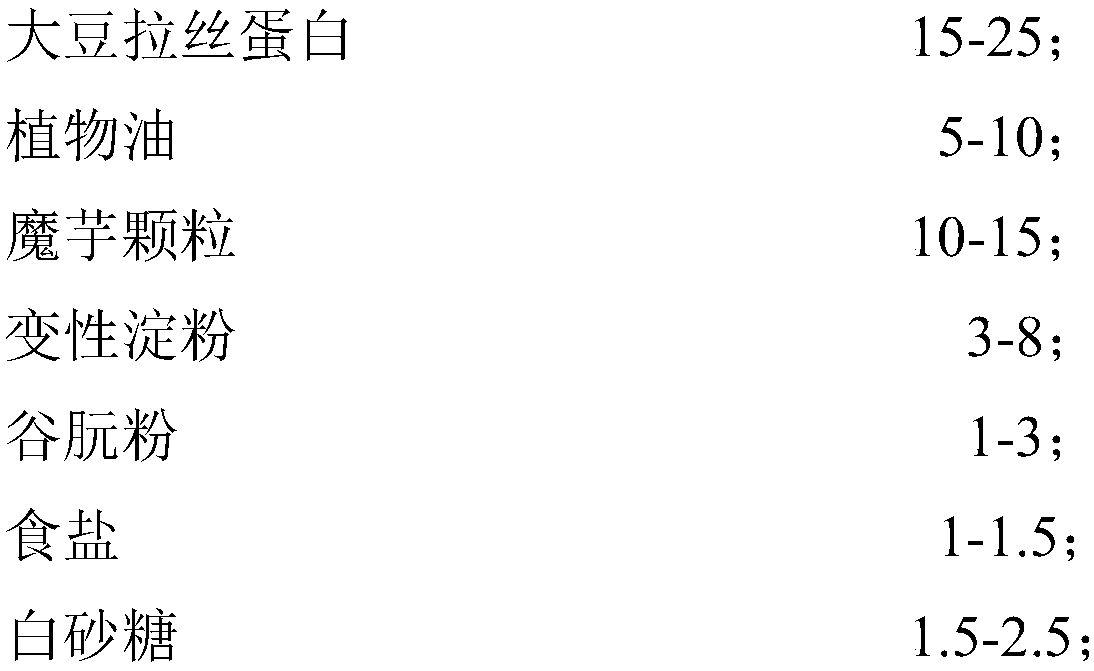

[0107] A soybean-drawn protein vegetarian ham is made from the following raw materials in parts by weight:

[0108]

[0109] The preparation method is as follows:

[0110] (1) Preparation of Konjac Granules:

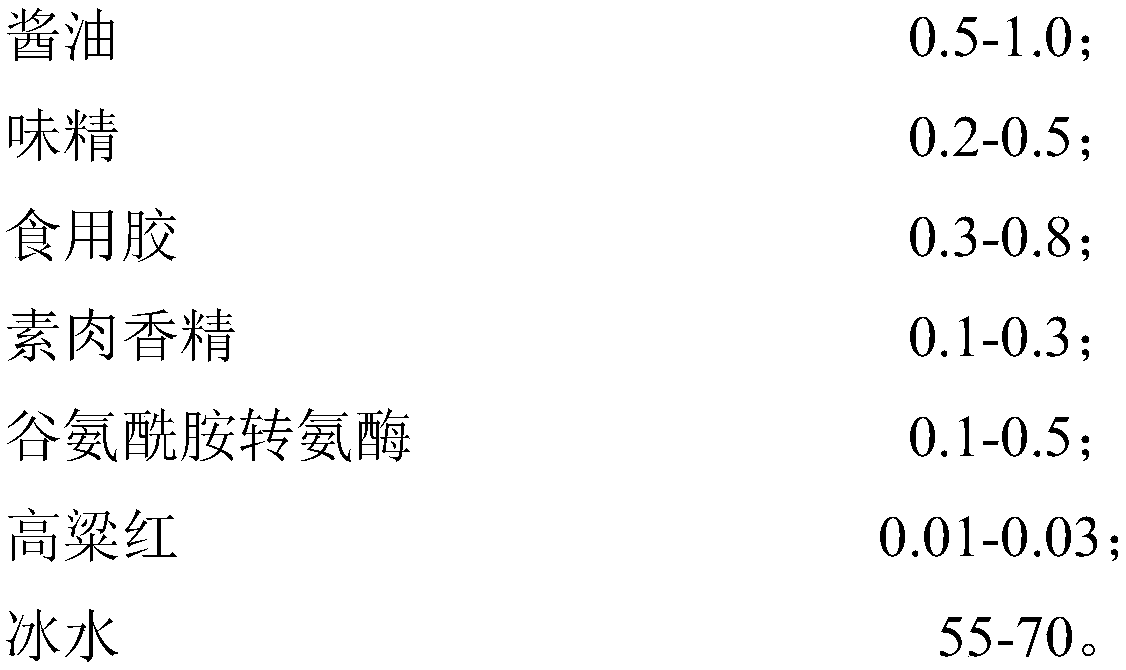

[0111] ①Hydration: put 85 parts by weight of normal temperature water into the chopping pot, and the chopping knife runs at a speed of 150r / min. At the same time, slowly add 4 parts by weight of konjac powder. After 30s, increase the speed of the chopping knife to 3500r / min and then Continue chopping and mixing for 3 minutes until the konjac powder is fully dissolved;

[0112] ② Mixing: When the hydration is about to end, adjust the chopping knife speed to 300r / min, add 1 weight part of cornstarch, 0.15 weight part of sodium alginate and 0.010 weight part of silicon dioxide at the same time, chop and mix until there is no dry powder, continue to After chopping and stirring for 3 minutes under the condition of 3500r / min, an emulsion was obtained;

[0113] ③Swelling ...

Embodiment 2

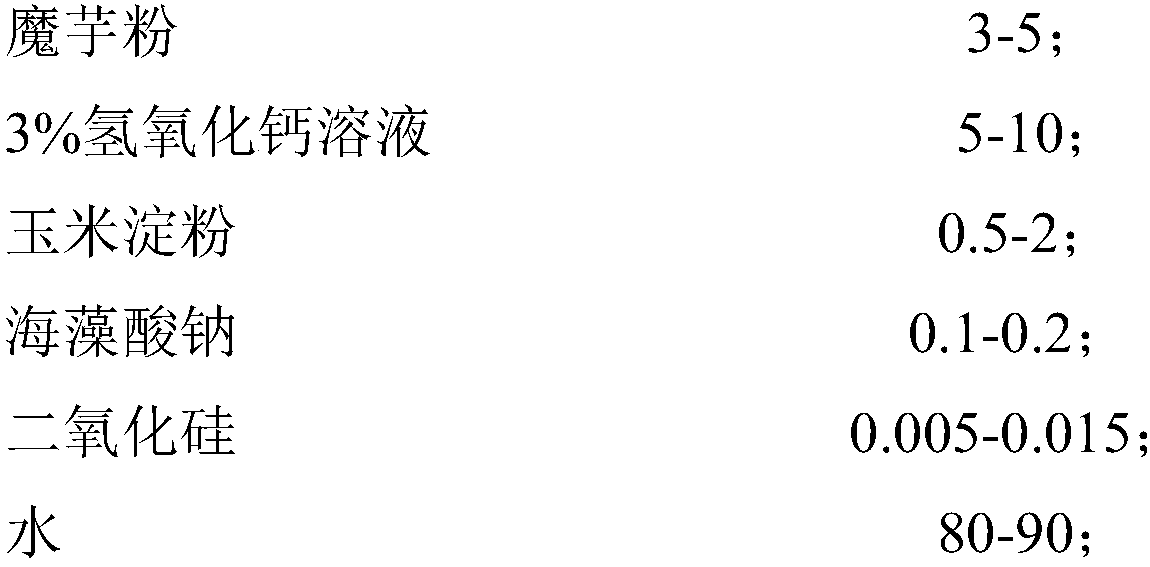

[0130] A soybean-drawn protein vegetarian ham is made from the following raw materials in parts by weight:

[0131]

[0132]

[0133] The preparation method is as follows:

[0134] (1) Preparation of Konjac Granules:

[0135] ①Hydration: put 85 parts by weight of normal temperature water into the chopping pot, and the chopping knife runs at a speed of 150r / min. At the same time, slowly add 4 parts by weight of konjac powder. After 30s, increase the speed of the chopping knife to 3500r / min and then Continue chopping and mixing for 3 minutes until the konjac powder is fully dissolved;

[0136] ② Mixing: When the hydration is about to end, adjust the chopping knife speed to 300r / min, add 1 weight part of cornstarch, 0.15 weight part of sodium alginate and 0.010 weight part of silicon dioxide at the same time, chop and mix until there is no dry powder, continue to After chopping and stirring for 3 minutes under the condition of 3500r / min, an emulsion was obtained;

[0137...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com