Cutting element

A technology for cutting components and components, which is applied in the field of cutting components and can solve problems such as edge fracture

Active Publication Date: 2010-09-08

REEDHYCALOG UK

View PDF7 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In such a construction there is a risk of breaking the unsupported edge

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

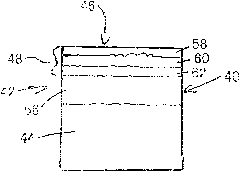

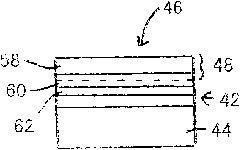

A cutting element comprises a multilayer polycrystalline diamond element 42 bonded to a substrate 44 of a less hard material, the polycrystalline diamond element 42 defining a matrix of interstitial volumes, the interstitial volumes of a first region of the diamond layer 42 adjacent a working surface 46 thereof being substantially free of a catalysing material, the interstitial volumes of a second region of the diamond layer 42 remote from the working surface 46 containing catalysing material.

Description

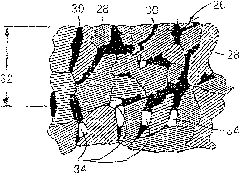

cutting element field of invention The present invention relates to a cutting element, and more particularly to a cutting element suitable for use in a drill bit for forming a borehole. Background technique One type of cutting element used on a drill bit consists of a series of superhard materials, such as polycrystalline diamond, bonded to a substrate of a lower hardness material, such as tungsten carbide. Cutting elements of this type are well known and are used in a range of shapes and sizes and in a range of applications. Cutting elements of the type described are manufactured through a high temperature, high pressure process in which portions of the tungsten carbide substrate, diamond powder, and bonded catalyst (e.g. in the form of cobalt) are exposed to high temperature, high pressure conditions resulting in diamond crystals in the diamond powder A chemical bond is formed between them, forming a polycrystalline diamond layer that is also partially bonded to the su...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23B51/00C04B41/85

CPCE21B10/5676B22F7/06C22C29/08B22F2999/00E21B10/567C22C26/00B22F2005/001B22F2207/13B22F2207/03E21B10/46E21B10/54E21B10/5735

Inventor N·D·格里芬P·R·休斯

Owner REEDHYCALOG UK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com