Patents

Literature

56 results about "Stonelayer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A stonelayer, or soil stonelayer, or stone line, is a three-dimensional subsurface layer, or soil horizon, dominated by coarse particles (>2mm), that generally follows (mimics) the surface topography (Sharpe 1938). A stonelayer occupies the basal horizon of two-layered soil biomantles (Paton et al. 1995; Schaetzl and Anderson 2005; Fey 2009; Wilkinson et al. 2009). A stonelayer may be one stone thick, and thus appear in a trench or pit as a "stone line," or it may be several stones thick and appear as a "stone zone" (Johnson 1989). The gravel components of stonelayers may be compositionally variable, and while many are lithic clasts, often of quartzose composition, others may be metallic nodules and concretions of iron and manganese oxides, human artifacts, snail and clam shells (in highly calcareous soils), precious and semi-precious stones, or some combination thereof (Aleva 1983, 1987; Johnson 2002).

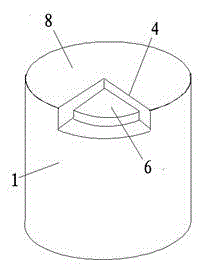

Cutting tool insert and drill bit so equipped

ActiveUS7730977B2Reducing and preferably eliminating and spalling and chipping typeImproved wear behaviorDrill bitsWorkpiecesLeading edgeMetallurgy

Owner:BAKER HUGHES INC

Hydroxyl apatite layer-wrapped photocatalytic nano titanium dioxide powder and application thereof

InactiveCN103551170AHas absorptionWith sterilizationPhysical/chemical process catalystsWater/sewage treatment by irradiationFiberBenzene

The invention provides photocatalytic powder capable of being applied to environment purifying and atmospheric pollutant governing. Each titanium dioxide particle is wrapped by a hydroxyl apatite layer, and holes with controllable size are formed in the hydroxyl apatite layer, so that target products such as formaldehyde and benzene are selectively degraded, and other larger molecules such as methyl orange are not damaged. The photocatalytic chemical powder can be extensively applied to various organic polymer setting products, especially organic fibers, plastic products or paint.

Owner:SKSHU PAINT

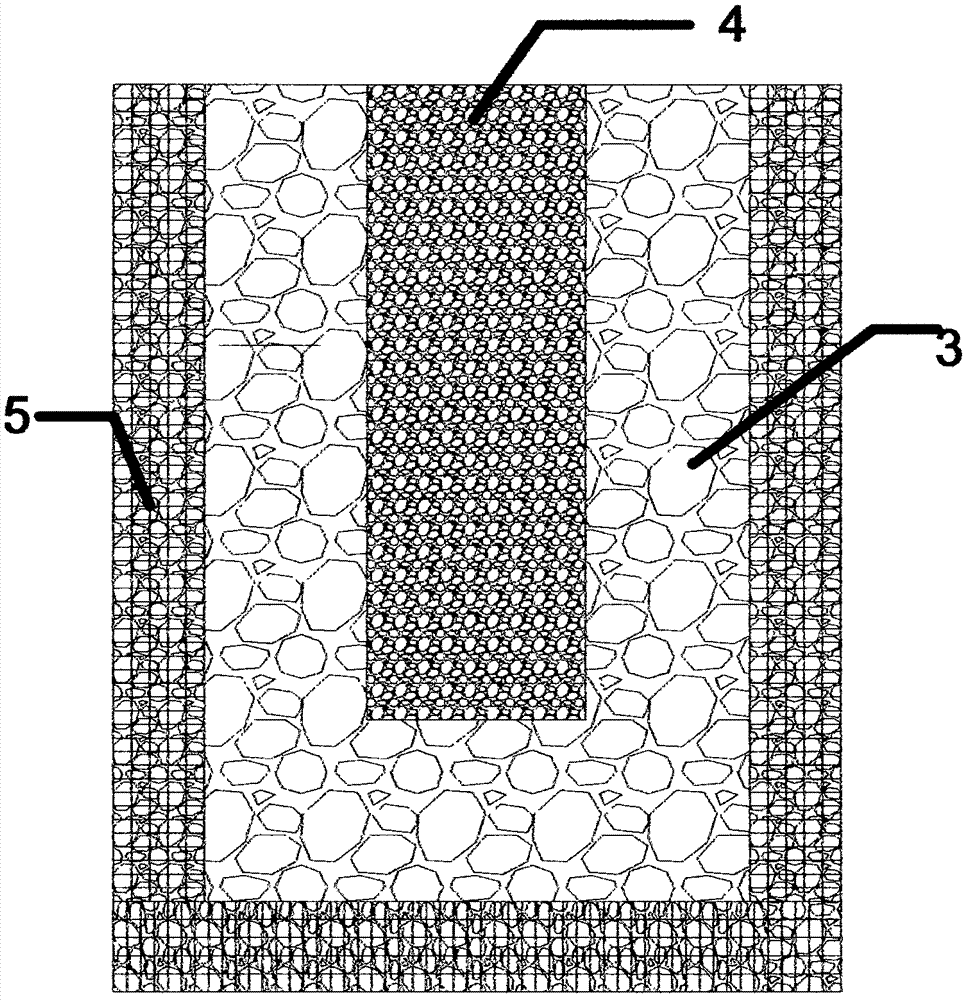

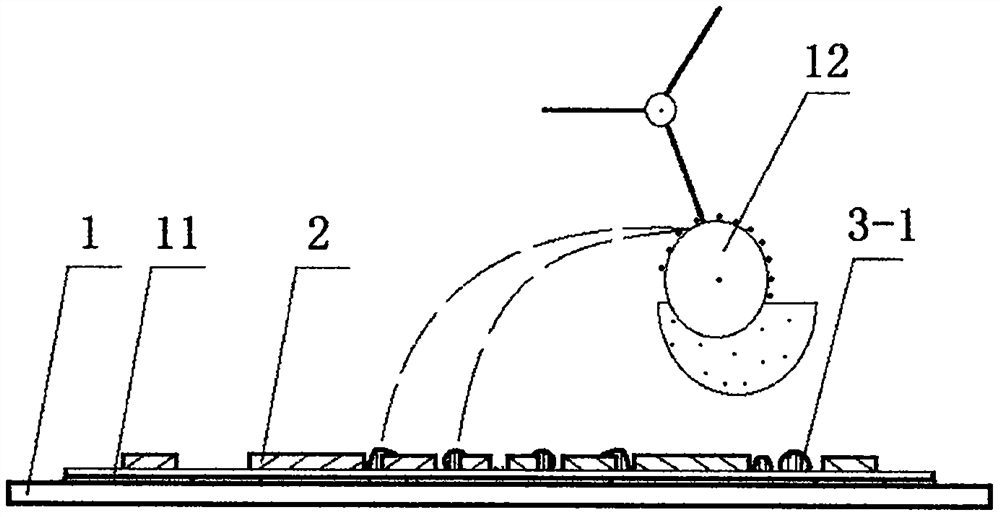

Sponge city drainage structure and sponge city water circulating method

InactiveCN110528351AIncrease profitSave waterGeneral water supply conservationPaving gutters/kerbsEngineeringWater circulation

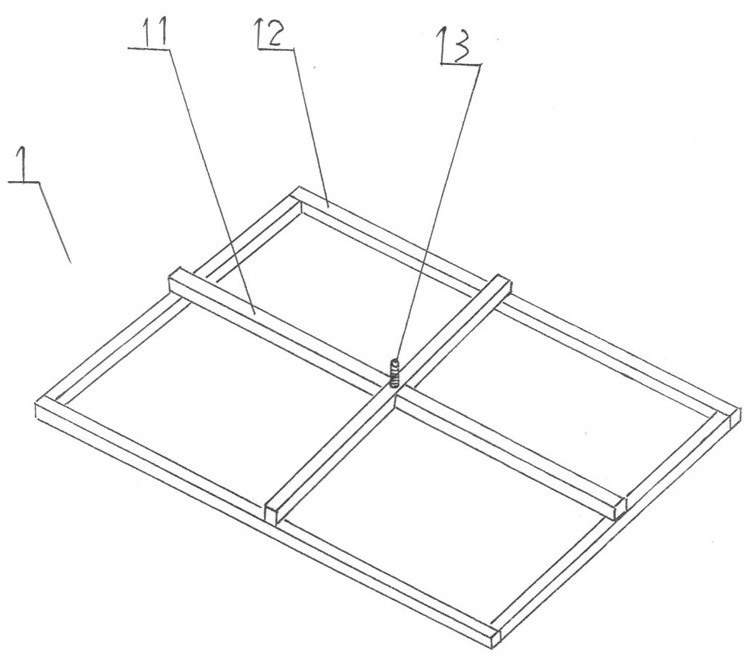

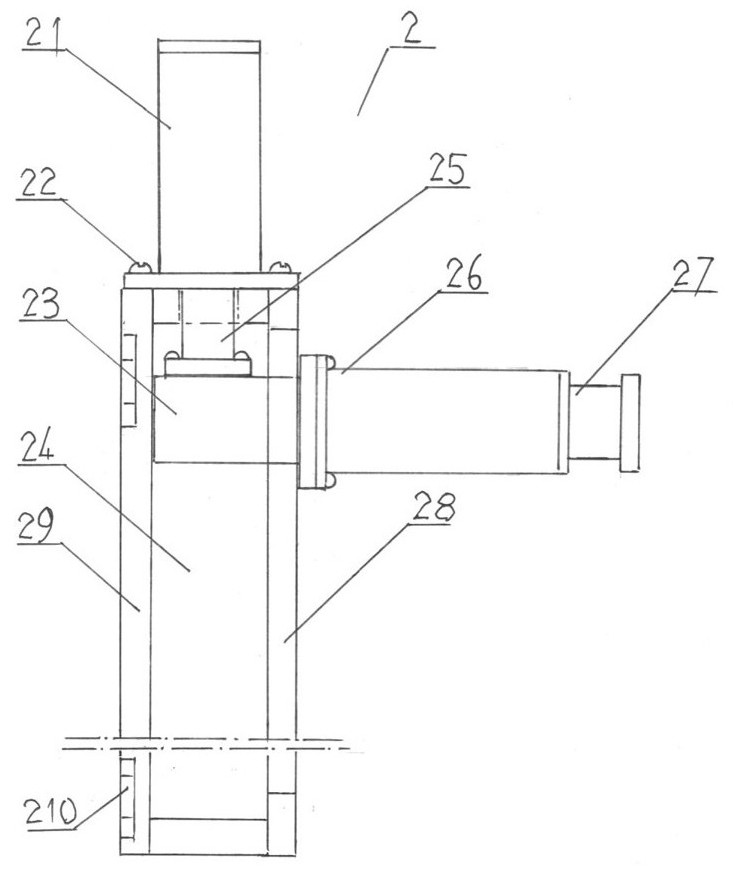

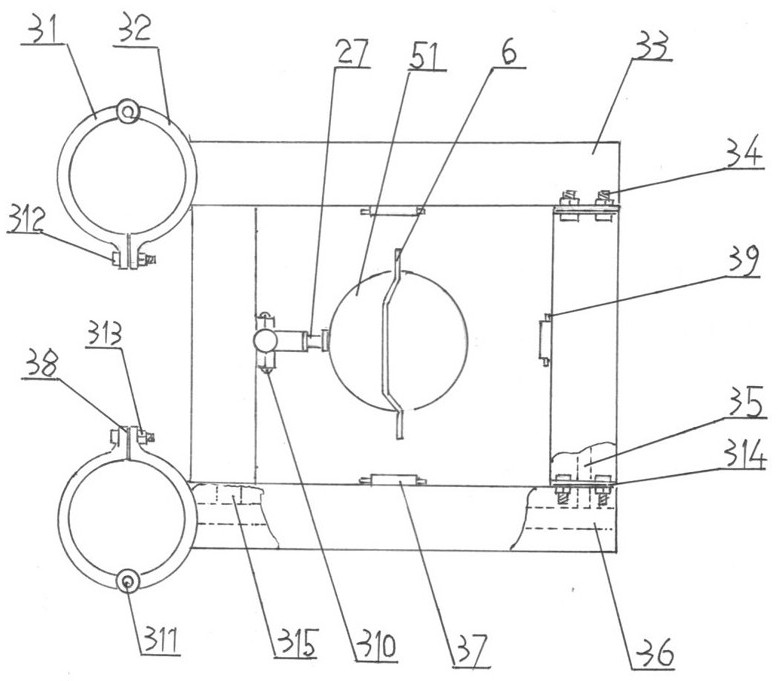

The invention relates to a sponge city drainage structure and a sponge city water circulating method. A road structure comprises a permeable concrete layer, a mortar leveling layer, a graded broken stone layer and a plain soil layer from top to bottom in sequence; support grids are arranged in the mortar leveling layer; a guide pipe for drainage is arranged in the graded broken stone layer; drainage ditches and road traffic stones are arranged on the two sides of the road layer structure; the drainage ditches are positioned between the road layer structure and the road traffic stones; drain pipes are arranged at the bottoms of the drainage ditches; water storage cavities are formed in the road traffic stones, and communicate with the drainage ditches through drainage holes; the other sides, relative to the drainage holes, of the water storage cavities communicate with green belts through permeable holes; the green belts comprise pebble beds, planting soil layers and green broken stonelayers in sequence from top to bottom; drainage pipes for drainage are arranged in the green broken stone layers; a water collecting pool is connected with a main pipe; and the guide pipe, the drain pipes and the drainage pipes communicate with the main pipe. The structure achieves the effects of reducing the city road ponding conditions and improving the rainwater utilization rate.

Owner:广东洋艺建设有限公司

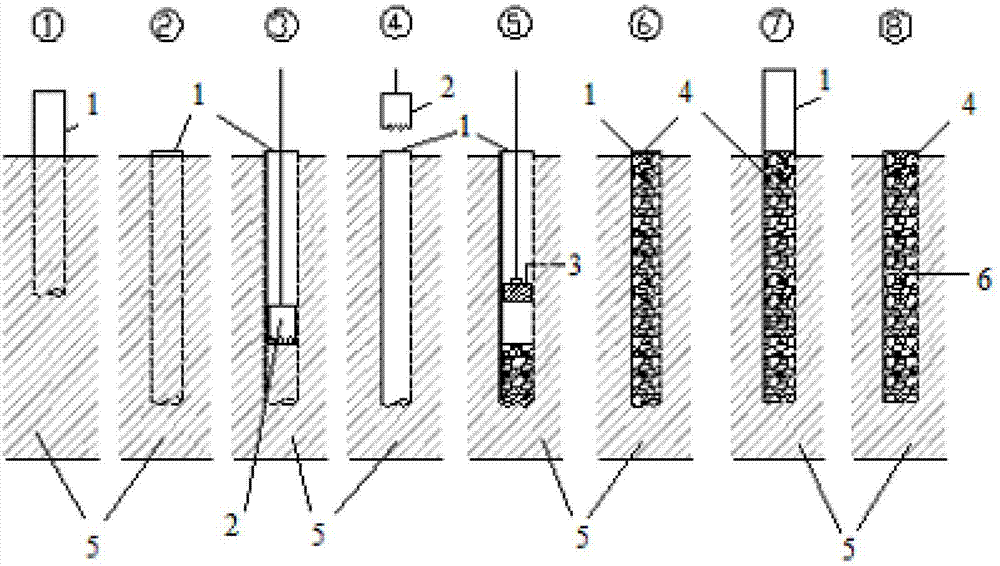

Construction method of large-diameter crushed stone pile

ActiveCN102888834AReduce penetration resistanceReduce equipment performance requirementsSoil preservationThin walledEngineering

Owner:SHANGHAI SHEN YUAN GEOTECHN +2

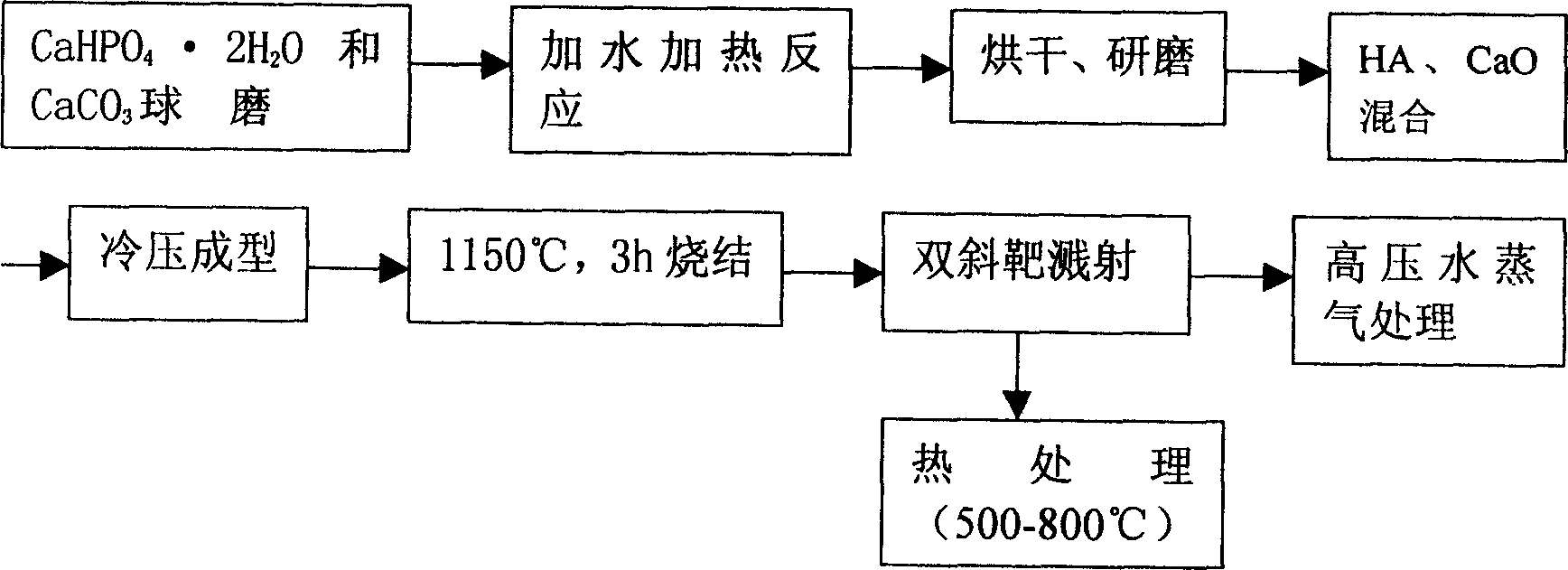

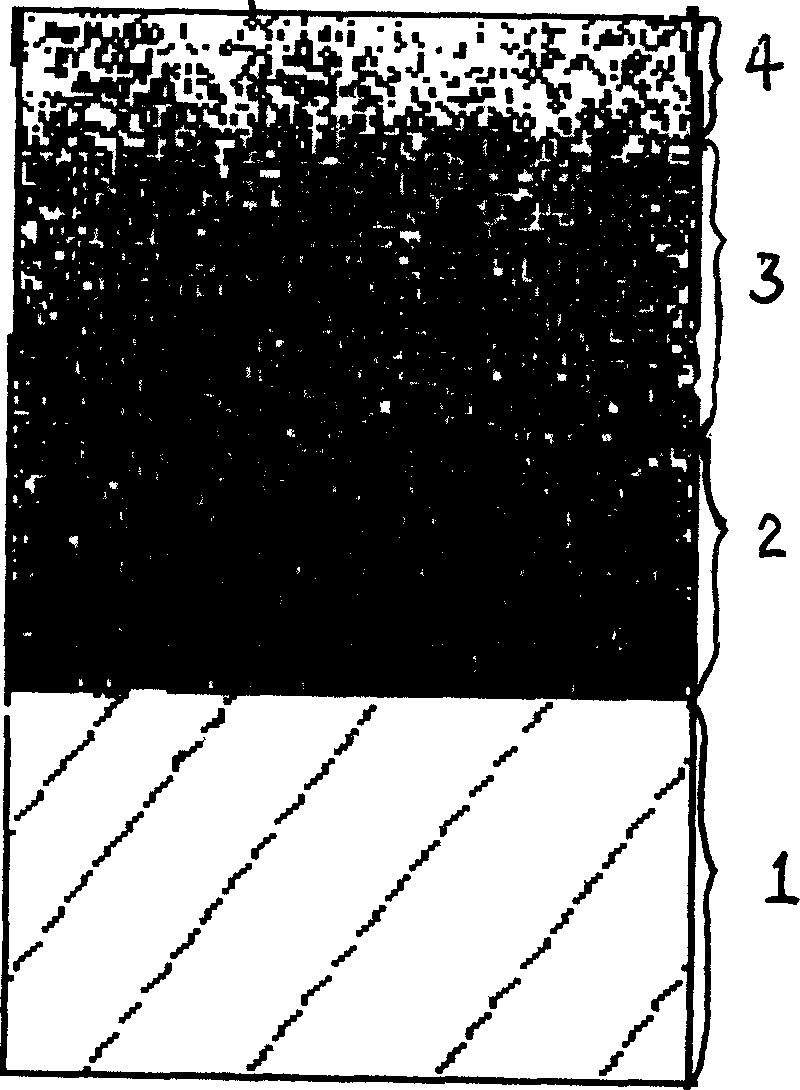

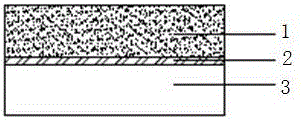

Method and product of sputtering and depositing bioactive gradient hydroxyapatite/Ti layer on Ti alloy surface

InactiveCN1487117AImprove stabilityWeakening interface mutationVacuum evaporation coatingSputtering coatingTitaniumBiological activation

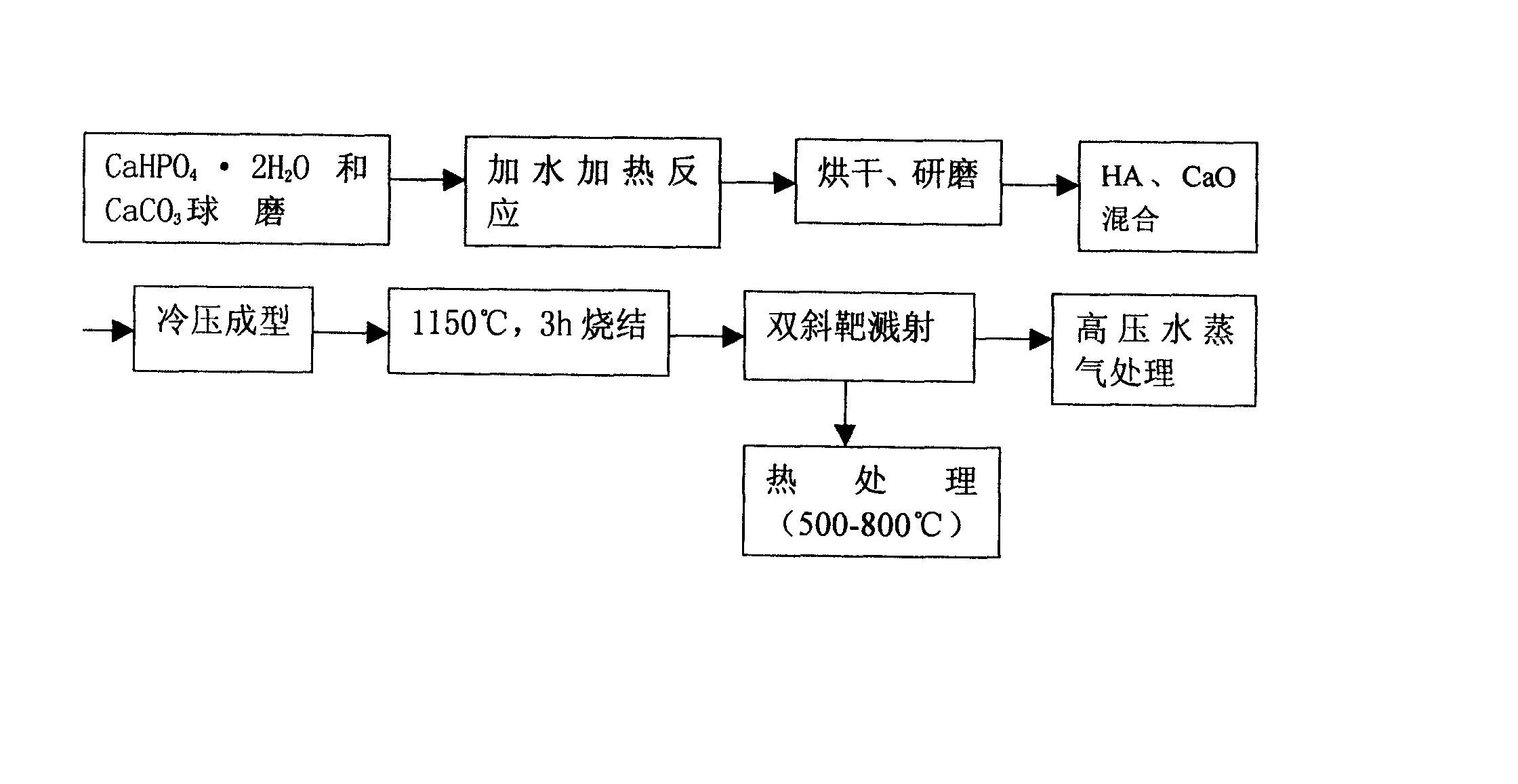

The method of sputtering and depositing bioactive gradient hydroxyapatite / Ti layer on Ti alloy surface includes the following steps: mixing and ball milling material powder; hydrothermal reaction; stoving and grinding; mixing target material; cold pressing at 200-300 MPa to form; sintering; double-inclined target sputtering; and heat treatment of the sputtered film. The product has multilayer structure of Ti alloy matrix, compact transition TiO2 layer I with dispersed hydroxyapatite, TiO2 reinforced transition hydroxyapatite layer II, and porous hydroxyapatite layer. The present invention realizes the double gradient of both component and structure, and raises the interface binding strength effectively. The present invention has simple film preparing process and homogeneous film thickness, is suitable for surface activation of implant with complicated shape, and can prepare hard tissue for clinical need, especially as bearing bone repairing and substituting material.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

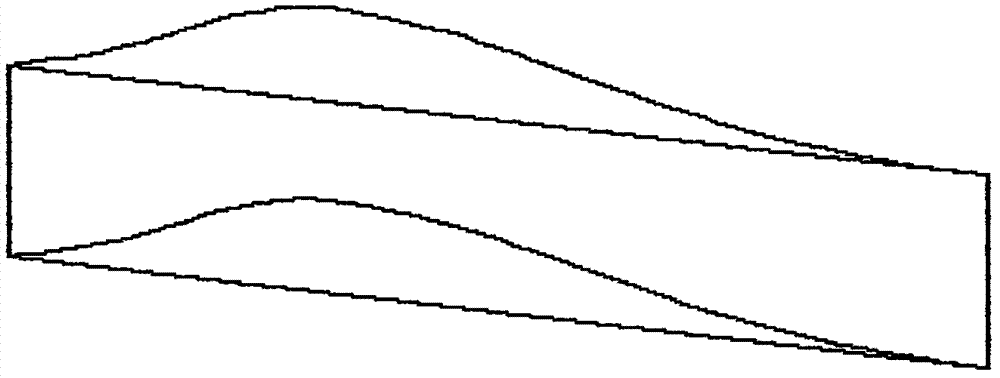

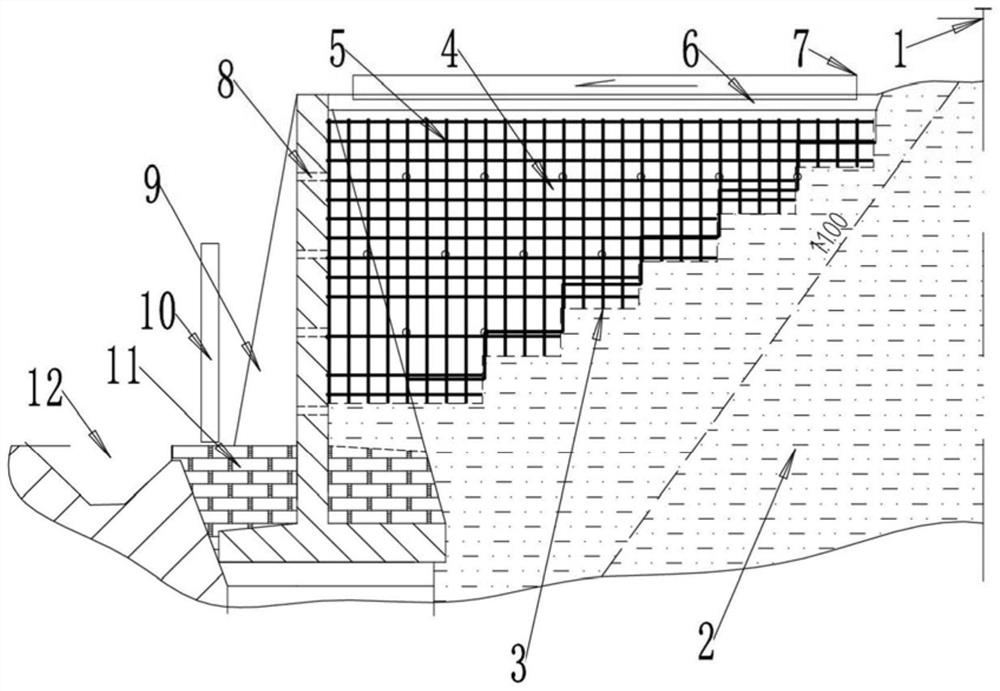

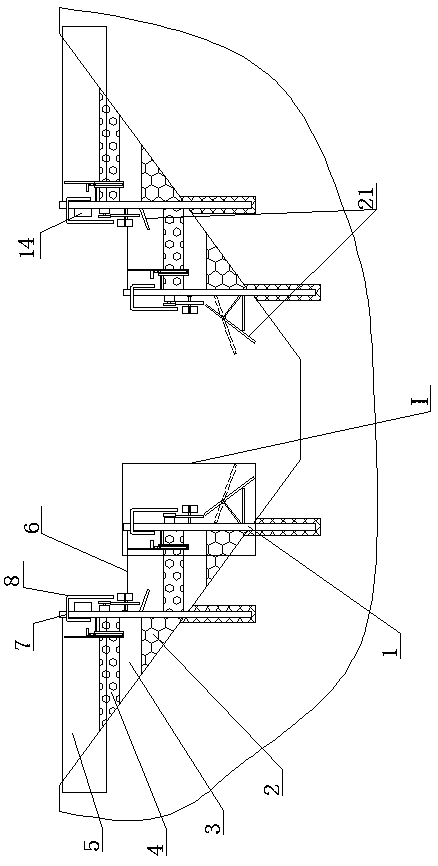

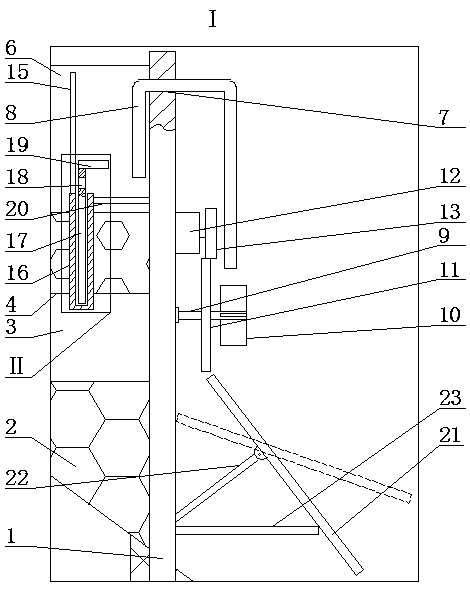

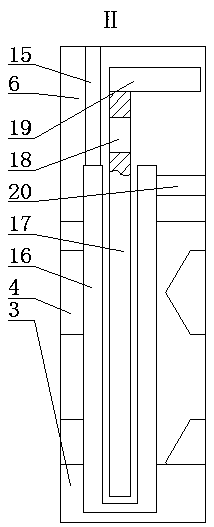

Anti-slide pile and frame arch combined structure and construction method

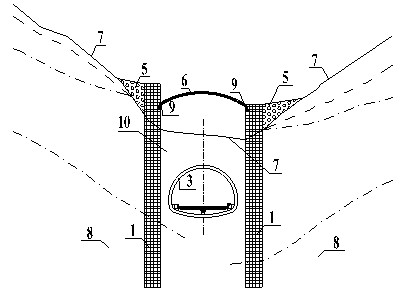

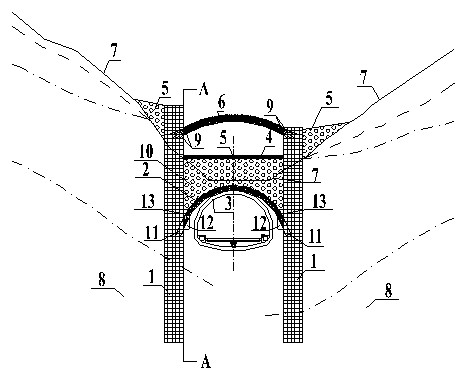

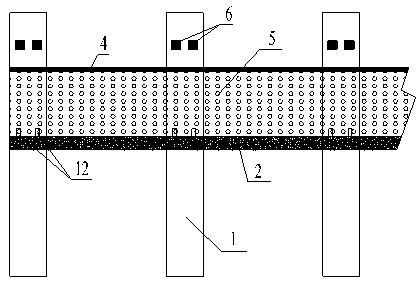

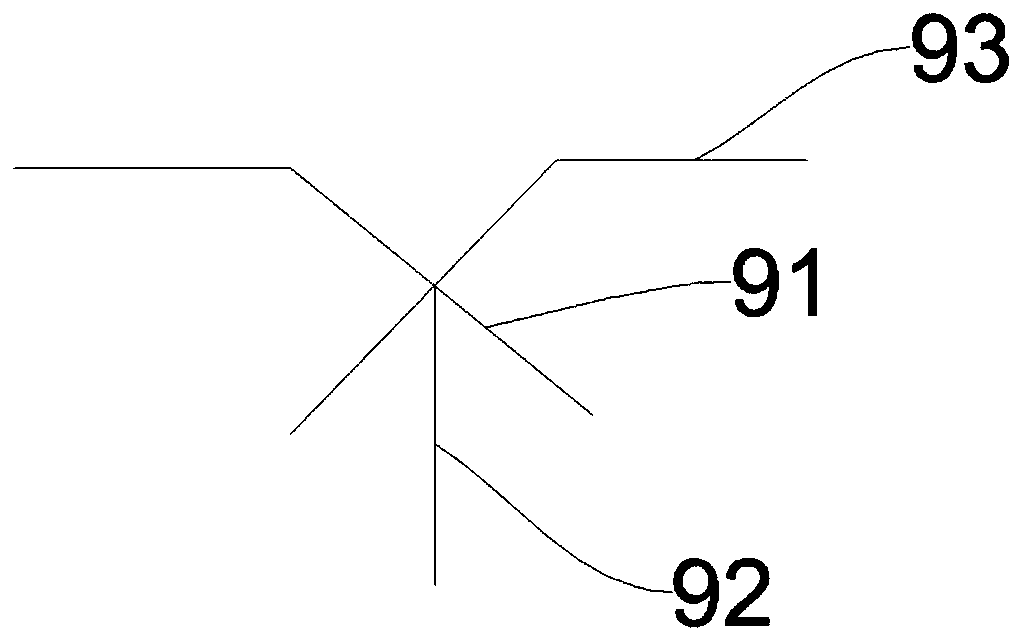

The invention discloses an anti-slide pile and frame arch combined structure and a construction method. The combined structure comprises anti-slide piles (1) arranged on two sides of a tunnel body in an embedded mode, and the anti-slide piles (1) extend to a stable base rock (8); a frame arch (6) is connected with the anti-slide piles (1) on the two sides; a guard arch (2) connected with I steels (11) of the pile bodies of the anti-slide piles (1) on the two sides is arranged above a tunnel arch ring (3); and the guard arch (2) is provided with a backfilled soil rock layer (5) in back of the piles. The combined structure is suitable for a pre-supporting reinforcement structure of a tunnel portal under a ditch heart terrain when thin soil is covered on the tunnel and the stability of slopes of two sides is poor or relatively poor; by a mode of combining the anti-slide piles, the frame arch and the guard arch into a whole, the stress performance of the anti-slide piles is greatly improved; and the slopes of the two sides of the ditch heart tunnel portal and the covered soil layer are integrally reinforced, so that digging and reinforcement of the slopes of the two sides of the ditch heart are reduced, stability and ecology of the original slopes are ensured, the reinforcing cost of the slopes of the two sides is saved, and the construction is simple.

Owner:CHONGQING UNIV

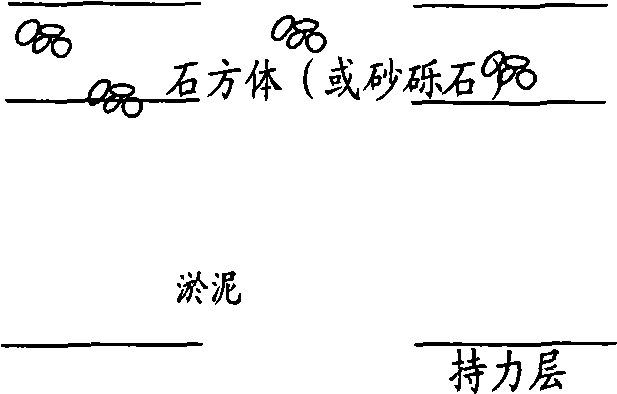

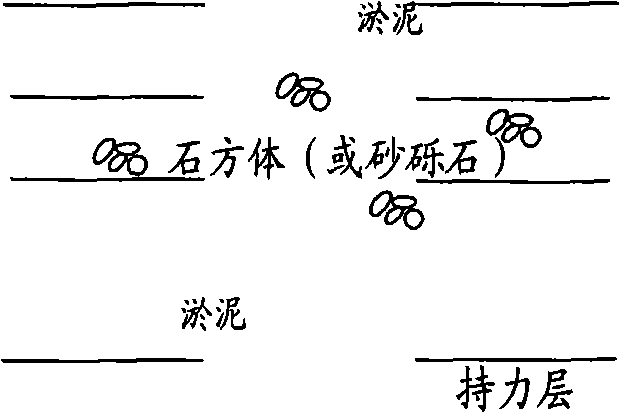

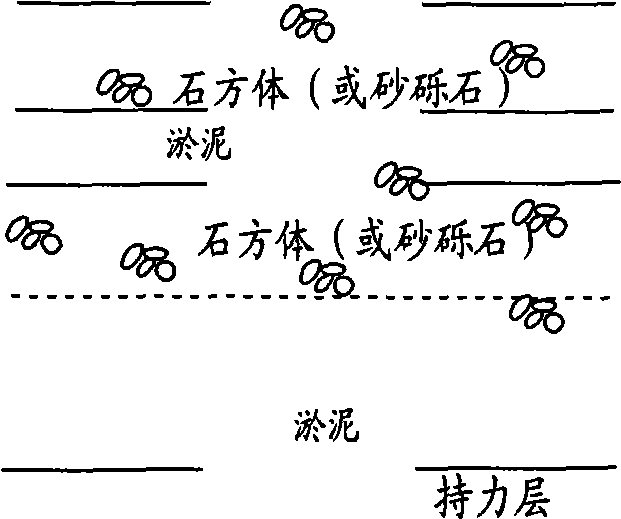

Method for embankment by blasting and silt squeezing on complex soft foundation

The invention discloses a method for embankment by blasting and silt squeezing on a complex soft foundation, which is characterized by: taking advantage of the characteristics of ocean tide rising and falling, using the depth of covering water instead of a resistance line in blasting, applying most energy onto the top face of the complex soft foundation, squeezing down the complex soft foundation, adopting the combined action of blasting at a dyke head or on two sides of a dyke and other various blasting modes at the same time, continuously squeezing down jackstones by using the gravity of the jackstone dyke body under the action of explosion shock to remove the silt soft foundation under the jackstones, allowing the stone layer of the dyke body to fall onto bottom to form a sea dyke cross-section meeting design requirements, allowing two sides of the dyke body to fall onto the ground completely with certain ground width, and ensuring the stability of the dyke body; and avoiding landslip frequently occurring in on-site backfill and direct random sea dyke fill, as well as increasing embankment construction speed, reducing cost by 50 to 90 percent and achieving considerable economic benefits compared with a processing method which is to first excavate soft foundation and then fill back.

Owner:宁波高新区围海工程技术开发有限公司

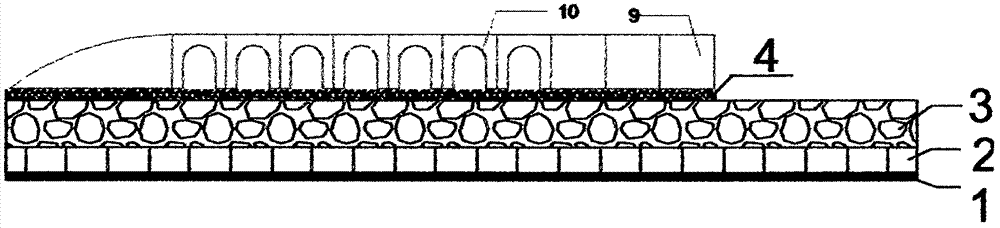

Ecological environmental-protection permeable spur dike structure

PendingCN107119626AReduce shockSmooth and convenient construction conditionsBreakwatersQuaysGeotextileEngineering

The invention relates to an ecological environmental-protection permeable spur dike structure which consists of a river bottom protection structure and a spur dike structure part; the river bottom protection structure consists of a geotechnical waterproof material layer, a grouted rubble layer, a rubble layer and a crushed stone layer from the bottom up sequentially; the crushed stone layer is simply laid within the range of the spur dike structure part; gabion net cages are arranged at the external edges of the river bottom protection structure, then the river bottom protection structure is leveled, and the spur dike structure part is arranged on the leveled crushed stone layer; the spur dike structure part is formed by splicing a dike root, a dike body and a dike head; the dike root is formed by splicing a plurality of entity components, the bottom of each entity component is a plane, and the upper part of each entity component is a sloping surface structure consisting of a riverside slope and a landside slope; the dike body is formed by splicing a plurality of permeable components; the upper parts of the permeable components are sloping surface structures consisting of riverside slopes and landside slopes; and permeable holes are formed in the middles of the permeable components. The permeable holes of the permeable components are arch-cave-shaped, so that flow turbulent fluctuation at the permeable holes and erosion to the dike body are reduced, and harm to fish in water is reduced.

Owner:CHONGQING JIAOTONG UNIVERSITY

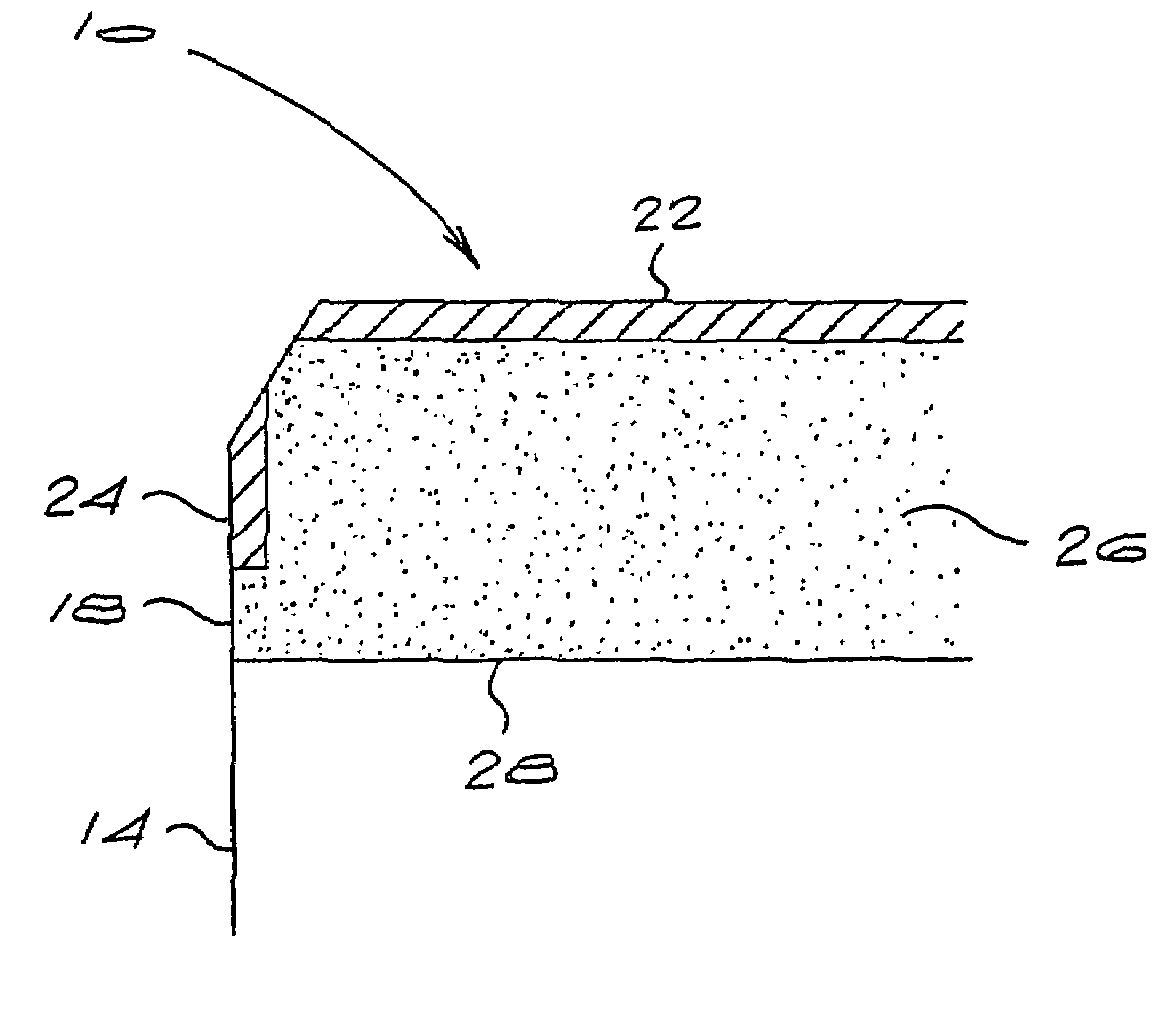

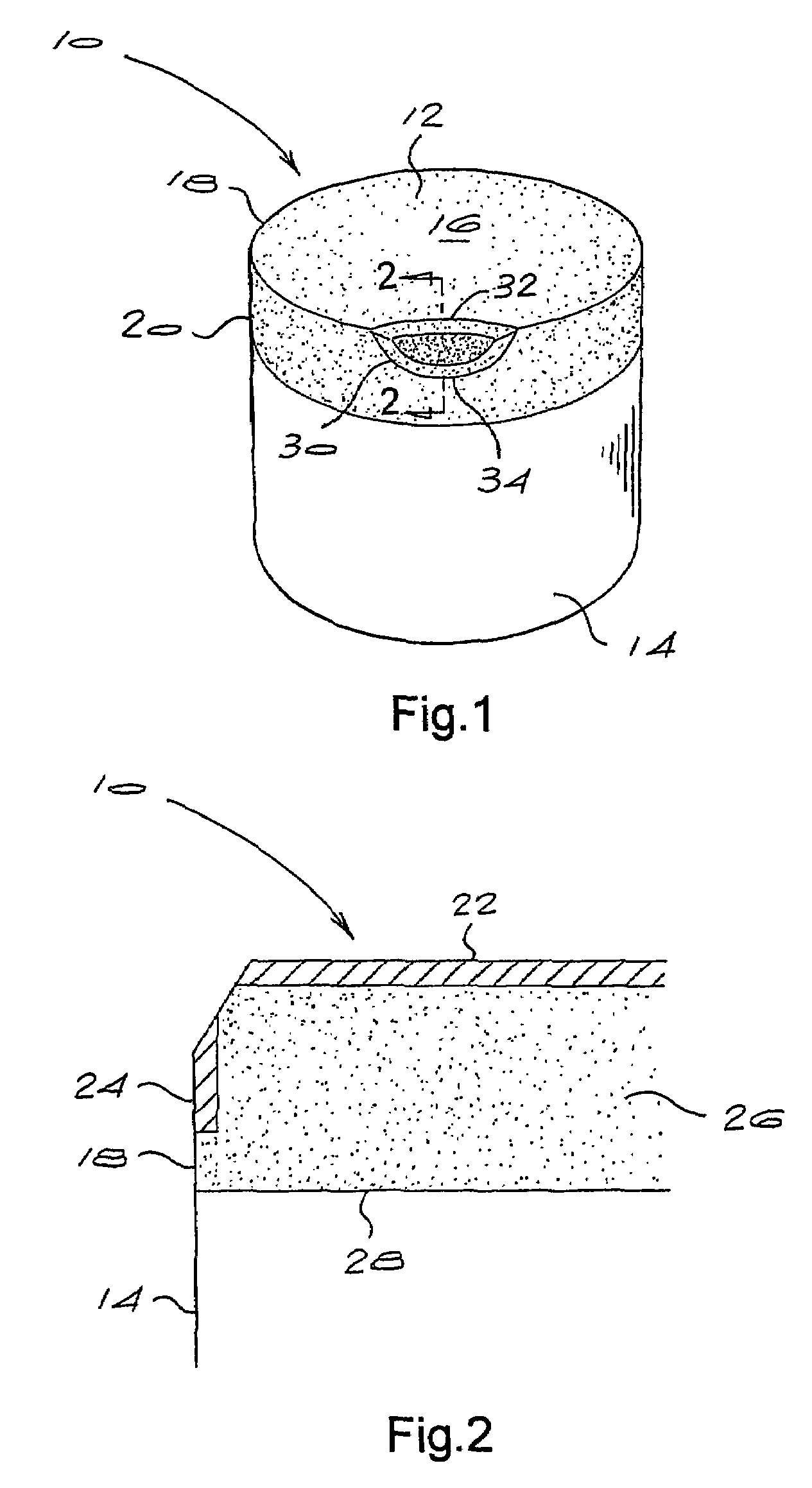

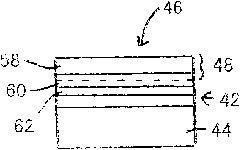

Cutting element

A cutting element comprises a multilayer polycrystalline diamond element 42 bonded to a substrate 44 of a less hard material, the polycrystalline diamond element 42 defining a matrix of interstitial volumes, the interstitial volumes of a first region of the diamond layer 42 adjacent a working surface 46 thereof being substantially free of a catalysing material, the interstitial volumes of a second region of the diamond layer 42 remote from the working surface 46 containing catalysing material.

Owner:REEDHYCALOG UK

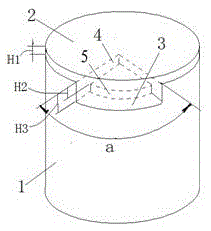

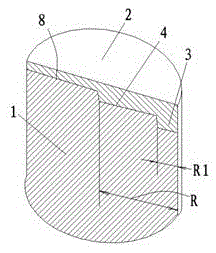

Manufacturing method of polycrystalline diamond compacts with super-thick diamond layers

The invention discloses a manufacturing method of polycrystalline diamond compacts with super-thick diamond layers and solves the problem that the polycrystalline diamond compacts cannot be synthesized when the thickness of the diamond layers is 3.0mm. The method comprises the following steps: firstly synthesizing polycrystalline diamond blank wafers by using diamond micro powder and metal powder under the high-temperature and high-pressure condition, manufacturing transition layers mixed with a plurality of metals on the polycrystalline diamond blank wafers and stacking tungsten carbide alloys on the transition layers, and sintering to form the polycrystalline diamond compacts with super-thick diamond layers. According to the technical scheme, the method is capable of producing batches of polycrystalline diamond compacts with the diamond layers with thickness being greater than or equal to 3.0mm; the yield is greater than 90%.

Owner:SF DIAMOND CO LTD

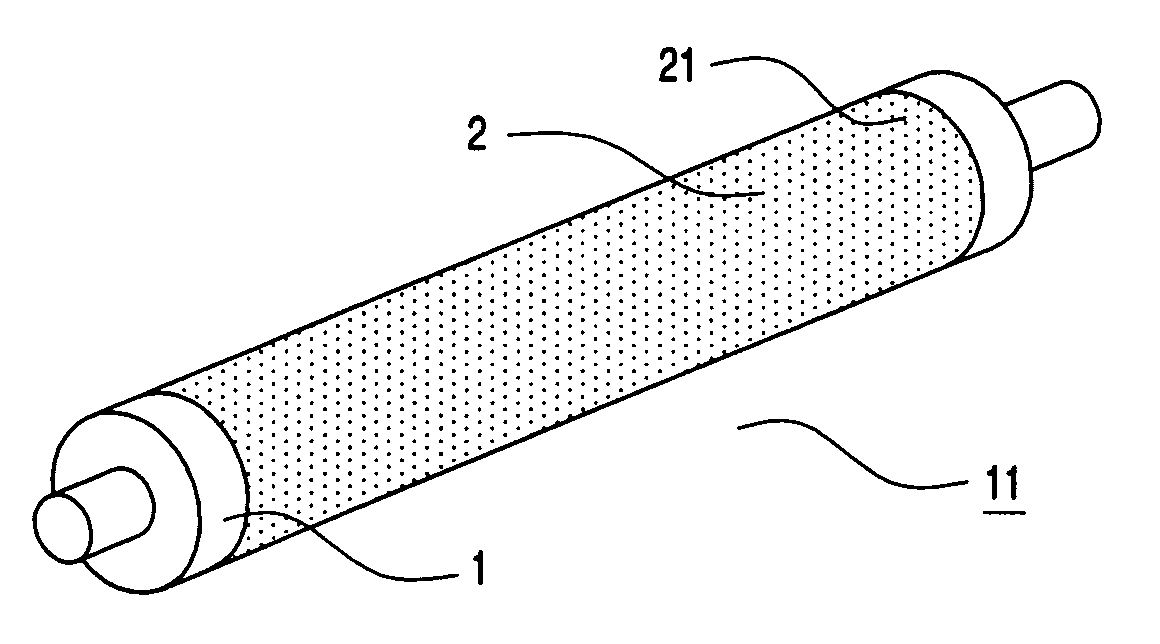

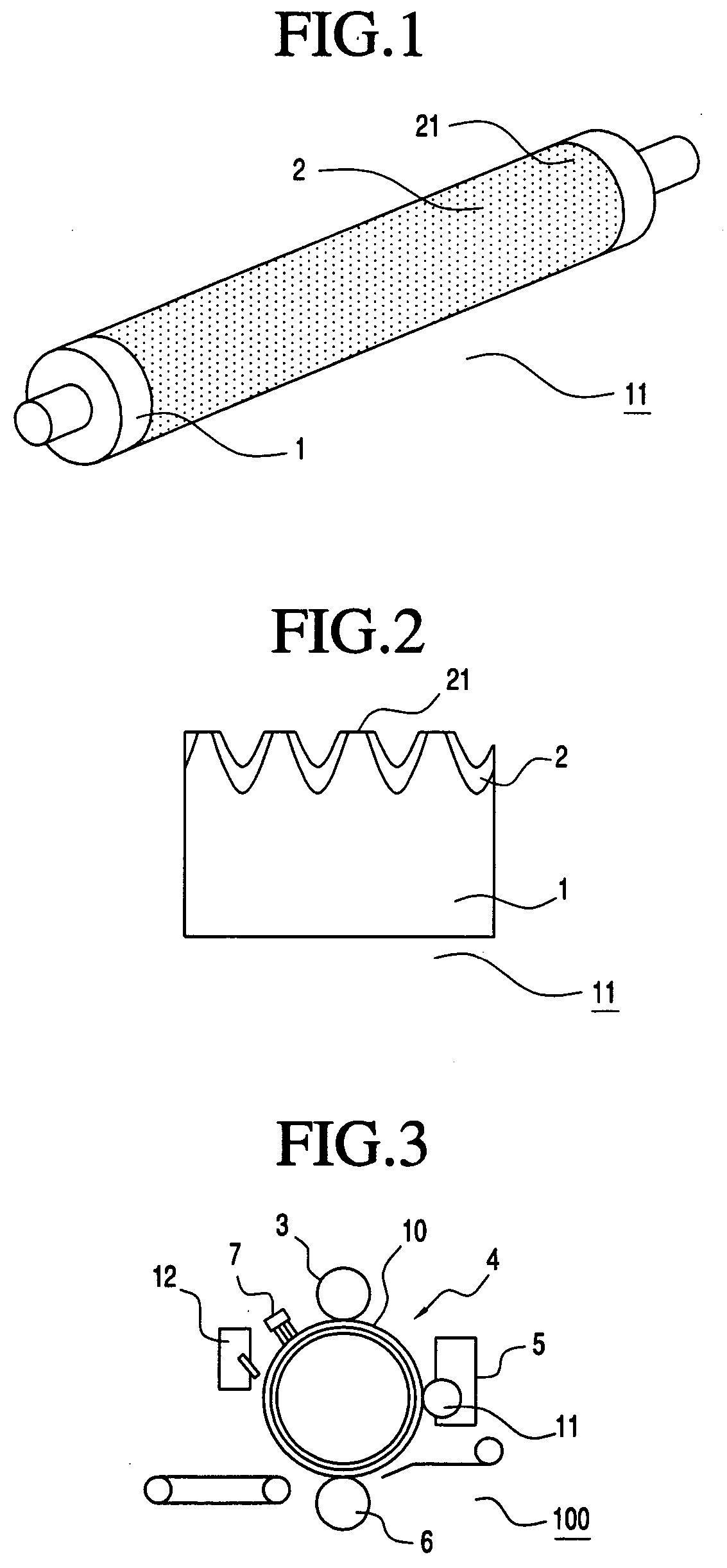

Cylindrical developer carrier and production method thereof

A cylindrical developer carrier capable of fully charging a toner compound on a developing sleeve via frictional force even after being used repeatedly. The cylindrical developer carrier includes an electrically conductive substrate having an evenly roughened surface, and an alumite layer formed on the roughened surface, wherein the alumite layer has a uniform distribution of minute holes that reach the substrate surface. A method for manufacturing the cylindrical developer carrier includes roughening the electrically conductive substrate surface by blasting it with spherical fine particles, forming the alumite layer on the roughened surface by an anodizing method, and blasting the surface of the alumite-layer with amorphous fine particles that a diameter greater than that of the spherical fine particles.

Owner:FUJI ELECTRIC IMAGING DEVICE

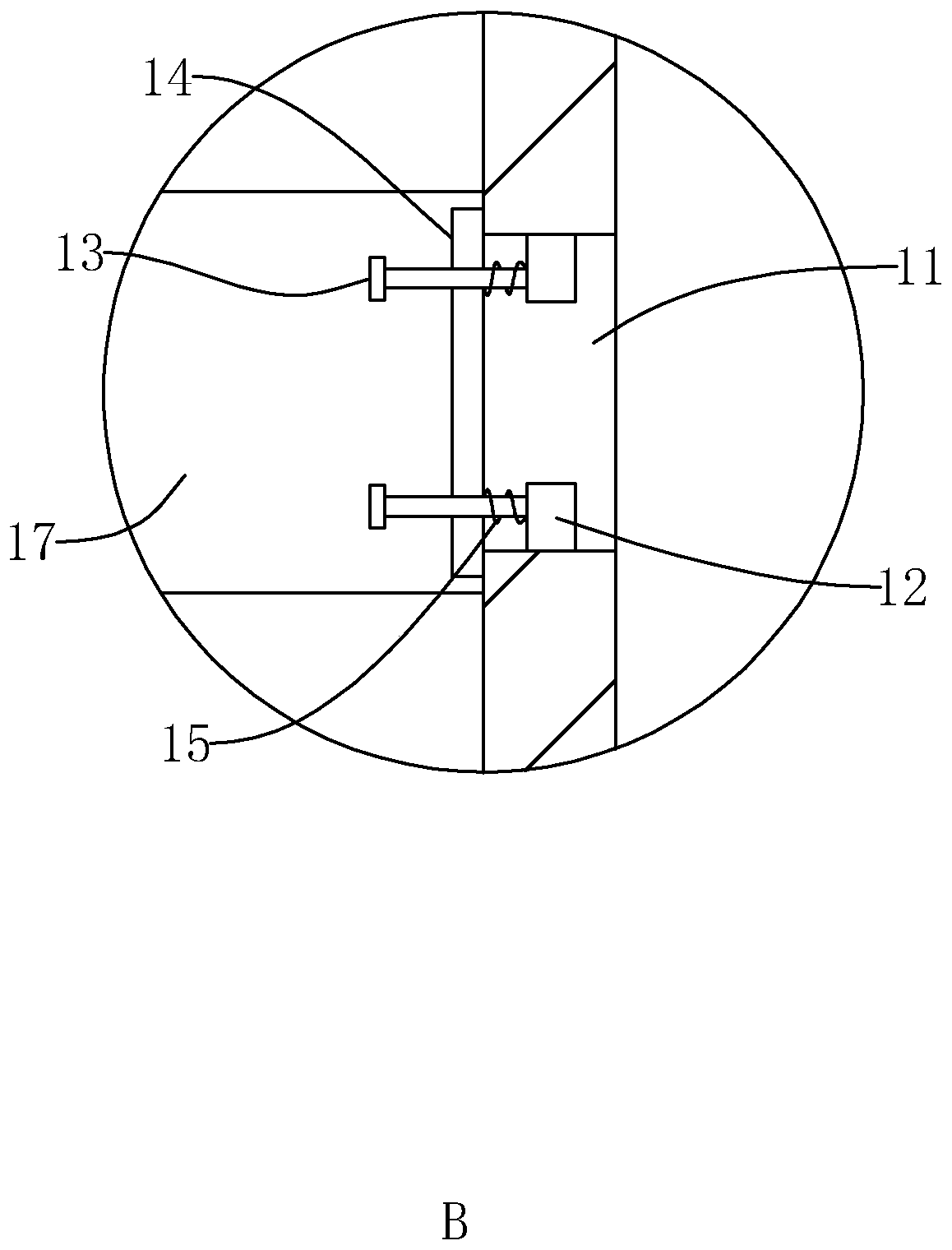

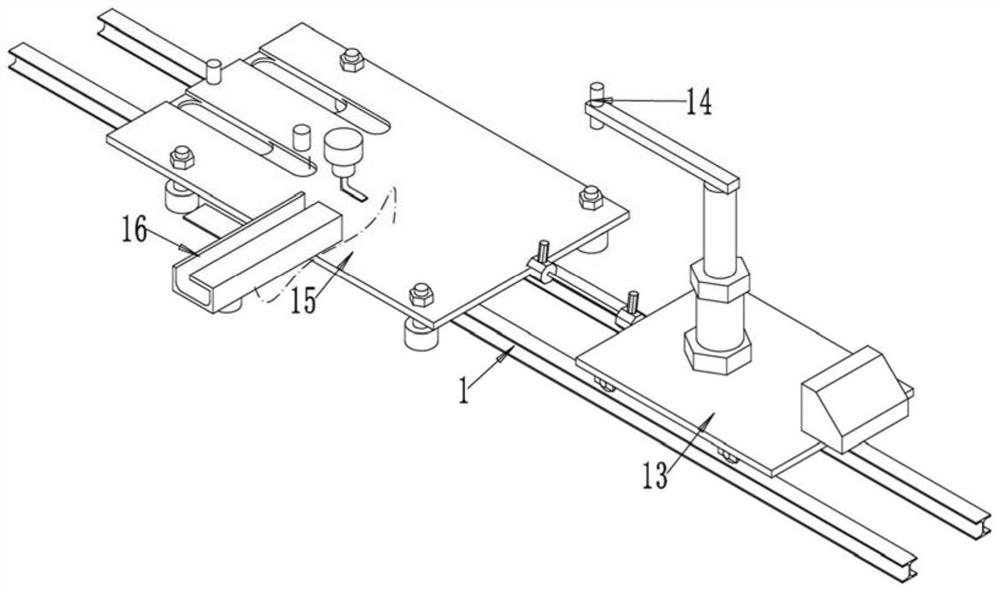

Method and device for installing steel sheet piles in large-diameter boulder and sandstone stratum

The invention belongs to a method and a device for installing steel sheet piles in a large-diameter boulder and sandstone stratum. The device comprises a pile casing construction measuring and positioning device, a steel sheet pile movable sample corrector and a movable operation platform. The method comprises the following steps that a steel trestle is built along the outer side of the peripheryof the designed cofferdam steel sheet piles, the movable operation platform is installed, a steel pile casing is installed in a hole jumping mode and excavated, a rotary drilling rig and a vibrating hammer are matched to excavate and guide holes in a boulder layer at the lower end of the steel pile casing till the lower end of the steel pile casing penetrates through the boulder layer, clay is backfilled into the steel pile casing, a static pressure pile planting machine is used for planting the steel sheet piles along a backfilling clay line till a steel sheet pile cofferdam is completed, andthe inclined steel sheet piles are corrected through the steel sheet pile movable sample corrector on the movable operation platform in the steel sheet pile pressing-in process. The steel sheet pileplanting speed and efficiency in the large-diameter boulder and sandstone stratum can be improved, and the cofferdam construction safety risk is reduced.

Owner:NO 1 ENG CO LTD OF FHEC OF CCCC

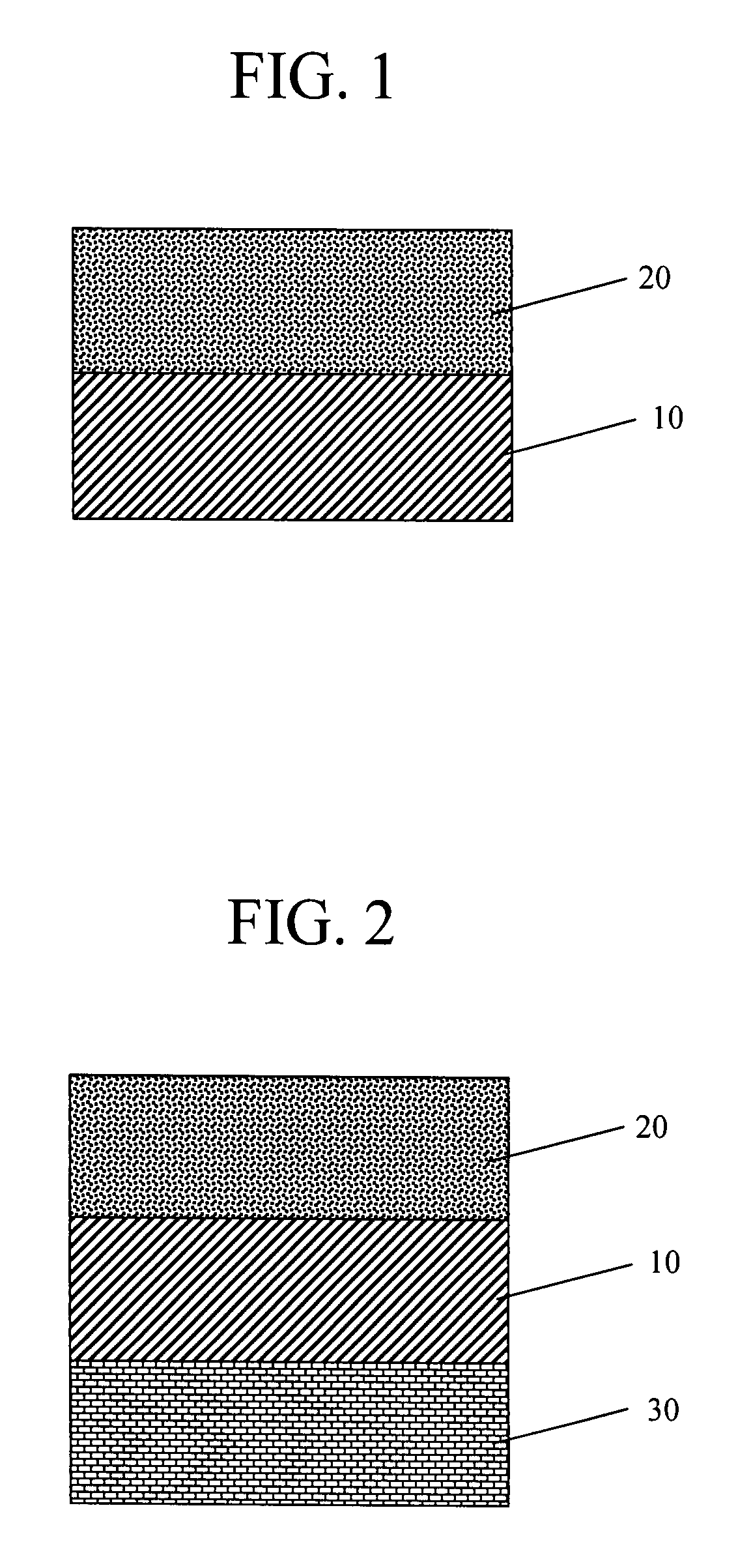

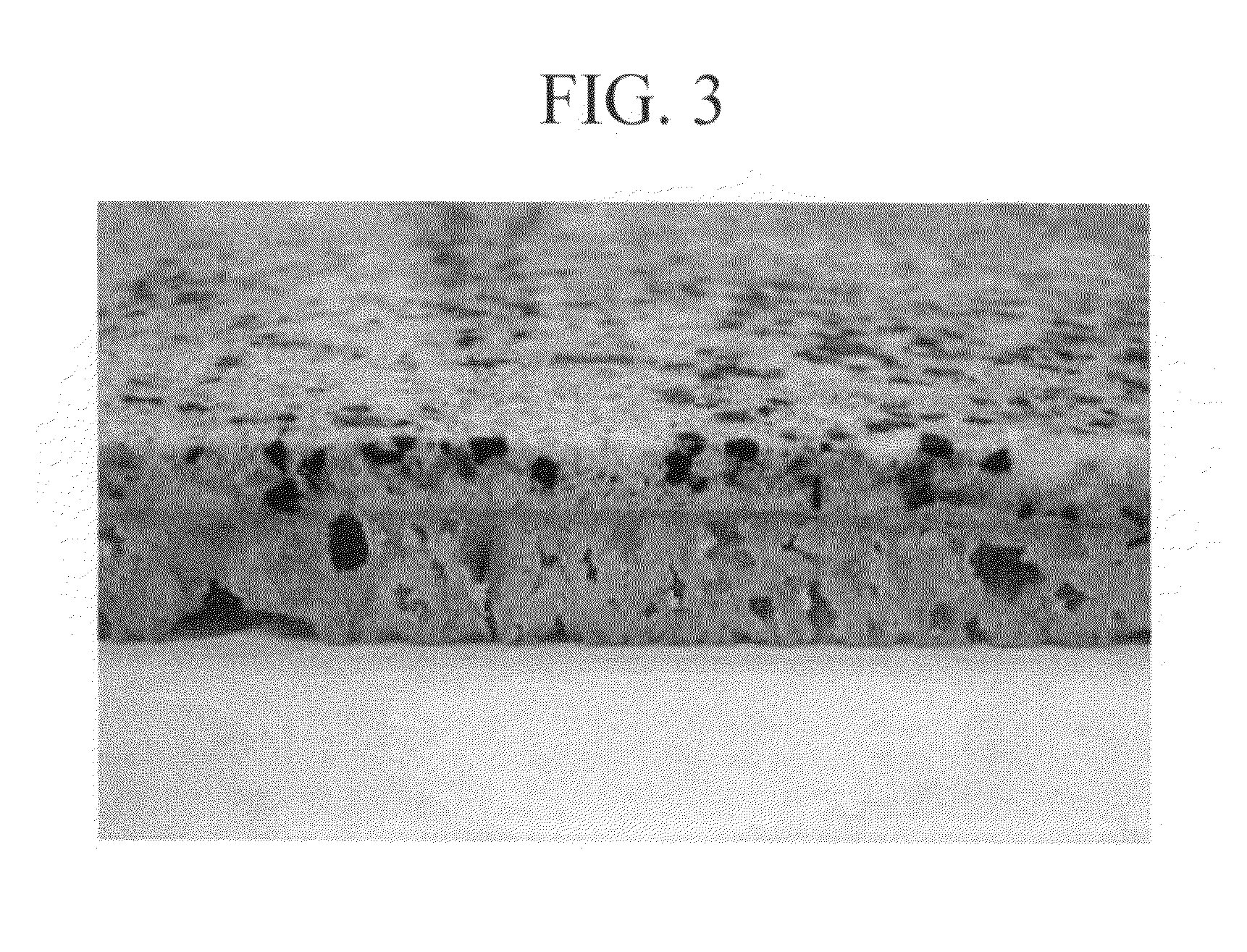

Foamed stone article and method for preparing the same

InactiveUS7566492B2Easy to processSynthetic resin layered productsCoatingsAcrylic resinSolid particle

Owner:LOTTE ADVANCED MATERIALS CO LTD

Diamond compact and manufacturing method thereof

ActiveCN105569575AExtended service lifeReduced amount of fine powderDrill bitsSlitting machinesSlurryAlloy

The invention discloses a diamond compact. The diamond compact comprises a hard alloy matrix and a diamond layer, wherein the diamond layer is compounded on the hard alloy matrix; the diamond layer at the work cutting edge position of the diamond compact is thicker than the diamond layer at the non-cutting edge position. The thickness of the diamond layer is only increased at the work cutting edge position of the diamond compact, and the thickness of the diamond layer is locally increased to change the integral property of the diamond compact, so that the integral impact resistance is improved and the abrasion of slurry to the matrix is relieved. According to the invention, the diamond layer is locally thickened, compared to the situation that the whole diamond layer of the compact is thickened, the diamond micropowder amount required is greatly reduced, so that the production cost is lowered, but the whole diamond layer thickening effect can be achieved.

Owner:ZHUZHOU XIANGYU CEMENTED CARBIDE

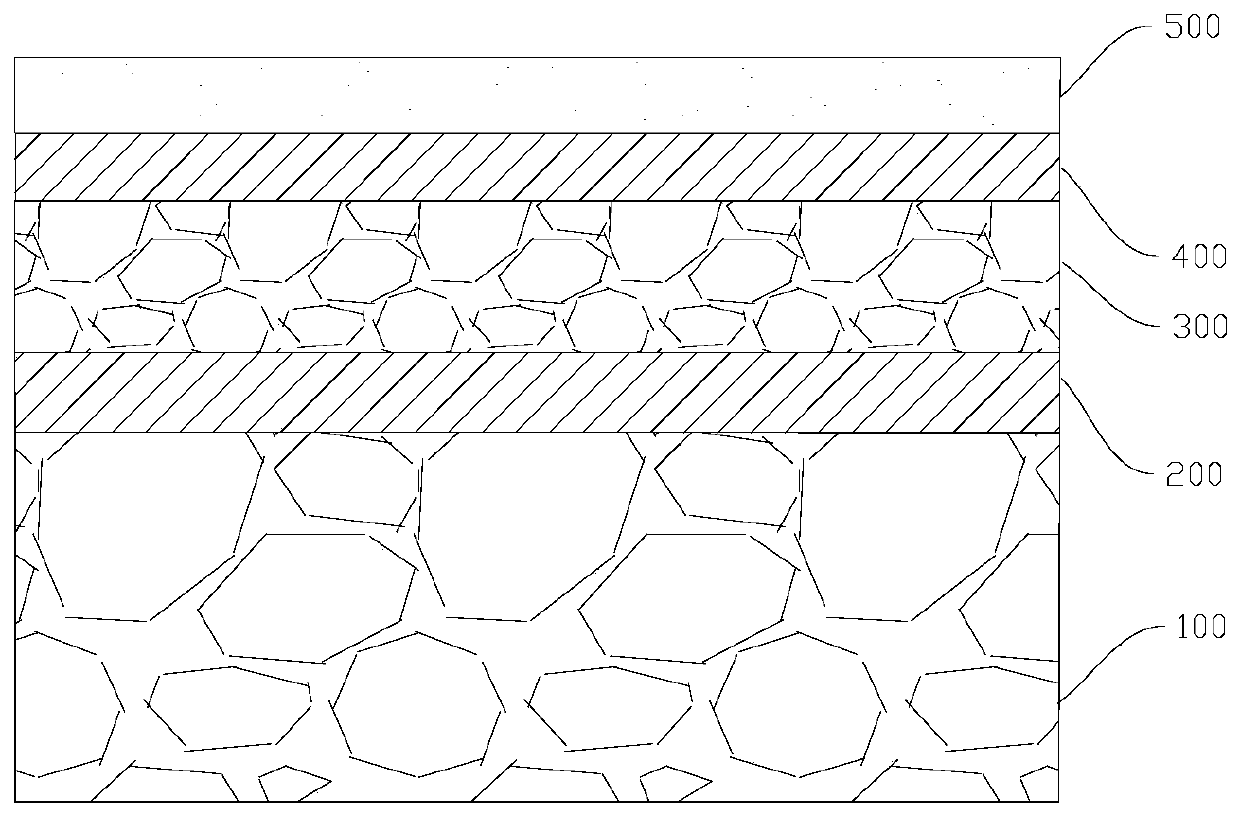

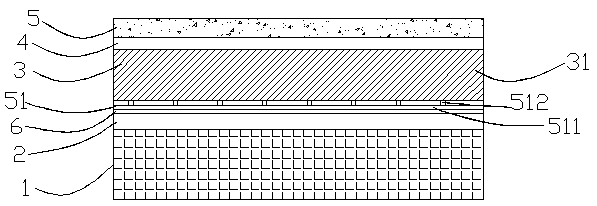

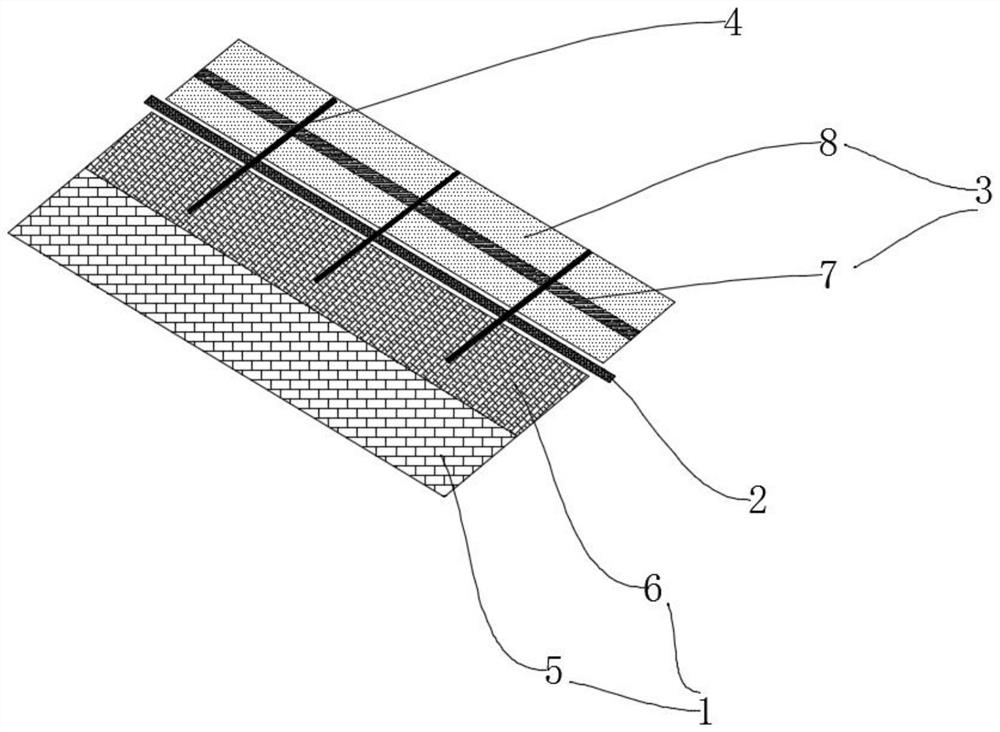

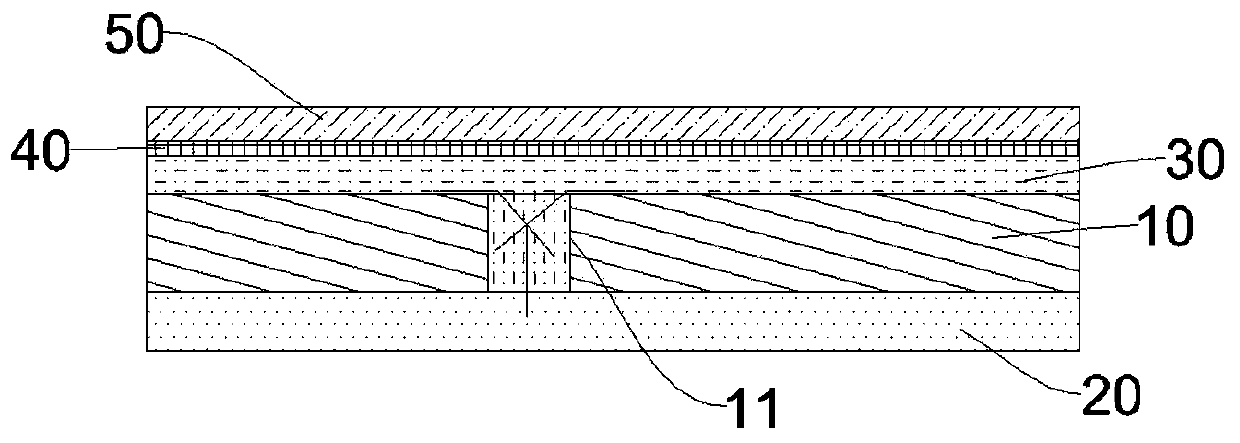

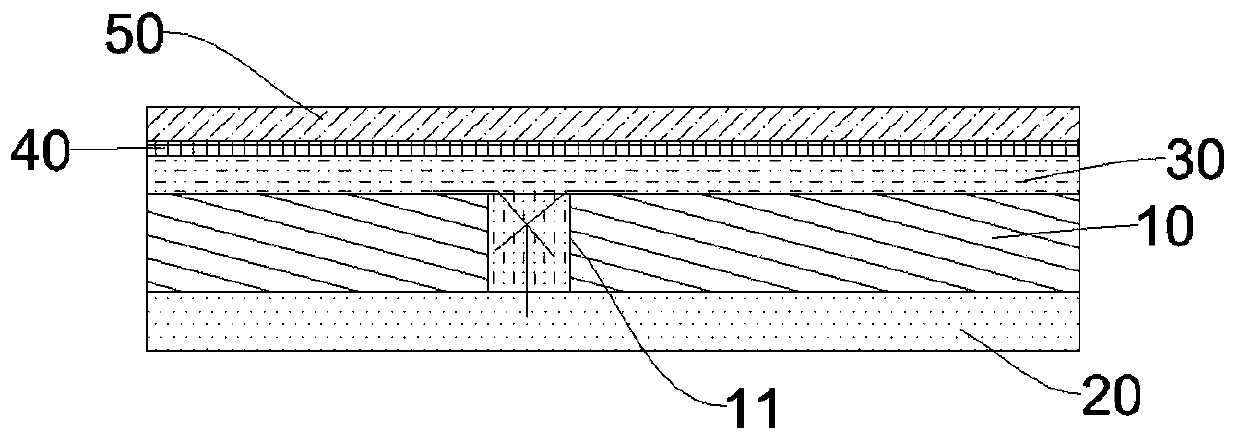

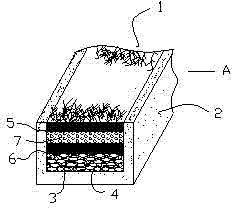

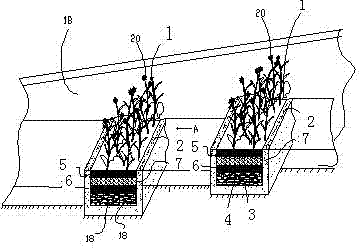

Saline-alkali land restoration system and method

PendingCN110679223ARaise threshold for precipitation rainfallDischarge in timeSoil lifting machinesPlant cultivationAlkali soilCrushed stone

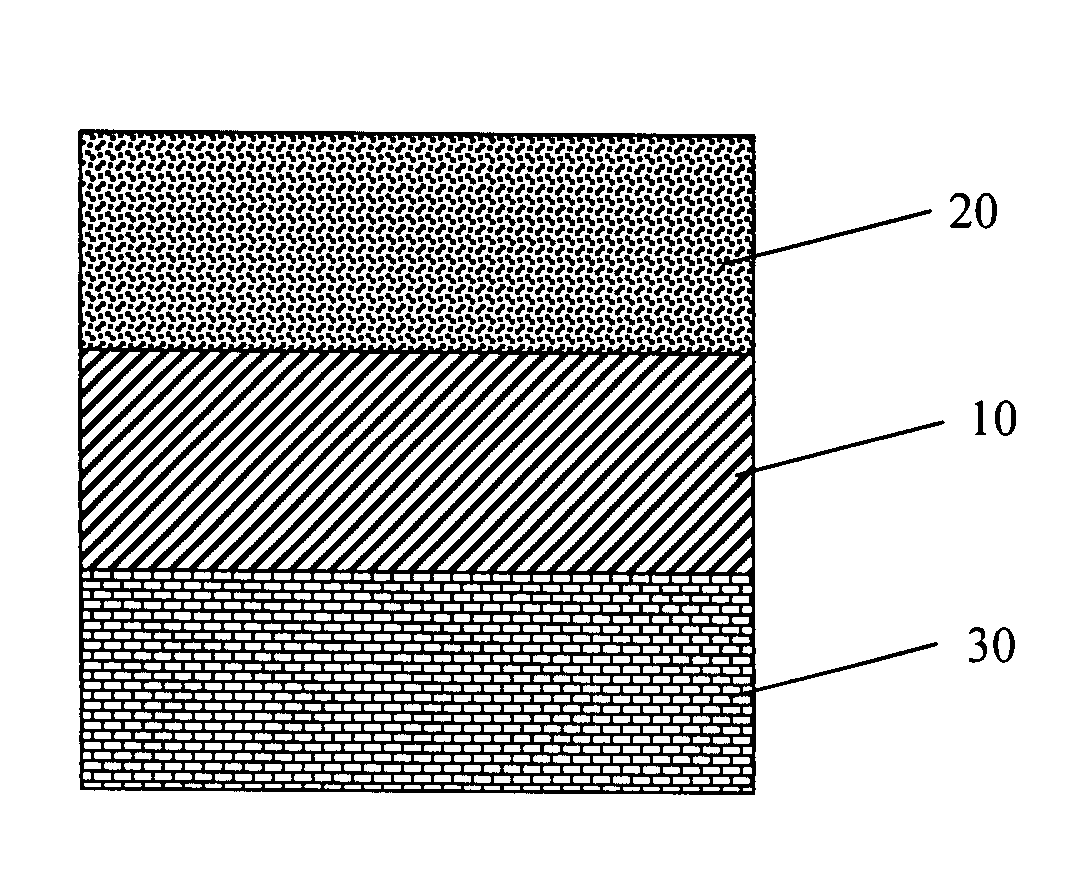

The invention discloses a saline-alkali land restoration system and method. The saline-alkali land restoration system comprises a rubble layer, a first geotextile layer, a crushed stone layer, a second geotextile layer and a planting soil layer, wherein the rubble layer is mainly formed by rubbles with the particle sizes of 200 mm to 300 mm; the first geotextile layer covers the rubble layer; thecrushed stone layer is positioned above the first geotextile layer and mainly formed by crushed stone with the particle size of 20 mm to 30 mm; the second geotextile layer covers the crushed stone layer; and the planting soil layer is positioned above the second geotextile layer. The rubble layer and the first geotextile layer are added below the crushed stone layer, so that the rubble layer can effectively form an isolation effect between the first geotextile layer and the original saline-alkali land, salt migration and salt return caused by the reason that effective isolation cannot be formed due to too small gap of the crushed stone are avoided, and the salt discharge effect is improved; and the first geotextile layer can form enough support for separation of the rubble layer and the crushed stone layer, meanwhile, salt which migrates along with evaporation of water is effectively intercepted, and the salt is blocked below the first geotextile layer.

Owner:深圳市国艺园林建设有限公司

Diamond covered substrate, filtration filter, and electrode

InactiveCN101090999APhysical stabilityChemically stablePolycrystalline material growthWater/sewage treatment by electrochemical methodsElectrolysisFiltration

By providing a substrate that can be used as an electrode, the invention solves the problem of corrosion of the substrate itself during an electrochemical oxidation treatment, the problem of discontinued electrolysis caused by delamination between a diamond layer and a substrate, or the problem of severely impaired electrolysis efficiency. The present invention is a diamond-covered substrate comprising a substrate and a conductive diamond layer covering the substrate, wherein the largest area of the portion where the diamond comprising the diamond layer is continuous ranges from 1 mum<2 >to 1,000 mum<2>. Preferably, the substrate is porous and has open pores, and the open pores preferably have a diameter from 0.1 mum to 1,000 mum.

Owner:SUMITOMO ELECTRIC IND LTD

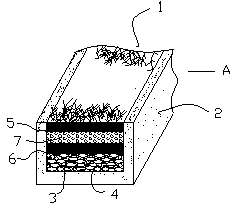

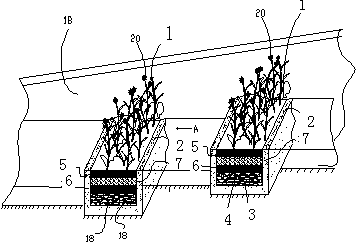

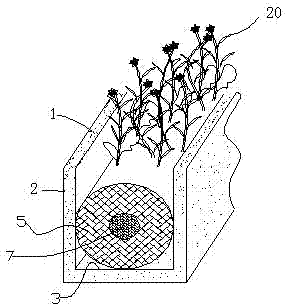

River and lake water greening and purifying method and river and lake water greening and purifying device

InactiveCN103539264AWith greeneryPurifyingSustainable biological treatmentBiological water/sewage treatmentVegetationWater quality

The invention discloses a river and lake water greening and purifying method. A groove structure formed by porous concrete is used as a main body; a vegetation pad and a water purifying material are configured in the groove structure; an aquatic plant is planted on the vegetation pad, and water treatment microorganism is applied into the groove; the groove formed by porous concrete, the vegetation pad and the water purifying layer together serve as a carrier for adding aerobic or facultative water treatment microorganism. Freestone is paved at the bottom in the groove structure; a vegetable fiber planar pad, the water purifying layer and another vegetation fiber plane pad are sequentially placed on the freestone layer. The cross section of the structure is in a U shape. The device disclosed by the invention has the advantages of simple structure, convenience in construction, low cost and the like; the device is arranged on the two sides or bridge side of a river, a lake or a landscape pool, and two major aims of water purifying and greening are achieved at the same time.

Owner:NANJING UNIV +3

Construction process of novel counterfort retaining wall

The invention relates to a construction process of a novel counterfort retaining wall, which is arranged at concrete retaining wall toes on two side parts of an existing road shoulder of a steel rail piece, and is of a stepped structure. Ditching at the bottom of the outer side of the toe of the concrete retaining wall and placing the bottom of the buttress; gravel soil layers are filled and tamped on the upper surfaces and the bottoms of the bottoms of the buttress pieces; a backfill earth-rock layer is placed between the vertical wall of the buttress piece and the toe of the concrete retaining wall; drain holes are respectively formed in the backfill soil and stone layer and the vertical wall of the buttress piece; a reinforcing steel bar assembly in the wall body is arranged in the backfill soil and stone layer and is in lap joint with reinforcing steel bars of the buttress pieces; the device is reasonable in design, compact in structure and convenient to use.

Owner:SHUOHUANG RAILWAY DEV +1

Imitation marble thermal-insulation aluminum magnesium board

InactiveCN108071179AImprove insulation effectLight materialSynthetic resin layered productsHeat proofingSheet steelThermal insulation

The invention discloses an imitation marble thermal-insulation aluminum magnesium board. The imitation marble thermal-insulation aluminum magnesium board includes an aluminum magnesium substrate layer, a primary coat bonding layer, an insulation board layer and a natural color sand layer; the primary coat bonding layer for strengthening the adhesive force covers the aluminum magnesium substrate layer, the insulation board layer is arranged between the primary coat layer and the natural color sand layer, and the natural color sand layer is formed by mixing various colorful natural color sand inproportion to enable the boards to present marble appearance; and the insulation board layer is made of organic foams, connecting parts are arranged between the organic foams and the primary coat bonding layer, and thermal mortar is filled between the connecting parts and the organic foams. According to the imitation marble thermal-insulation aluminum magnesium board, the insulation board layer is made of phenolic foams which has a good thermal insulation property and can be combined with steel plate and other materials, and fire prevention grade A can be achieved; steel wire mesh nails of the connecting parts can be tightly connected with the insulation board layer; and the thermal mortar is filled between the connecting parts and the organic foams for tightly connecting the insulation board layer and the primary coat bonding layer.

Owner:安徽信耀玻璃有限公司

Ecological protection system for waste limestone slag yard

InactiveCN111837828AGood nutrient protection abilityCorrosion resistantGrowth substratesCulture mediaMicroorganismEnvironmental engineering

The invention relates to the technical field of stone slag protection, and discloses an ecological protection system for a waste limestone slag yard. The ecological protection system comprises a stoneslag layer, water guide cloth and a functional layer which are sequentially arranged from bottom to top, and further comprises a plurality of anchor rods for fixing the water guide cloth and the functional layer on the stone slag layer, wherein the stone slag layer comprises a bottom layer and a transition layer which is positioned above the bottom layer and is poured with a stabilizer; and the functional layer comprises a substrate layer and functional nets arranged on the upper side and the lower side of the substrate layer respectively. According to the characteristics of the waste limestone slag yard, a functional microorganism-plant synergistic protection system is established, synergistic stability of the waste limestone slag yard is achieved, ecological protection effect on the waste limestone slag yard is improved, and the problems of water erosion collapse of a limestone area and stable growth of plants under an alkaline condition of a traditional ecological protection structure are solved.

Owner:国家管网集团重庆天然气管道有限责任公司

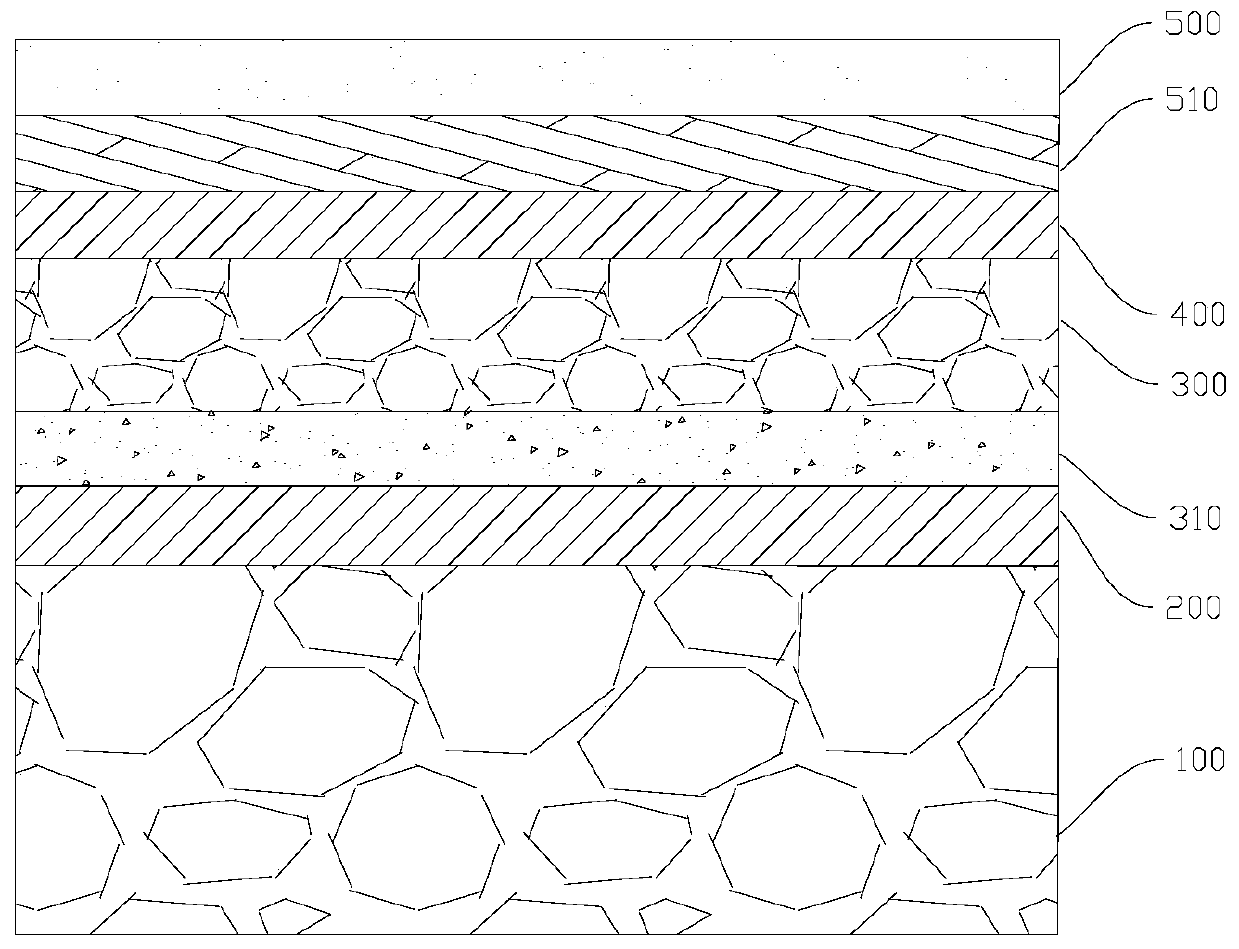

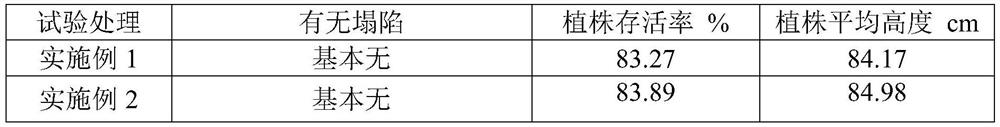

Salt-water and fresh-water root-divided alternative irrigation method and application of irrigation method to planting of tall ligustrum lucidum in saline and alkaline land

InactiveCN106069598APromote growthFast growthWatering devicesDispersed particle separationPhosphateUrsolic acid

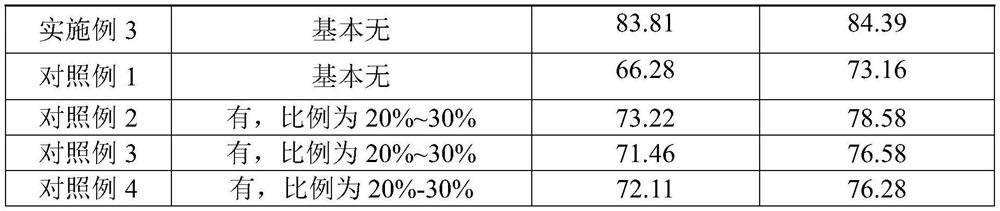

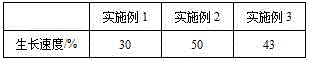

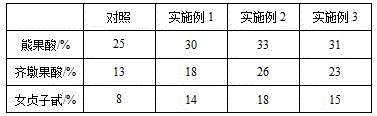

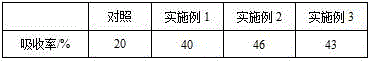

The invention provides a salt-water and fresh-water root-divided alternative irrigation method. A salt isolating layer is adopted, sequentially comprises a rubble layer, a reed layer, a fine stone layer and a mixed soil layer from bottom to top, and is laid on a planting area. The upper surface of the salt isolating layer is 100 cm to 140 cm away from the earth surface. The rubble layer is prepared fromvermiculite, ceramsite and coarse sand, the fine stone layer is prepared from powdered rock phosphate, biogas residues and wheat bran, and the mixed soil layer is prepared from Luzhao soil and Chiyu soil. The invention further provides an application of the salt-water and fresh-water root-divided alternative irrigation method to planting of tall ligustrum lucidum in saline and alkaline land. By means of the root-divided alternative irrigation method, the growing speed of plants is increased, and the medical value of plants is increased; taking tall ligustrum lucidum as an example, the content of ursolic acid in fruits of tall ligustrum lucidum is 30% to 33%; the capacity of absorbing toxic gas of plants is improved, and the environment is purified.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

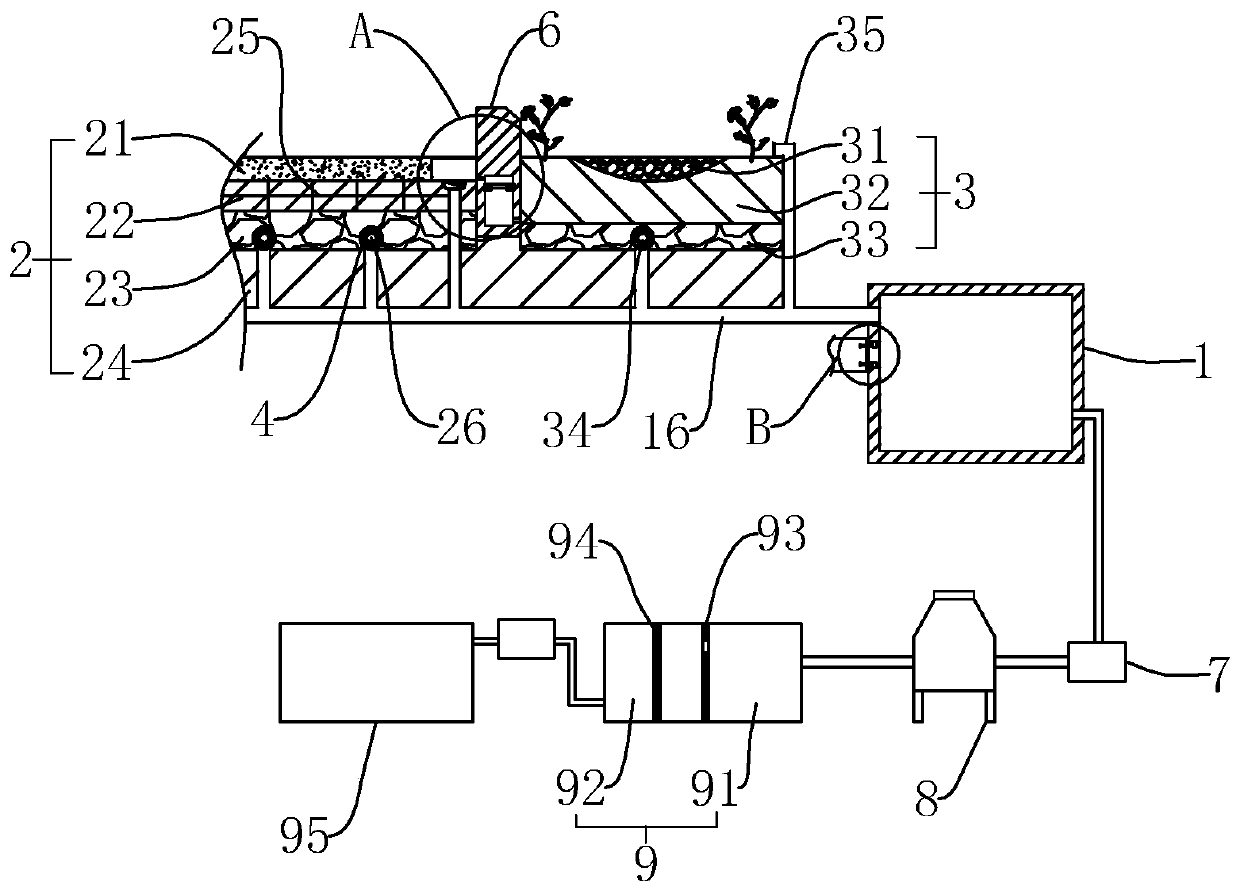

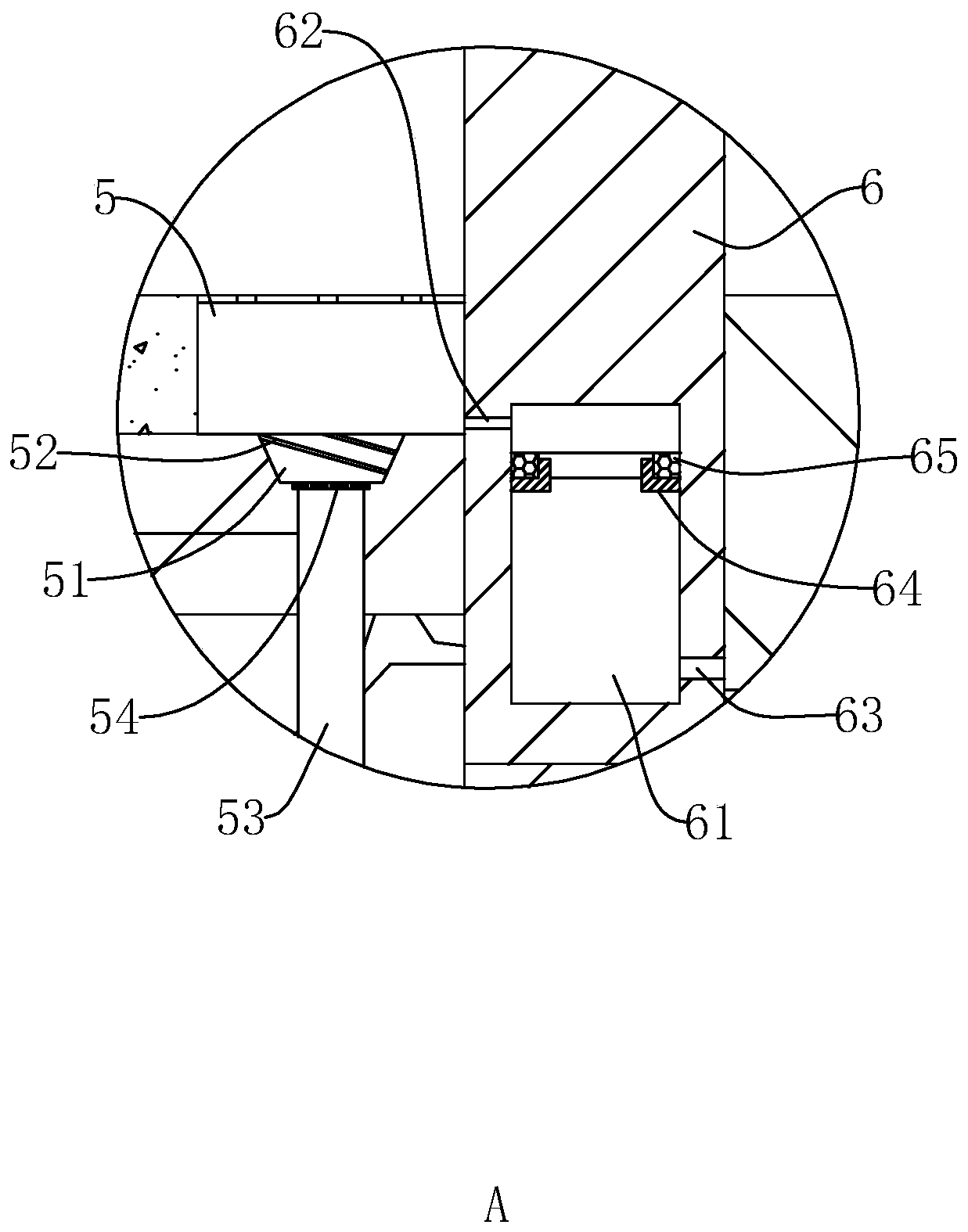

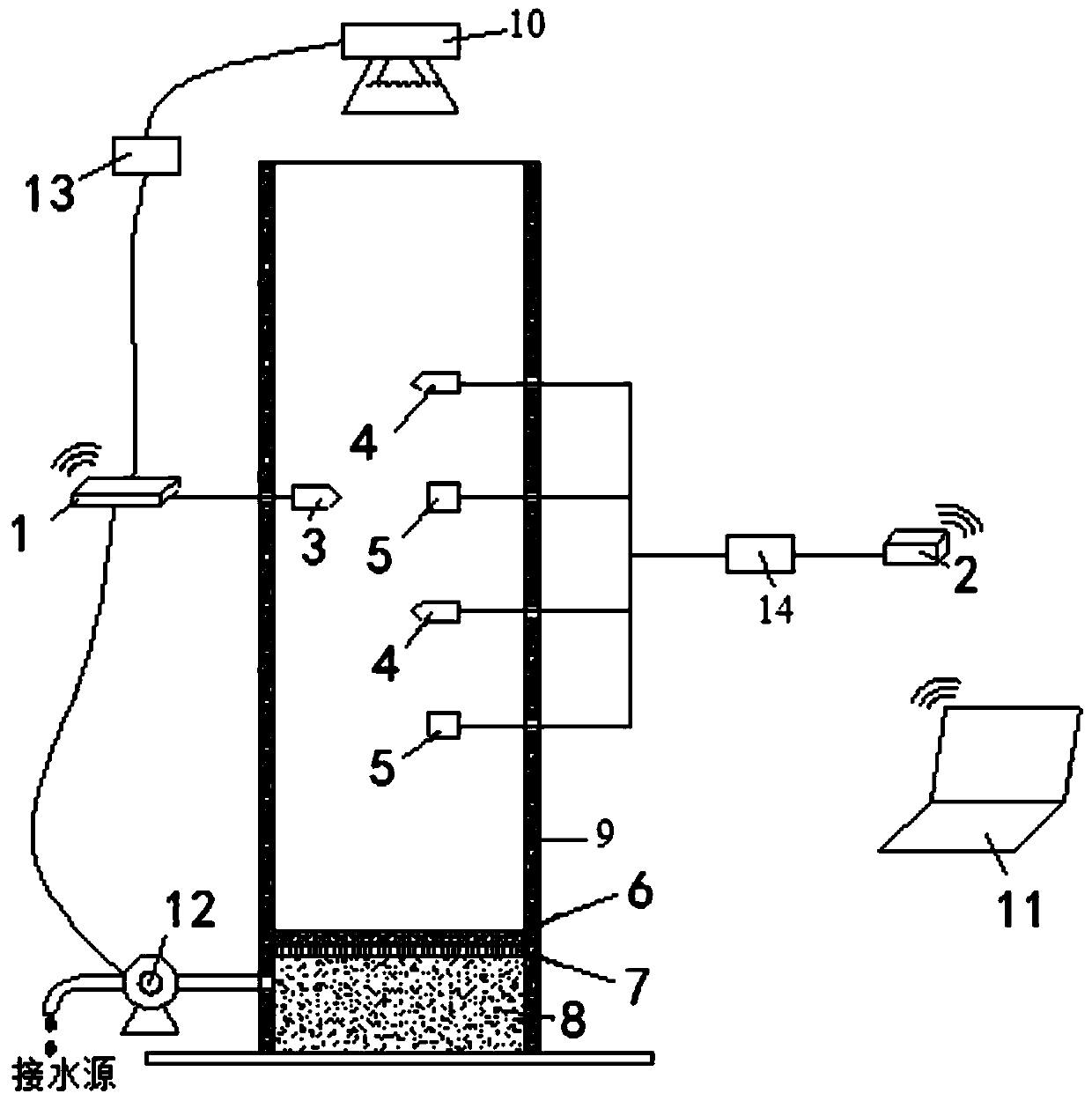

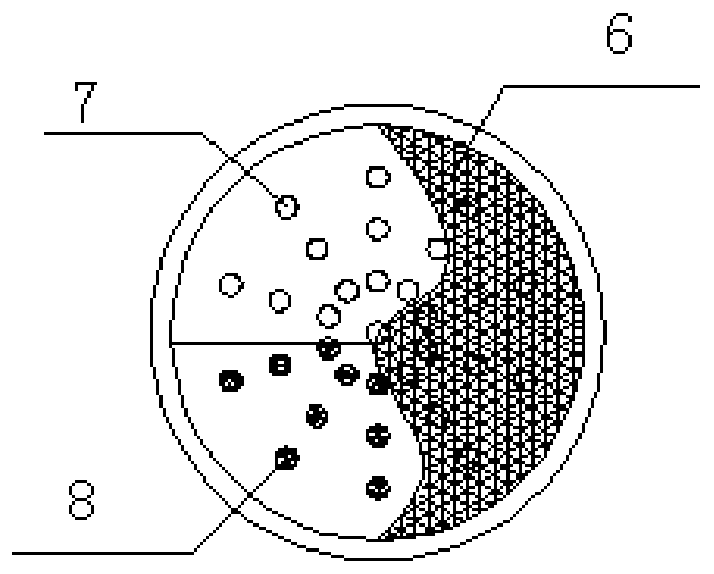

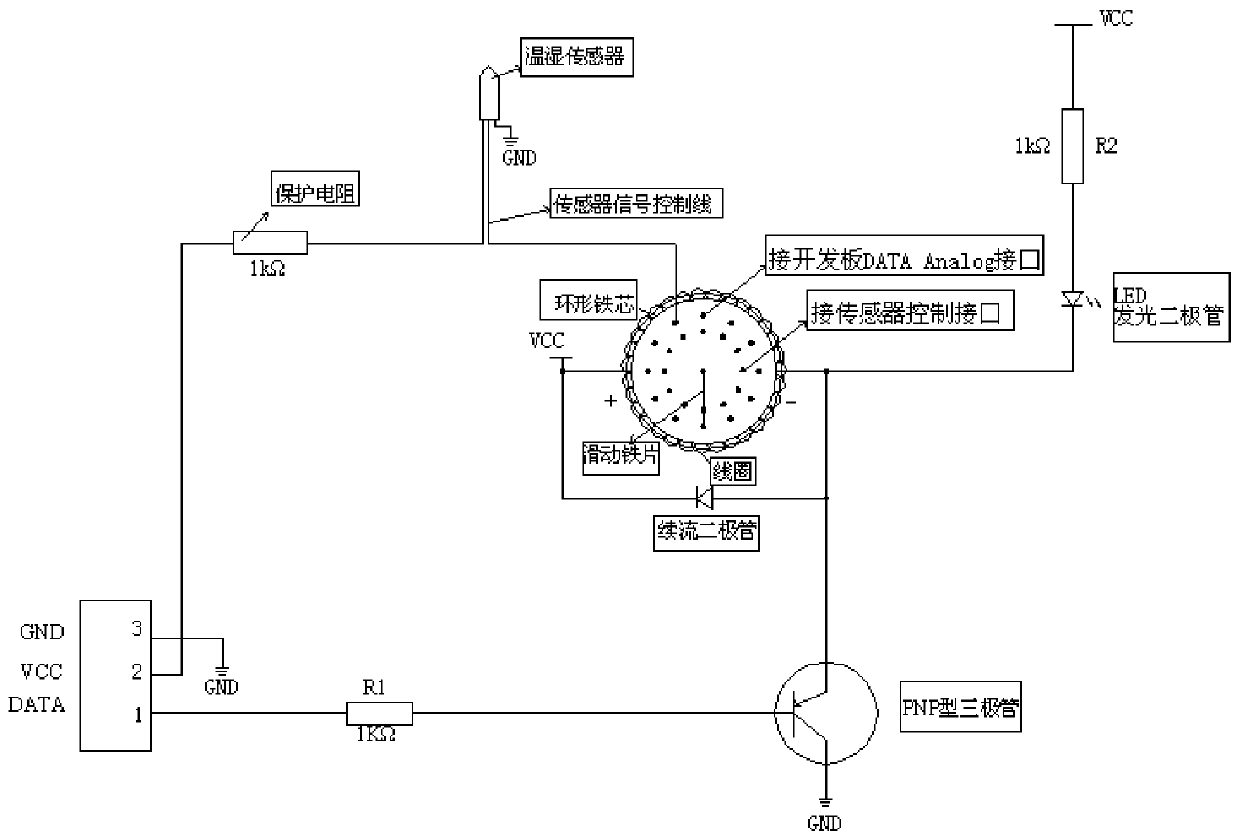

Roadbed soil temperature and humidity monitoring experiment device with controllable dry and wet threshold value and experiment method

ActiveCN111239036ARealize remote operationAvoid Mutual Interference SituationsWeather/light/corrosion resistanceMaterial thermal analysisMoisture capacityDynamic monitoring

The invention discloses a roadbed soil temperature and humidity monitoring experiment device with a controllable dry and wet threshold. The device comprises an experiment tank device and a temperatureand humidity monitoring device, wherein the experiment tank device comprises a tank with a water permeable pore plate at the bottom, and a water permeable gauze layer and a water permeable stone layer are respectively arranged above and below the water permeable pore plate; a water pump is connected to the exterior of the tank body, and a water outlet of the water pump is communicated with the permeable stone layer. Aiming at the problems and defects in the prior art, the invention provides the monitoring device which can automatically monitor the dry-wet cycle process of roadbed soil and perform specific quantitative operation on the dry-wet threshold value of the roadbed soil. And changes of a temperature field and a humidity field in the soil body and in the vertical direction in the dry-wet cycle process can be dynamically monitored and measured.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

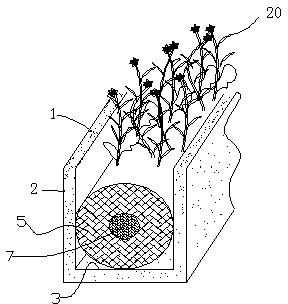

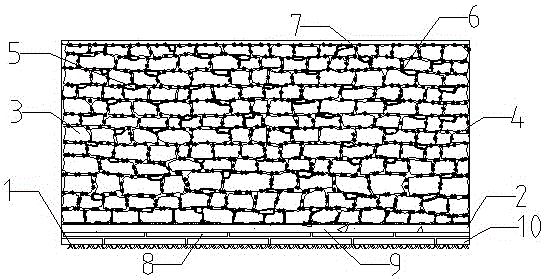

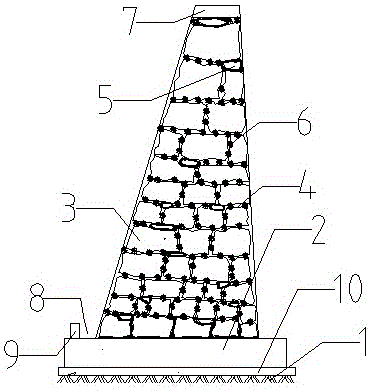

Gravity type point-adhered rubble stone plant caulking ecological retaining wall and construction method thereof

ActiveCN105002928APromote growthDurable growthArtificial islandsUnderwater structuresEnvironmental resource managementPlant roots

The invention discloses a gravity type point-adhered rubble stone plant caulking ecological retaining wall and a construction method thereof. The retaining wall comprises compaction pure soil, a concrete cushion and a rubble stone base layer, wherein a trapezoidal wall body is arranged above the rubble stone base layer; the wall body is composed of multiple rubble stone layers and a concrete coping at the upper part; each rubble stone layer is formed by laying multiple blocks of rubble stone through cement mortar; a space between cracks of outer walls of the rubble stone layers on an air face is filled with point-adhered rubble stone or residual soil slurry; cement mortar bricking is carried out between the point-adhered rubble stone and rubble stone; vegetation is uniformly transplanted on the outer wall of cracks of residual soil slurry at intervals; a drainage ditch is formed in the upper end face of the rubble stone base layer; a drainage ditch retaining wall is arranged on the outer side of the drainage ditch. The gravity type point-adhered rubble stone plant caulking ecological retaining wall disclosed by the invention has the advantages as follows: (1), cement dosage is less; (2), the engineering cost is low; (3), plants grow quickly, are attractive and durable, and can absorb heat greatly, reduce the heat island effect, adsorb dust, retain soil and allow water to permeate through; (4), the whole permeability coefficient is high, plenty of moisture can permeate through the wall body while plant roots retain soil; (5), drainage holes are not required to be reserved; (6), the stability is good.

Owner:山东中建八局投资建设有限公司

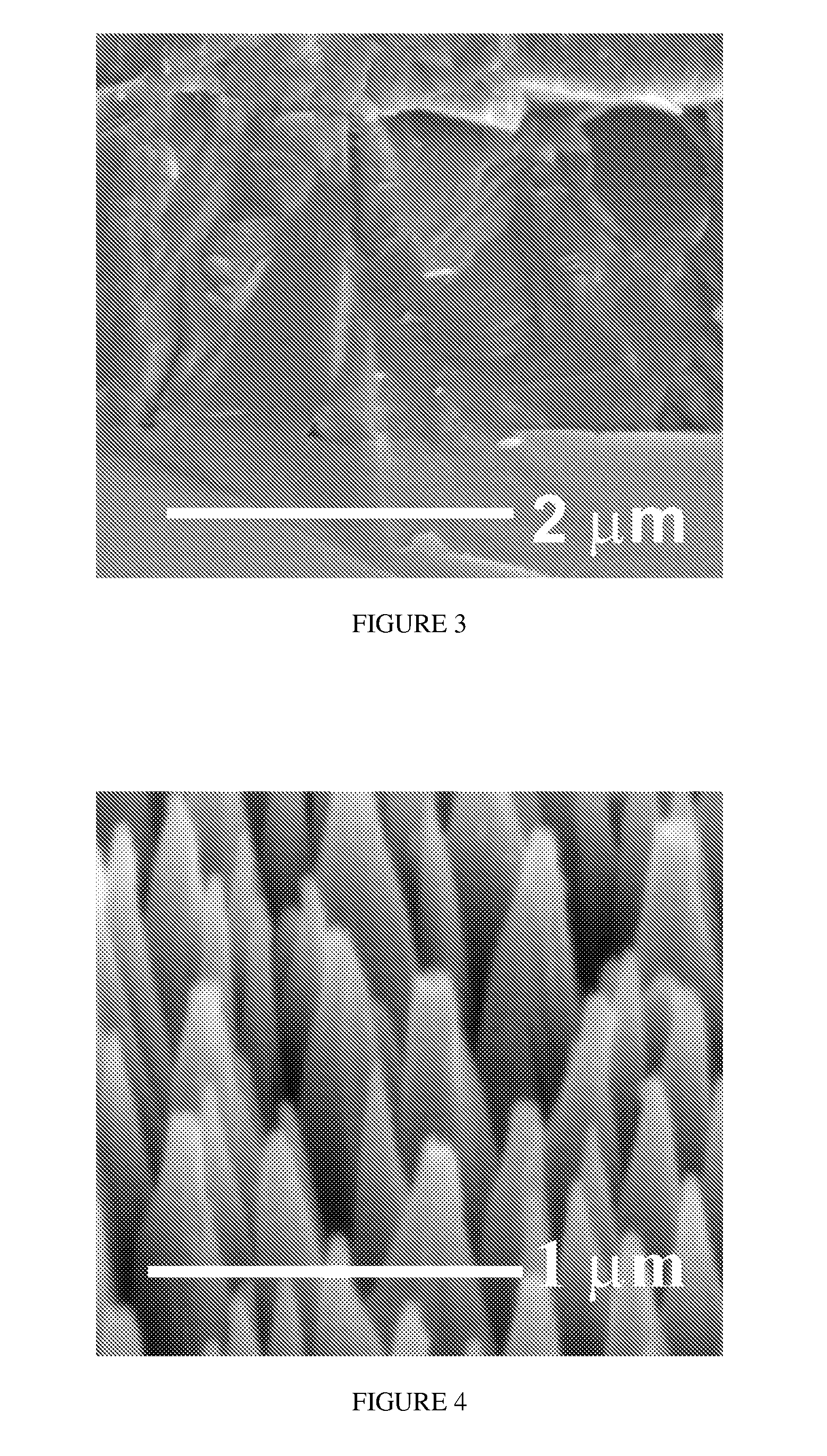

Method of fabrication of cubic boron nitride conical microstructures

ActiveUS8158011B2Extreme supporting capacityIncrease depositionPolycrystalline material growthDecorative surface effectsField electron emissionBoron nitride

A conical structure of cubic Boron Nitride (cBN) is formed on a diamond layered substrate. A method of forming the cBN structure includes steps of (a) forming diamond nuclei on a substrate, (b) growing a layer of diamond film on the substrate, (c) depositing a cBN film on said diamond layer, (d) pre-depositing nanoscale etching masks on the cBN film, and (e) etching the deposited cBN film. In particular, though not exclusively, the cubic Boron Nitride structure has great potential applications in probe analytical and testing techniques including scanning probe microscopy (SPM) and nanoindentation, nanomechanics and nanomachining in progressing microelectromechanical system (MEMS) and nanoelectyromechanical system (NEMS) devices, field electron emission, vacuum microelectronic devices, sensors and different electrode systems including those used in electrochemistry.

Owner:CITY UNIVERSITY OF HONG KONG

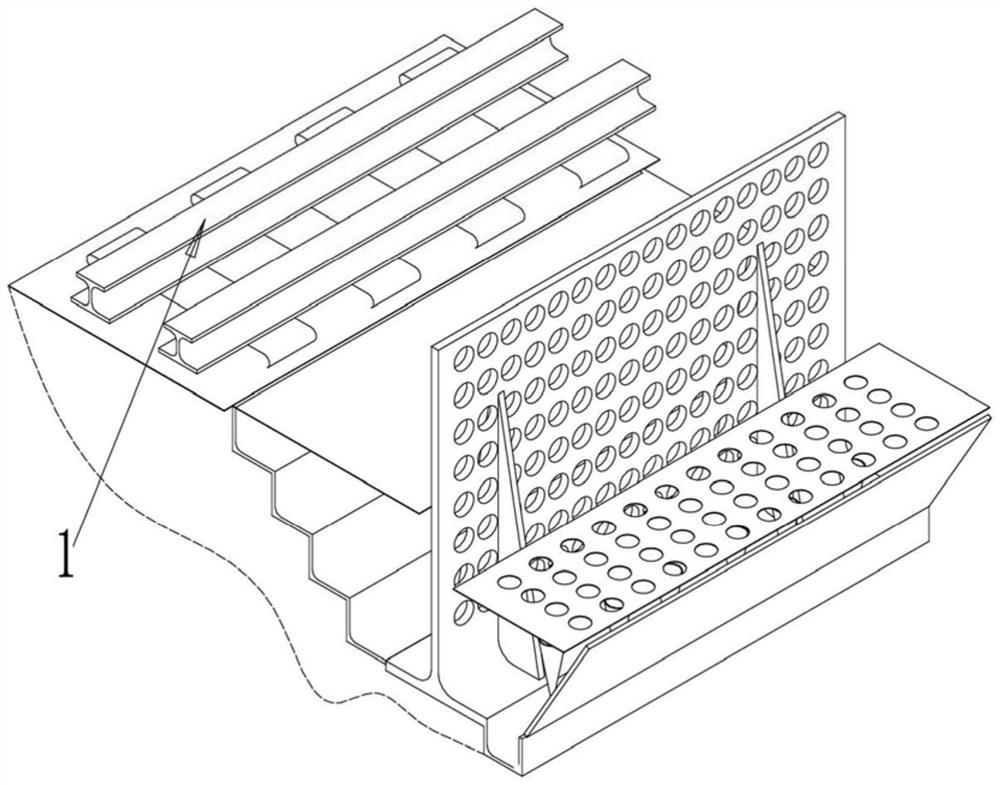

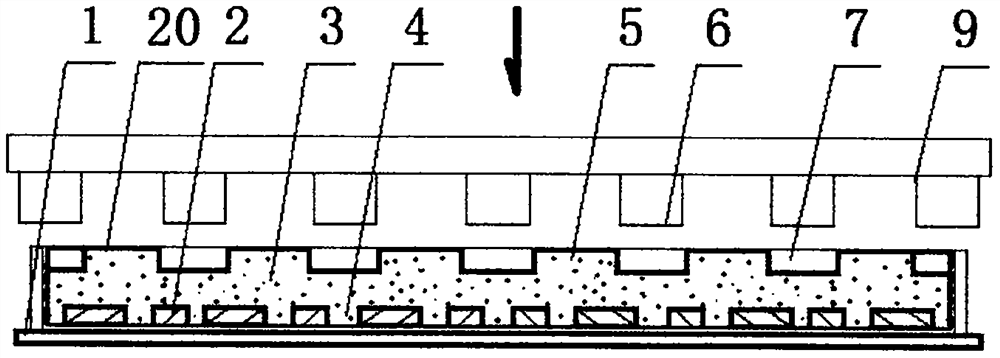

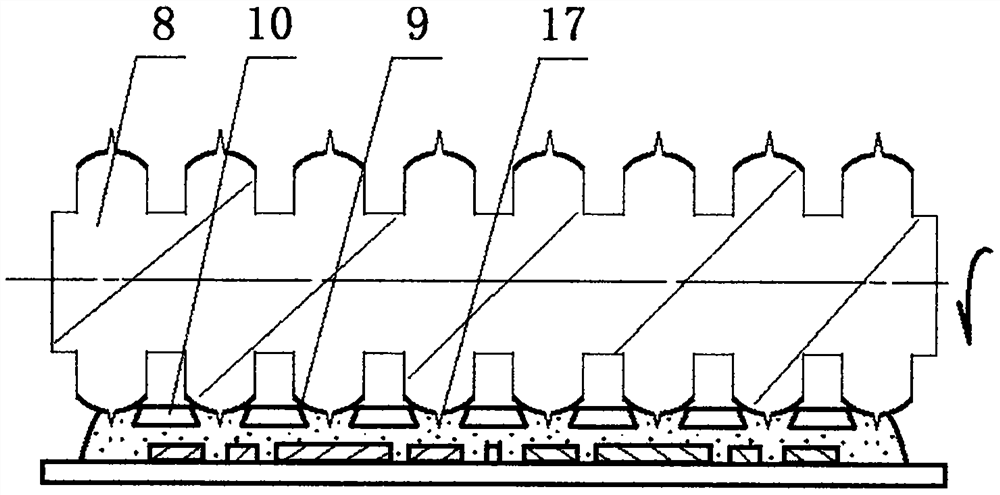

Modularized ecological stagnant water revetment for conserving water and soil

ActiveCN110792062APromote absorptionImprove impact performanceWatering devicesCoastlines protectionWater storageWater flow

The invention discloses a modularized ecological stagnant water revetment for conserving water and soil. The modularized ecological stagnant water revetment for conserving water and soil comprises supporting vertical plates; a row of the multiple supporting vertical plates are uniformly distributed on slopes on two sides of a river channel; rough stone layers are respectively paved on the slopes on the outer sides of the supporting vertical plates; fine stone layers are paved on the top sides of the rough stone layers; planting soil layers are paved on the top sides of the fine stone layers; the front end and the rear end of the outer sides of the outermost supporting vertical plates are fixedly and respectively connected with the inner sides of first partition plates; and the outer sidesand the bottom sides of the first partition plates are sequentially buried into slope soil and planting soil. According to the modularized ecological stagnant water revetment for conserving water andsoil, the structure is simple, the conception is ingenious, a multi-stage water storage device is arranged, so that flowing water temporarily exists on the top sides of the planting soil, the absorption of the flowing water by the planting soil is facilitated, the flowing water can permeate to underground through the planting soil, the impact of the flowing water on the planting soil can be sloweddown, meanwhile, soil carried in the flowing water is conveniently precipitated on the top sides of the planting soil, the flowing water is improved by utilizing a siphon phenomenon, the potential energy of the flowing water is improved to generate electricity, the high order position potential energy of the flowing water can be utilized, and the actual requirement can be met.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Construction method for preventing and controlling reflection cracks of airfield pavement overlay

ActiveCN109914215AGuaranteed connectionImprove waterproof performanceRoads maintainenceGlass fiberLoad resistance

The invention discloses a construction method for preventing and controlling reflection cracks of an airfield pavement overlay. The construction method comprises the following steps: step 1, cleaningthe surface of an airfield pavement and cracks produced on the surface, and forming a slot in the extending direction of the crack at the crack to widen the crack; step 2, arranging multiple stiffeners in the slot at intervals; step 3, pouring rubber-asphalt pouring sealant at a temperature of 225 DEG C into the slot, laying MAC modified asphalt, and laying a layer of glass fiber grid after the MAC modified asphalt cools to room temperature; and step 4, laying a stress absorbing layer on the glass fiber grid, wherein the stress absorbing layer comprises a high viscosity asphalt layer, a stonelayer and a common asphalt layer from bottom to top. According to the construction method for preventing and controlling the reflection cracks of the airfield pavement overlay, load resistance capacity of the airfield pavement is effectively improved, reflection cracks are prevented from being formed upward, and the service life of the airfield pavement is prolonged.

Owner:CHINA HARBOUR ENGINEERING

Method for treating large-particle-size block stones in hydraulic full-pile-casing rotary excavating pile construction

The invention relates to a method for treating large-particle-size block stones in hydraulic full-pile-casing rotary excavating pile construction. The method comprises the steps that when block stonelayers are distributed shallowly and are not thick, the block stone layers are directly removed within a small range through an excavator, and then soil is backfilled for pile foundation construction;when the buried depth or thickness of the block stone layers is 1-2 m, treatment is conducted according to the following steps that when the block stones are positioned in the center of a pile position, a pile casing is pressed downwards to the elevation of the block stone layers, and workers are arranged to conduct manual removal; when only part of the block stones are positioned in the pile position, the block stones are extruded through a pile casing hydraulic device, and if the block stones cannot be extruded out of the pile position, the workers are arranged to chisel the block stones positioned in the pile position; and for the block stones with the medium and small particle sizes, a drill bit of the rotary excavator is adopted for repeated soil taking, and for the block stones withthe large particle sizes, the workers are arranged to take the block stones out of holes through a crane under protection of the pile casing. According to the method, the time is saved for project construction, the cost is saved, and the economic, reasonable and practical effects are achieved.

Owner:SHANGHAI FOUND ENG GRP

A kind of preparation method of imitation stone colorful coating

ActiveCN109162417BGood reproducibilityNot easy to polluteCovering/liningsPolyurea/polyurethane coatingsMechanical engineeringStonelayer

Owner:吉安天晟新材料有限公司

Manufacturing method of stone-like fastening hole decorative sheet and stone-like fastening hole decorative sheet

PendingCN113756535AExtended service lifeFastening strengthCovering/liningsFlooringAluminium hydroxideSlurry

The invention discloses a manufacturing method of a stone-like fastening hole decorative sheet and the stone-like fastening hole decorative sheet. It is characterized in that fragments and flocculent and filiform objects are ararnged and bonded on the surface of a stone-like layer in an embedded mode to form a stone-like surface, and the backing surface is provided with fastening holes. According to a stone-like mixed slurry, the fragments or the filaments, glass sand, glass beads and aluminum hydroxide are embedded and bonded into a whole to form the stone-like layer, the stone-like mixed slurry and the backing reinforcing slurry are mixed into a whole before initial setting, fastening holes are integrally formed, the manufacturing method of the stone-like fastening hole decorative sheet and the stone-like fastening hole decorative sheet have the remarkable advantages that the service life is long, the stone-like layer, the backing layer and the fastening holes do not peel off, the fastening holes are recessed in the backing layer, the backing layer forms the fastening holes, the fastening holes are high in fastening strength, safe and reliable, the stone-like effect is vivid, the material cost is low, the manufacturing method is simple and convenient, and the application market is wide.

Owner:许浒

River and lake water greening and purifying method and river and lake water greening and purifying device

InactiveCN103539264BSimple structureEasy constructionSustainable biological treatmentBiological water/sewage treatmentVegetationWater quality

The water quality purification method for greening rivers and lakes uses a groove structure made of porous concrete as the main body. Plant mats and water purification materials are arranged inside the groove structure. Aquatic plants are cultivated on the plant mats. Water treatment microorganisms are applied in the grooves. The groove structure is made of porous concrete. The tank, vegetation mat and water purification layer simultaneously serve as carriers of microorganisms for water treatment that can add both aerobic and inter-aerobic types. Lay rubble at the bottom of the groove structure, and then place a flat mat of plant fiber, a water purification layer, and a flat mat of plant fiber on the rubble layer in sequence. The cross-section of this structure is U-shaped. The invention has the advantages of simple structure, convenient construction, low cost, etc. It is installed on both sides of rivers, lakes, landscape pools or bridge sides to achieve the two major purposes of water purification and greening at the same time.

Owner:NANJING UNIV +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com