Mortar-coated heat-preserving plate

A thermal insulation board and mortar technology, applied in thermal insulation, insulation improvement, building components, etc., can solve the problems of airgel fragility and water combination, airgel is easy to break, etc., to reduce hollowing, reduce cracking, Guarantee the effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

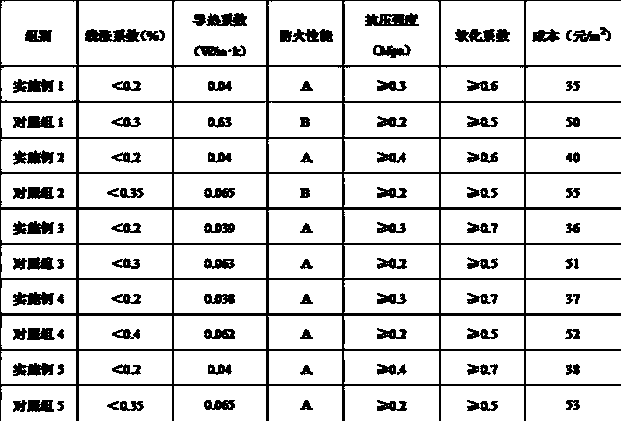

Embodiment 1

[0033] A surface-modified airgel thermal insulation mortar, comprising: 30 parts of Portland cement, 5 parts of brucite fiber, 20 parts of perlite, 0.2 part of hypromellose, 0.05 part of polypropylene fiber, calcium stearate 0.1 parts, 15 parts of modified airgel particles, 0.12 parts of additives;

[0034] Among them, the auxiliary agent is a mixture of early strength agent, water reducer and regulator, 0.04 part of early strength agent, 0.04 part of water reducer, and 0.04 part of regulator;

[0035] A surface modifier for surface modification of airgel particles, comprising the following components in parts by weight: 0.5 parts of sodium silicate aqueous solution, 0.5 parts of organic silicon surfactant, and 2 parts of water; aqueous sodium silicate solution, organic silicon surface The active agent and water are uniformly mixed to form a surface modifier, and the surface of the airgel is sprayed three times, and the modified airgel particles are obtained after drying; the ...

Embodiment 2

[0037] A surface-modified airgel thermal insulation mortar, comprising: 40 parts of Portland cement, 10 parts of brucite fiber, 30 parts of perlite, 0.4 part of hypromellose, 0.2 part of polypropylene fiber, calcium stearate 1 part, 25 parts of modified airgel particles, 0.99 parts of additives;

[0038] Among them, the auxiliary agent is a mixture of early strength agent, water reducing agent and regulator, 0.33 parts of early strength agent, 0.33 parts of water reducing agent, and 0.33 parts of regulator;

[0039] The surface modifier for surface modification of airgel particles includes the following components in parts by weight: 1 part of sodium silicate aqueous solution, 1 part of organic silicon surfactant, and 4 parts of water; aqueous sodium silicate solution, organic silicon surface The active agent and water are uniformly mixed to form a surface modifier, and the surface of the airgel is sprayed three times to obtain modified airgel particles after drying; the weight ...

Embodiment 3

[0041] A surface-modified airgel thermal insulation mortar, comprising: 33 parts of Portland cement, 7 parts of brucite fiber, 23 parts of perlite, 0.3 part of hypromellose, 0.1 part of polypropylene fiber, calcium stearate 0.5 parts, 17 parts of modified airgel particles, 0.3 parts of additives;

[0042] Among them, the auxiliary agent is a mixture of early strength agent, water reducer and regulator, 0.1 part of early strength agent, 0.1 part of water reducer, and 0.1 part of regulator;

[0043] The surface modifier for surface modification of airgel particles includes the following components in parts by weight: 0.7 parts of sodium silicate aqueous solution, 0.7 parts of organic silicon surfactant, 3.2 parts of water; aqueous sodium silicate solution, organic silicon surface The active agent and water are evenly mixed to form a surface modifier, and the surface of the airgel is sprayed three times, and the modified airgel particles are obtained after drying; the weight rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com