Preparation method of ultrahigh thermal conductivity, surface machinable diamond‑al composites

A composite material and diamond technology, which is applied in the field of ultra-high thermal conductivity metal matrix composite materials, can solve the problems of large contact thermal resistance, difficult processing, and complicated process, and achieve the effects of improving production efficiency, short preparation period and reducing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

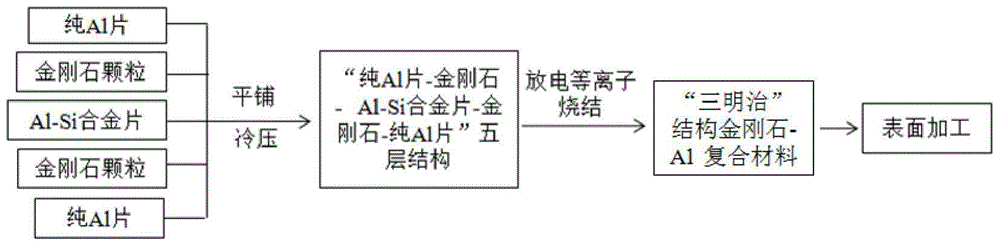

[0040] A kind of preparation method of ultrahigh thermal conductivity, surface machinable diamond-Al composite material of the present invention comprises the following steps:

[0041] Step 1: Put a second pure Al sheet 10, a flat second diamond particle layer 9 with a thickness of h, and an Al-Si alloy sheet 8 with a thickness of H in order from bottom to top in the graphite mold. A flat first diamond particle layer 7 with a thickness of h, and a first pure Al sheet 6, forming five layers of "pure Al sheet-diamond particle layer-Al-Si alloy sheet-diamond particle layer-pure Al sheet" structure;

[0042] Step 2: Cold press the formed five-layer structure with a pressure of 15-20MPa, so that the layers of the structure are in close contact;

[0043] The third step: put the upper pressure head 1 with the overflow groove 2 into the graphite mold, and put the assembled mold into the discharge plasma sintering furnace;

[0044] The fourth step: heat and pressurize the five-layer ...

Embodiment 1

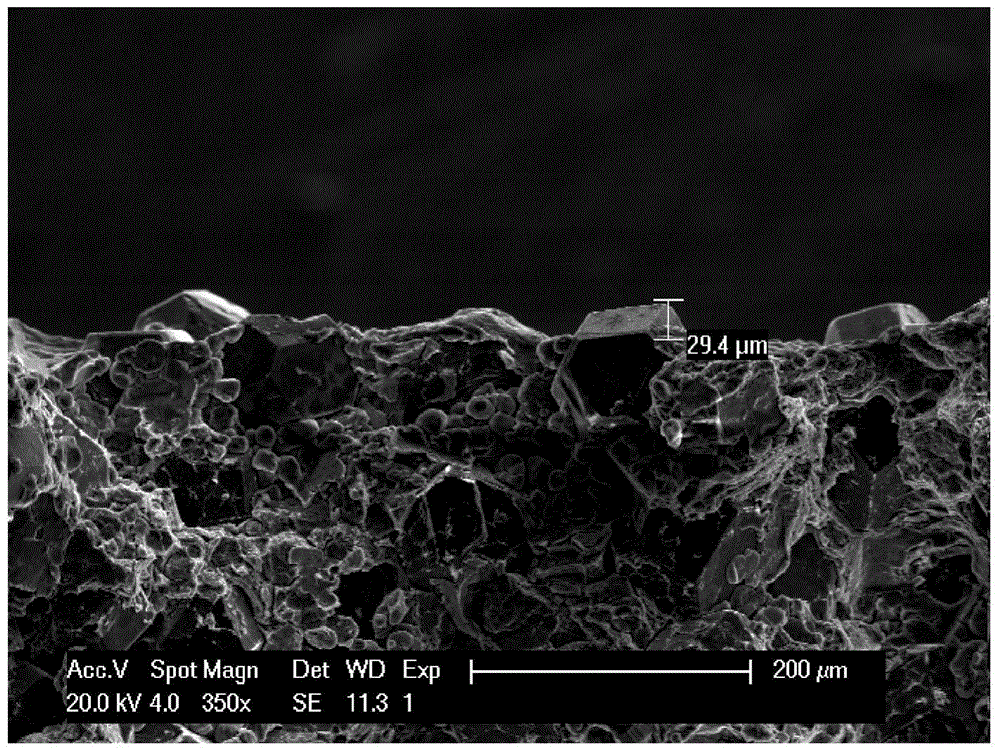

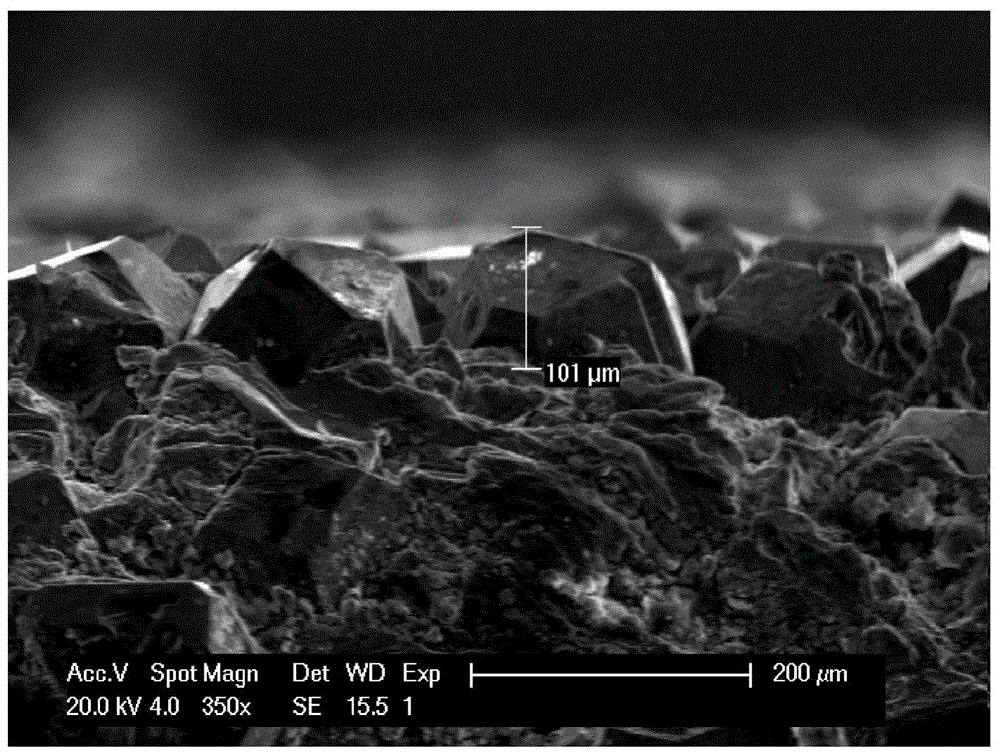

[0048] In a graphite mold with an inner diameter of 20mm, a 2mm thick pure Al sheet with a purity of 99.7%, a 1mm thick (0.69g) MBD4 type diamond stacked layer with an average particle size of 89μm, a 0.85mm thick (0.71g ) Al-Si alloy sheet (Si content is 7wt%), 1mm thick (0.69g) MBD4 type diamond deposition layer with an average particle size of 89 μm, and a 2mm thick pure Al sheet with a purity of 99.7%, cold pressing the deposition system, The cold pressing pressure is 20MPa. Put the upper pressure head with an overflow tank into the mold, then put the mold into the discharge plasma sintering furnace for sintering, the sintering temperature is 620°C, the sintering pressure is 15MPa, the vacuum degree is 10Pa, keep the pressure for 10 minutes and then cool down, and keep the pressure To cooling end, obtain sandwich structure diamond-Al composite material (composite section see Figure 8 and 9 ). The excess Al on the surface of the composite material was pre-grinded with 4...

Embodiment 2

[0050] In a graphite mold with an inner diameter of 20mm, a 2mm thick pure Al sheet with a purity of 99.7% and a 1mm thick (0.69g) MBD4 type diamond accumulation layer with an average particle size of 200μm (diamond particle density of 3.5g) are laid from bottom to top. / cm 3 , stacking density is 63%), 0.8mm thick (0.66g) Al-Si alloy sheet (Si content is 12.5wt%), 1mm thick (0.69g) average particle diameter is the MBD4 type diamond stacked layer of 200 μ m, the purity is 99.7% of 2mm thick pure Al sheets are cold-pressed to the stacking system, and the cold-pressing pressure is 15MPa. Put the upper pressure head with an overflow tank into the mold, then put the mold into the discharge plasma sintering furnace for sintering, the sintering temperature is 580°C, the sintering pressure is 10MPa, the vacuum degree is 5Pa, keep the pressure for 30 minutes and then cool down, and keep the pressure At the end of cooling, a sandwich-structured diamond-Al composite material is obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com