Anti-slide pile and frame arch combined structure and construction method

A technology of combined structure and construction method, which is applied in the direction of earth drilling, mining equipment, tunnels, etc., can solve the problems of high cost of slope reinforcement on both sides, destruction of geological bodies and ecology, and failure to achieve safe entry into the tunnel, etc., to achieve reinforcement The effects of preventing tunnel arch collapse, ensuring stability and ecology, and saving reinforcement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

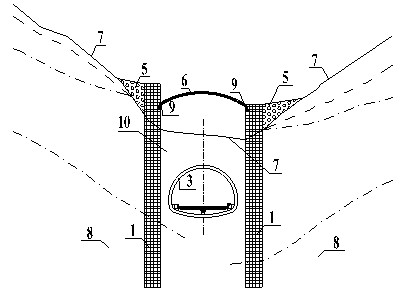

[0035] Example 1, such as figure 1 and Figure 9 As shown, the anti-slide pile frame-arch combination structure in the present invention is used to reinforce the slopes on both sides of the tunnel entrance section and the overlying rock and soil mass in the trench center terrain, including anti-slide piles 1 and frame arches 6, which are suitable for Under the topography of the ditch center, when the overlying soil layer on the tunnel arch is greater than 5m, the stability of the side slopes on both sides is poor or the tunnel opening is poor. The anti-sliding pile 1 adopts on-site pouring of reinforced concrete, which goes deep into the stable bedrock 8 and exposes a small amount of the original surface (about 0.5-1m), and is arranged on both sides of the tunnel body. Pressure reinforcement of the slopes on both sides of the tunnel entrance. The depth, cross-sectional size, and reinforcement strength of the anti-slide pile 1 to stabilize the bedrock 8 need to be determined ...

Embodiment 2

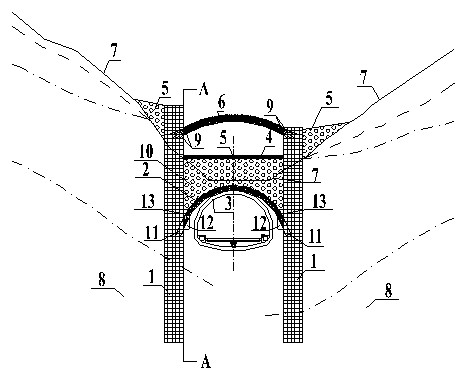

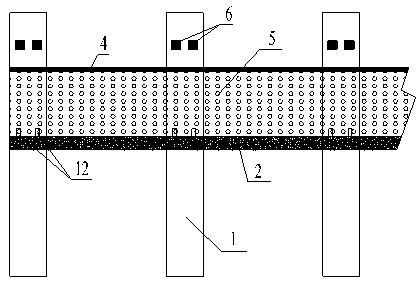

[0036] Example 2, such as figure 2 , image 3 , Figure 4 to Figure 8 As shown, what its frame arch 6 adopts is arch beam arrangement. The difference from Example 1 is that when the thickness of the overlying soil layer 10 of the tunnel is less than 5m, the protective arch 2 needs to be constructed. The protective arch 2 adopts the steel concrete structure commonly used at the tunnel entrance. The conditions are determined. The guard arch 2 is a continuous arch structure, and is connected with the anti-slide pile 1 by connecting steel plates 13 and bolts 15 through the I-beam 11 pre-embedded in the body of the anti-slide pile 1 . The implementation sequence is to carry out the construction of the anti-slide pile 1 first, then excavate the overlying soil and the construction of the arch protection 2, then backfill the soil layer and construct the arch 6, and wait for the concrete of the anti-slide pile 1, protection arch 2 and arch 6 After the structure is completely solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com