Resonant cavity for verifying wood microwave pretreatment temperature distribution

A temperature distribution and resonant cavity technology, applied in microwave heating, heating devices, dryers, etc., can solve the problems of high wood cracking rate, unimprovable temperature distribution, unsatisfactory temperature distribution uniformity, etc., and achieve low wood cracking rate , Good uniformity of temperature distribution, microwave can evenly disperse the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

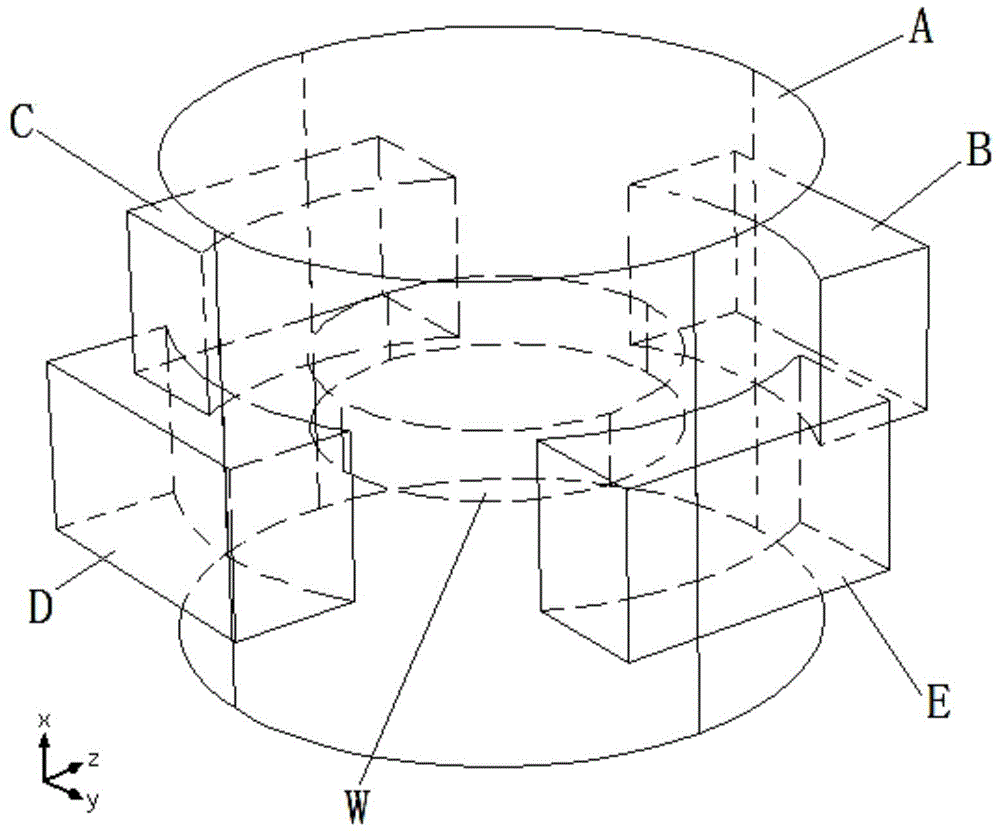

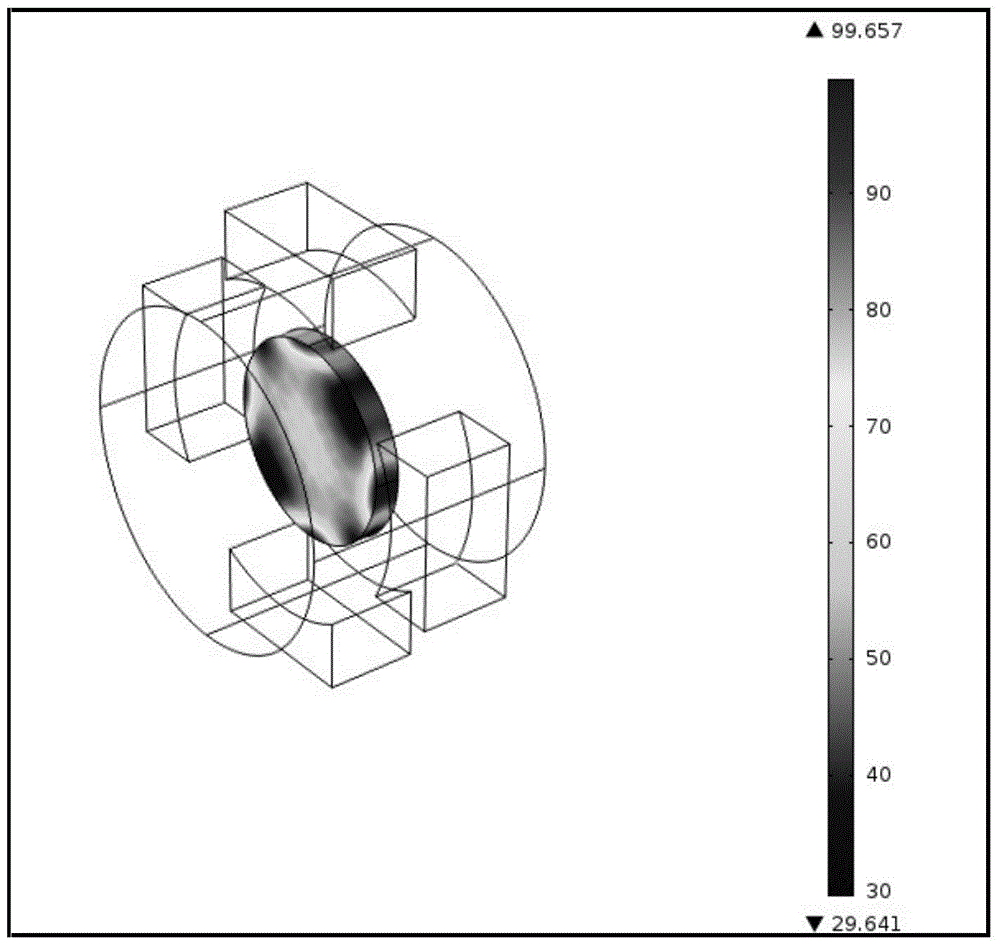

[0029] like figure 1 As shown, the resonant cavity used in this embodiment to verify the temperature distribution of wood microwave pretreatment includes a horizontally arranged main resonant cavity A, and at least one feed-in waveguide is provided on the side of the main resonant cavity A, and the main resonant cavity and the feed-in waveguide The feed-in waveguides are arranged horizontally along the direction outward from the center of the main resonant cavity A, and both end faces of the feed-in waveguides are hollow openings. see figure 1 , in this embodiment, W represents the wood placed in the center of the main resonator A.

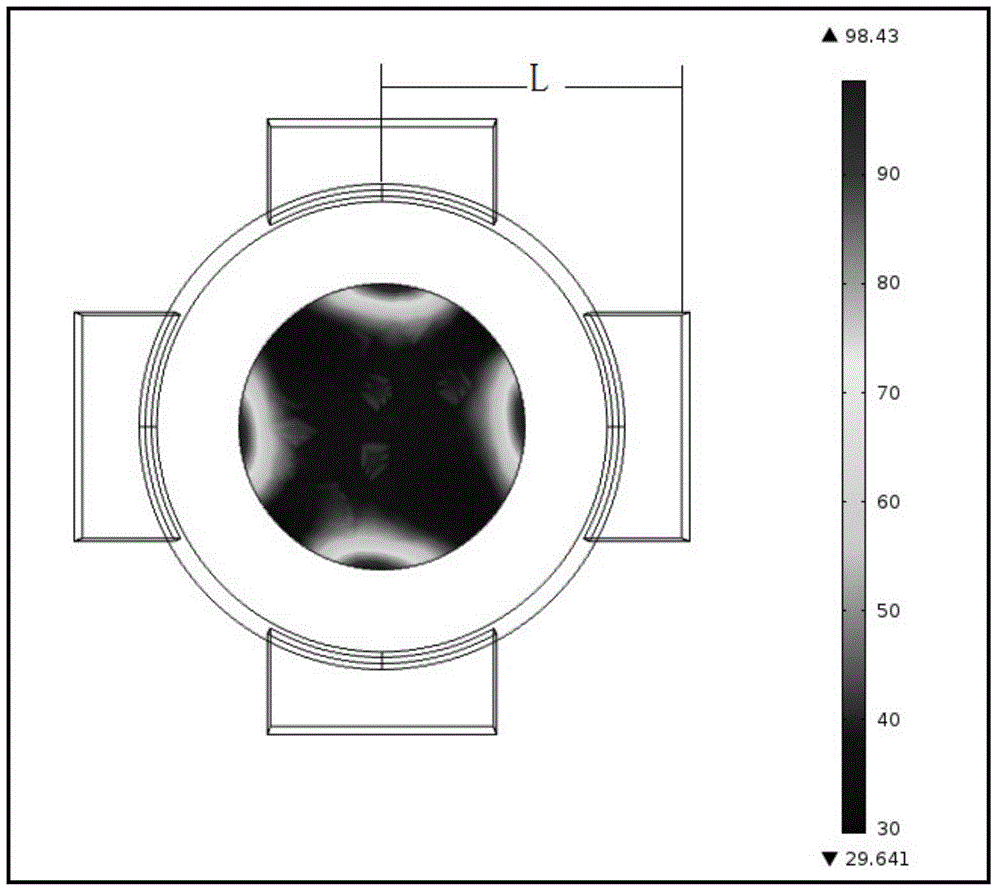

[0030] like figure 1 As shown, the cross-section of the feed-in waveguide is rectangular, and the length of the rectangle is arranged along the horizontal direction, and the width of the rectangle is arranged along the vertical direction. The distance L between the centers of A (see image 3 The mark in ) is greater than 1.1 times the length o...

Embodiment 2

[0082] The basic structure of this embodiment is the same as that of the first embodiment, and the main difference is that the number of feed-in waveguides is different.

[0083] like Figure 4 As shown, the number of feed-in waveguides in this embodiment is three (see B, C, D in the figure), and the three feed-in waveguides B, C, and D are symmetrically arranged on the side of the main resonant cavity A .

[0084] In this embodiment, the finite element analysis software COMSOL Multiphysics is used for simulation, and the establishment of the electromagnetic field and microwave energy distribution model and the thermal migration model used to calculate the heat transfer inside the wood are exactly the same as those in the first embodiment. Finally, after the finite element analysis software COMSOL Multiphysics simulation calculation, the simulated temperature distribution on the surface of the wood W when the resonant cavity of this embodiment is used to heat is obtained as f...

Embodiment 3

[0086] The basic structure of this embodiment is the same as that of the first embodiment, and the main differences are: the shape of the main resonant cavity A and the number of feeding waveguides are different. And generally speaking, the wood W is placed at the center of the main resonant cavity A, and in order to achieve uniform distribution of microwaves, the shape of the wood W is related to the shape of the main resonant cavity A, for example, the shape of the wood W in this embodiment is a cuboid, It is different from the shape of the wood W in the first embodiment which is a cylinder.

[0087] like Figure 7 As shown, the shapes of the main resonator A and the feed-in waveguide in this embodiment are both cuboid, and the number of feed-in waveguides is two (see B and C in the figure), and the two feed-in waveguides B and C are respectively Symmetrically arranged on the side of the main resonant cavity A, that is: the feeding waveguide B is arranged on one side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com